Method and device for detecting nuts in trunk cover plate production

A technology for detecting devices and nuts, which is applied in the direction of optical device exploration, etc., can solve the problems of large quantity, small size of nuts, and difficult detection, etc., and achieve the effects of stable light source, easy handling, and reliable detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

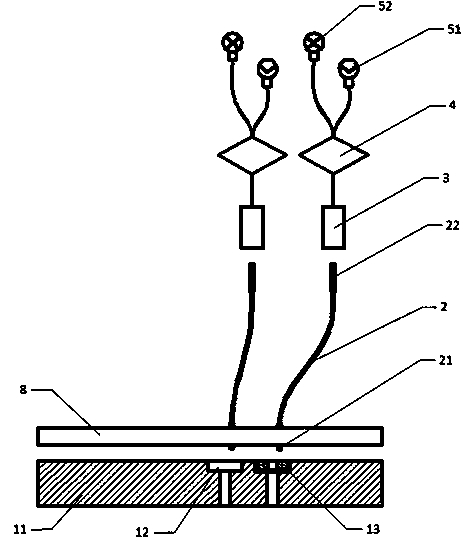

[0040] Such as figure 1 As shown, the base plate 11 is provided with a nut installation position 12 on which a nut 13 needs to be installed.

[0041] The opposite position of the substrate is provided with a probe fixing plate 8, on which the input end 21 of the first optical fiber 2 is arranged, aligned with the nut installation position 12, and the reflected light is transmitted to the photoelectric conversion element 3 corresponding to the output end 22, and converted into The electrical signal is sent to the judging unit 4 for judging.

[0042] When the nut 13 is not installed, the nut installation position 12 corresponding to the input end 21 is a composite material, the reflection intensity is low, and the electric signal is weak; after the nut 13 is installed, the nut 13 corresponding to the input end 21 is a metal material, so the reflection intensity Higher, stronger electrical signal.

[0043] In the two cases, the electrical signal will be significantly different,...

Embodiment 2

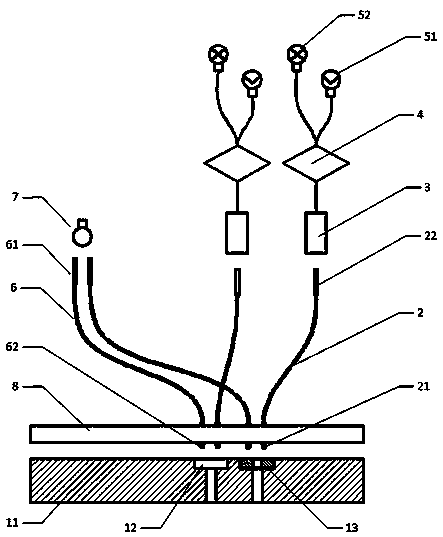

[0048] See attached figure 2 , on the basis of Embodiment 1, the second optical fiber 6 and the auxiliary light source 7 are set.

[0049] The first optical fiber 2, the photoelectric conversion element 3, and the judging unit 4 are set to be the same as in Embodiment 1, and the nut installed indicating device 51 and the nut missing indicating device 52 shown in the figure may also be provided, the difference being that the probe fixing plate The output end 62 of the second optical fiber 6 is also arranged above the nut installation position 12 on 8 , and the input end 61 is facing the auxiliary light source 7 .

[0050] The auxiliary light source 7 can correspond to a plurality of nut installation positions 12 through the second optical fiber 6, and can also be provided with a plurality of auxiliary light sources 7, and each auxiliary light source corresponds to a nut installation position 12

[0051] The light emitted by the auxiliary light source 7 is irradiated on the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com