Traction system for traction type elevator

A traction system and traction-type technology, which is applied in the field of traction systems, achieves the effects of convenient implementation, meeting installation requirements, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

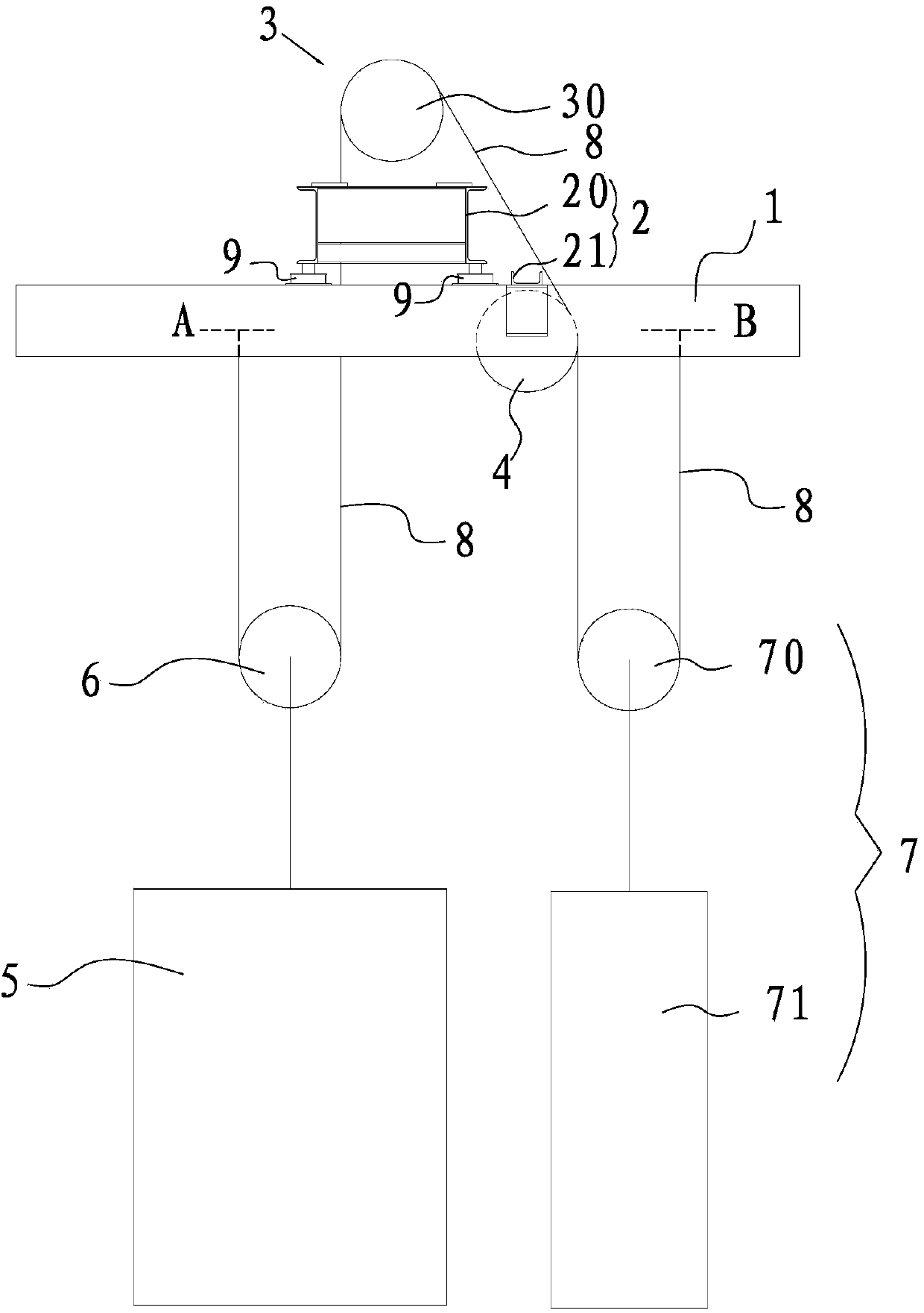

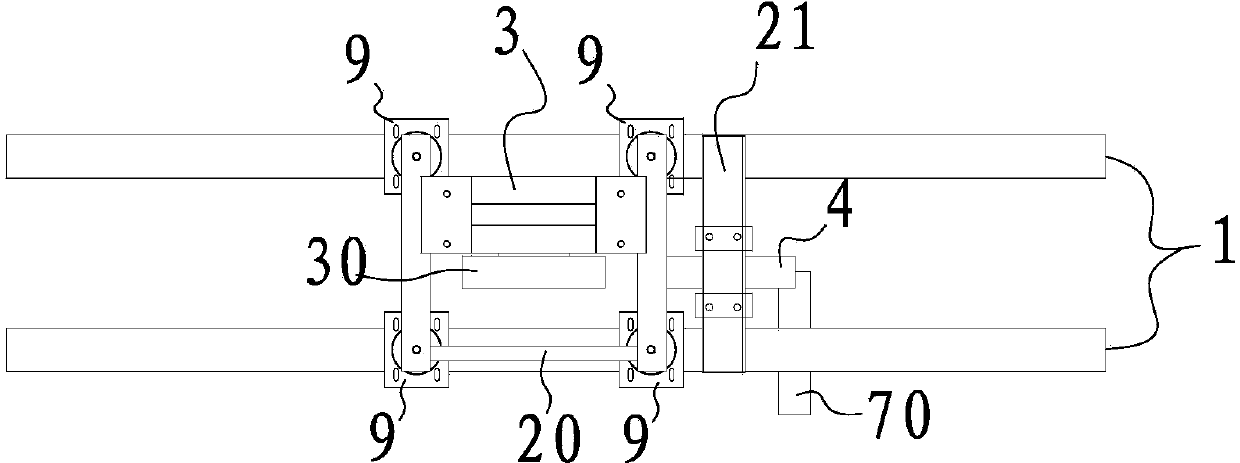

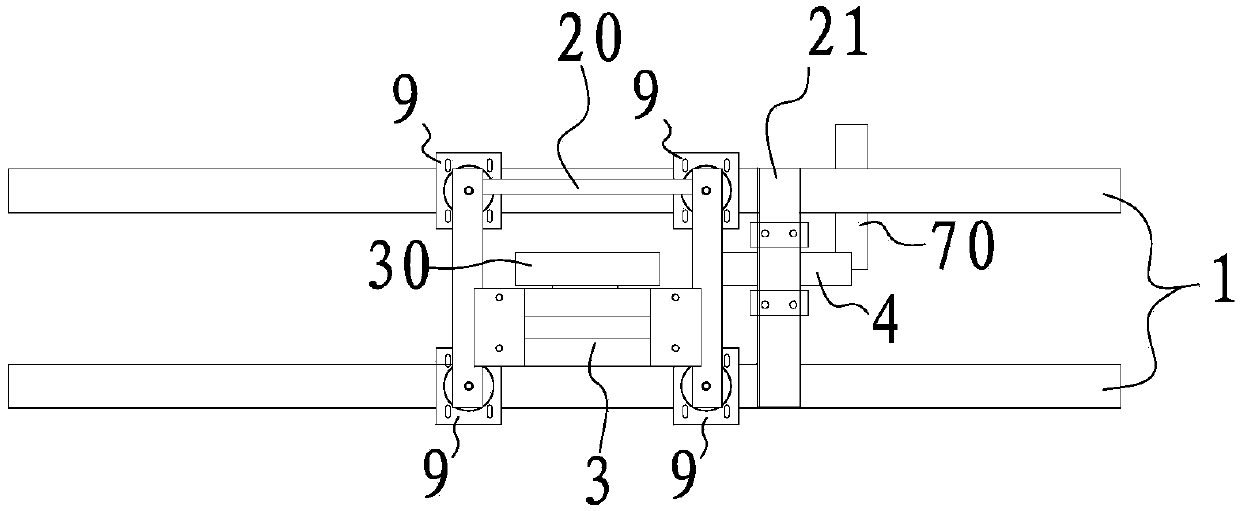

[0019] Such as Figure 1 to Figure 3 As shown, the traction system of the traction elevator in this embodiment includes a frame 2 erected on the frame 1, a traction machine 3 and guide wheels 4 arranged on the frame 2, and a car 5, the car top wheel 6 at the top is used for the counterweight mechanism 7 of the counterweight car 5 and is used to connect the traction sheave 30 of the traction machine 3, the guide wheel 4 and the counterweight wheel 70 of the counterweight mechanism 7 and The two ends are respectively fixed on the traction rope 8 on the machine girder 1 .

[0020] In this example, the above-mentioned frame 2 adopts a split type, and specifically includes a traction frame 20 for installing the traction machine 3, and a guide wheel frame 21 that can move horizontally and is arranged on the horizontal beam 1. The traction machine The frame 20 is arranged symmetrically along the center line parallel to the extension direction of the machine girder 1, and the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com