Patents

Literature

35results about How to "Solve the problem of not being able to weld" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

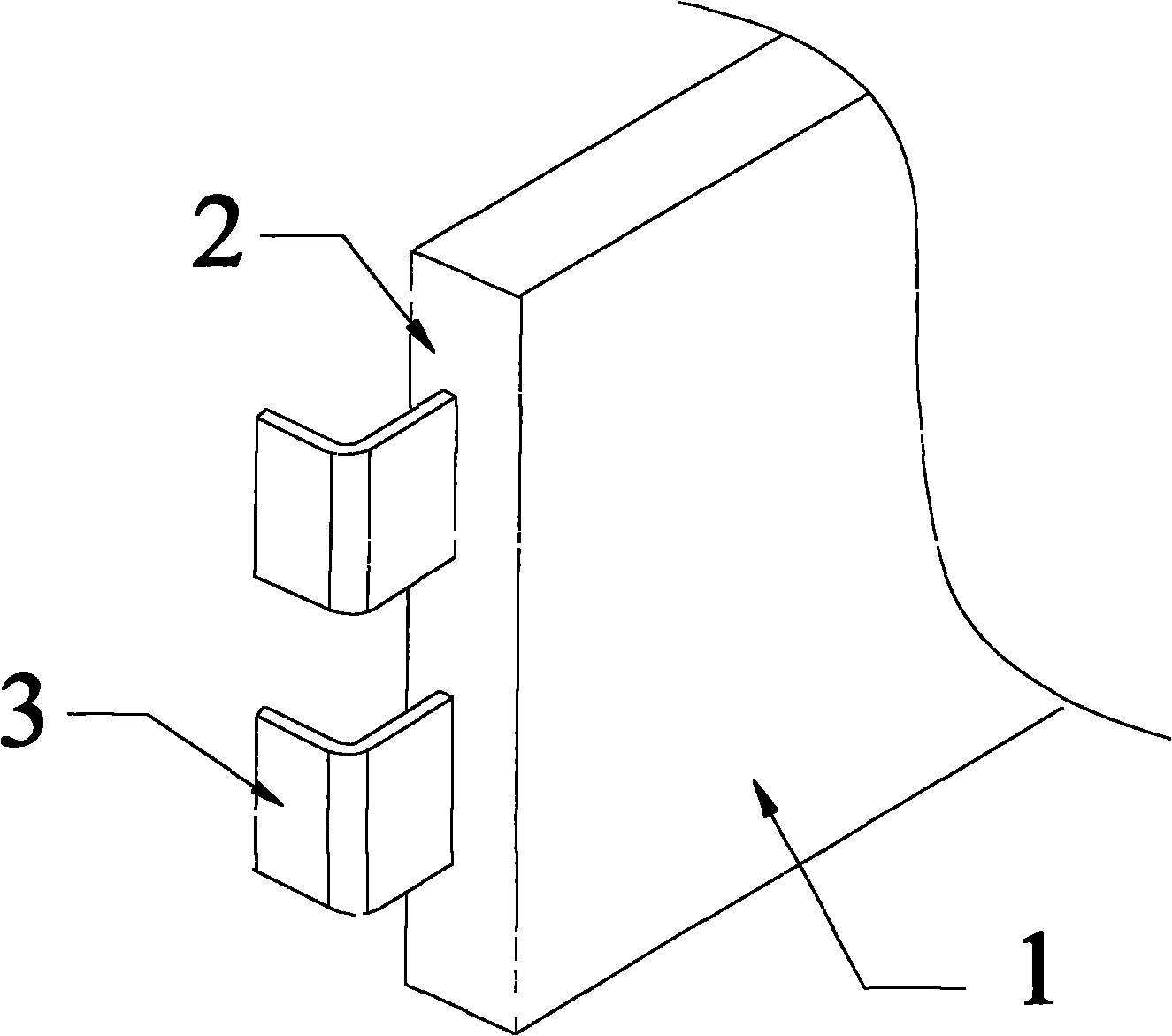

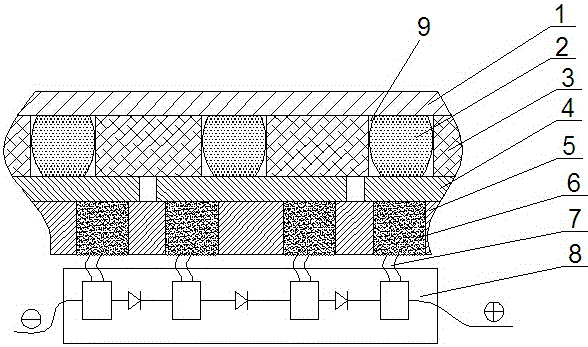

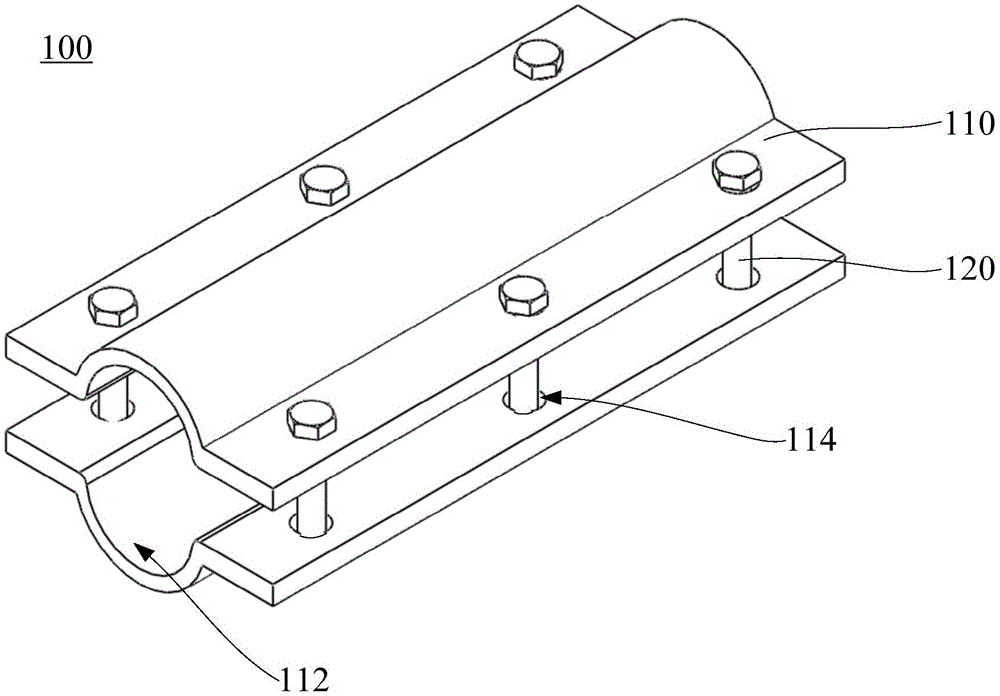

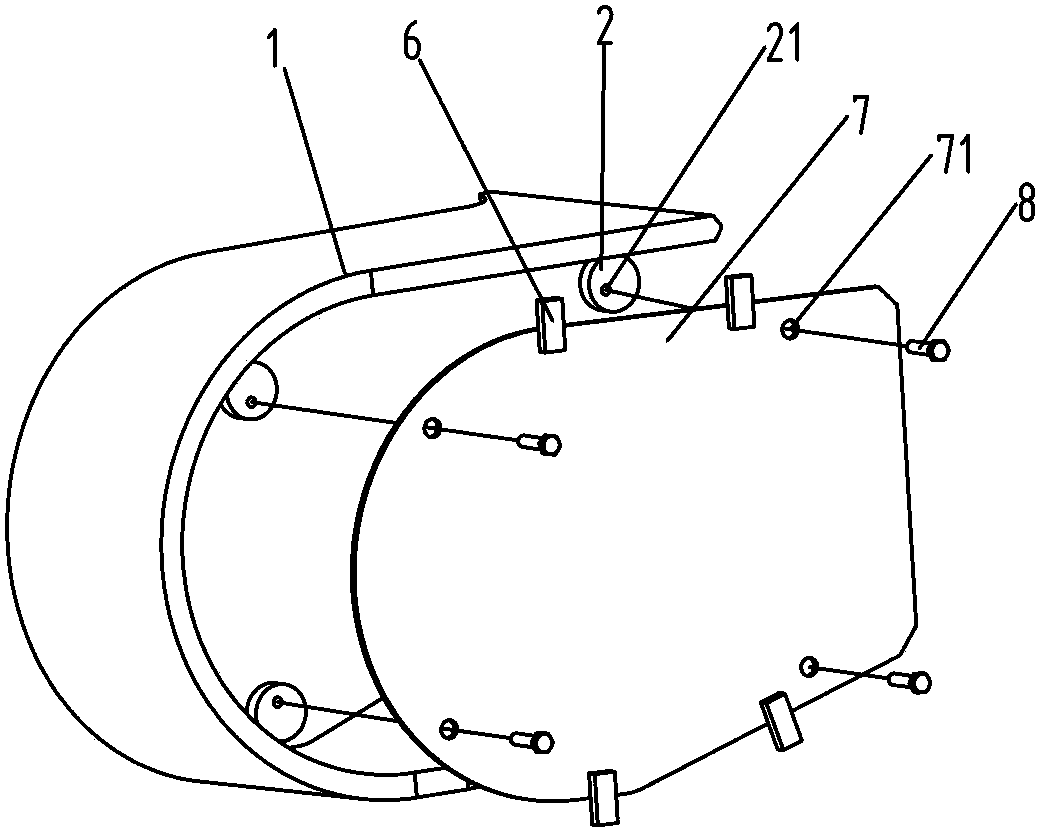

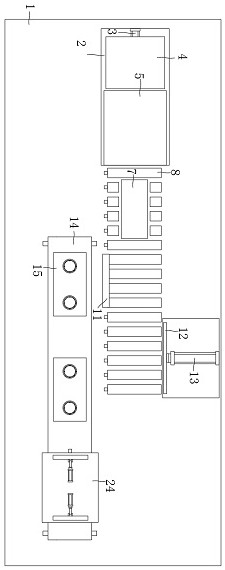

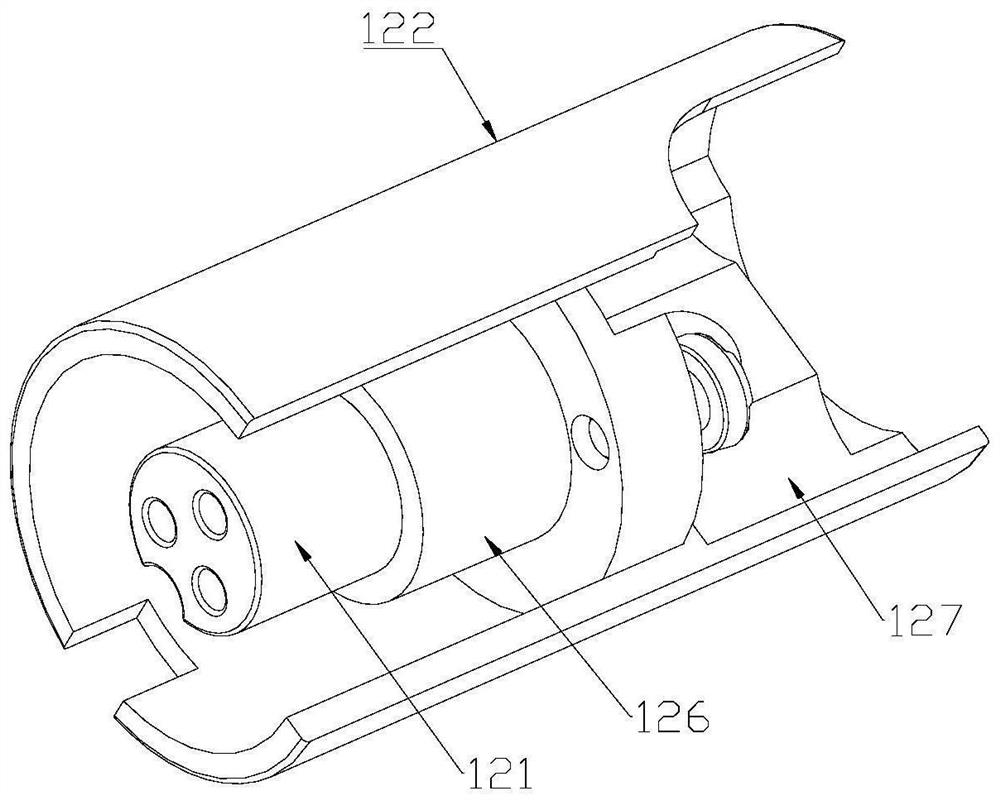

Monomer battery and power battery pack containing same

ActiveCN101877413AImproved high-rate discharge characteristicsIncrease capacityLarge-sized flat cells/batteriesFinal product manufacturePower batteryBattery pack

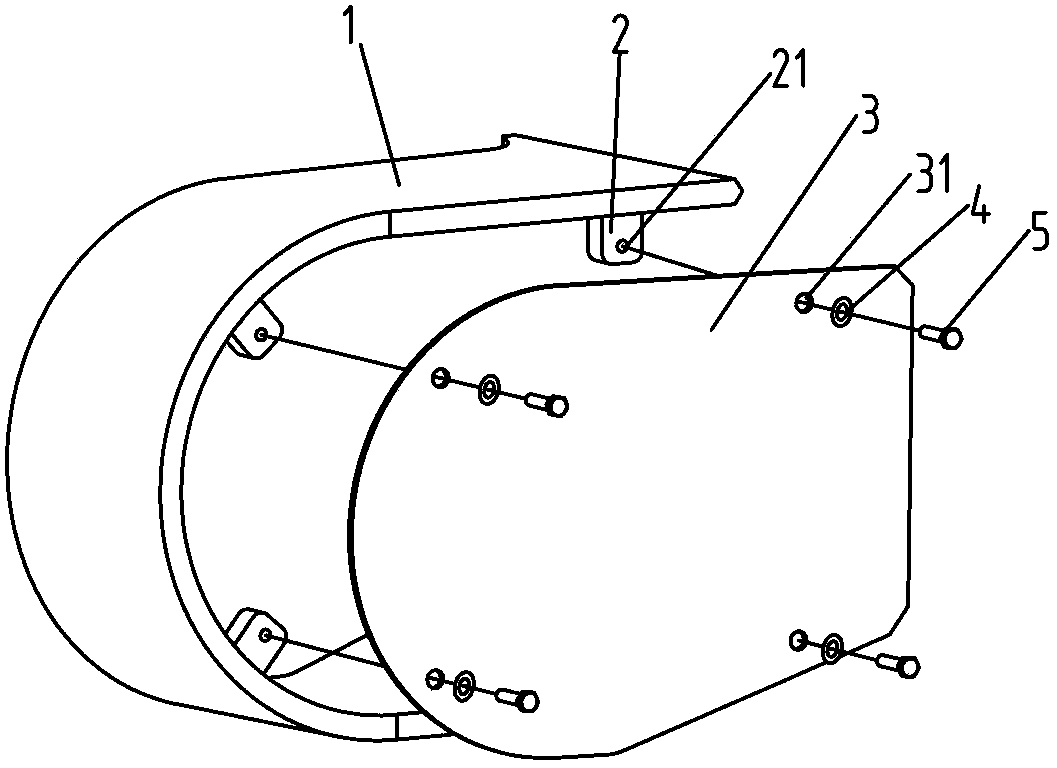

The invention provides a monomer battery which comprises a battery shell, a cover plate and a polepiece, wherein the cover plate is in a seal connection with the battery shell; the polepiece is positioned in a space formed by the battery shell and the cover plate; pole terminals, which penetrate through the cover plate and are used for leading the current out, are arranged in the cover plate; and each polarity at least has two pole terminals; the invention also provides a power battery pack containing the monomer battery. The battery and the battery pack enhance the high-power discharge characteristic, and especially can further solve the problems in welding, so that the technique is simpler and can further solve the problems in heat emission, weight and the like in the battery. The battery with the structure and the battery pack have the advantages of firmer connection, and higher safety and reliability; and the battery pack has a longer service life.

Owner:BYD CO LTD

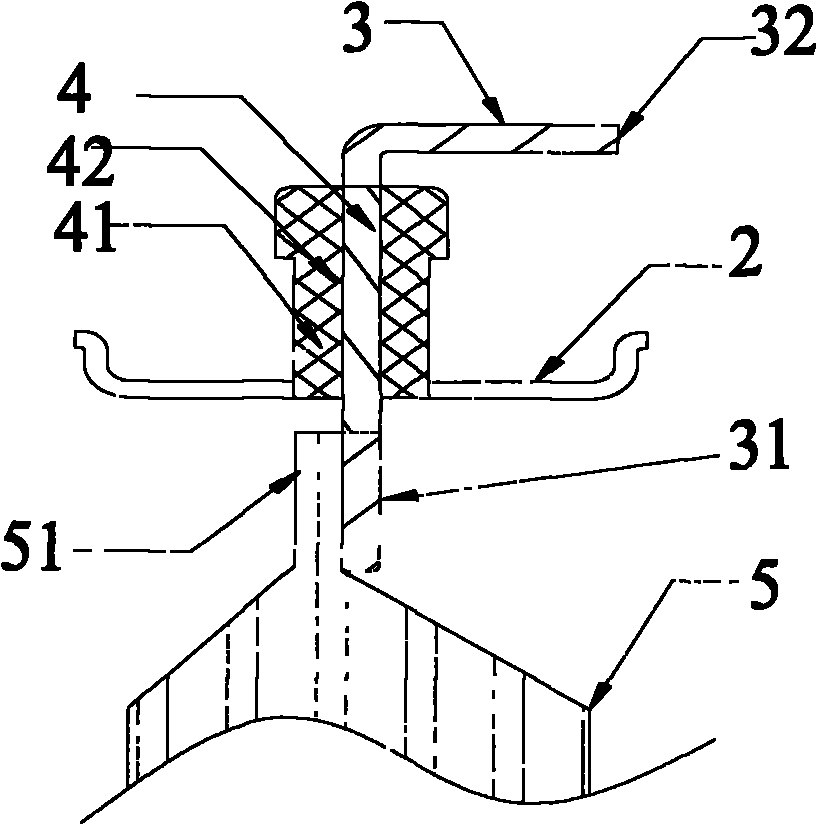

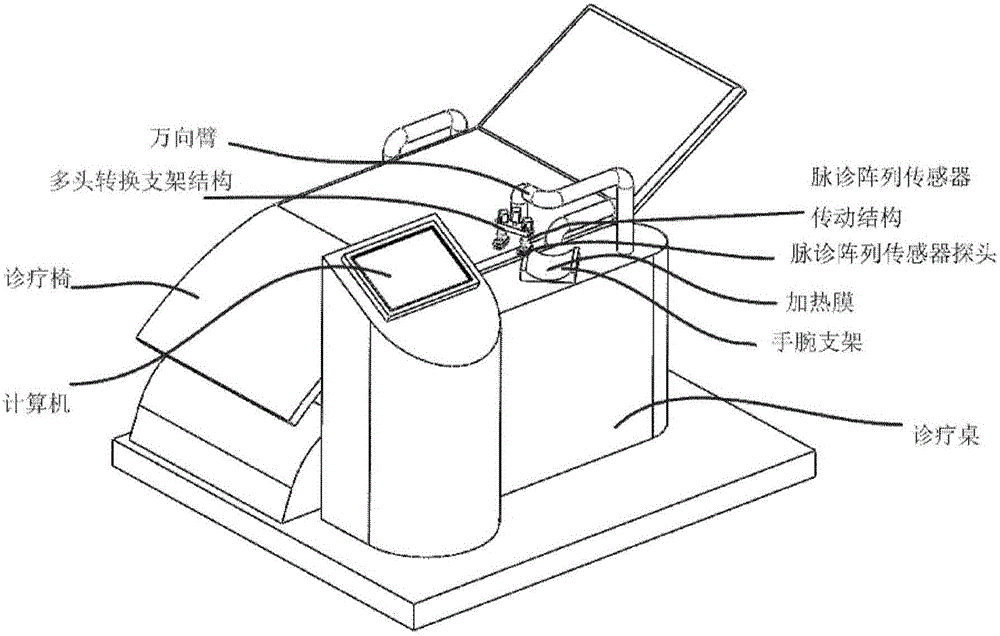

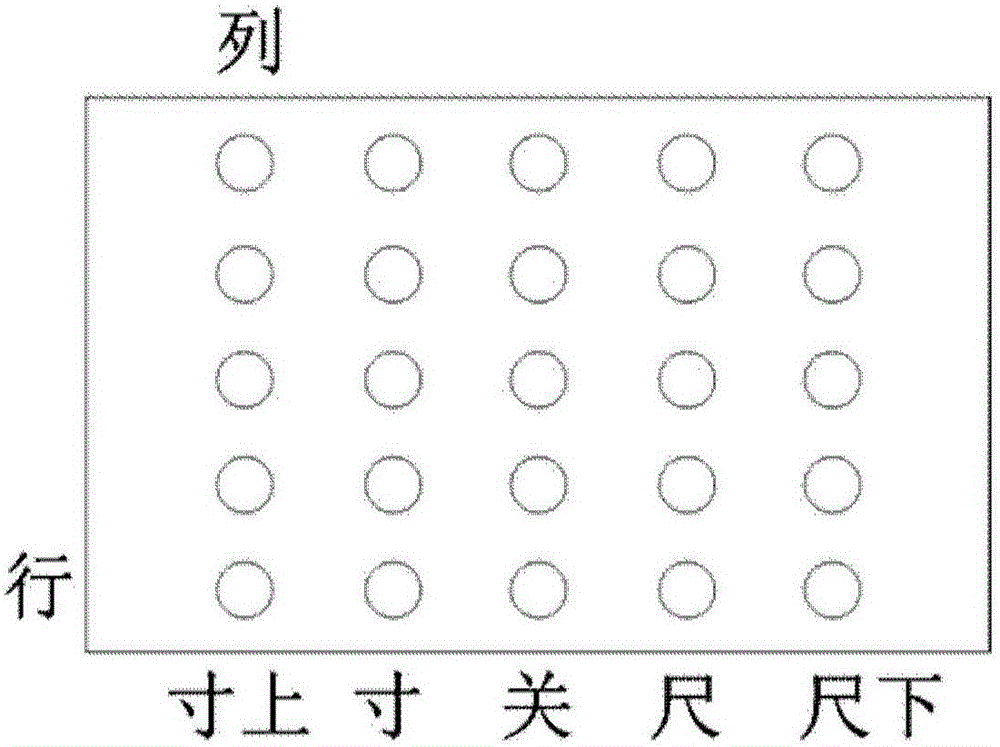

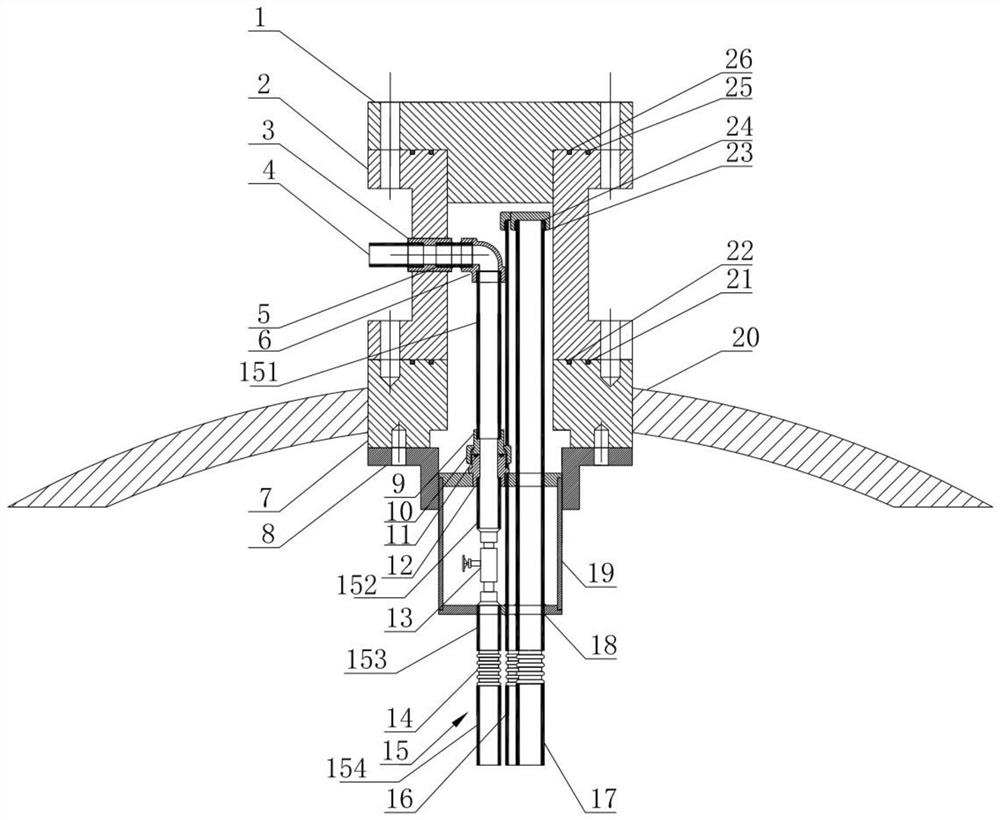

Traditional Chinese medicine pulse-taking sensor, traditional Chinese medicine pulse-taking diagnosis and treatment system and a health service platform

ActiveCN105662368AGuarantee stabilityEnsure repeatabilityOperating chairsCatheterDiseaseSensor array

A traditional Chinese medicine pulse-taking sensor device comprises a pulse-taking array sensor, and the sensor array position is designed according to the gold standard of diagnosis of the portion above the wrist end, the wrist end, the processus styloideus radii, the elbow end and the portion below the elbow end.The traditional Chinese medicine pulse-taking sensor device comprises a difference closed-loop sampling system, a pulse-taking instrument, a traditional Chinese medicine pulse-taking diagnosis and treatment system and a traditional Chinese medicine pulse-taking system health service platform.The health service platform comprises a cloud storage and cloud processing platform, is used for conducting cloud storage on detection results, and matches later-period diseases and selecting treatment schemes by using cloud computing.Stability and repeatability of taking patient pulses are ensured through mechanical design, pulse data of a patient is collected more objectively and accurately through the difference closed-loop sampling system, traditional Chinese medicine resources are optimally configured through an Internet of Things implementing scheme, and the cognition degree of people to traditional Chinese medicine is improved.The 25-point array is set according to the portion above the wrist end, the wrist end, the processus styloideus radii, the elbow end and the portion below the elbow end, and array arranging space with a good diagnosis and treatment effect is obtained.

Owner:北京中科芯健医疗科技有限公司

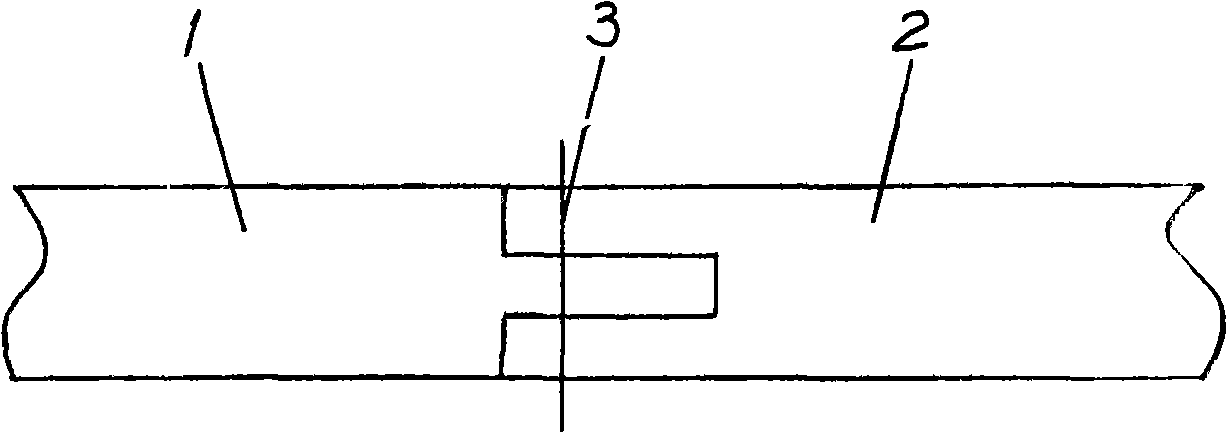

Connection method for titanium plate and stainless steel plate

InactiveCN101504021ASimple production processSolve the problem of not being able to weldSheet joiningSteel platesTitanium

The invention relates to a method for connecting a titanium plate with a stainless steel plate, which comprises the titanium plate, the stainless steel plate and a stainless steel strip welding material, and comprises the following steps: firstly, punching a plurality of small holes at the end part of the titanium plate and the end part of the stainless steel plate respectively; secondly, pulling a plurality of prepared stainless narrow strips into the small holes at the end parts of the titanium plate and the stainless steel plate so that the titanium plate is flexibly connected with the stainless steel plate; and thirdly, welding the stainless narrow strips with the welding material so as to weld a connecting piece of the titanium plate and the stainless steel plate. When a pure titanium plate strip is switched with stainless steel, the method is adopted to prepare certain number of the connecting pieces of the titanium plate and the stainless steel plate in advance; and according to production requirements, two ends of the connecting pieces can be welded with a titanium strip and a stainless steel leading strip so as to meet the requirements on collinear scale and the continuous production of titanium and stainless steel and the like. The method for preparing the connecting piece of the titanium plate and the stainless steel plate has a concise production process and improves the economic benefit.

Owner:BAOSTEEL ENG & TECH GRP

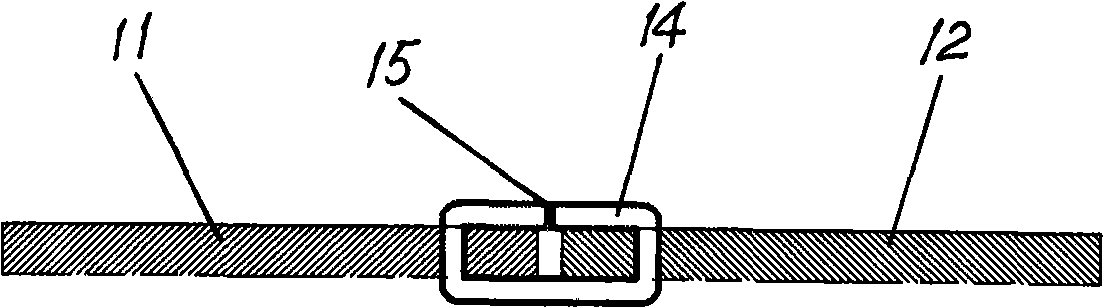

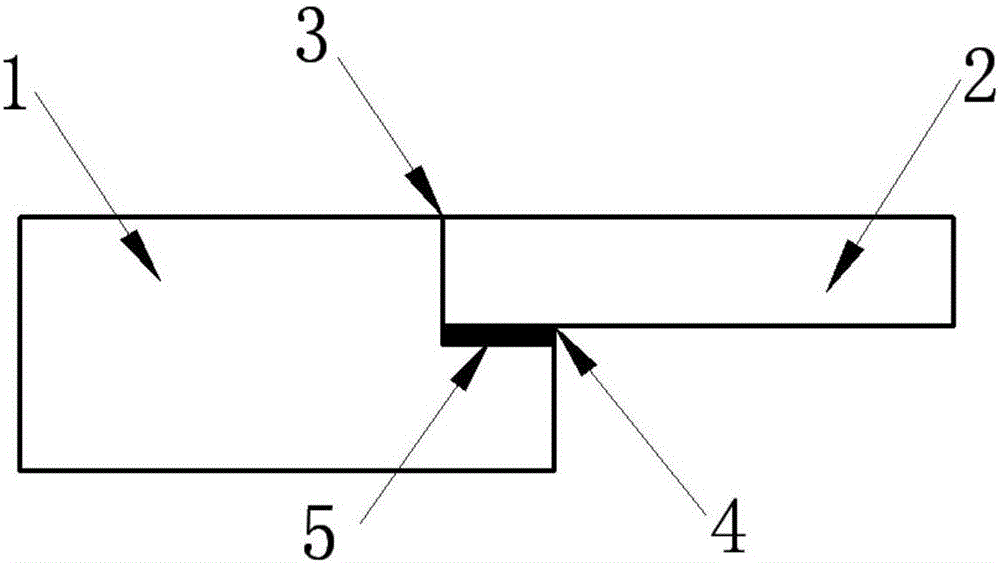

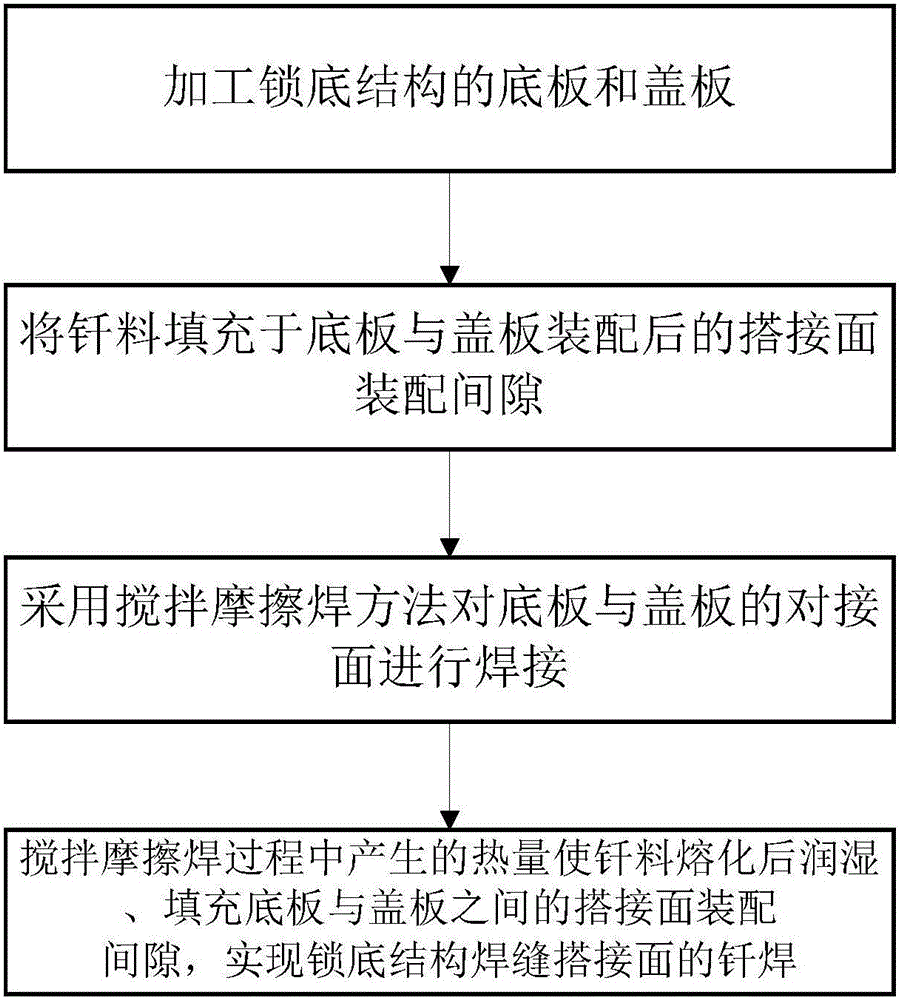

Friction stir welding-soldering composite welding method

The invention provides a friction stir welding-soldering composite welding method comprising following steps: 1) machining a bottom plate and a cover plate of a lock bottom structure, machining a process step at one side of the bottom plate, wherein the thickness of the cover plate is less than the height of the process step by 0.5mm to 1mm; 2) filling solder in faying surface assembly gap between the assembled bottom plate and the cover plate, wherein soft solder having melting point between 300 to 400 DEG C is selected as the solder; 3) welding the butt joint surface of the bottom plate and the cover plate through friction stir welding; 4) melting the solder with the heat generated during the friction stir welding, wherein the faying surface assembly gap between the bottom plate and the cover plate is wetted and filled with the melted solder to realize soldering of the lock bottom structure welded seam faying surfaces. By means of the friction stir welding-soldering composite welding method, the problem that the friction stir welding faying surfaces of the lock bottom structure cannot be welded is solved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

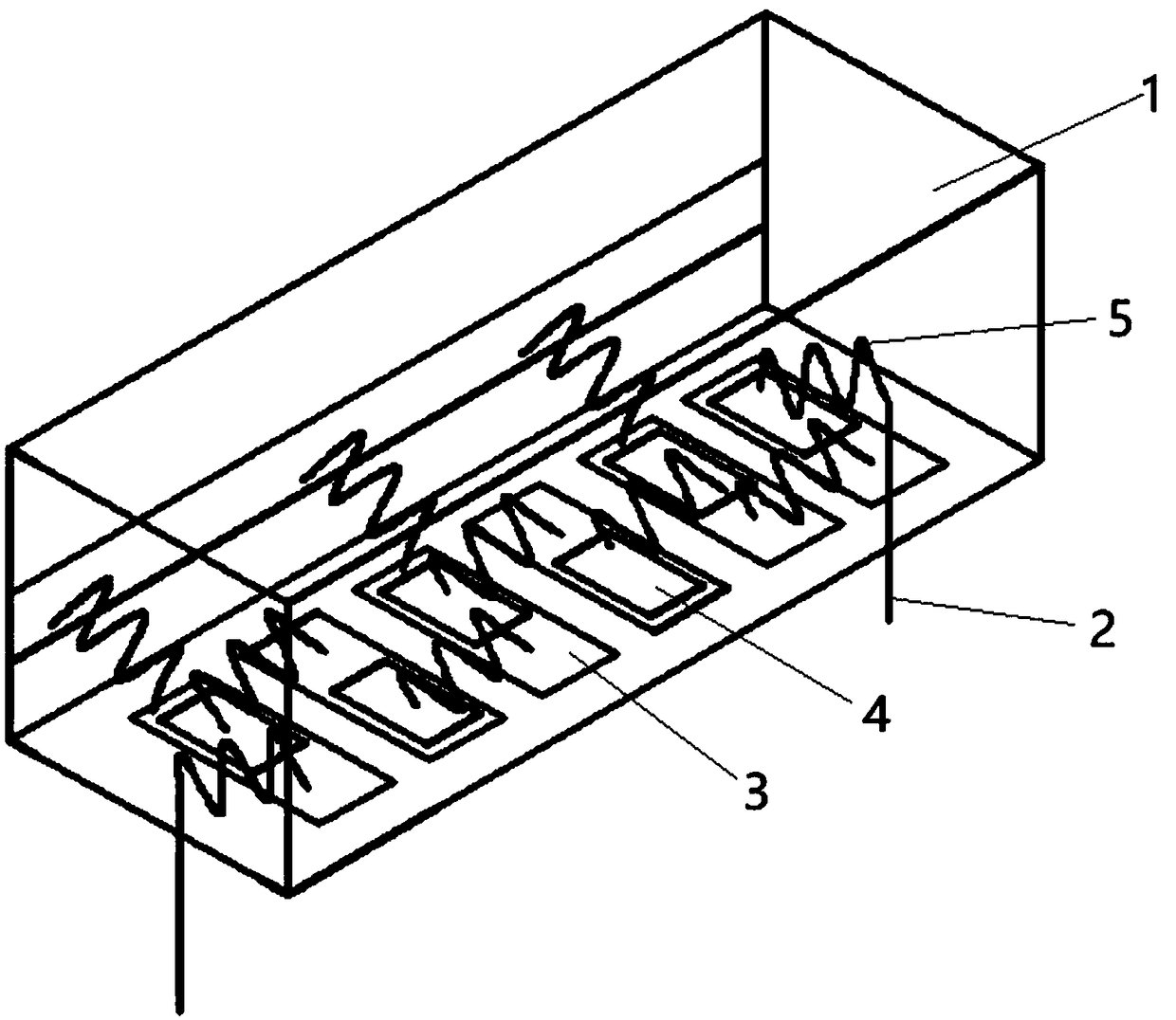

Current extraction device for aluminium base flexible conductive backboard

InactiveCN105895710AEasy to implementLow production costPhotovoltaic energy generationSemiconductor devicesAluminium foilCopper foil

The invention discloses a current extraction device for an aluminium base flexible conductive backboard. The current extraction device includes a solar battery piece layer 1, an insulation adhesive film layer 3, an aluminium foil conducting layer 4 and a solar battery backboard film layer 5, wherein the solar battery piece layer 1, the insulation adhesive film layer 3, the aluminium foil conducting layer 4 and the solar battery backboard film layer 5 are pressed together successively; a plurality of conductive through holes 9 are formed in the insulation adhesive film layer 3; conductive silver adhesives 2 are injected in each conductive through hole 9; a plurality of accommodating through holes are formed in the solar battery backboard film layer 5; an electrode extraction cluster point 6 is formed in each accommodating through hole through deposition by means of an ultrasonic cold spraying technology; a conductive belt 7 is welded on each electrode extraction cluster point 6; and the current is output to a photovoltaic conjunction box 8. For the current extraction device for an aluminium base flexible conductive backboard, electrical connection is established between the aluminium foils and the conductive belts through the electrode extraction cluster points; the problem that welding with the conductive belts cannot be realized because of existence of an aluminium foil backboard oxide layer is solved; and the aluminium foil successfully replaces a copper foil so that the manufacturing cost of a solar back contact assembly is greatly improved.

Owner:山东拜科通新材料科技有限公司

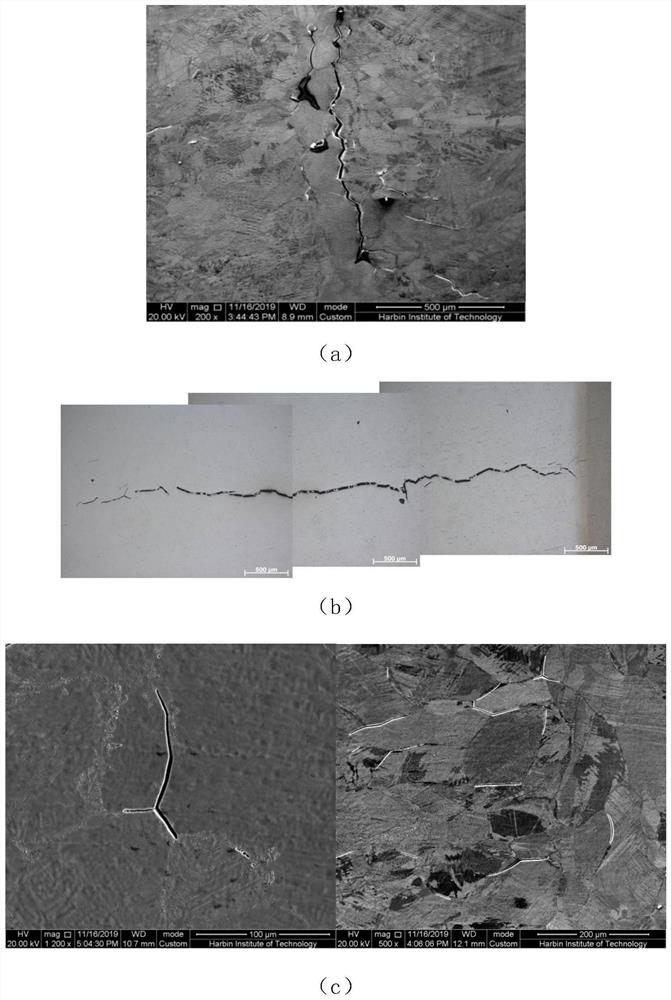

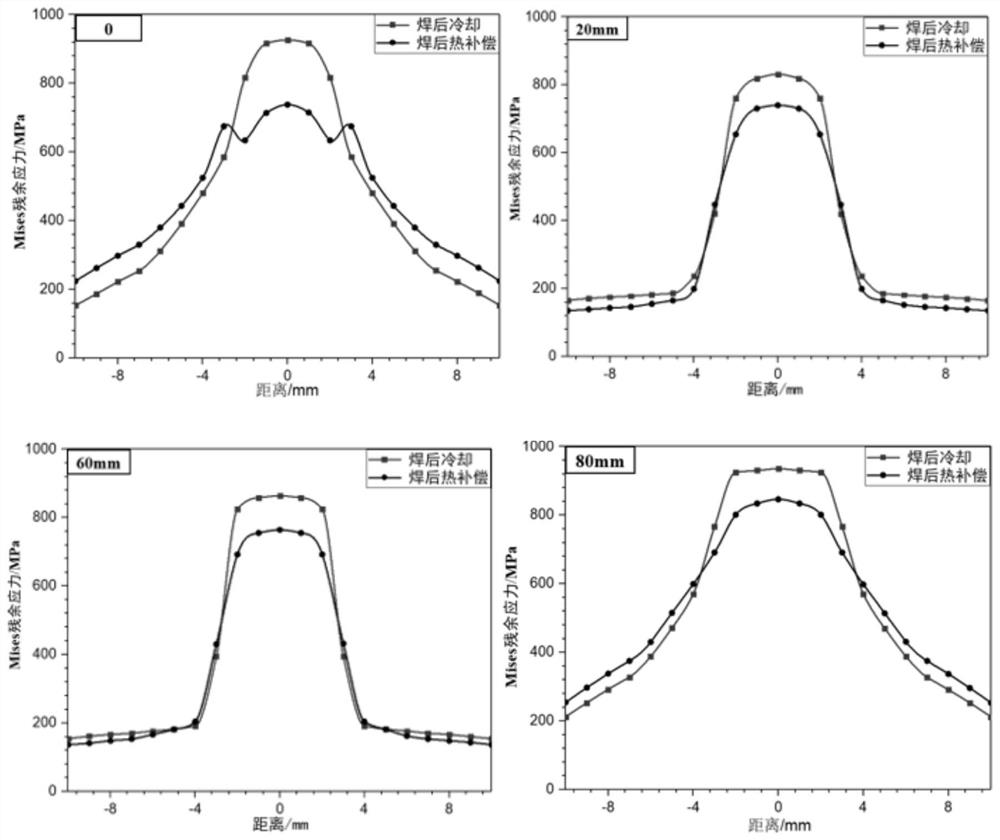

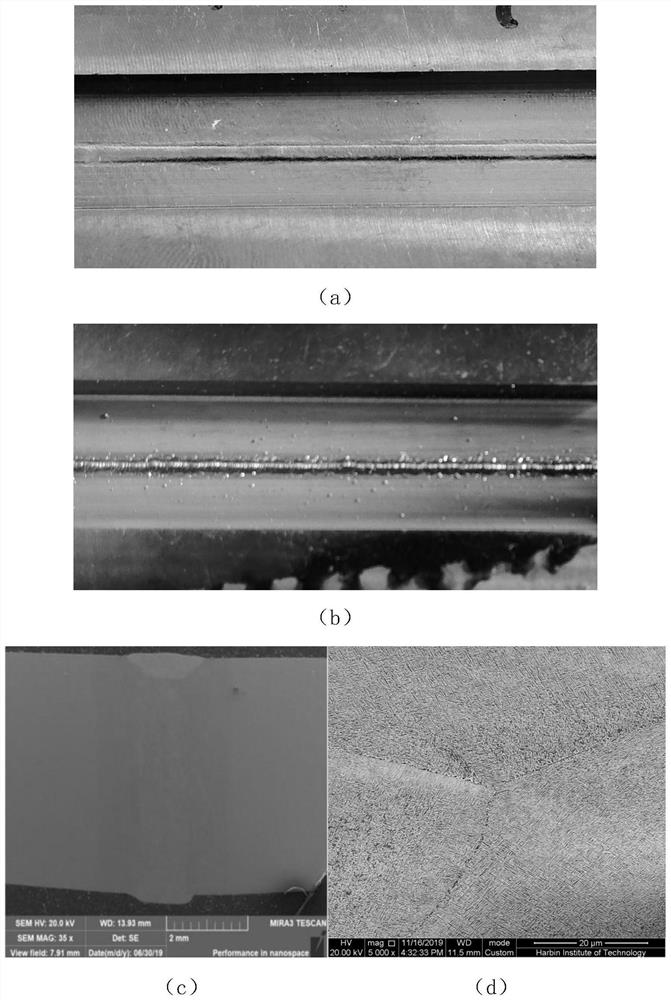

Electron beam weld joint micro-crack control method for Ti2AlNb material

ActiveCN112091399ASolve the problem of not being able to weldAchieving a solder connectionElectron beam welding apparatusCrazingSlow cooling

The invention belongs to the field of welding of intermetallic compounds, and particularly relates to an electron beam weld joint micro-crack control method for an intermetallic compound Ti2AlNb material. In order to solve the problems that a Ti2A1Nb material is low in plasticity, large in brittleness, poor in weldability, prone to generating micro-cracks and the like, according to the property and the reason of crack generation, in combination with the characteristics of an electron beam welding process, key parameters such as reasonable welding speed and current are determined, a reasonableelectron beam preheating and slow cooling process and a reasonable post-welding stepped heat treatment process are designed, and control over electron beam weld joint cracks is achieved. According tothe method, reliable electron beam weld joint connection of a Ti2AlNb structural part can be achieved, the manufacturing difficulty, cost and weight are reduced, the performance of parts is improved,the room temperature and high temperature performance of a weld joint reaches 90% or above of that of a base material, the quality can meet the standard I-level weld joint requirement, and the application range of Ti2AlNb in the aerospace field is widened.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

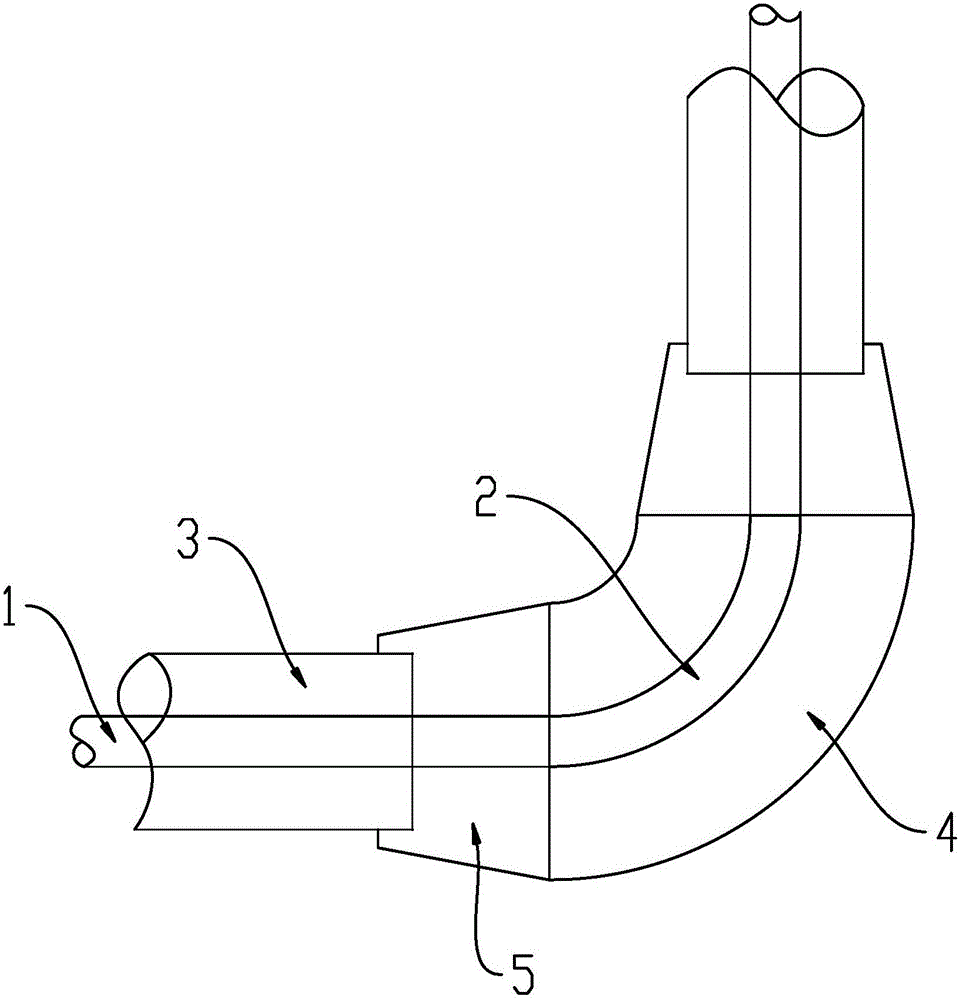

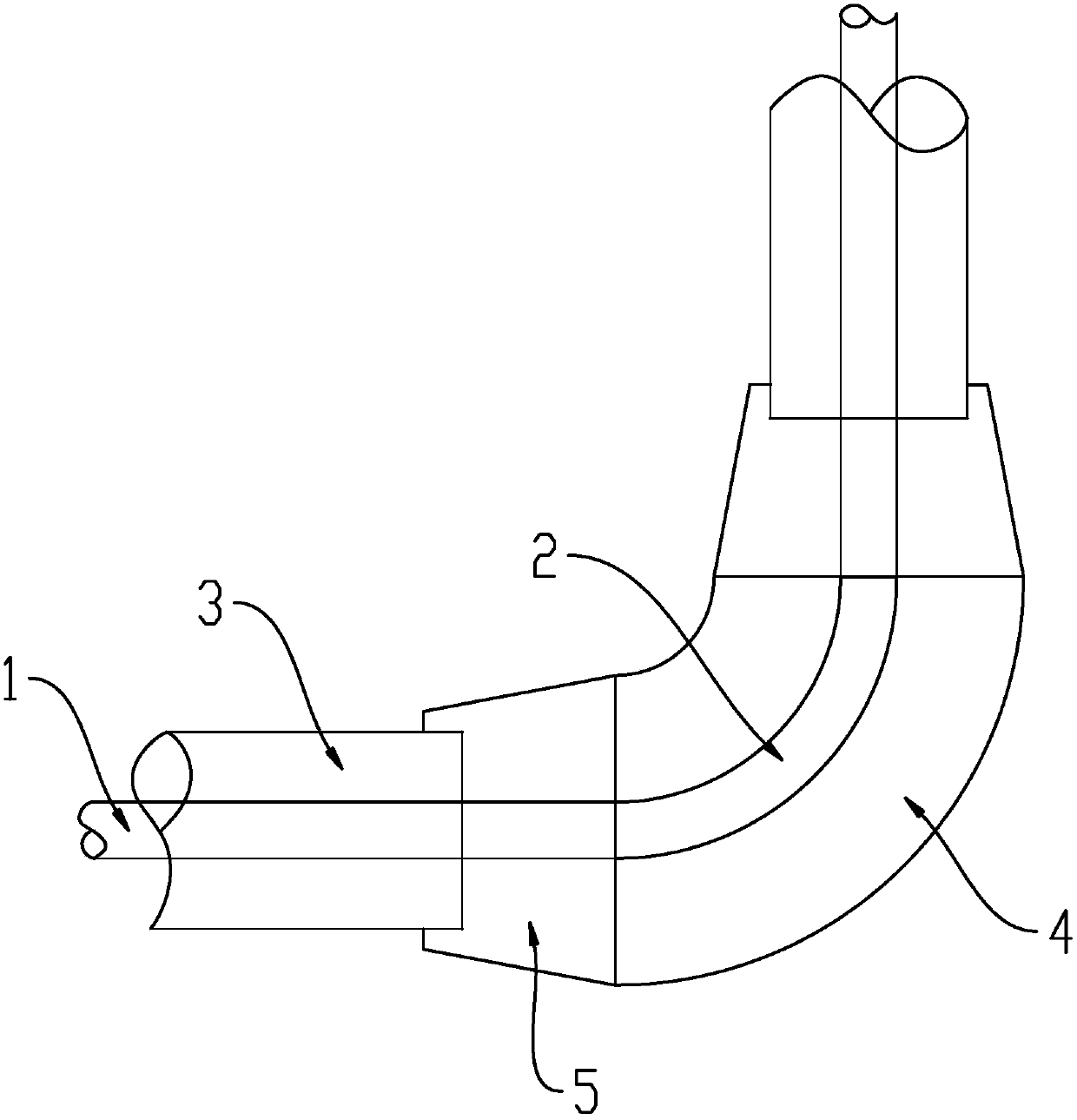

Welding method for two-layer pipe elbow

ActiveCN105834605ASolve the problem of not being able to installSolve the problem of not being able to weldWelding apparatusEngineering

The invention discloses a welding method for a two-layer pipe elbow. The two-layer pipe elbow comprises an inner straight pipe, an inner pipe elbow body, an outer straight pipe and an outer pipe elbow body. The inner diameter of the outer pipe elbow body is larger than the outer diameter of the outer straight pipe. The two sides of the outer pipe elbow body are provided with different-diameter connectors which are connected with the outer straight pipe. The problem that the two-layer pipe outer straight pipe cannot be installed is solved on the basis of the welding method for the two-layer pipe elbow. According to the welding method for the two-layer pipe elbow, the two-layer pipe elbow is reasonably divided into three parts, that is, the elbow body with an enlarged diameter and the two different-diameter connectors (welded to the outer straight pipe in an overlap mode), and thus the problem that the inner straight pipe cannot be welded is solved; and meanwhile, the outer pipe elbow body can be welded at last, and a space is easily transferred out by the outer pipe elbow body through moving of the different-diameter connectors on the outer straight pipe.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Environmental protection ionic metal welding and cutting gas

The invention relates to a new type environmental protection ion metal welding-cutting gas. It uses oxyacetylene flame to weld and cut metal. It has advanced product mechanism and wide market prospect. Its mother liquor is oil liquefied gas or propane. And its additive is made up of potassium permanganate, hydrogen peroxide, acetone, toluene, xylene, and ligroin. Its advantages are that it has good cutting and welding effect and can work under water; and its using is safe and has no pollution and the three wastes.

Owner:金志杰 +1

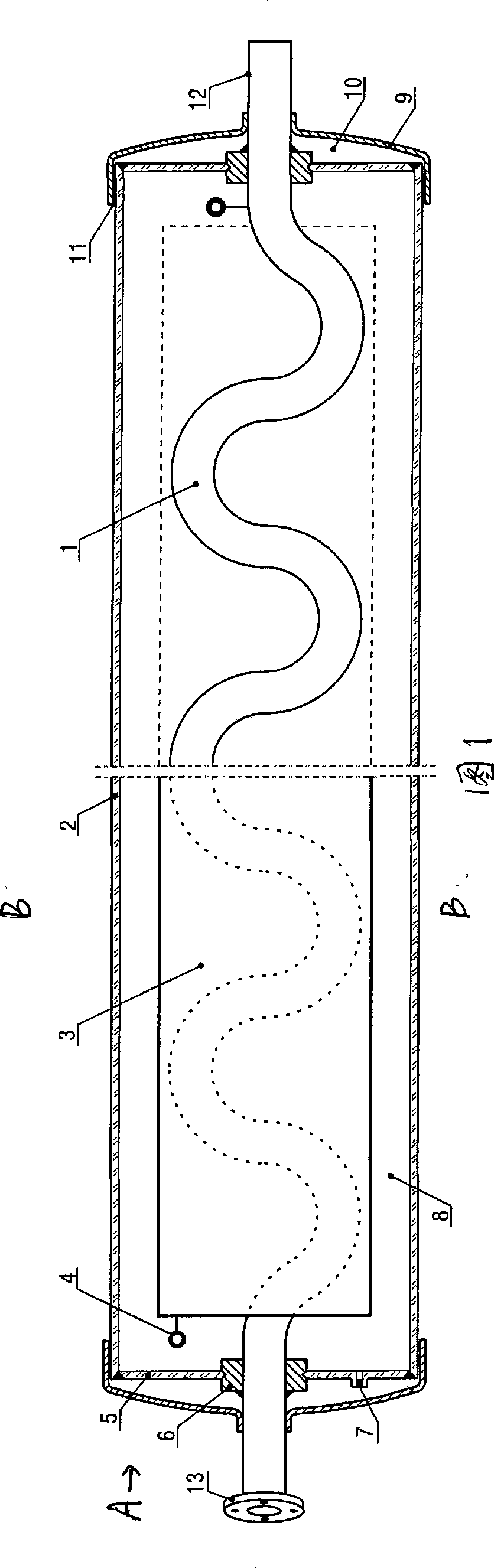

S-shaped through type solar thermal-collecting tube

InactiveCN101368763ASolve the problem of not being able to weldSolve the problem of maintaining a vacuumSolar heating energySolar heat devicesHeating energyGlass tube

Disclosed is an S-shaped through solar energy collector tube which mainly comprises an inner metal tube and an outer glass tube; the inner metal tube is an S-shaped bent metal tube; both ends of the outer glass tube are at least sealed by glass end covers; the vacuum state is formed between the inner tube and the outer tube; the middle parts of the glass end covers are pressed or fused with alloy material; the inner metal tube is extended from the alloy material; the alloy material is in closed welding with the inner metal tube; the glass end covers are fixed connected with the outer glass tube through fusion joint or adhesion; the alloy material is used for the close welding when the S-shaped metal inner tube and the glass tube are integrated into a whole; the S-shaped through solar energy collector tube has the advantages of high heat energy utilization rate, no sundry accumulation, uneasy scaling, good anti-compression ability, generating water or steam with high heat quantity, not only being applicable to the solar energy heat source for households, but also being applicable to the production requirements of large-scale groups and enterprises.

Owner:周锡明

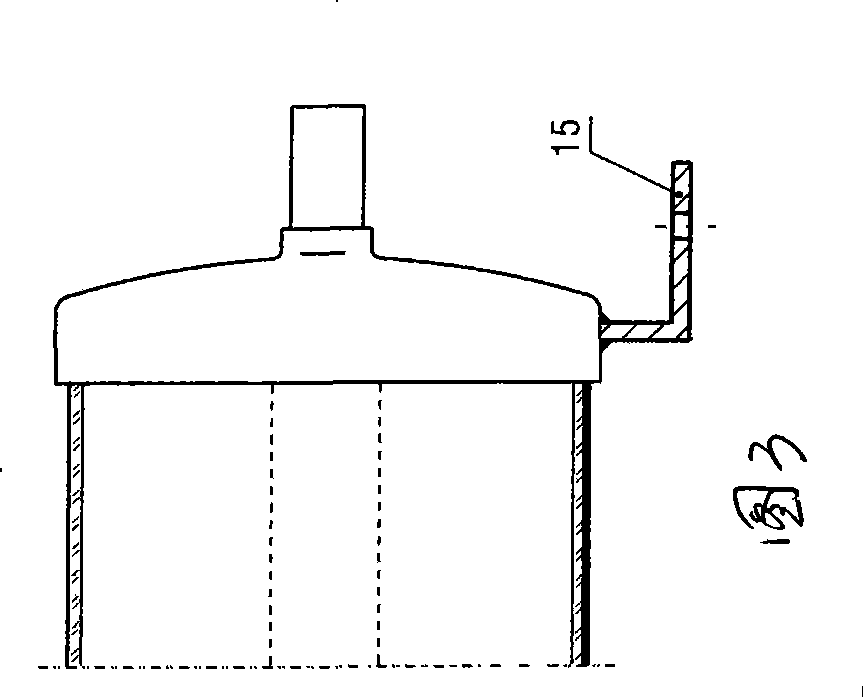

Connector and connection method of graphite composite grounding bodies

InactiveCN105633606AFirmly connectedSolve the problem of not being able to weldClip conductor connectionClamped/spring connectionsUltimate tensile strengthGraphite composite

The present invention relates to a connector and connection method used for connecting a plurality of graphite composite grounding bodies. The connector comprises two conductive clamping plates, and bolts, nuts and spacers which are used to connect the two conductive clamping plates fixedly. The two sides of the conductive clamping plates are respectively equipped with a plurality of fixing holes which are arranged at equal intervals and through which the bolts can penetrate, and the fixing holes at the two sides of the conductive clamping plates are in one-to-one correspondence respectively. The two conductive clamping plates are used to clamp the graphite composite grounding bodies by the cooperation of the bolts, the nuts and the spacers, and connect the plurality of graphite composite grounding bodies electrically. The connector of the graphite composite grounding bodies can be widely used in the connection field of the graphite composite grounding materials, can solve the problems that the conventional graphite composite grounding bodies can not be connected by the electrowelding, gas welding, heat-released jointing, etc., can connect the graphite composite grounding bodies more stably, is large in connection intensity and low in connection resistance of connection points, and can satisfy the actual grounding construction demands.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID +1

Welding-free film frame

InactiveCN104860484AReduce dosageShort processing timeMultistage water/sewage treatmentMultiple frameEngineering

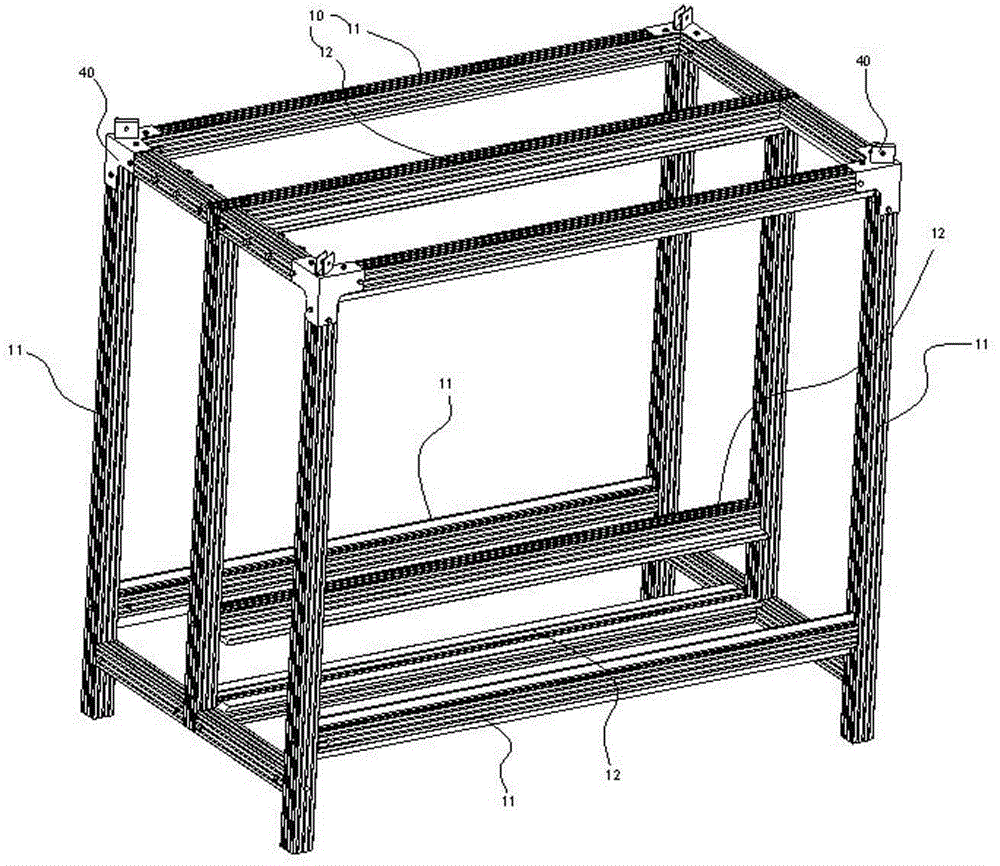

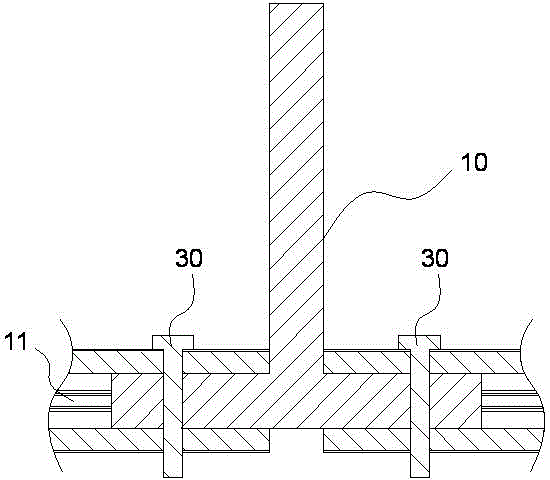

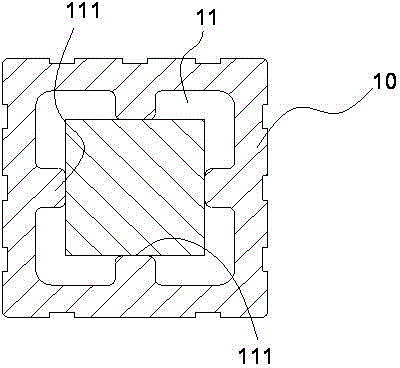

The invention provides a welding-free film frame. The welding-free film frame structurally comprises a plurality of elongated frame components, a plurality of connecting pieces and a plurality of locking pieces, wherein an accommodating groove is formed inside each frame component; each connecting piece is inserted into the accommodating groove of the corresponding frame component, so that the multiple frame components are butted with one another to form a rectangular frame; each locking piece penetrates through the corresponding frame component and the corresponding connecting piece to fixedly connect the frame component and the connecting piece. According to the welding-free film frame, the problems of a conventional stainless steel film frame are solved. Through the structural improvement, a welding process is eliminated, and the problem that welding cannot be carried out in the manufacturing process of the film frame by adopting new materials such as plastic and bamboo charcoal fibers to replace stainless steel is solved; moreover, the consumption of screws and sheet metal components is low, the processing time is short, and the manufacturing cost is low.

Owner:广东景天环境科技股份有限公司

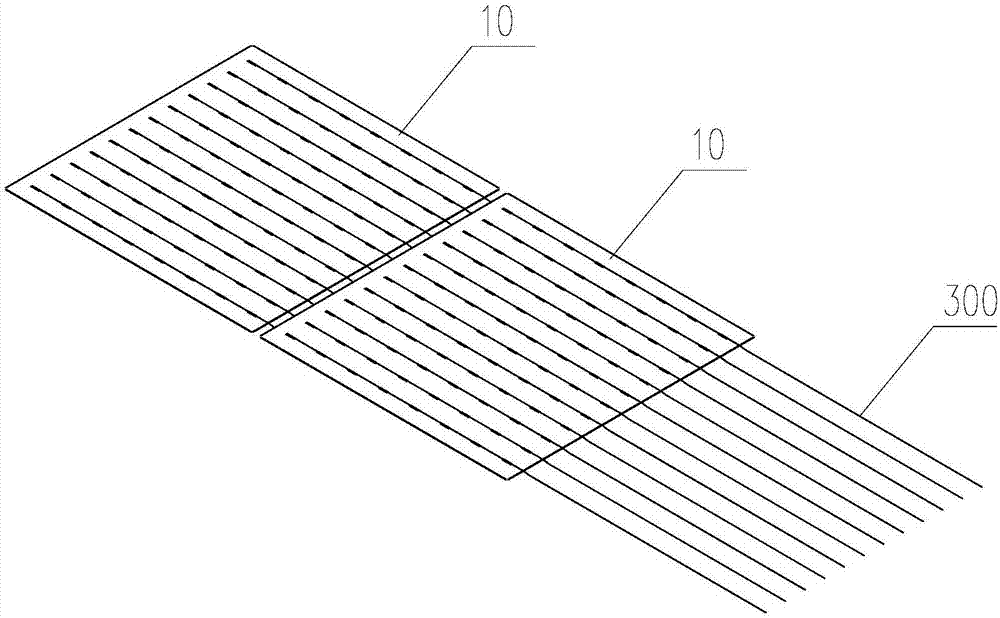

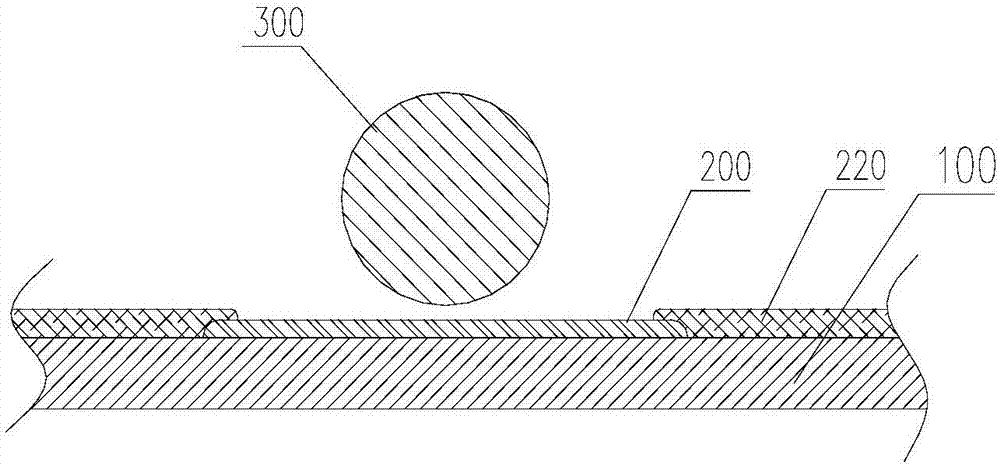

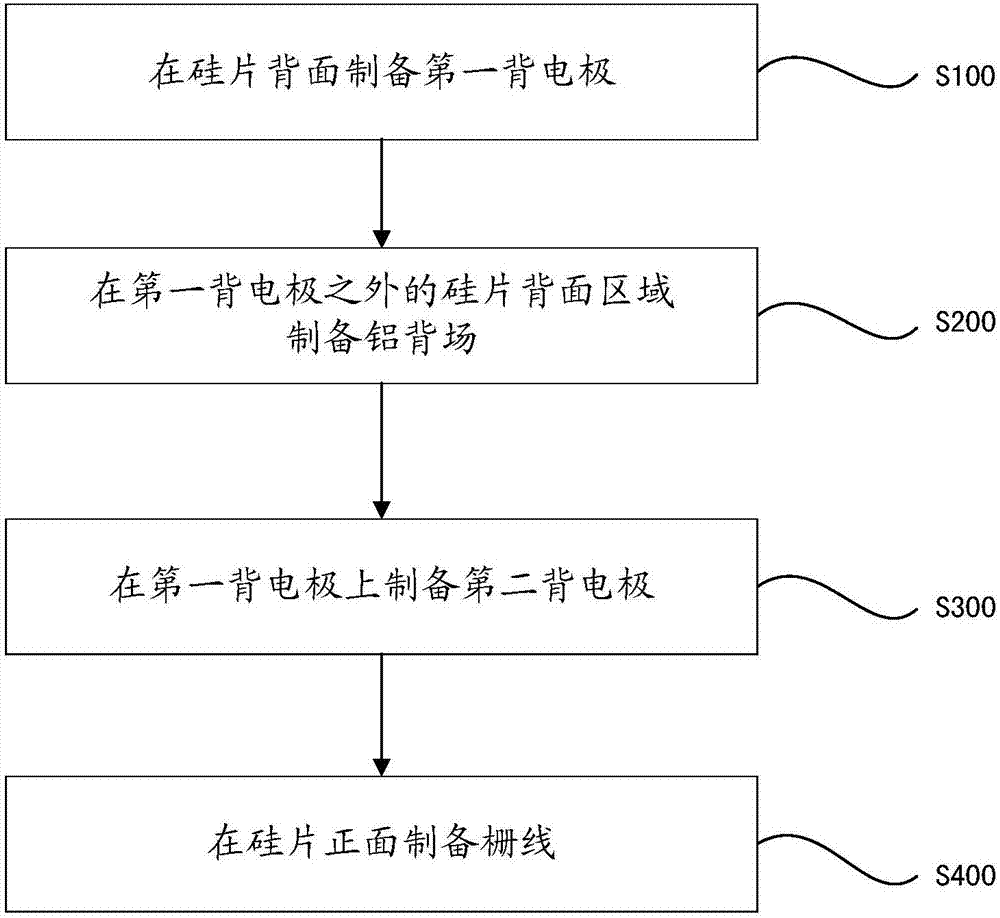

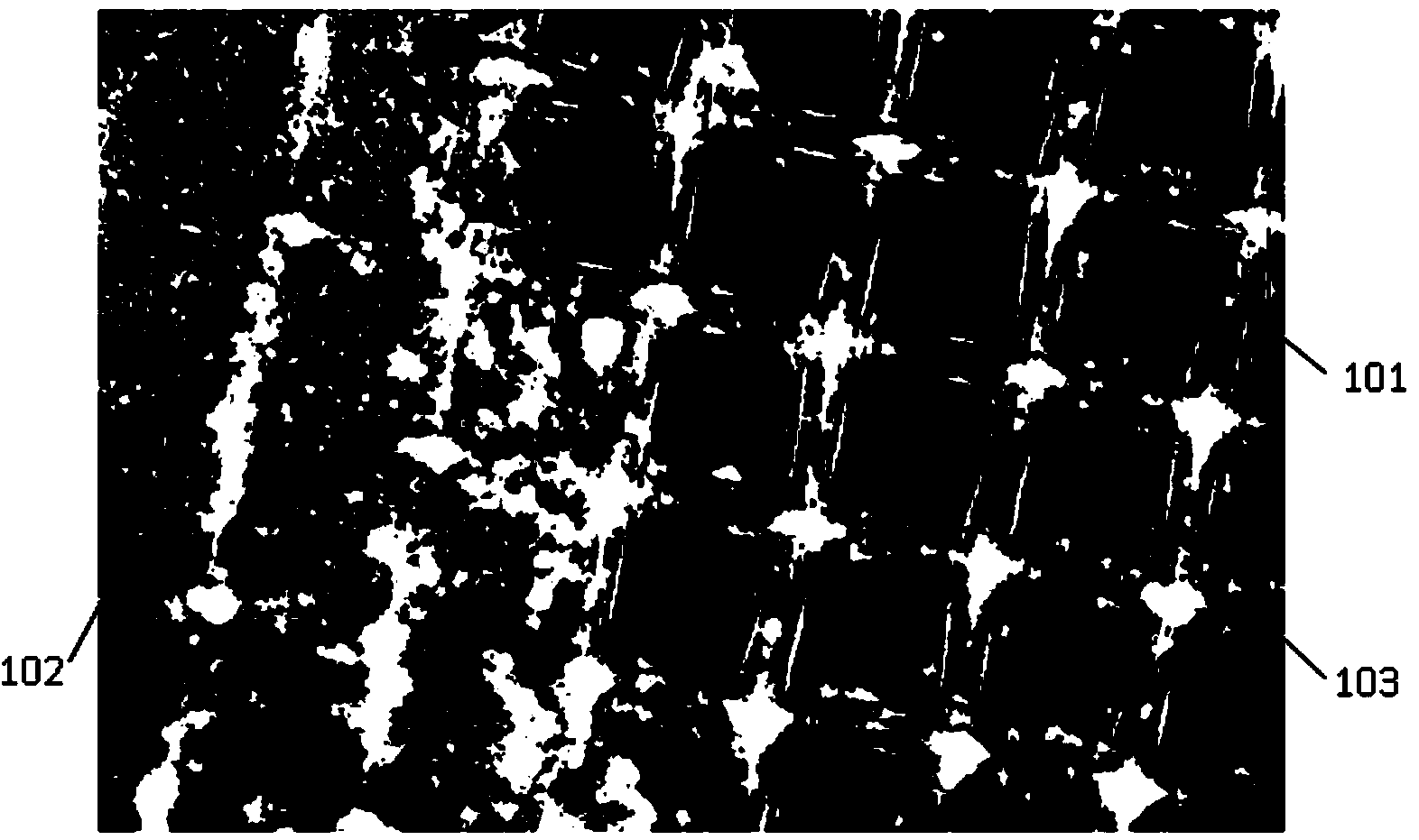

Solar cell piece and preparation method thereof

InactiveCN107394011AEliminate hard-to-reach defectsAvoid solderingFinal product manufacturePhotovoltaic energy generationSolderingSolar cell

The invention provides a solar cell piece and a preparation method thereof. The preparation method comprises: a first back electrode is prepared on the back of a silicon wafer; an aluminum back field is prepared at the back, beyond the first back electrode, of the silicon wafer, wherein the n aluminum back field is in conduction with the first back electrode; a second back electrode is prepared on the first back electrode and the first back electrode and the second back electrode are combined to form a back electrode, so that the thickness of the back electrode is not less than that of the aluminum back field; and a front electrode is prepared on the front side of the silicon wafer. According to the solar cell piece prepared based on the preparation method, because the thickness of the back electrode is not less than that of the aluminum back field, the back electrode and a solder strip are in full contact during cell piece series welding, so that a problem that the back electrode can not be welded with the solder strip or insufficient soldering exists is solved; and a technical bottleneck of volume production of the solar photovoltaic assembly is solved and the industrialization target of the products is realized.

Owner:ZHANGJIAGANG GCL INTEGRATION TECH CO LTD

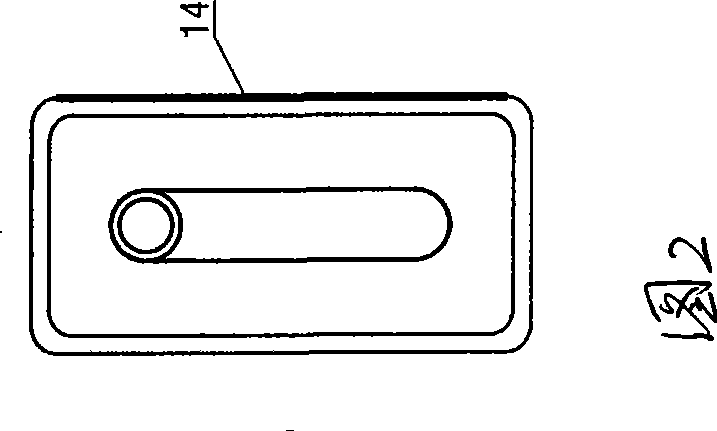

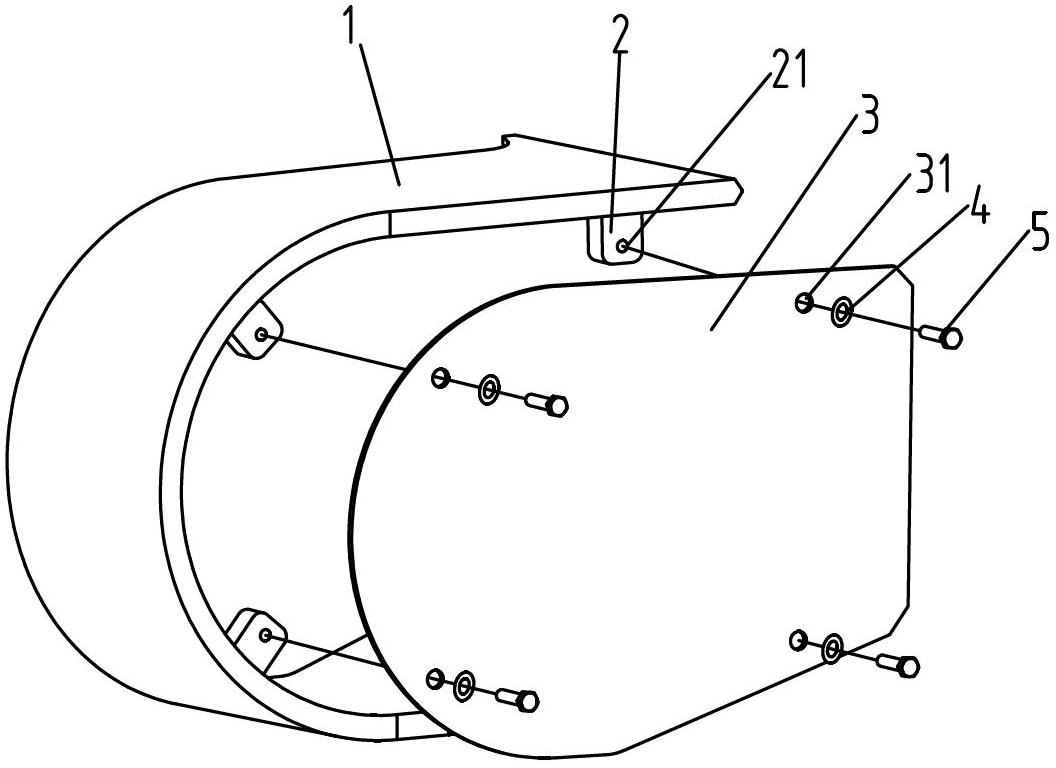

Solar battery main grid mask plate

InactiveCN104241444APut an end to weldingSimple structural designFinal product manufacturePhotovoltaic energy generationEngineeringSolar battery

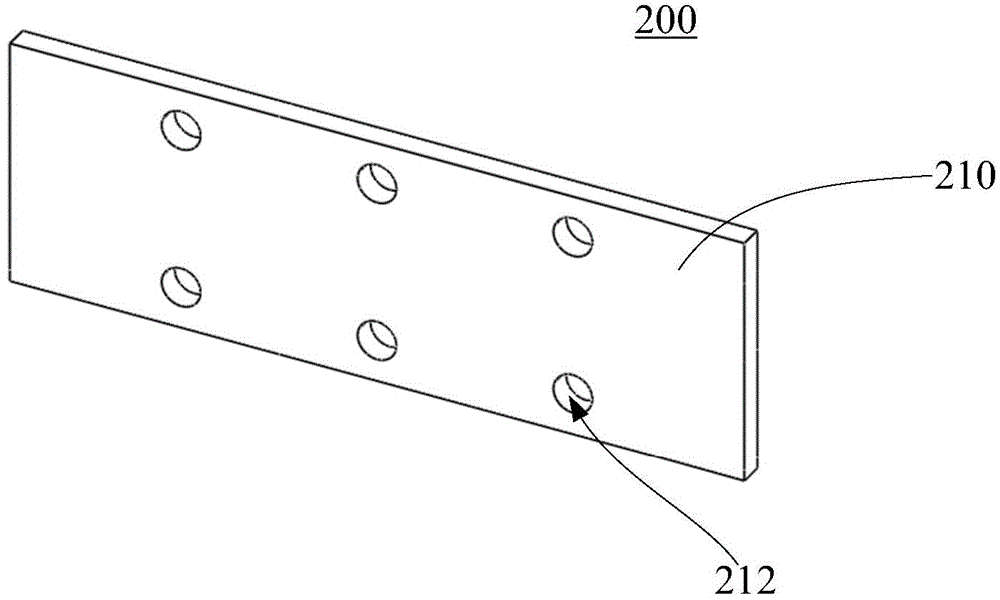

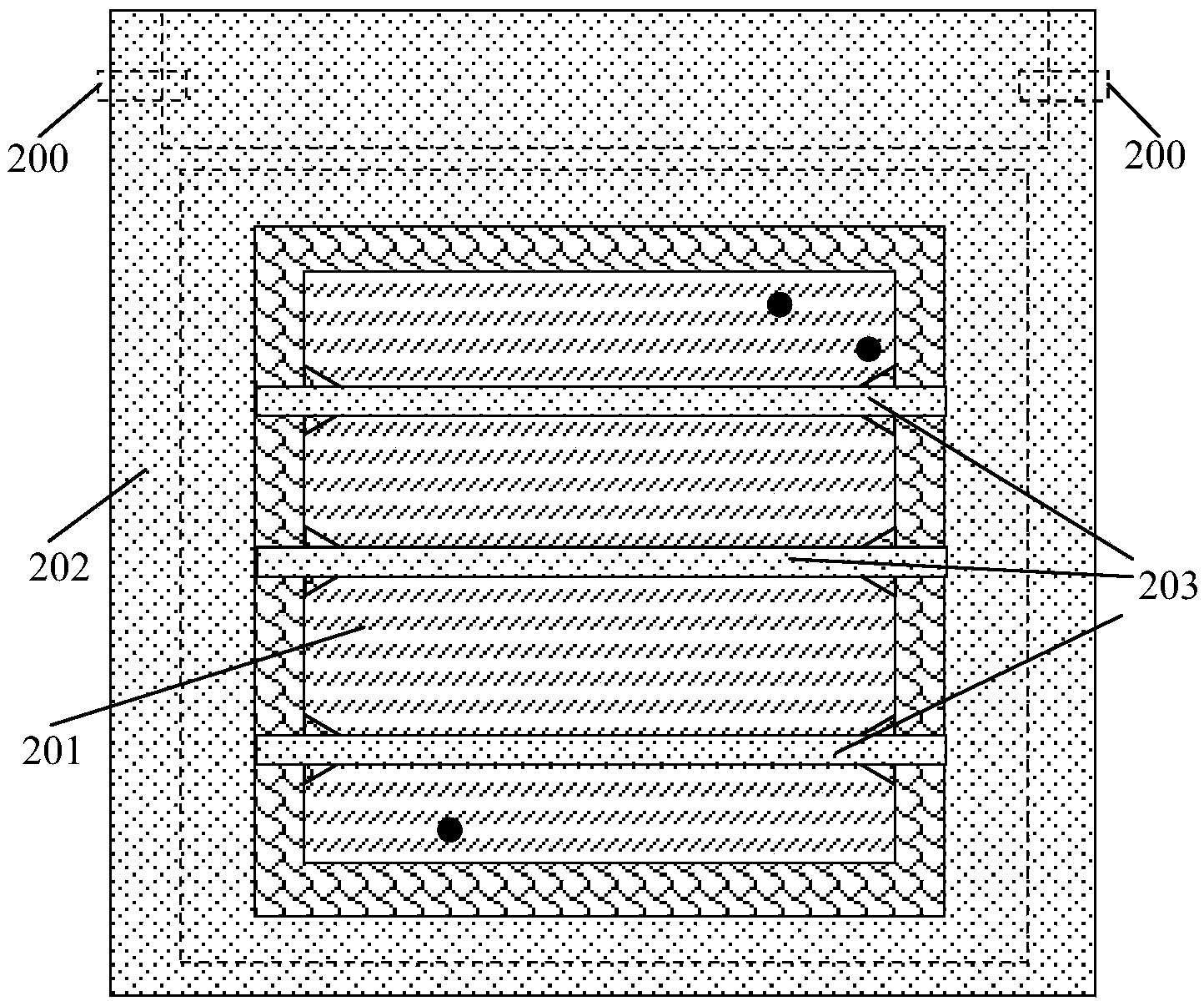

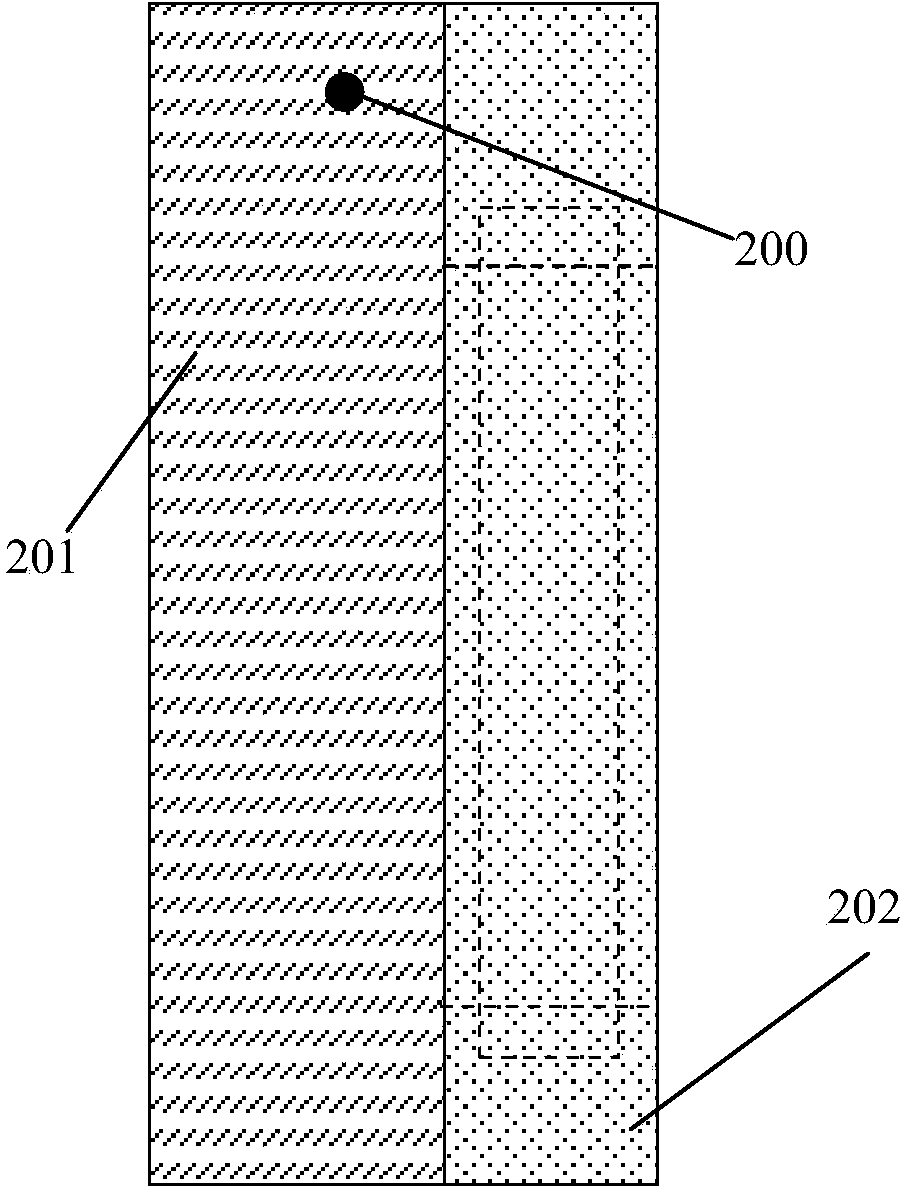

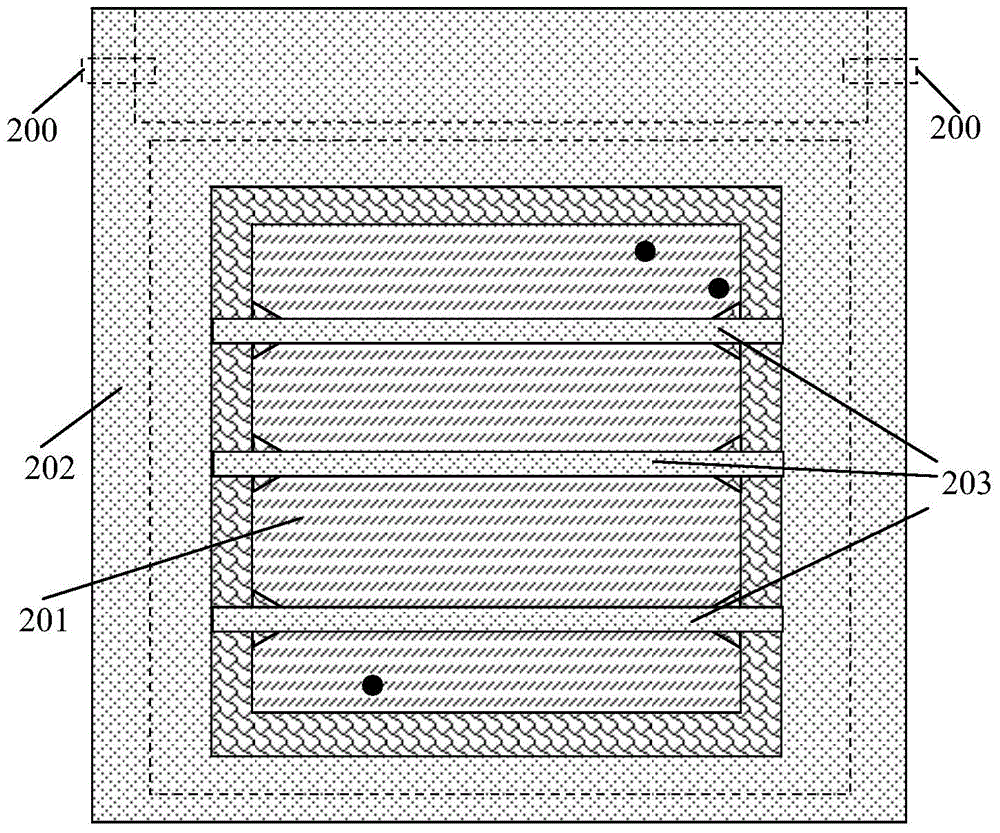

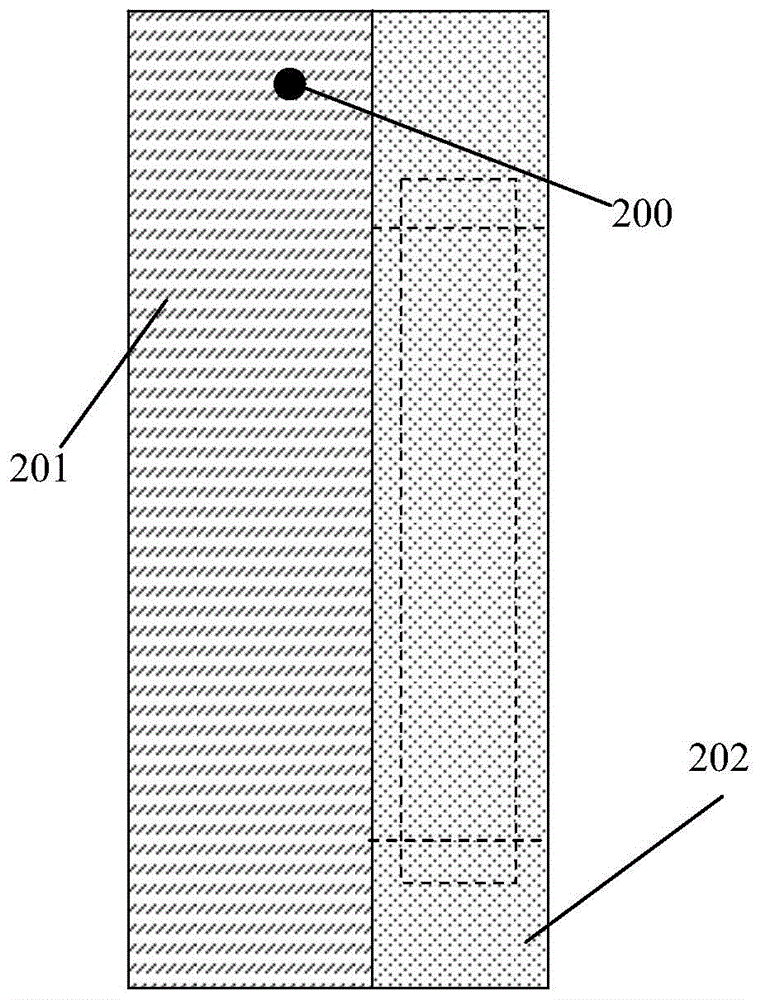

A solar battery main grid mask plate is composed of bolts (200), a base plate (201), a cover plate (202) and mask strips (203). The solar battery main grid mask plate is horizontally arranged. The base plate (201) is arranged at the lower portion. The cover plate (202) is arranged on the base plate (201). The mask strips (203) are arranged inside the middle area on the cover plate (202). The number of the mask strips (203) is equal to that of main grids needed when a solar battery forms a mask. Base plate latch holes and cover plate latch holes are symmetrically distributed in the sides of the base plate (201) and the cover plate (202) in the same direction. The bolts (200) are adopted for fixing the base plate and the cover plate through the base plate latch holes and the cover plate latch holes, so that the solar battery main grid mask plate forms a hinge structure capable of being opened and closed freely.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

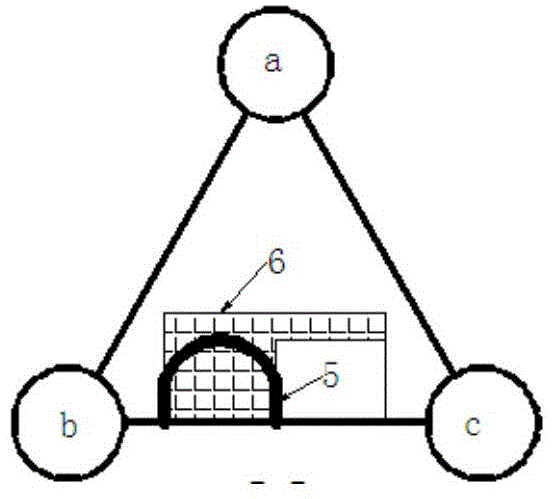

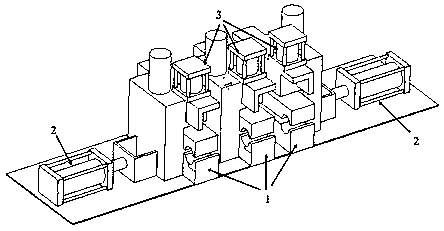

Synergetic operating device with integration of inner pipelines and longitudinal maintenance ladders in LNG storage tank

ActiveCN104358998AMeet the process layout requirementsMeet the needs of troubleshootingPressure vesselsLaddersLNG storage tankStorage tank

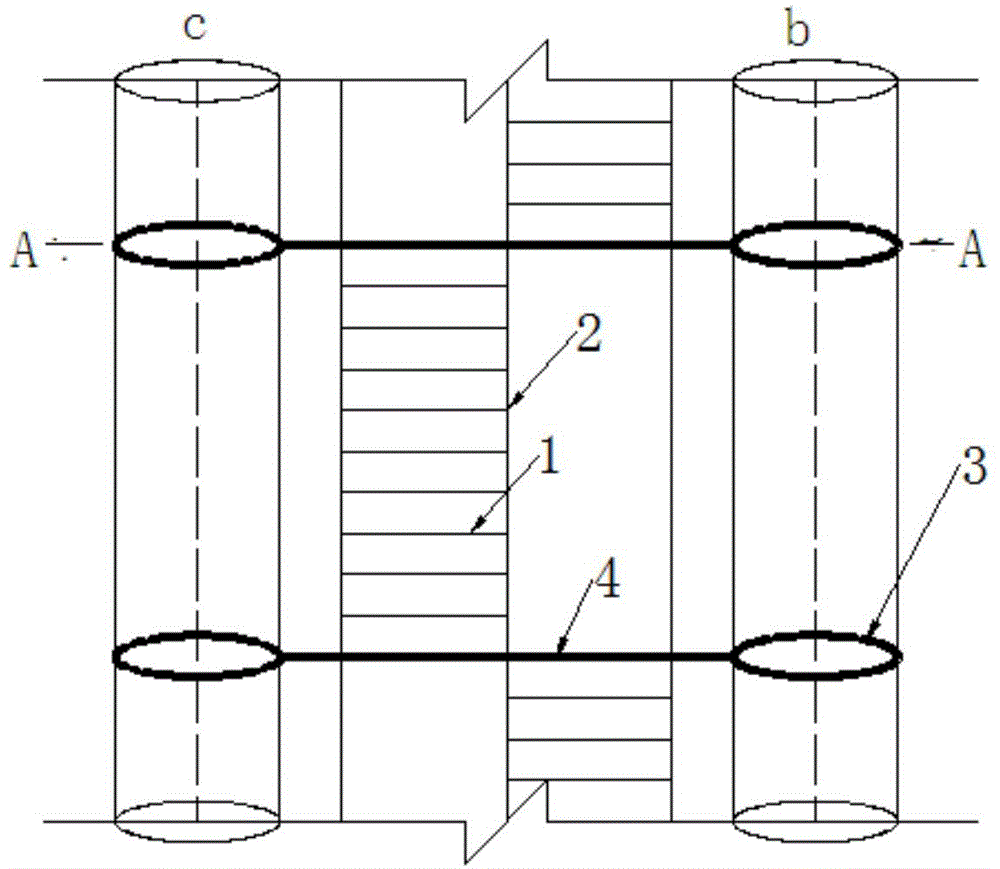

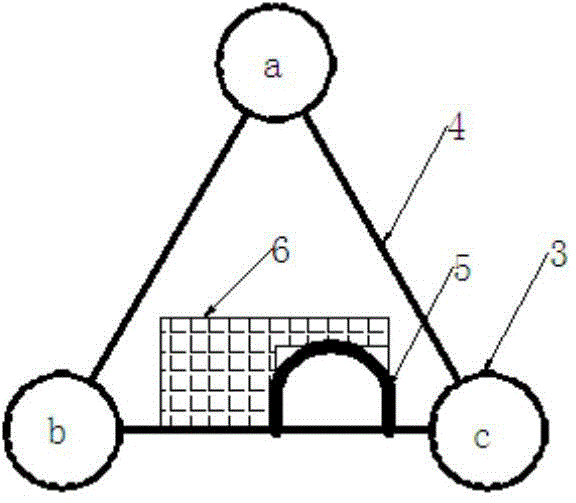

The invention discloses a synergetic operating device with integration of LNG storage tank inner pipelines and longitudinal maintenance ladders. The synergetic operating device comprises three LNG storage pipelines and longitudinal maintenance ladders which are arranged in an LNG storage tank, wherein the three LNG storage tank pipelines are arranged at the bottom of the LNG storage tank; connection lines in the horizontal direction are triangular; the three LNG storage tank pipelines are parallel to one another; a plurality of annular connection parts are welded on the LNG storage tank pipelines; three annular connection parts, arranged on the same plane, on the three LNG storage tank pipelines are connected with one another in a welding mode by virtue of horizontal connection parts; the longitudinal maintenance ladders are arranged on two adjacent horizontal connection parts; each longitudinal maintenance ladder comprises two parallel vertical pull rods and a plurality of step beams which are connected among the vertical pull rods. According to the synergetic operating device, the maintenance ladders and the pipelines are combined into an integrated structure; the safety of the structure is improved; the stress of the single pipeline constraint position is alleviated; the site construction is facilitated; the construction period can be shortened.

Owner:CHINA NAT OFFSHORE OIL CORP +1

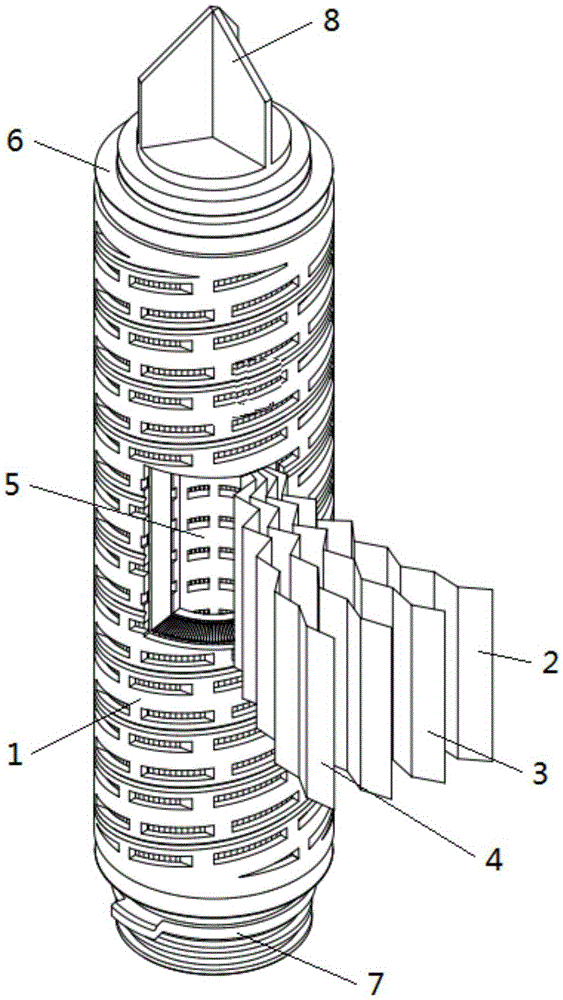

Anti-aging air-sterilization filter core

ActiveCN105413495ASolve the problem of not being able to weldSolve the phenomenon of yellowing and falling powderReverse osmosisGaseous substancesPolyesterGlass fiber

The invention relates an anti-aging air-sterilization filter core. The filter core is composed of a filter membrane, a supporting layer, a flow guide layer, an outer frame, an end cover, a central column, connection ports and fins. The flow guide layer, the filter membrane and the supporting layer are formed in a W-shaped folded manner with edges being sealed through hot melting to totally form a cylindrical body which is installed between the outer frame and the central column, wherein the end surface is sealed by means of the end cover in a hot melting manner. The connection ports and the fins are welded to the two ends to form the complete filter core. The outer frame and the central column are made from a polypropylene material being 25-30 wt% in glass fiber content and 0.5 wt% in anti-oxidizing agent content. The end cover is made from pure polypropylene resin being 164-167 DEG C in melting temperature and being 95-96% in content of isotactic polypropylene. The filter core is produced with PTFE membrane being 40-60 [mu]m in thickness. The flow guide layer and the supporting layer are produced with 100 wt% polyester or polyphenylene sulfide with gram weight being 80-120 g / m<2>. Compared with a filter core in the prior art, the filter core is good in temperature resistance, is excellent in resistance against steam sterilization, is high in gas throughput and low in resistance, and is high in reliability.

Owner:上海一鸣过滤技术有限公司

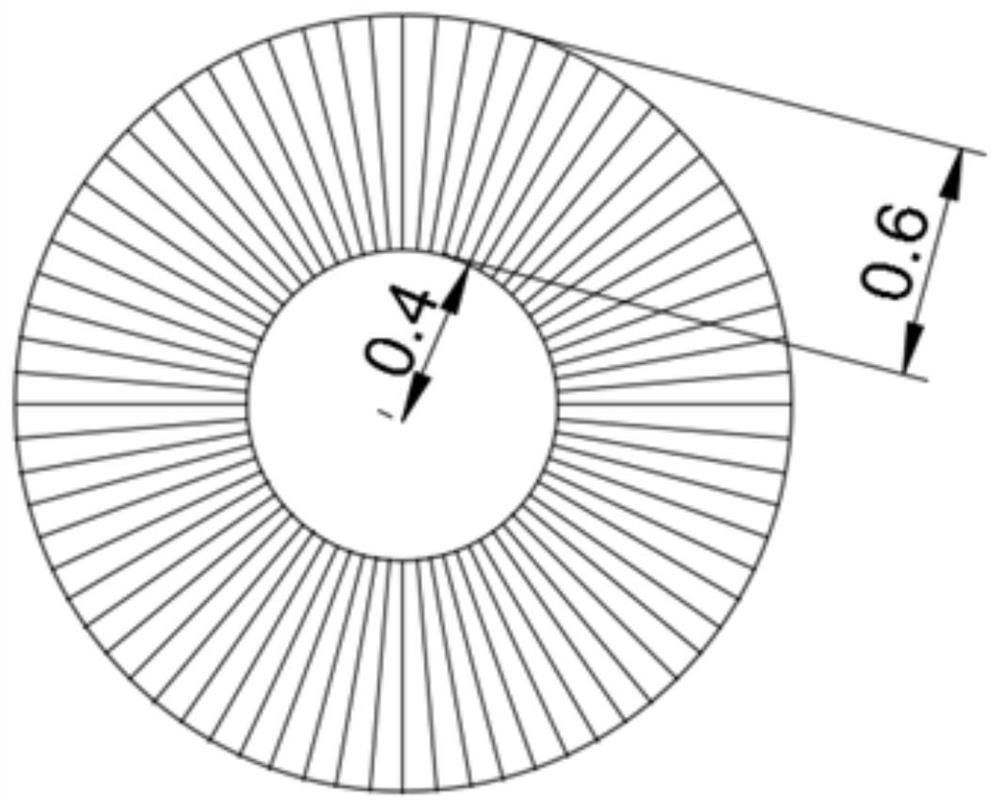

A copper mesh and copper foil welding method

ActiveCN112355469BReduce Depth of Focus FluctuationSolve the problem of not being able to weldLaser beam welding apparatusLaser scanningGalvanometer

The invention discloses a copper mesh and copper foil welding method, comprising the following steps: (1) laser type selection: a 50-150W Fiber laser is used as a welding light source, and the laser adopts MOPA, Q-switching, and QCW quasi-continuous pulse types; 2) Configuration of laser optics: Use galvanometers suitable for spot diameters of 10, 12, 14, 16, 18, 20, 25, and 30 mm as welding beam movement components; use quartz or polymer field mirrors as focusing optical components; The specification of the mirror is any one of F=160, 163, and 170mm; (3) Placement and compression of copper mesh and copper foil; (4) Determine the laser parameter settings; (5) The pattern formed by laser scanning by the galvanometer Track and process method: the invention realizes the reliability and strength of solder joints around the copper mesh.

Owner:SHENZHEN JIXIANGYUN TECH CO LTD

Welding method of double-layer pipe elbow

ActiveCN105834605BSolve the problem of not being able to installSolve the problem of not being able to weldWelding apparatusDouble tubeStraight tube

The invention discloses a welding method for a two-layer pipe elbow. The two-layer pipe elbow comprises an inner straight pipe, an inner pipe elbow body, an outer straight pipe and an outer pipe elbow body. The inner diameter of the outer pipe elbow body is larger than the outer diameter of the outer straight pipe. The two sides of the outer pipe elbow body are provided with different-diameter connectors which are connected with the outer straight pipe. The problem that the two-layer pipe outer straight pipe cannot be installed is solved on the basis of the welding method for the two-layer pipe elbow. According to the welding method for the two-layer pipe elbow, the two-layer pipe elbow is reasonably divided into three parts, that is, the elbow body with an enlarged diameter and the two different-diameter connectors (welded to the outer straight pipe in an overlap mode), and thus the problem that the inner straight pipe cannot be welded is solved; and meanwhile, the outer pipe elbow body can be welded at last, and a space is easily transferred out by the outer pipe elbow body through moving of the different-diameter connectors on the outer straight pipe.

Owner:JIANGNAN SHIPYARD GRP CO LTD

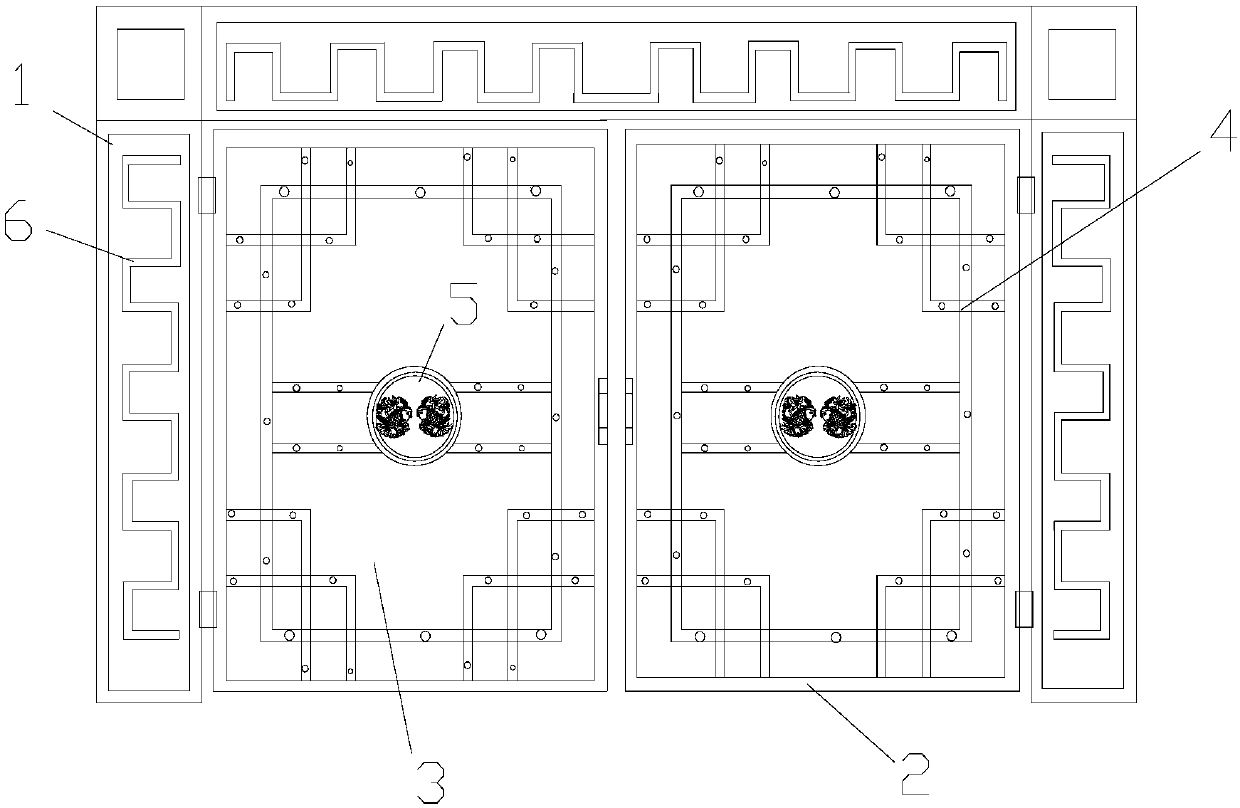

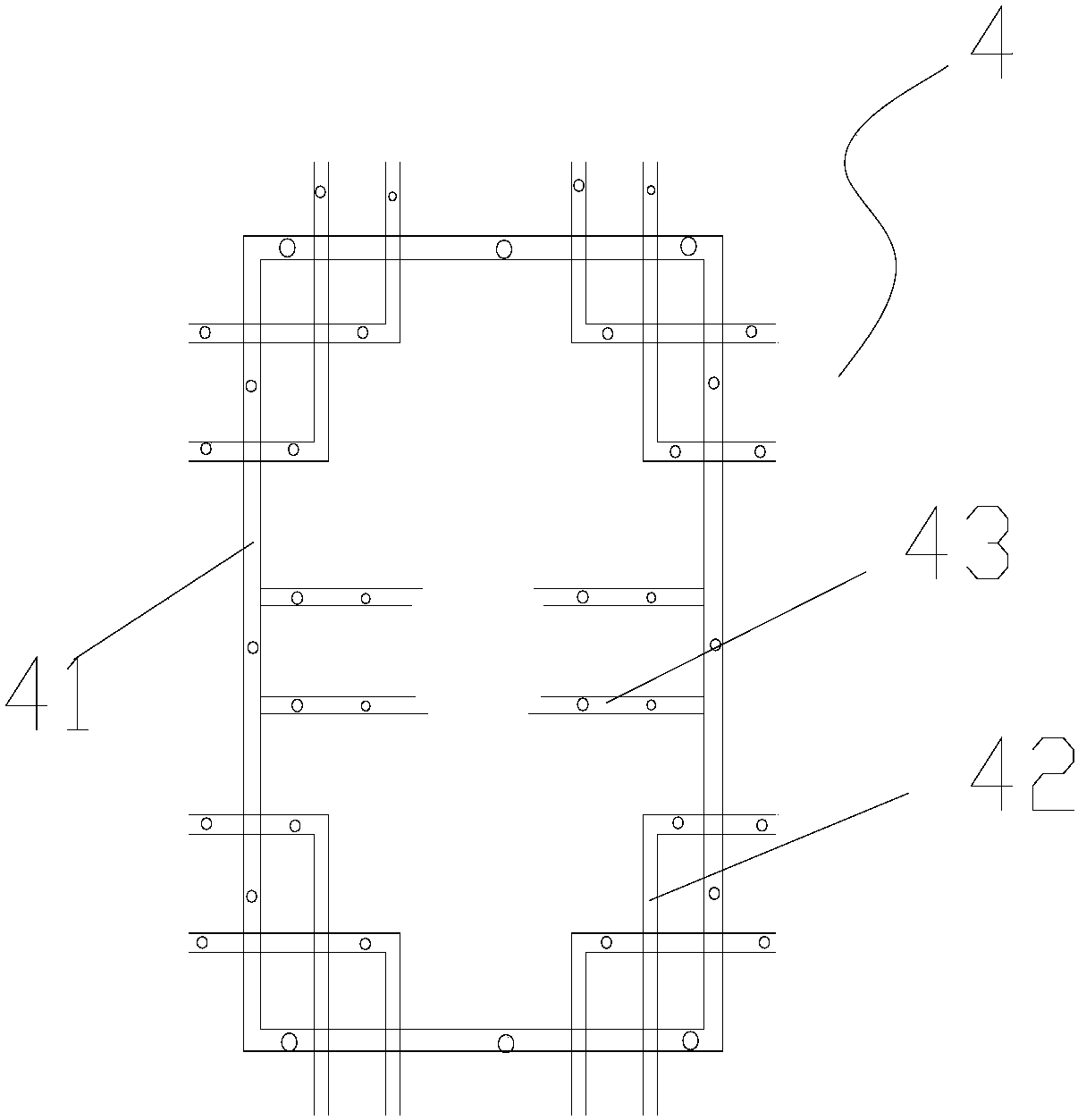

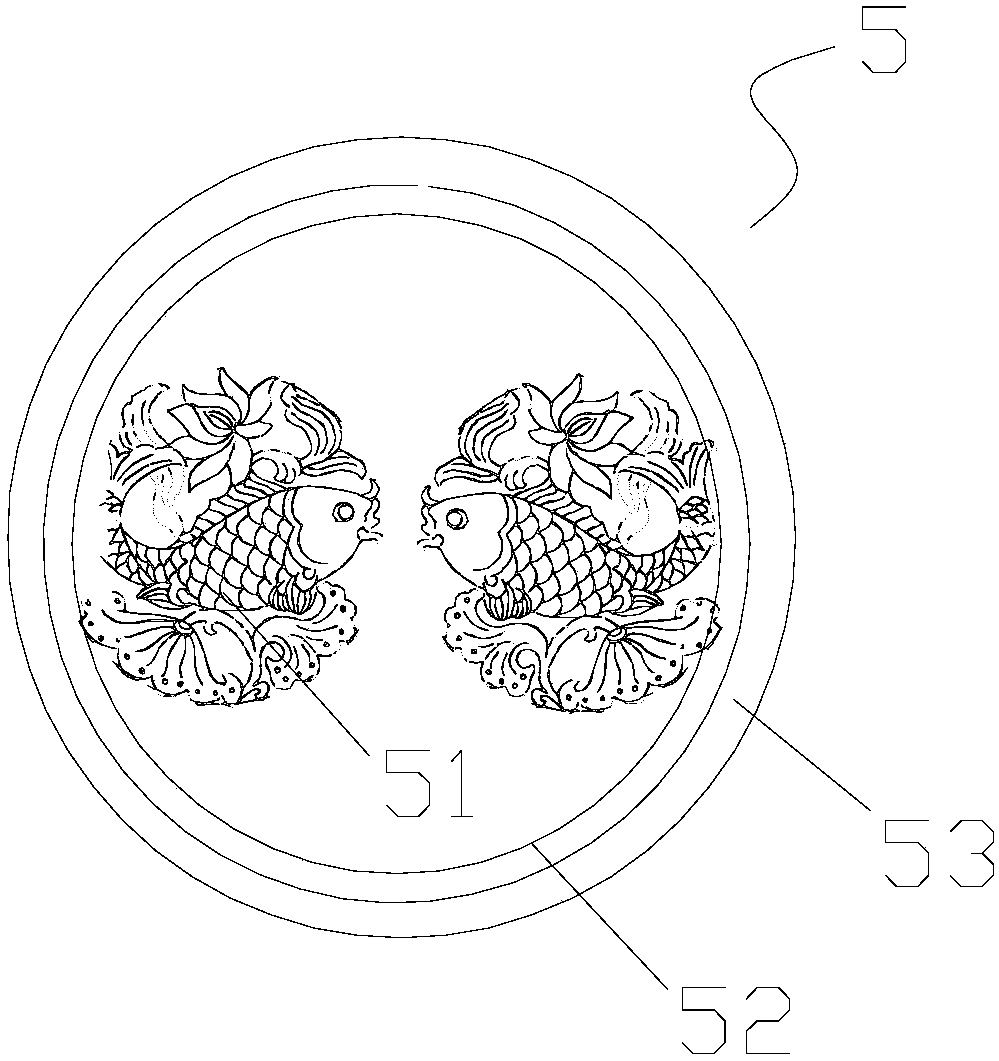

Composite door

InactiveCN109538076ASolve the problem of not being able to weldLight in massWindow/door framesDoor leavesEngineeringSkin structure

The invention discloses a composite door. The composite door comprises a door frame and two opposite door sheets, wherein the door sheets are hinged on the door frame, each door sheet comprises a frame, a skin and a fixing part, the door sheets are of a double-layer skin structure, the skins are arranged in areas formed by the frames, the fixing parts are located at the outer sides of the skins, the fixing parts and the frames are made from stainless steel, the skins are aluminum plates, the fixing parts are welded to the frames, the skins are connected with the fixing parts through bolts, andthe double-layer skins are clamped between the fixing parts at the two sides; the centers of the skins of the sides, facing outward, of the door sheets are provided with first decorative parts. The skins of the door sheets are aluminum plates, the weight is low, carvings are made from aluminum, molding is achieved through casting, the texture is fine, and processing is easy; the fixing parts arearranged at the two sides to clamp the skins in the middle, and the skins and the fixing parts are fixed through bolts, so that the skins, the frames and the fixing parts are fixed integrally, the overall stability is good, and the problem that stainless steel cannot be welded with the aluminum material is solved.

Owner:NANJING SLOW BLESSING OUTDOOR FURNITURE

Method for manufacturing medical NTC temperature sensor structure

PendingCN112277241AAutomateProvides productivityDomestic articlesCoatingsManufacturing efficiencyManufacturing engineering

The invention provides a method for manufacturing a medical NTC temperature sensor structure. The method comprises the following steps that stamping is carried out to form metal sheet bodies, metal pins are formed on the formed metal sheet bodies, the two metal sheet bodies are symmetrically arranged in an injection mold, a set distance is reserved between the two metal pins, a sensing element isprovided, a packaging material is injected into the injection mold so as to form packaging pieces for supporting the metal sheet bodies and wrapping the metal pins and the sensing element, so that manufacturing of the sensor structure is completed. The method is simple in step and convenient to operate, and can greatly improve the manufacturing efficiency and the quality of the manufactured product.

Owner:江苏易感素智能科技有限公司

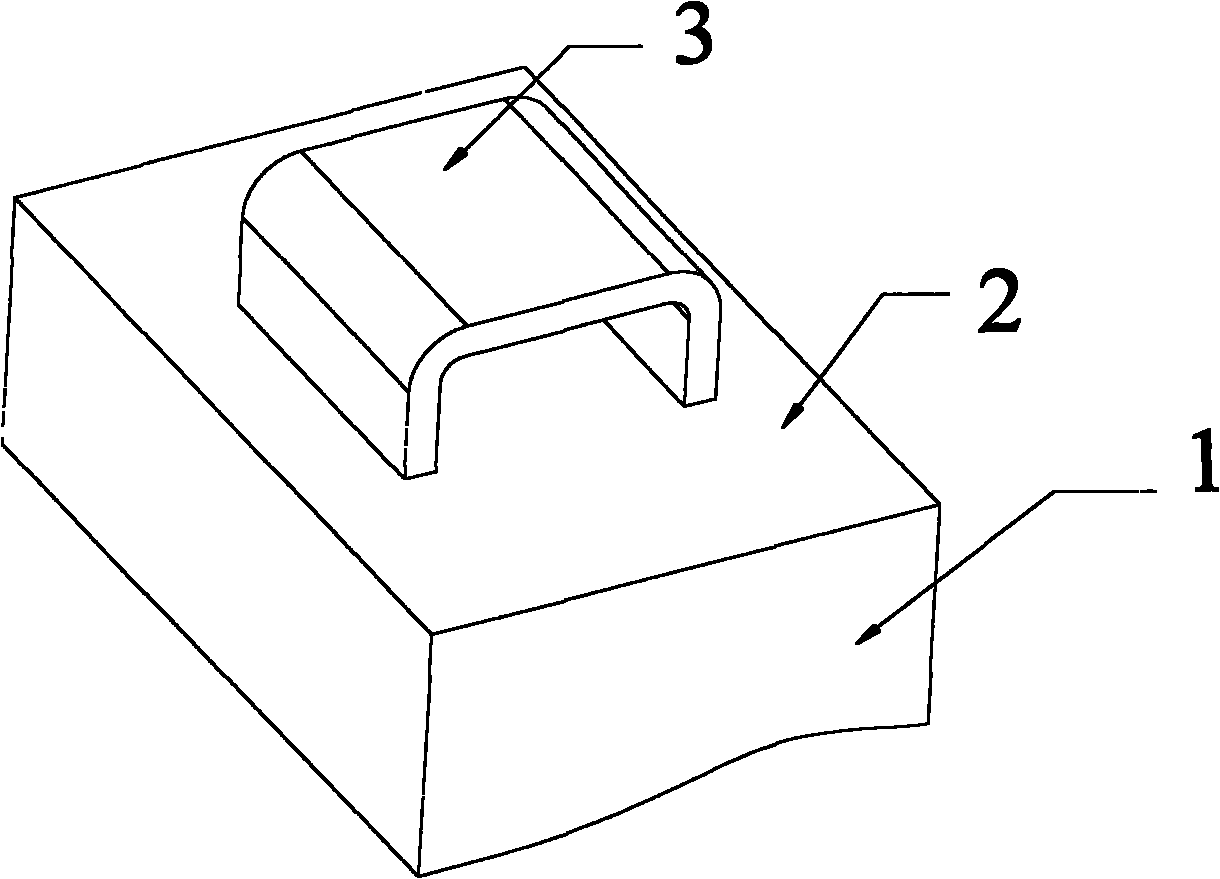

A solar cell busbar mask

InactiveCN104241444BSolve the problem of not being able to weldLow priceFinal product manufacturePhotovoltaic energy generationEngineeringSolar cell

A solar battery main grid mask plate is composed of bolts (200), a base plate (201), a cover plate (202) and mask strips (203). The solar battery main grid mask plate is horizontally arranged. The base plate (201) is arranged at the lower portion. The cover plate (202) is arranged on the base plate (201). The mask strips (203) are arranged inside the middle area on the cover plate (202). The number of the mask strips (203) is equal to that of main grids needed when a solar battery forms a mask. Base plate latch holes and cover plate latch holes are symmetrically distributed in the sides of the base plate (201) and the cover plate (202) in the same direction. The bolts (200) are adopted for fixing the base plate and the cover plate through the base plate latch holes and the cover plate latch holes, so that the solar battery main grid mask plate forms a hinge structure capable of being opened and closed freely.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

Processing method for welding supports on irregular plate

ActiveCN102658460BReasonable structureEasy to adjustWelding apparatusEngineeringMechanical engineering

The invention relates to a processing method for welding supports on an irregular plate. The method comprises the following steps of: (1) bending the irregular plate to form a required shape; (2) mounting a template on a side face of the irregular plate; (2) respectively penetrating more than two positioning pins which are arranged on the template in connecting holes of the supports, and positioning the supports, wherein each support is an eccentric wheel; (4) rotating the supports along the respective positioning pin, so that edges of the supports are connected with the irregular plate; and (5) welding the supports and the irregular plate, and removing the template. The supports have an eccentric wheel structure and are positioned by the positioning pins, so that the supports can rotate along the central axis of the connecting holes under positioning of the positioning pins; and therefore, the distance between the connecting holes on the supports and the irregular plate can be changed, the structure is reasonable, the welding distance between the supports and the irregular plate can be rapidly and accurately controlled, the operation is convenient, and the production efficiency can be improved.

Owner:SINOMACH CHANGLIN CO LTD

Filter capacitor assembling method

InactiveCN109454305ASolve the problem of not being able to weldAvoid disengagementSolder feeding devicesSoldering auxillary devicesFar distanceCapacitance

The invention provides a filter capacitor assembling method. The filter capacitor assembling method comprises the following steps that blocky capacitors are welded on the upper surface of sheet-shapedcapacitors through soldering irons, and capacitor assemblies are formed; leading-out pins penetrate through the left side and the right side of the lower surface of the filter shell, and welding andfixing are carried out through soldering iron; the filter shell is placed on a heating device to be heated to a certain temperature; a layer of soldering tin is added to the lower surface of the interior of the filter shell, then the capacitor assemblies are clamped and placed on the upper surface of the soldering tin, and then the capacitor assemblies are kept for a certain time and then loosened; the adjacent capacitor assemblies, the capacitor assemblies on the left side and the right side are connected with the lead-out pins through connecting lines, and then soldering tins are added at the joint to carry out welding fixation; when the capacitor assemblies with the far distance are connected, one connecting line is led out of one end of each capacitive assembly, and the connecting lines penetrate through the side face of the filter shell and are uniformly welded; taking down the assembled filter capacitor from the heating device and placing the filter capacitor in air to be cooledto normal temperature.

Owner:常州无线电厂有限公司

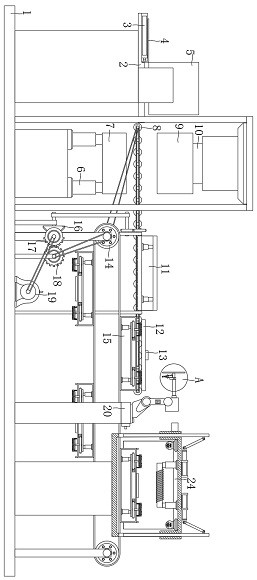

Processing equipment with heat resistance detection function for cooling fins of electric oil heaters

PendingCN113523131AWon't hurtAvoid Burst SituationsShaping toolsMetal-working feeding devicesGear wheelHeat resistance

The invention discloses processing equipment with a heat resistance detection function for cooling fins of electric oil heaters. The processing equipment with the heat resistance detection function for the cooling fins of the electric oil heaters comprises a chassis, wherein a material placing plate is arranged above the left of the chassis; a material pushing plate is arranged on the right of a material pushing rod; a lifting rod is arranged on the right of a material storage bin; multiple rolling shafts are arranged above a male die; a hydraulic rod is arranged above a female die; a turnover mechanism is arranged in the middles of the rolling shafts; a pushing plate is arranged behind the rolling shafts; a conveying belt is arranged in front of the turnover mechanism; a bevel gear is arranged below the conveying belt; a full gear is arranged on the right part of a half gear; a mechanical arm is arranged on the right part of a motor; and a positioning instrument is arranged on the left side of a welding machine. Compared with existing common processing equipment for the cooling fins of the electric oil heaters, the processing equipment with the heat resistance detection function for the cooling fins of the electric oil heaters has the advantages that the heat resistance of a product can be detected, the injury to a user caused by thermal deformation and even bursting of the product in the use process is avoided, and the processing efficiency and the processing quality of the product are improved.

Owner:重庆惠迈锐智能装备科技有限公司

Underwater gas and oxygen overpressure discharge device

ActiveCN109945069BEnsure safetyImprove securityContainer filling methodsPressure vesselsEngineeringGaseous oxygen

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Coiled tubing flash butt welding method capable of being used for on-site production

InactiveCN110303231ASolve the problem of not being able to weldFast welding speedTubular articlesResistance welding apparatusElectricityButt welding

The invention discloses a coiled tubing flash butt welding method capable of being used for on-site production. The coiled tubing flash butt welding method capable of being used for on-site productioncomprises the following steps that 1 ) equipment is started in a control cabinet, coiled tubing is placed in electrode clamps and is stably installed; 2) an electrode clamp button is pressed down inthe control cabinet, longitudinal air cylinders are started, and the electrode clamps perform tight clamping; 3) an electric system is started to supply power to the electrode clamps; 4) transverse air cylinders work to enable the electrode clamps on the two sides to be fed to the middle at the same speed, when samples in the electrode clamps on the two sides are in contact with a sample in the electrode clamp in the middle, two joints generate flash processes, after flash lasts by a certain distance, the electrode clamps at the two ends move reversely, after the electrode clamps at the two ends move away by a certain distance, the electrode clamps at the two ends carry the samples to feed to the sample in the middle at a certain speed, when a proper amount of flashes are generated in thetwo joints, the flash butt welding process is completed; and 5) under the action of the air cylinders, the electrode clamps perform loosening, and the formed sample is taken down. According to the coiled tubing flash butt welding method, the problem that due to the fact that the pipe walls are grounded during coiled tubing open field flash butt welding operation, welding can not be achieved is solved, the coiled tubing flash butt welding method can be used for coiled tubing open field on-site connection, the welding speed is high, the joint performance is good, and the quality is stable and reliable.

Owner:XI'AN PETROLEUM UNIVERSITY

Processing method for welding supports on irregular plate

ActiveCN102658460AReasonable structureEasy to adjustWelding apparatusEngineeringMechanical engineering

The invention relates to a processing method for welding supports on an irregular plate. The method comprises the following steps of: (1) bending the irregular plate to form a required shape; (2) mounting a template on a side face of the irregular plate; (2) respectively penetrating more than two positioning pins which are arranged on the template in connecting holes of the supports, and positioning the supports, wherein each support is an eccentric wheel; (4) rotating the supports along the respective positioning pin, so that edges of the supports are connected with the irregular plate; and (5) welding the supports and the irregular plate, and removing the template. The supports have an eccentric wheel structure and are positioned by the positioning pins, so that the supports can rotate along the central axis of the connecting holes under positioning of the positioning pins; and therefore, the distance between the connecting holes on the supports and the irregular plate can be changed, the structure is reasonable, the welding distance between the supports and the irregular plate can be rapidly and accurately controlled, the operation is convenient, and the production efficiency can be improved.

Owner:SINOMACH CHANGLIN CO LTD

Novel fascia gun

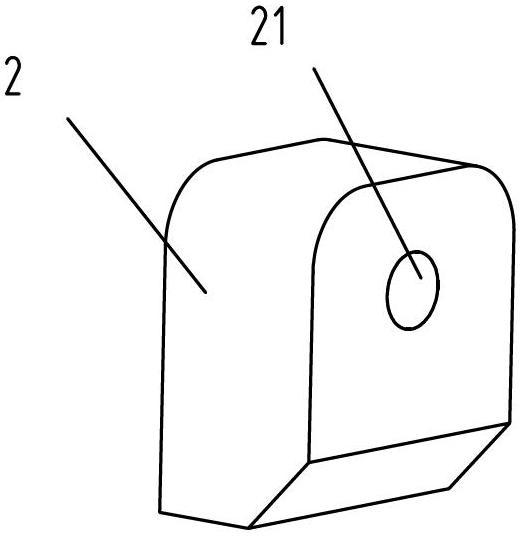

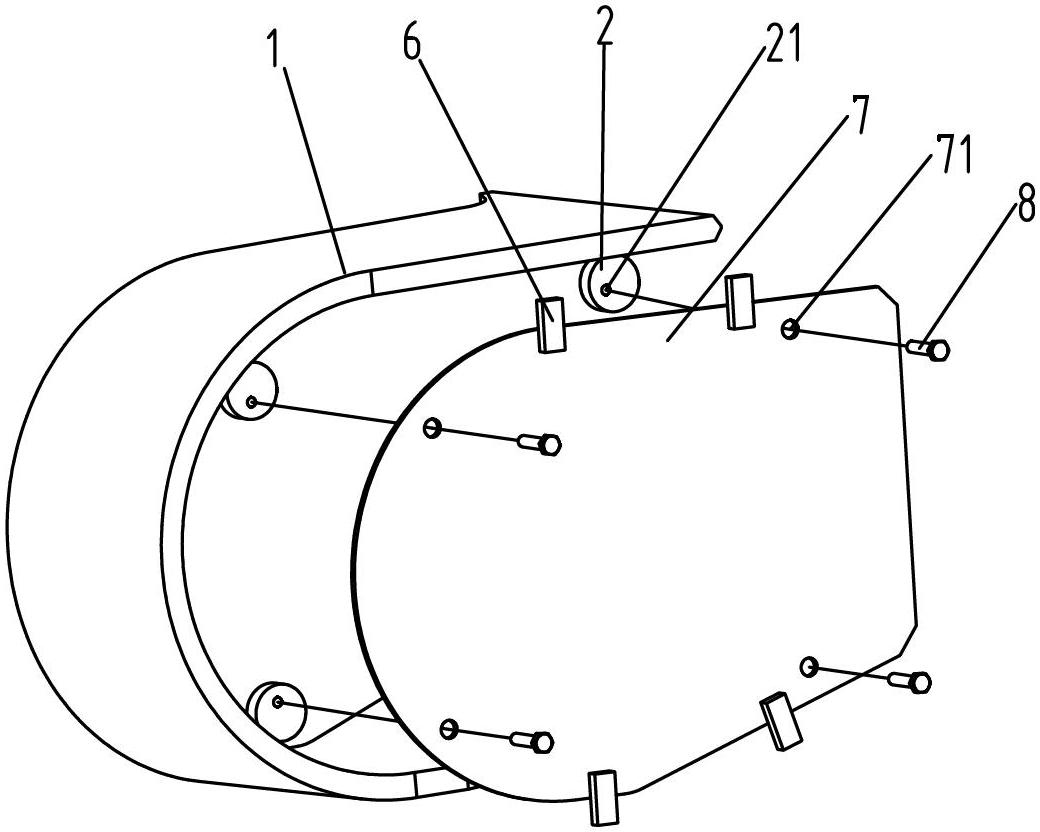

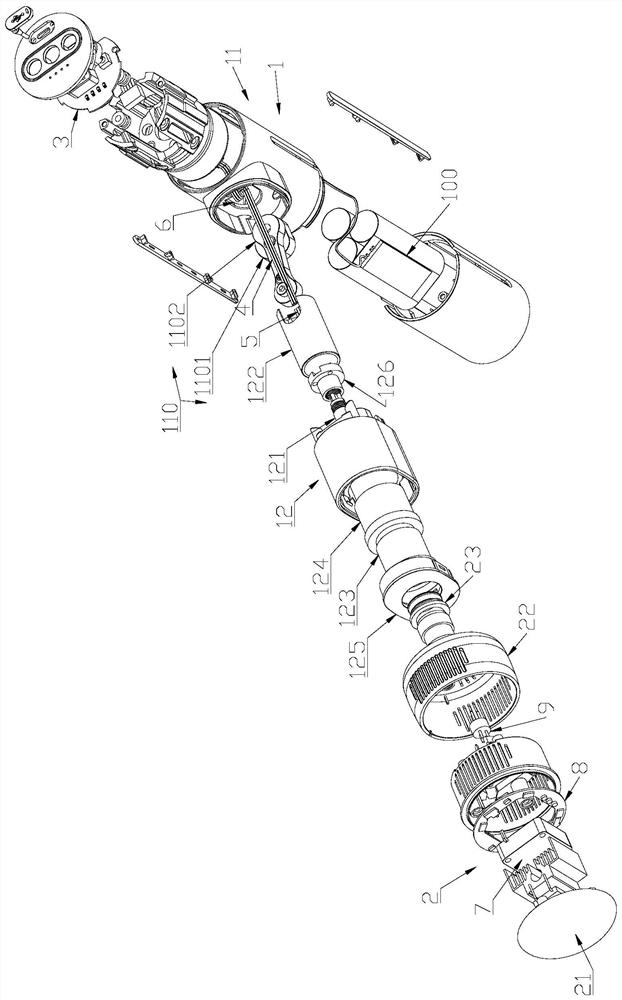

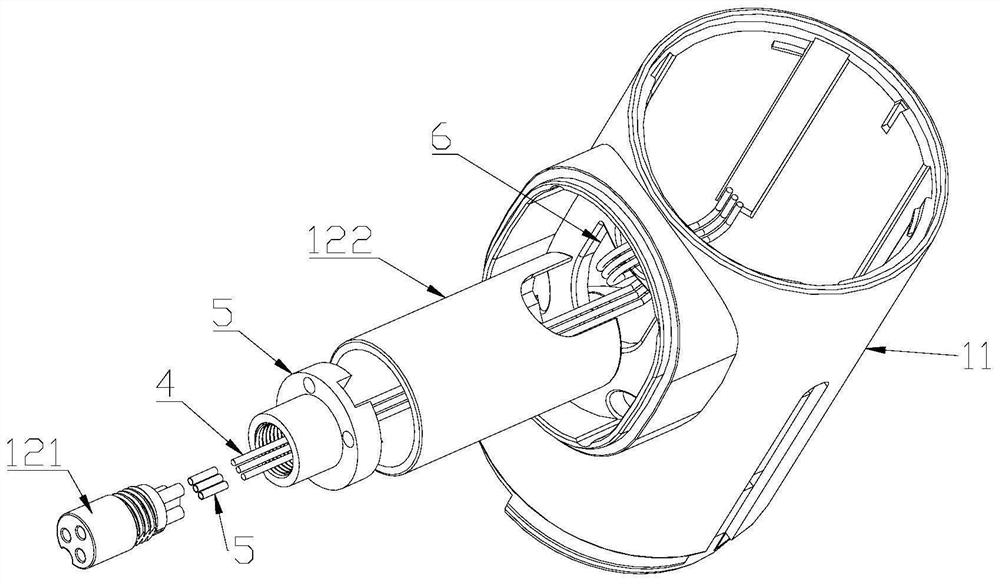

PendingCN112336610AMaintain electrical connectionExtend your lifeElectrotherapyIncorrect coupling preventionElectrically conductiveEngineering

The invention provides a novel fascia gun, relates to the technical field of massage equipment, and solves the technical problem that a wire between a handle and a massage head breaks easily when thefascia gun moves at a high speed. The novel fascia gun comprises a gun body, a massage head arranged on the gun body, an auxiliary physiotherapy assembly arranged in the massage head, a main circuit board arranged in the gun body, and a connecting cable electrically connected with the auxiliary physiotherapy assembly and the main circuit board, wherein the connecting cable is made of a conductivewire resistant to high-speed bending. The connecting cable electrically connected with the auxiliary physiotherapy assembly in the massage head is made of the conductive wire resistant to high-speed bending, the problem that when the fascia gun conducts high-speed piston movement, the connecting cable breaks easily is solved, due to the fact that the connecting cable does not breaks easily, electric connection can be kept, the service life of the fascia gun is prolonged, and the use cost is reduced.

Owner:ZHEJIANG E-COZY ELECTRONIC TECH CO LTD

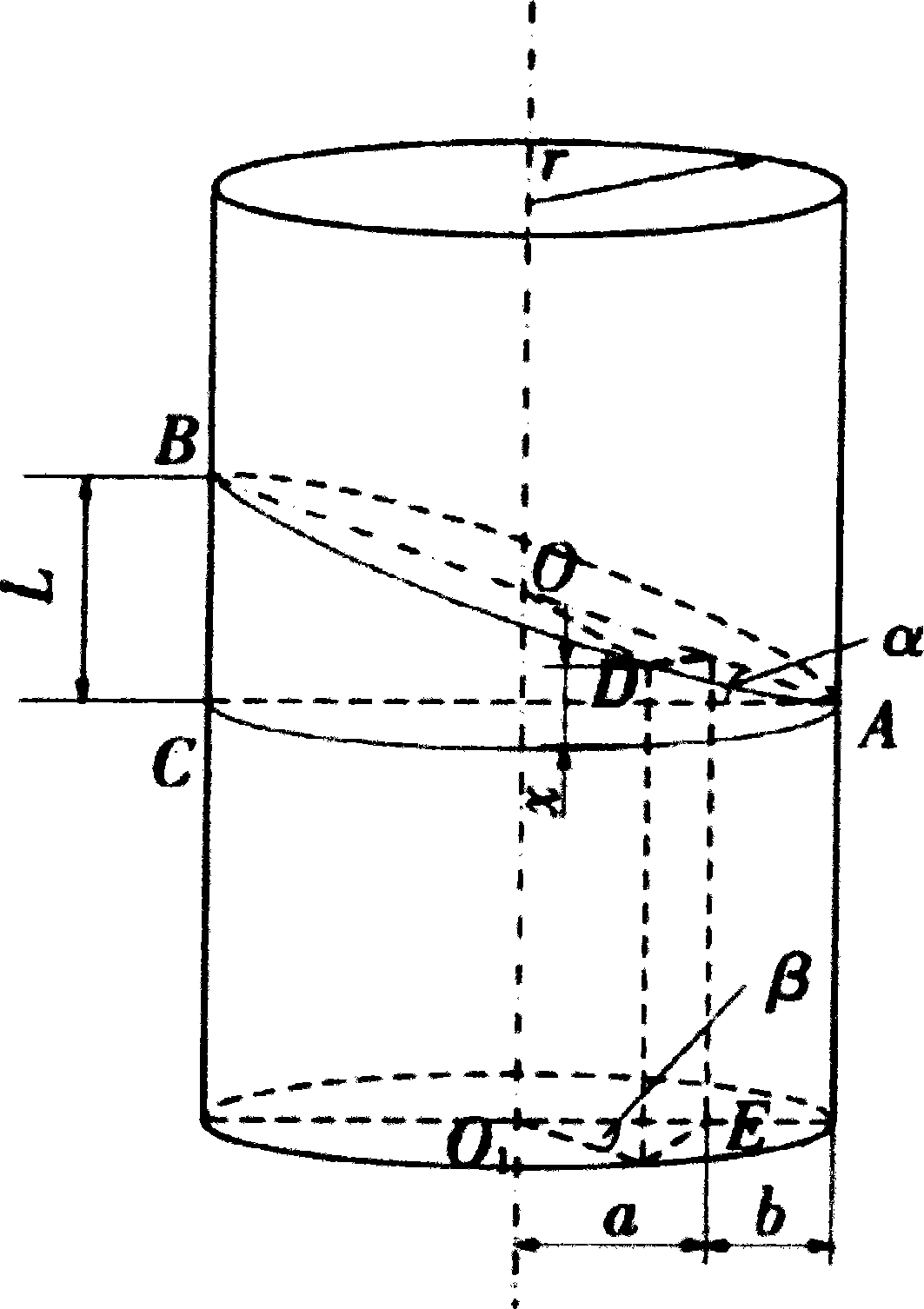

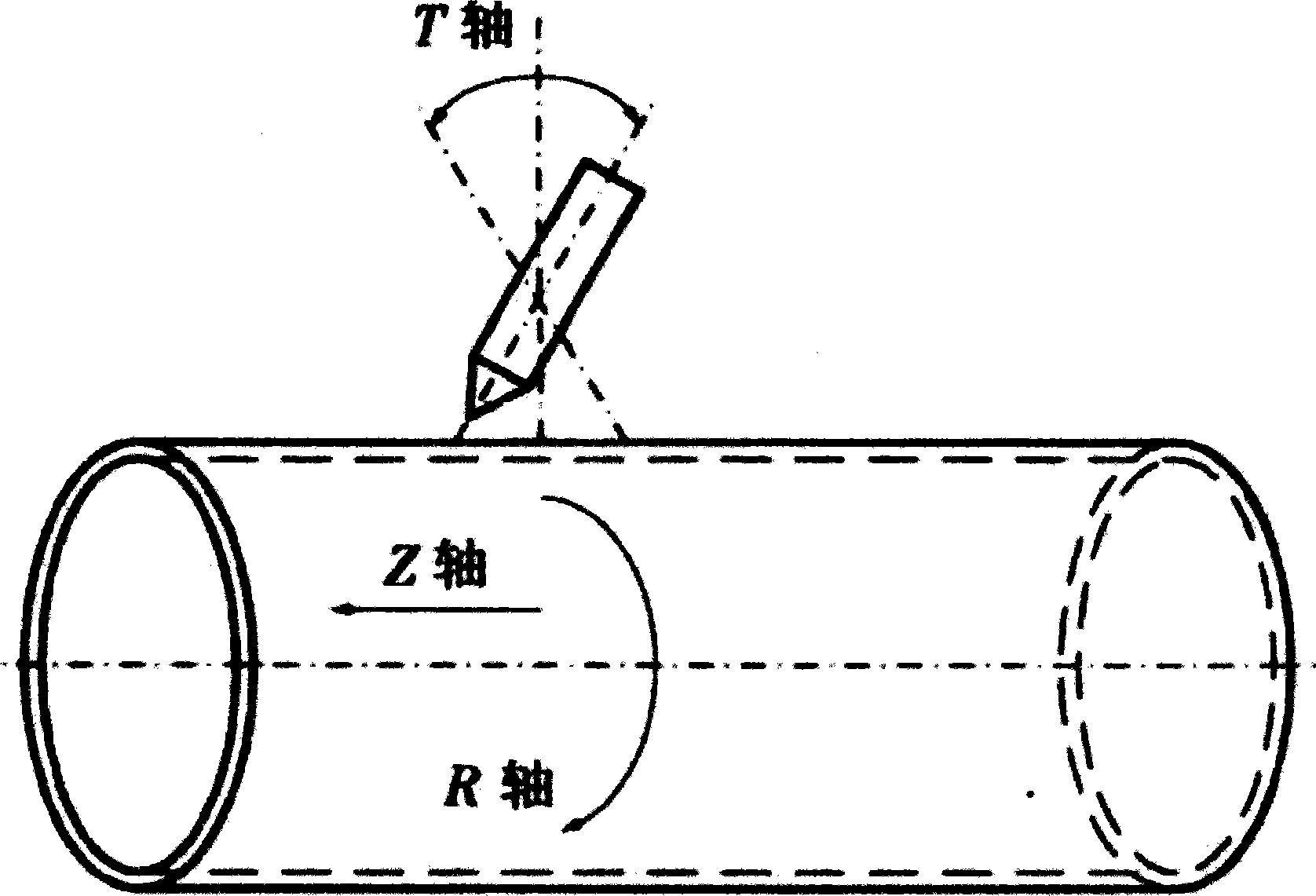

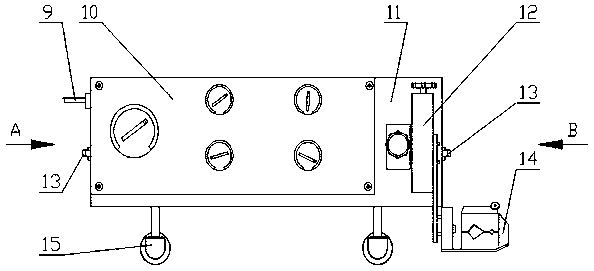

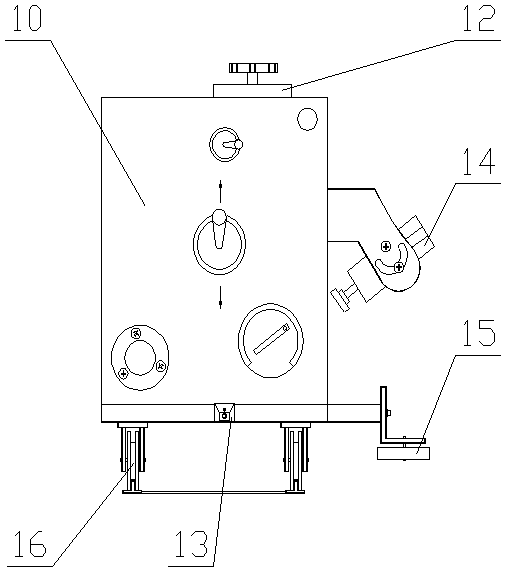

Three-dimensional linkage pipe beveling device

InactiveCN102554399BPrecise adjustment of axial displacementImproved angular deflection accuracyGas flame welding apparatusMicrocontrollerMicrocomputer

The invention provides a three-dimensional linkage pipe beveling device, which is used for beveling a pipe so that a pipe end meets the requirement of the pipe on welding process. The three-dimensional linkage pipe beveling device is characterized in that a cutting torch control mechanism is connected with a cutting torch through a cutting torch adjusting mechanism. During cutting, a single chip microcomputer is used for controlling three motors to simultaneously run, axial displacement of the cutting torch is adjusted by a stepping motor A, the angle of the cutting torch is adjusted by a stepping motor B in real time, and the cutting torch is driven by a travelling motor to travel circumferentially along the pipe, so that three-dimensional linkage of the cutting torch is realized. A motion driving angle sensor of each stepping motor transmits signals, the signals together with displacement feedback signals of a displacement sensor are timely transmitted to the single chip microcomputer, follow-up of the two stepping motors is conveniently adjusted, cutting precision is further improved, the problem that a beveled cut surface which is a complex surface cannot be welded is fundamentally solved, one-step forming is realized without trimming, and working efficiency is greatly improved.

Owner:TIANJIN SHENGJINKANG TECH DEV

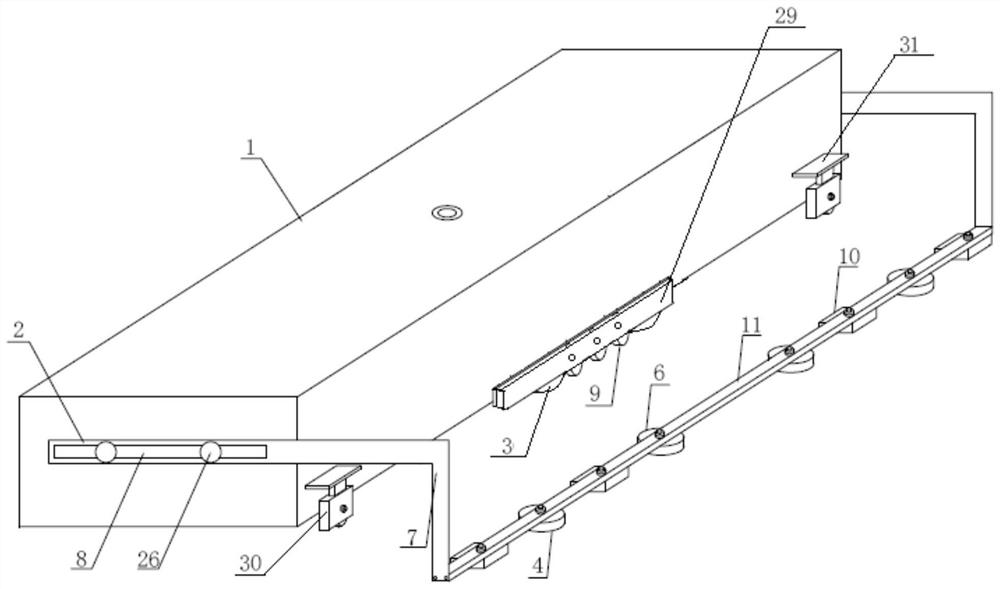

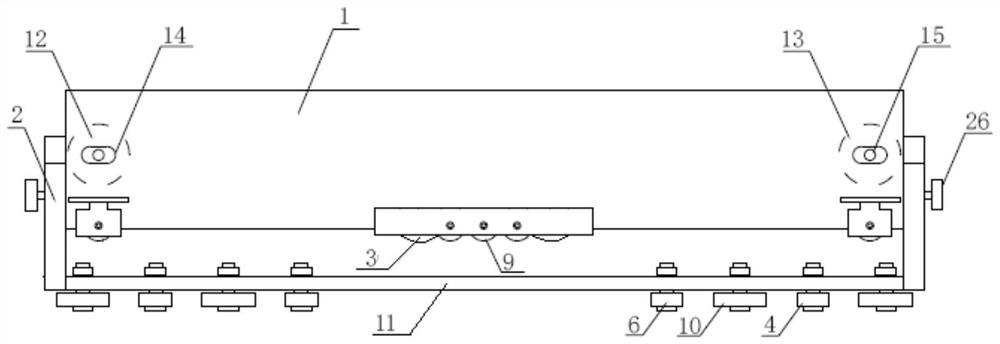

Traveling device of automatic welding tractor

PendingCN113458680AWalking smoothlyPrevent slippingWelding/cutting auxillary devicesAuxillary welding devicesGear driveDrive wheel

The invention provides a traveling device of an automatic welding tractor. The traveling device comprises an automatic welding tractor body with magnetic bases at two ends inside, guide arms are installed at two ends of the outer side of the tractor body, the other ends of the guide arms extend to the right side of the tractor body and are provided with straight rods, a guide rod is installed between the two straight rods, and a plurality of guide wheels and magnetic blocks are installed on the lower surfaces of the two ends of the guide rod at intervals through bolts; and traveling wheels are installed on the two sides, close to the guide arms, of the tractor body, a traveling driving mechanism is installed in the middle of the tractor body, the traveling driving mechanism drives gears to conduct transmission through a motor, and therefore, a plurality of driving wheels and the traveling wheels installed in the middle of the tractor body are driven to travel, and the automatic traveling function of the welding tractor is achieved. The attraction force of the magnetic bases to the upper surface of a workpiece and the attraction force of the magnetic blocks to the side face of the workpiece jointly guarantee that the automatic welding tractor stably runs on the surface of the workpiece along a straight line all the time and cannot fall or turn over, all welding seams at the end of the workpiece are welded at a time, the welding quality is good, and the efficiency is high.

Owner:NANJING CHINA CONSTR CHEM EQUIP MFG +1

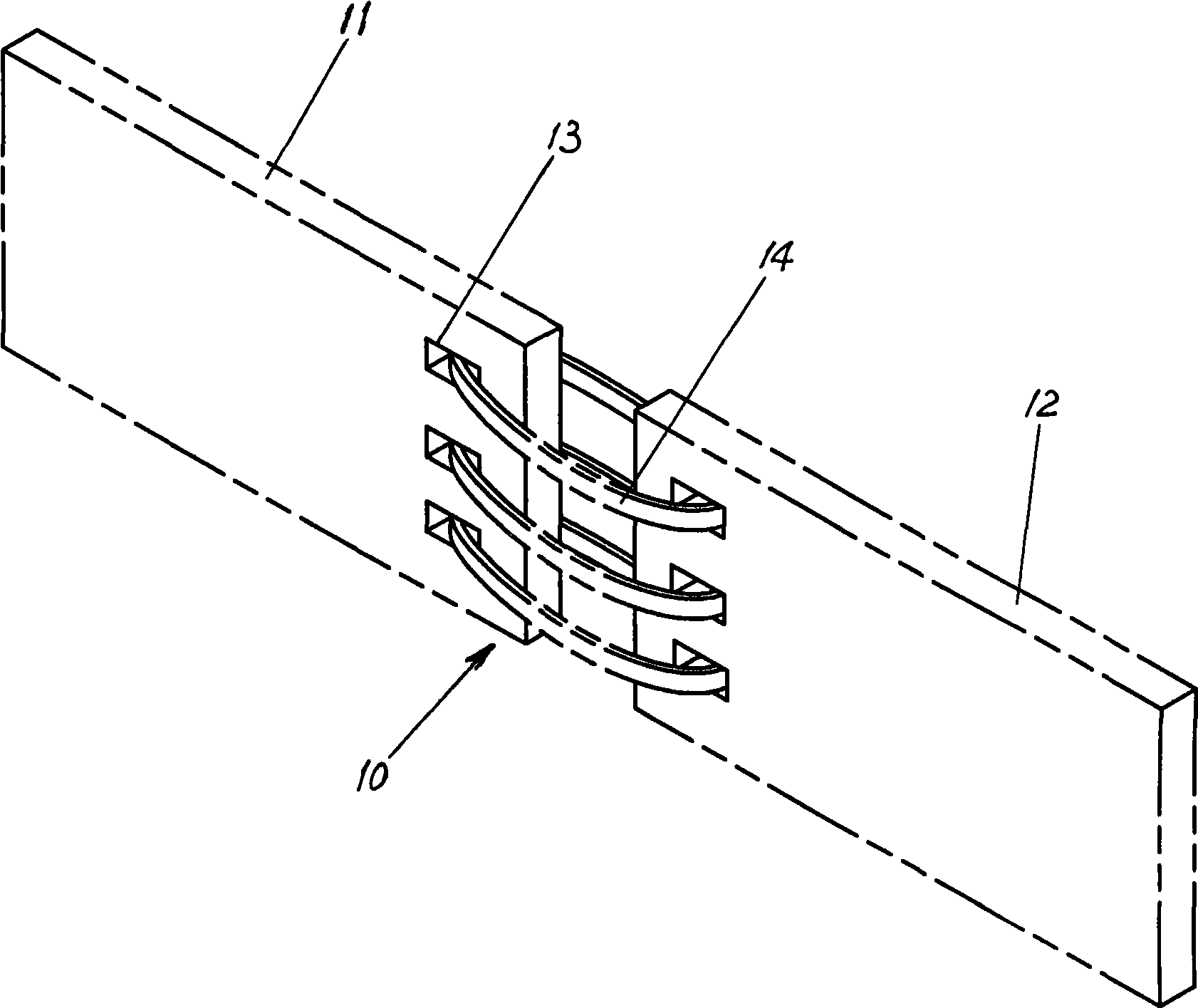

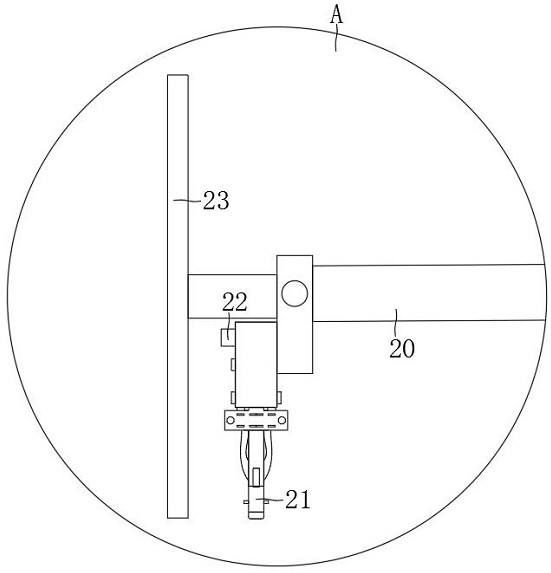

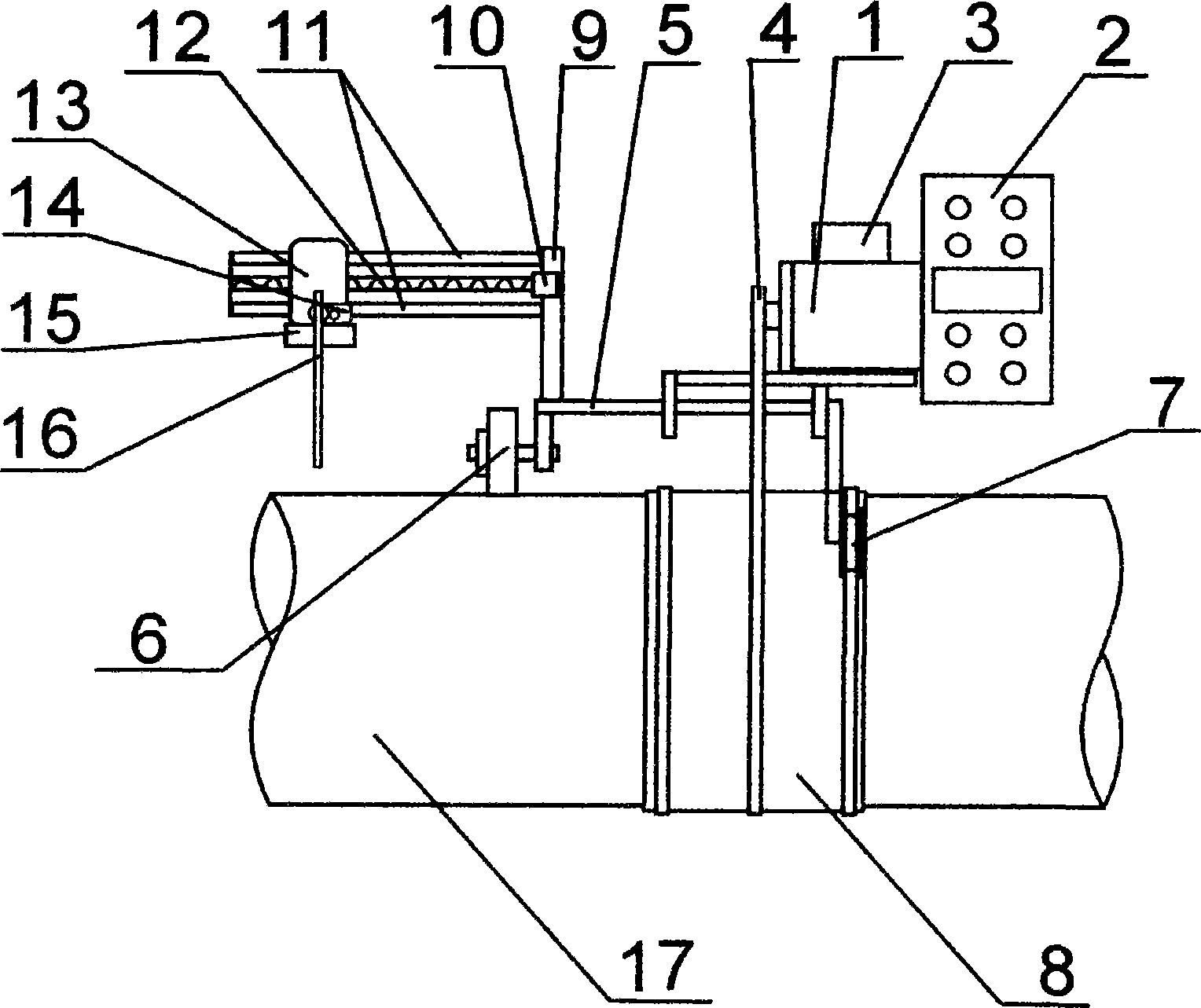

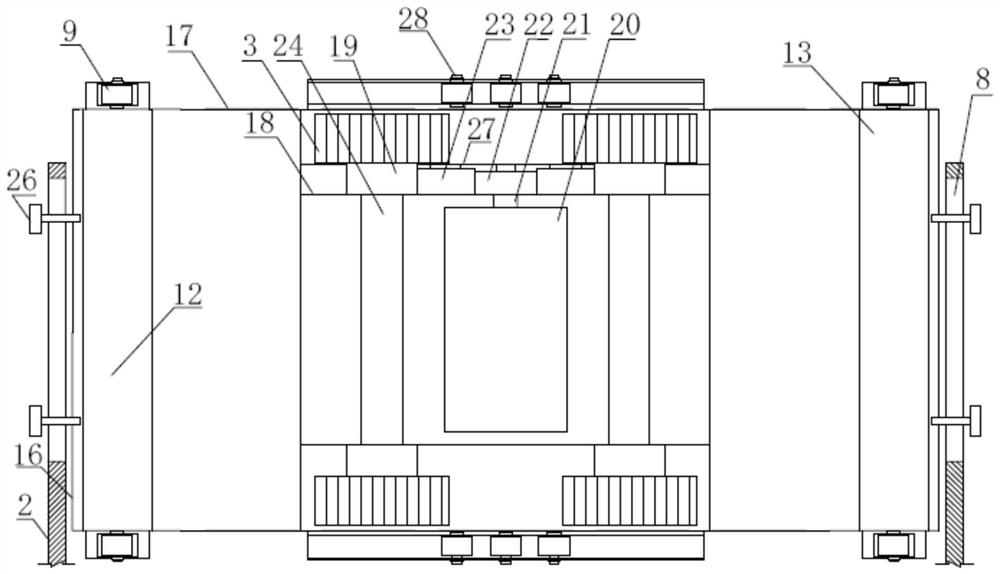

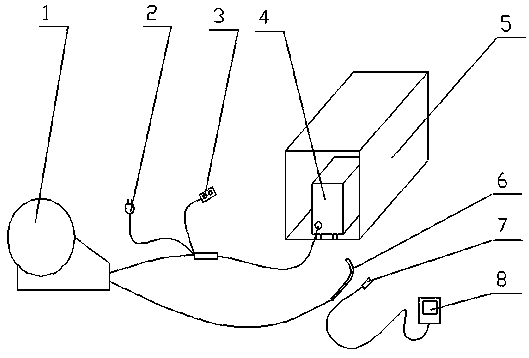

Device and method for performing automatic welding in long and narrow space

PendingCN109277736ARealize automatic weldingSolve the problem that long straight welds cannot be weldedWelding/cutting auxillary devicesAuxillary welding devicesComputer moduleDrive motor

The invention relates to a device and a method for performing automatic welding in a long and narrow space, and belongs to the technical field of welding. According to the technical scheme, the methodcomprises the following steps that a driving motor, a control module (10) and an X-Y adjusting sliding block (12) are arranged on a trolley body frame (11) of an automatic welding device (4), a welding gun clamp (14) is arranged on the X-Y adjusting sliding block (12), a welding gun (6) is arranged on the welding gun clamp (14), magnetic guide wheels (15) are arranged on the side face of the trolley body frame (11), magnetic walking wheels (16) with grooves are arranged at the bottom of the trolley body frame (11), and limiting switches (13) are arranged on the front and back of the trolley body frame (11) correspondingly. The device and the method have the beneficial effects that the problem that welding can not be performed in a long straight weld joint in a long and narrow space between workpieces or inside the workpiece is solved, automatic welding of the ferromagnetic workpiece and the non-ferromagnetic workpiece can be realized, the welding condition in the long and narrow spacecan be observed at any time in the welding process, and the device is small and flexible, has multiple functions and is simple, convenient and efficient.

Owner:BAODING TIANWEI ELECTRICAL EQUIP STRUCTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com