Deep water combined steel sheet pile cofferdam construction method

A technology combining steel sheet piles and construction methods, which is applied in infrastructure engineering, construction, etc., can solve the problems of high construction cost, small space, and large processing volume, and achieve the effect of solving the problem of being unable to install and reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

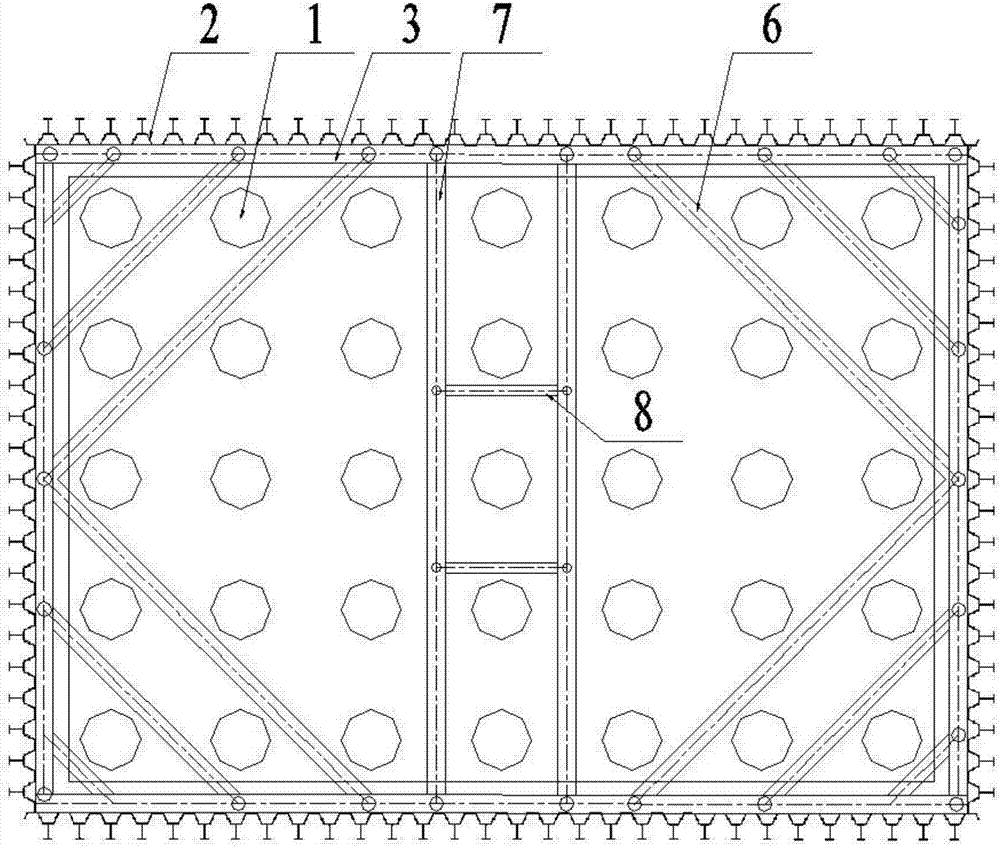

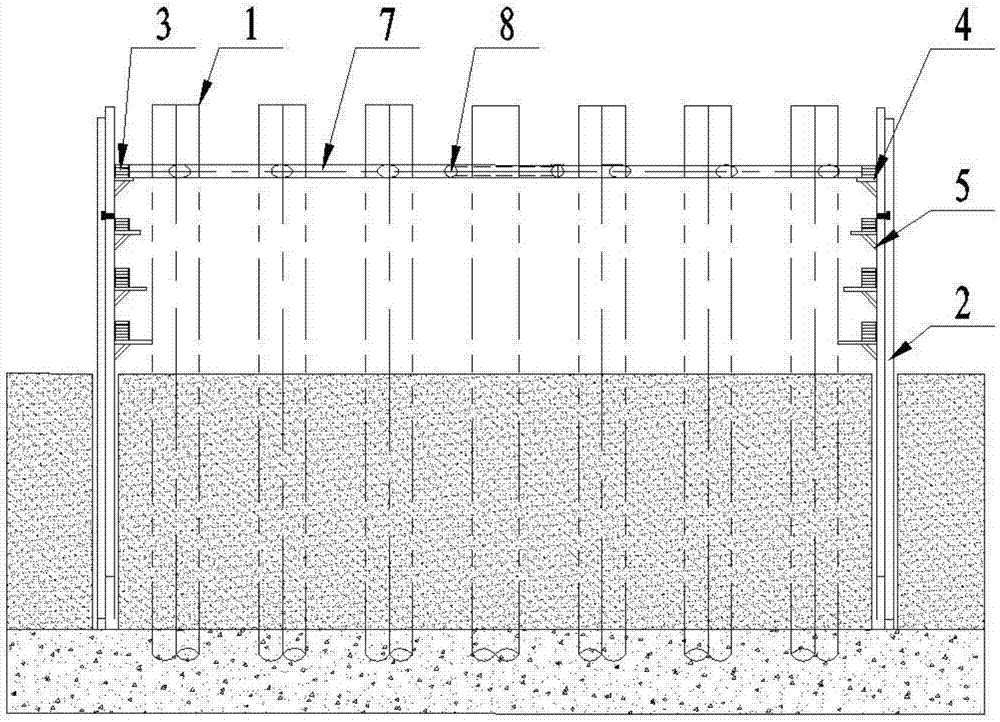

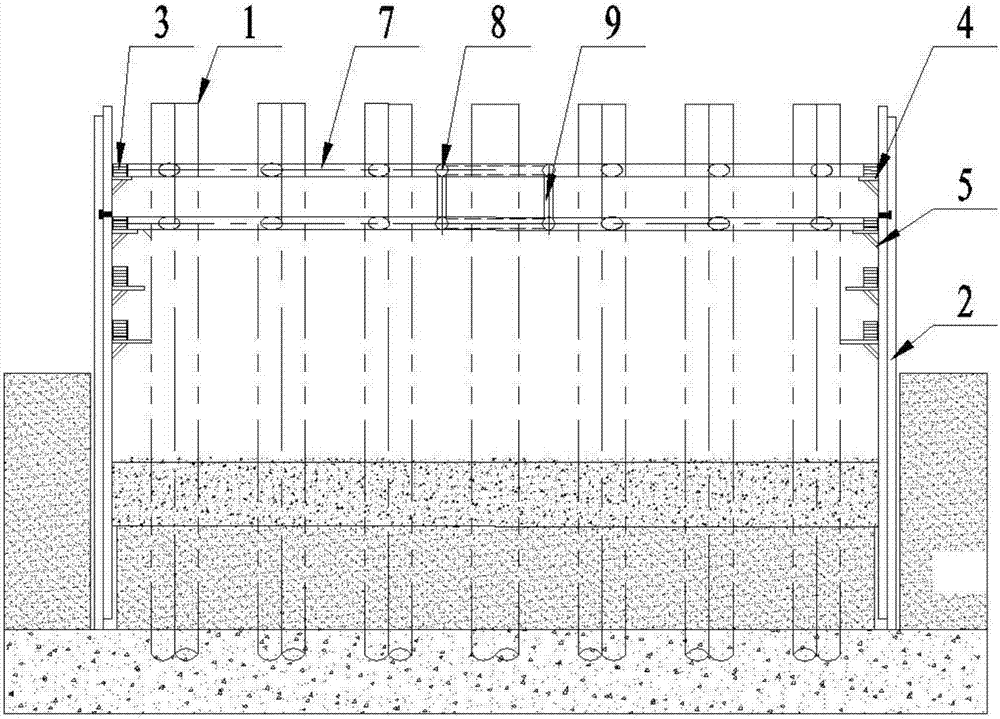

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] like Figure 1~3 , the cofferdam structure of this embodiment includes a steel casing 1, steel sheet piles 2, purlins 3, and an internal support structure. The steel sheet piles 2 of this embodiment rely on the guiding structure on the steel casing 1 for insertion and driving. The guiding structure is as in the patent The guide device described in the patent No. "201521102607.7" inserts and drives the steel sheet pile 2 through the guide structure on the steel casing 1, so as to prevent the steel sheet pile 2 from being accurately and quickly installed without the purlin 3 as a guide support.

[0024] The purlin 3 of this embodiment is split into several parts. For a square cofferdam, the purlin 3 is generally divided into four separate straight rod-shaped structures, and the purlin 3 is hoisted to the The sub-block hoisting o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com