Patents

Literature

51results about How to "Avoid soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

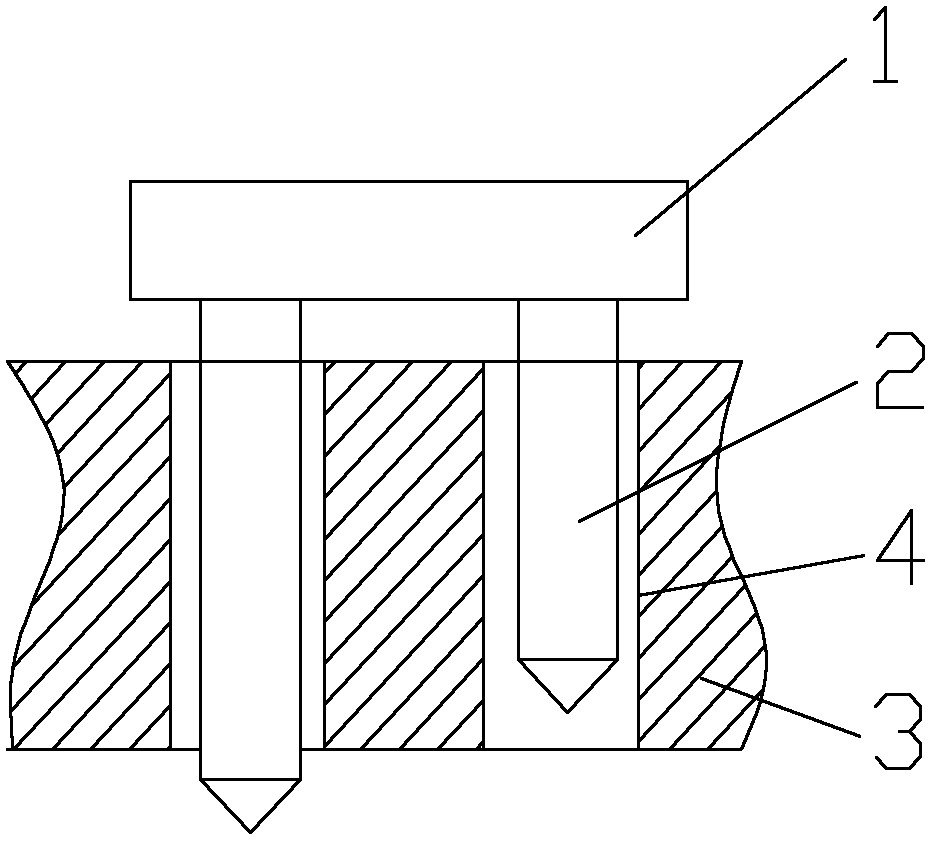

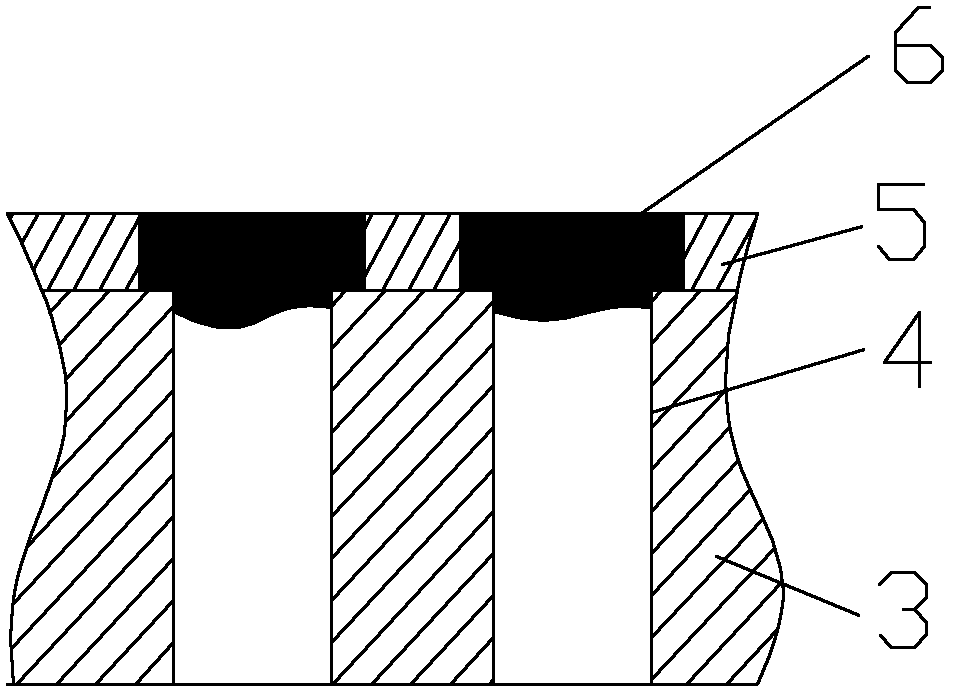

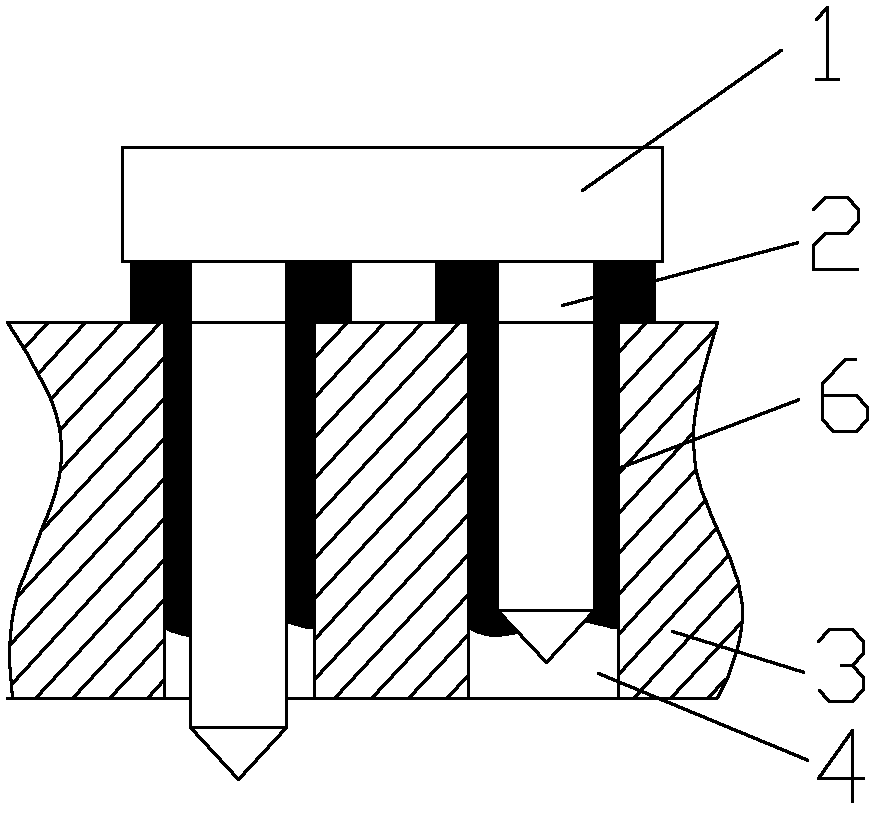

A method for through-hole reflow soldering

ActiveCN102291945AThe operation process is simple and convenientHigh welding quality and reliabilityPrinted circuit assemblingReflow solderingSolder paste

The invention relates to a through-hole reflow soldering method. The method is characterized by printing solder at the plug-in hole positions where exposed pins can not meet the wave soldering requirement on a PCB (printed circuit board), inserting pins of a corresponding plug-in component into plug-in holes, the pins bringing part of solder paste in the plug-in hole walls and then carrying out reflow soldering. The method has the following advantages: temperature damage to the plug-in component is not easy to cause, the lack of space for manual repair soldering during manual repair solderingis avoided, cold soldering, poor soldering and other soldering defects are not easy to cause, the soldering quality is good, the reliability is high, and the soldering efficiency is high, and the method is suitable for soldering of the plug-in components with the exposed pins failing to meet the wave soldering requirement.

Owner:南通卓效自动化有限公司

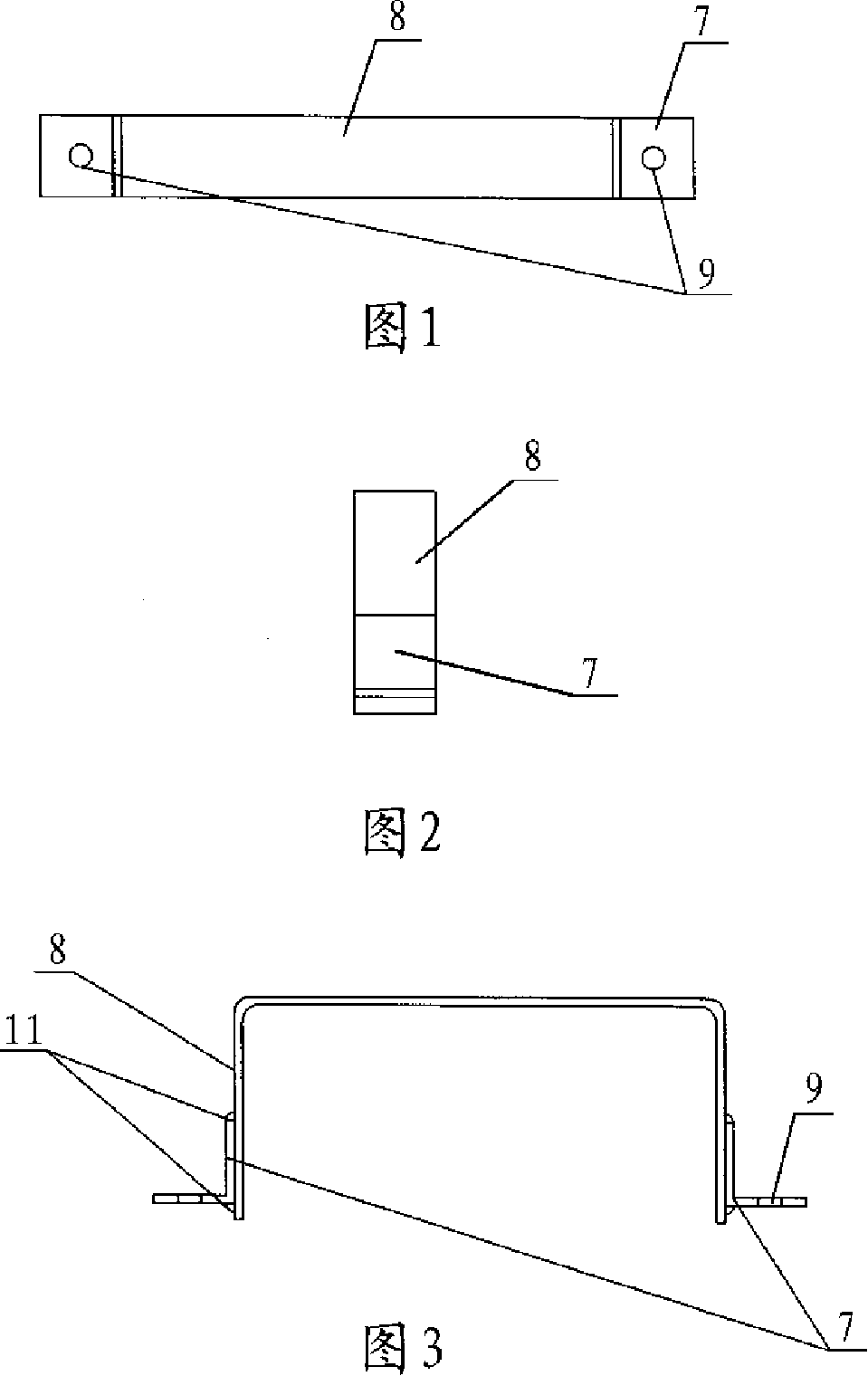

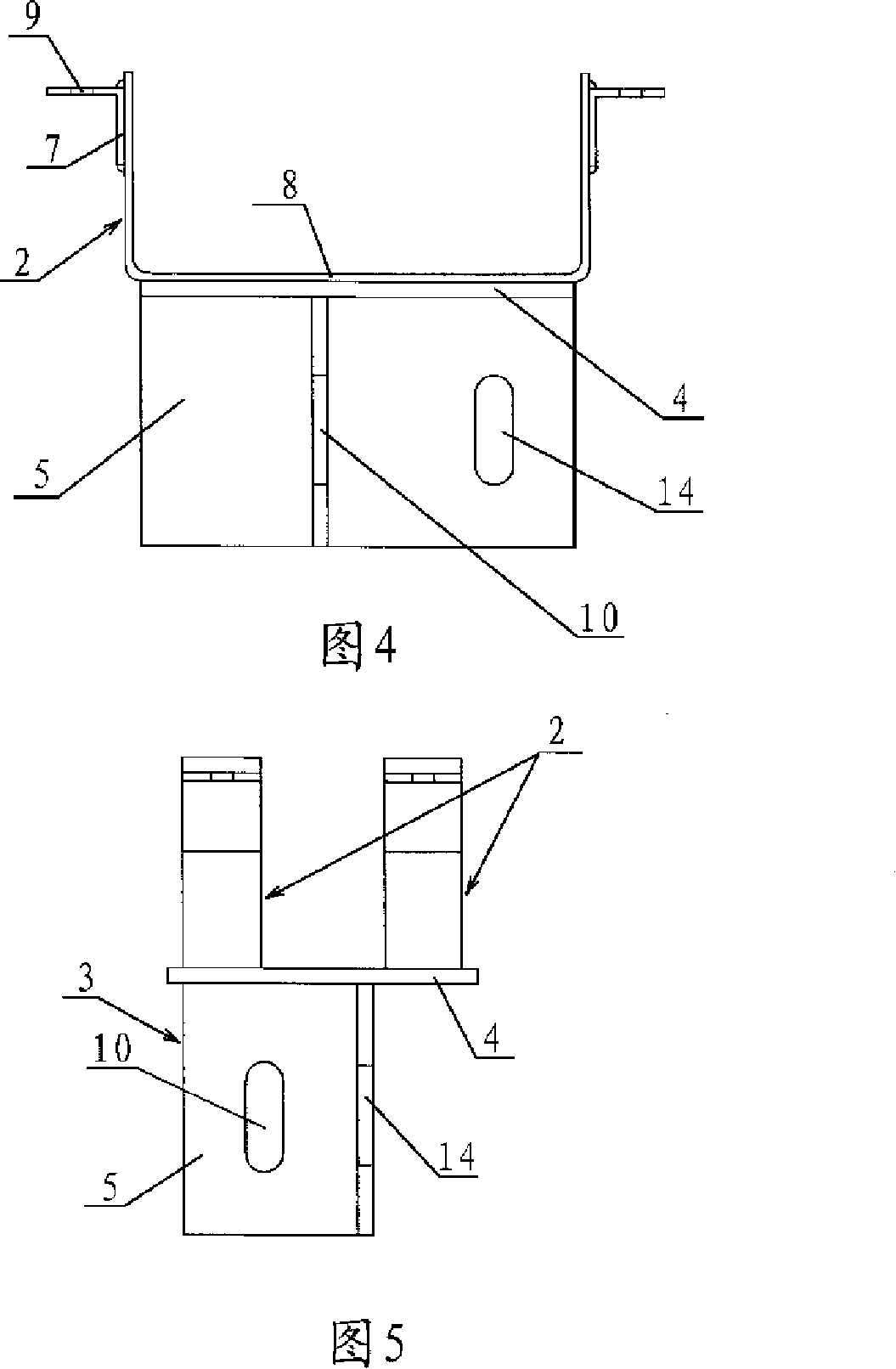

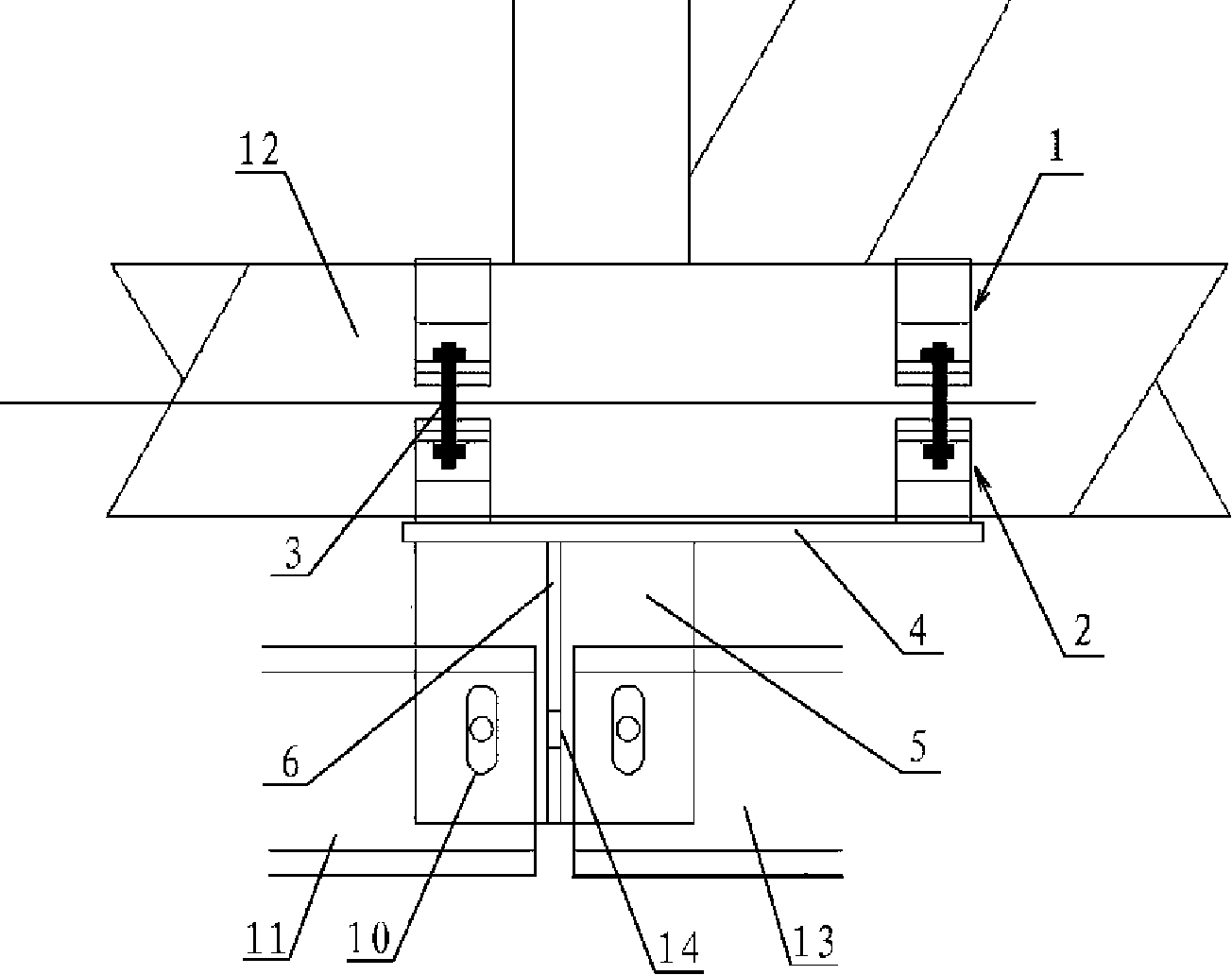

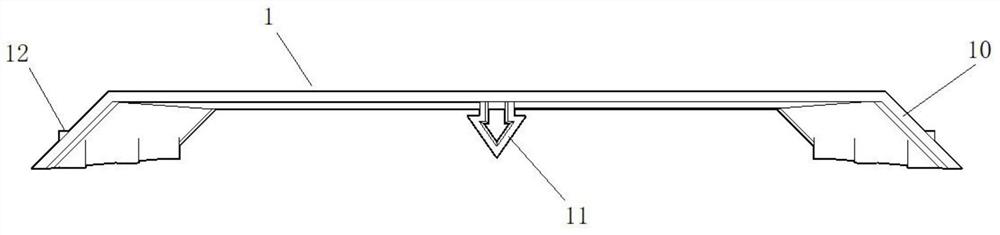

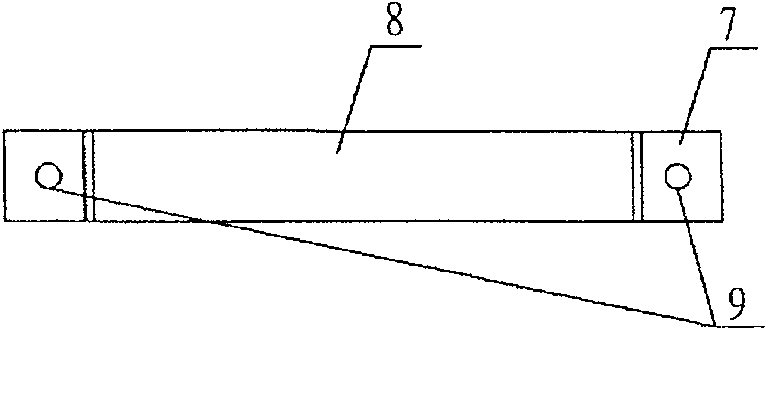

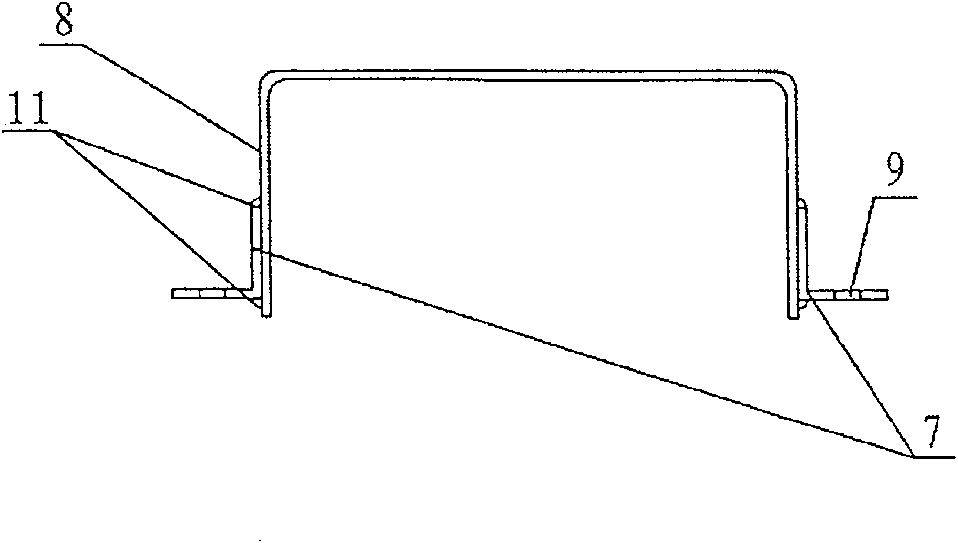

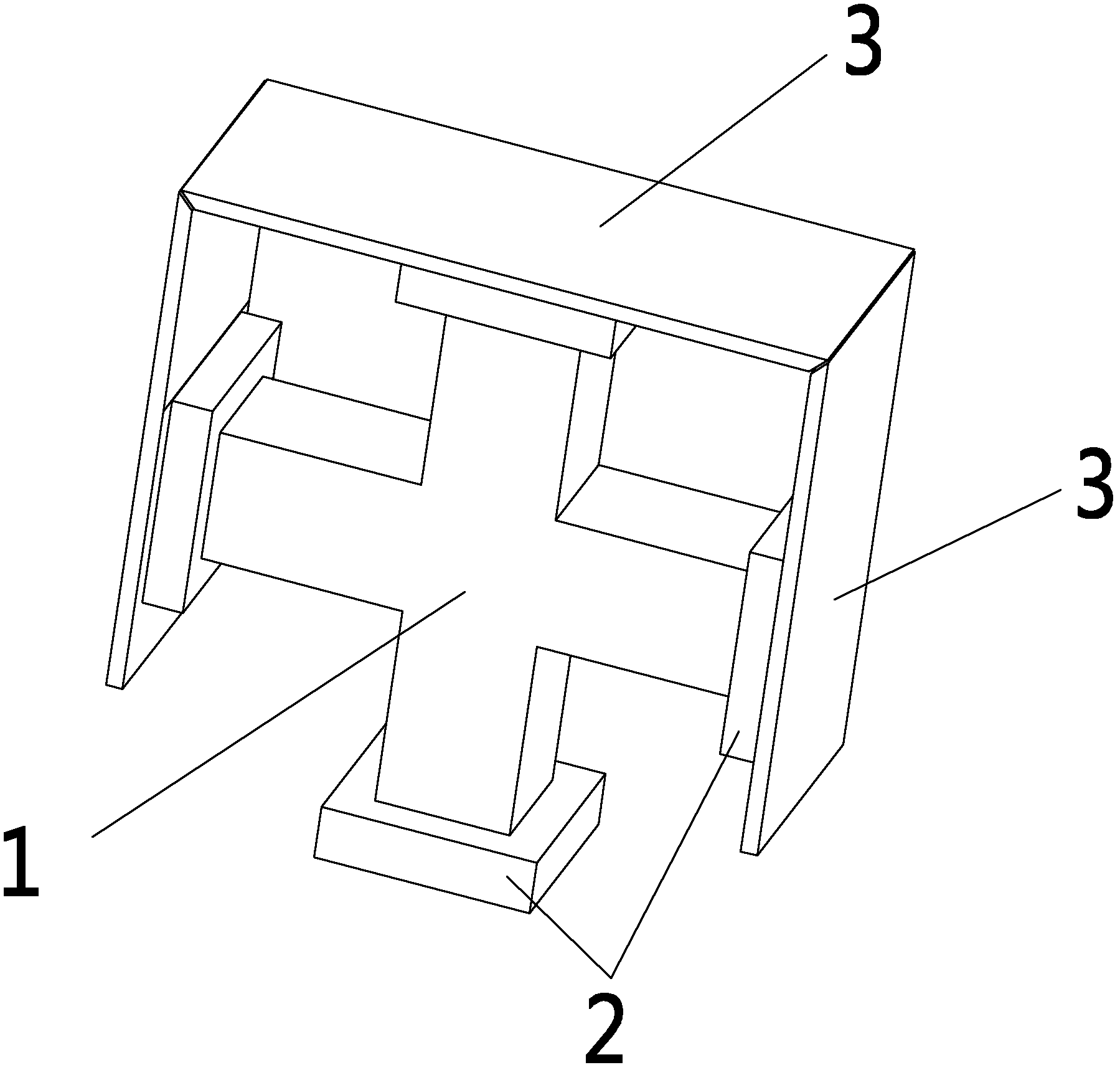

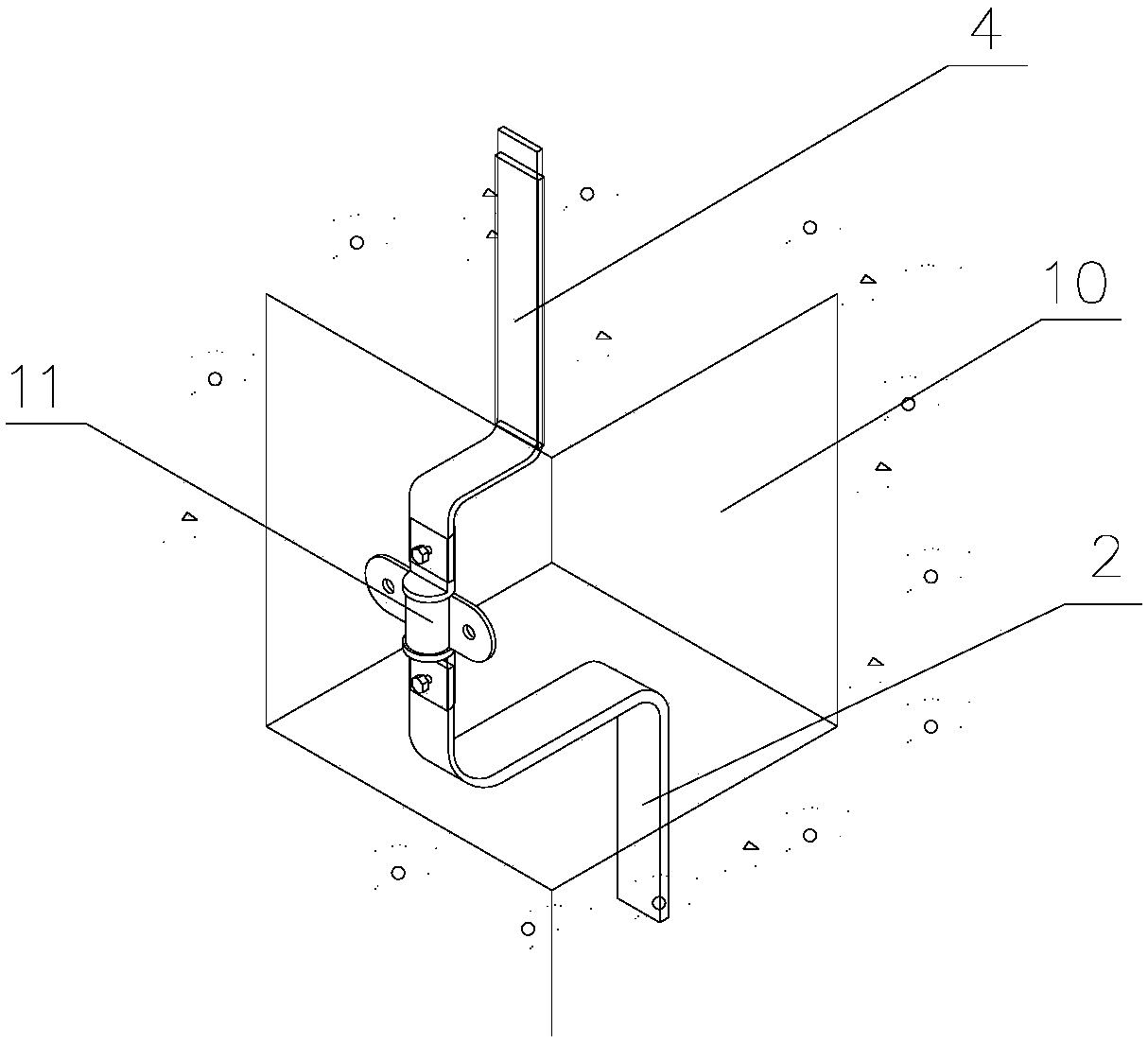

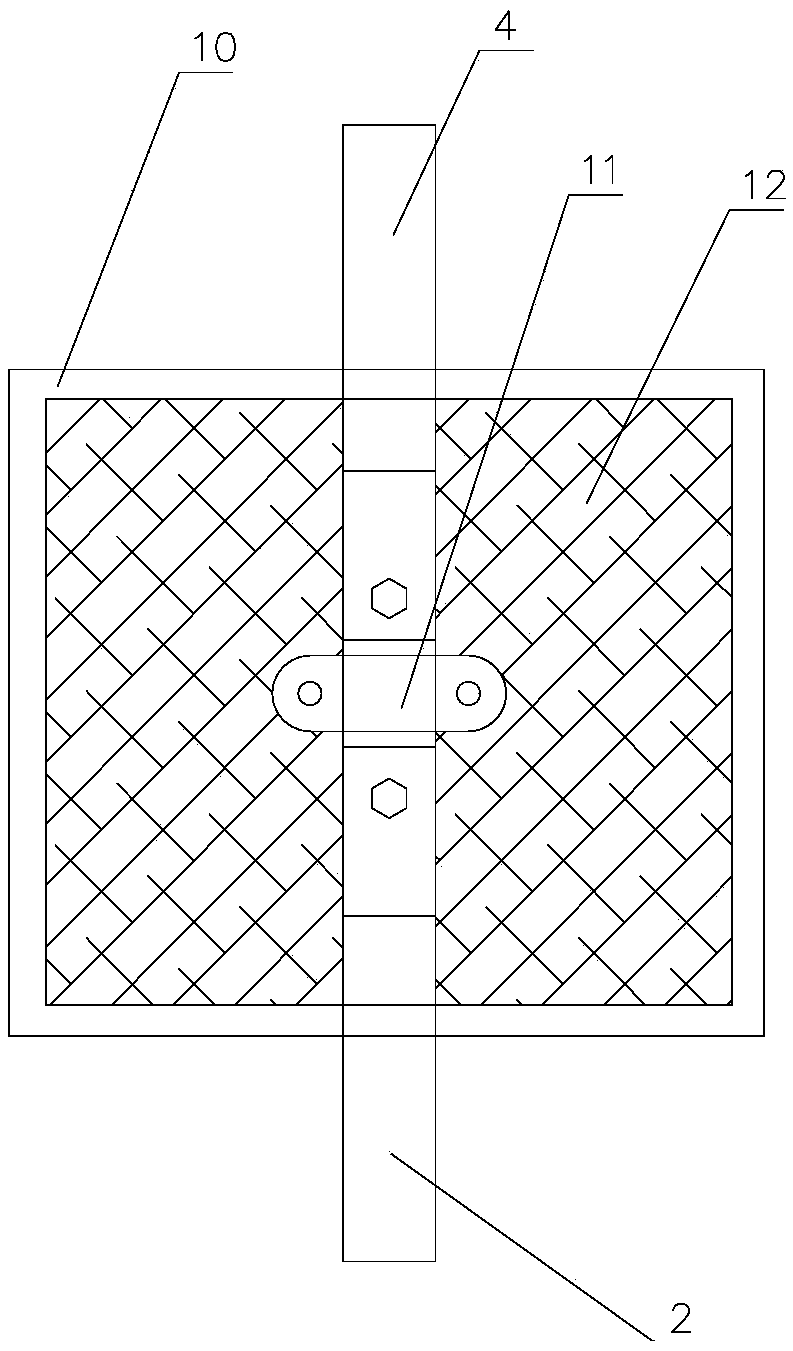

Anchor-ear node plate and construction method of ceiling joist

The invention provides a construction method of an anchor ear gusset plate and the ceiling joist. The main body of the upper half anchor ear plate is an inverted sulciform flat steel plate; the two lateral surfaces of the sulciform flat steel plate are symmetrically welded with two angular steel plates, which function as bolt connecting plates, wherein the bottoms of the angular steel plates are provided with bolt holes. The structure of the lower half anchor ear plate is symmetrical with the structure of the upper half anchor ear plate, wherein the bottom surface of the lower half anchor ear plate is connected with the gusset plate; the bottom surface of the gusset plate is connected with the horizontal gusset plate and the vertical gusset plate which intercross vertically; the horizontal gusset plate and the vertical gusset plate are respectively provided with a main keel connecting hole and a secondary keel connecting hole. The upper half anchor ear plate and the lower half anchor ear plate environ the steel truss steel truss; the upper half anchor ear plate, the lower half anchor ear plate and the steel truss are connected with each other fixedly via bolts, the main connecting hole is connected with the main keel via bolts and the secondary keel is connected with the secondary keel via bolts. The fabricated construction product and the construction method are capable of avoiding redundant welding modes, reducing the building energy consumption, speeding up the construction speed, and are widely applicable in the ceiling suspending work of buildings of various steel structures.

Owner:BEIJING CONSTR ENG GRP CO LTD +1

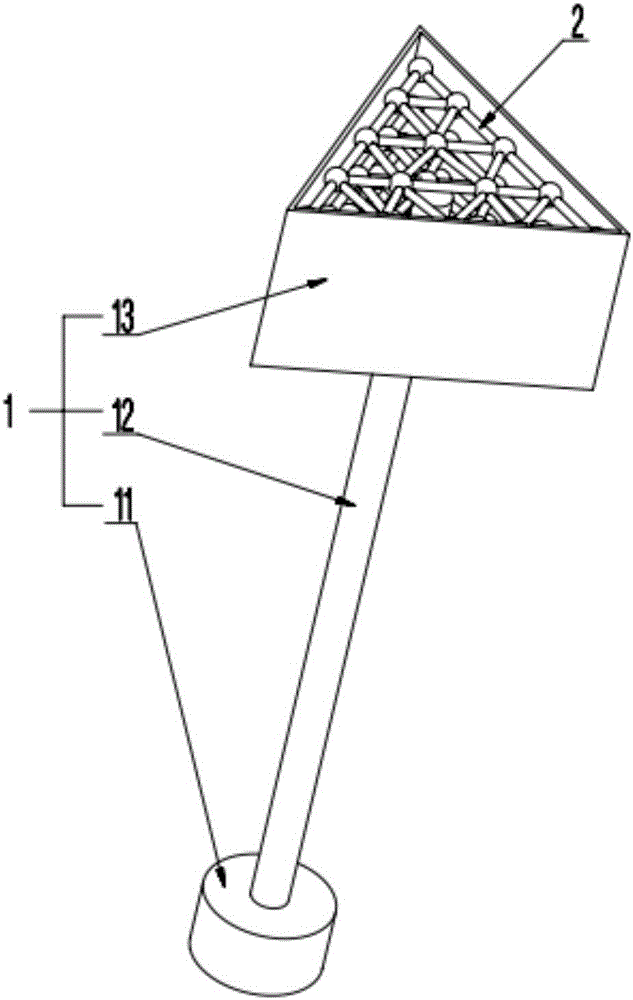

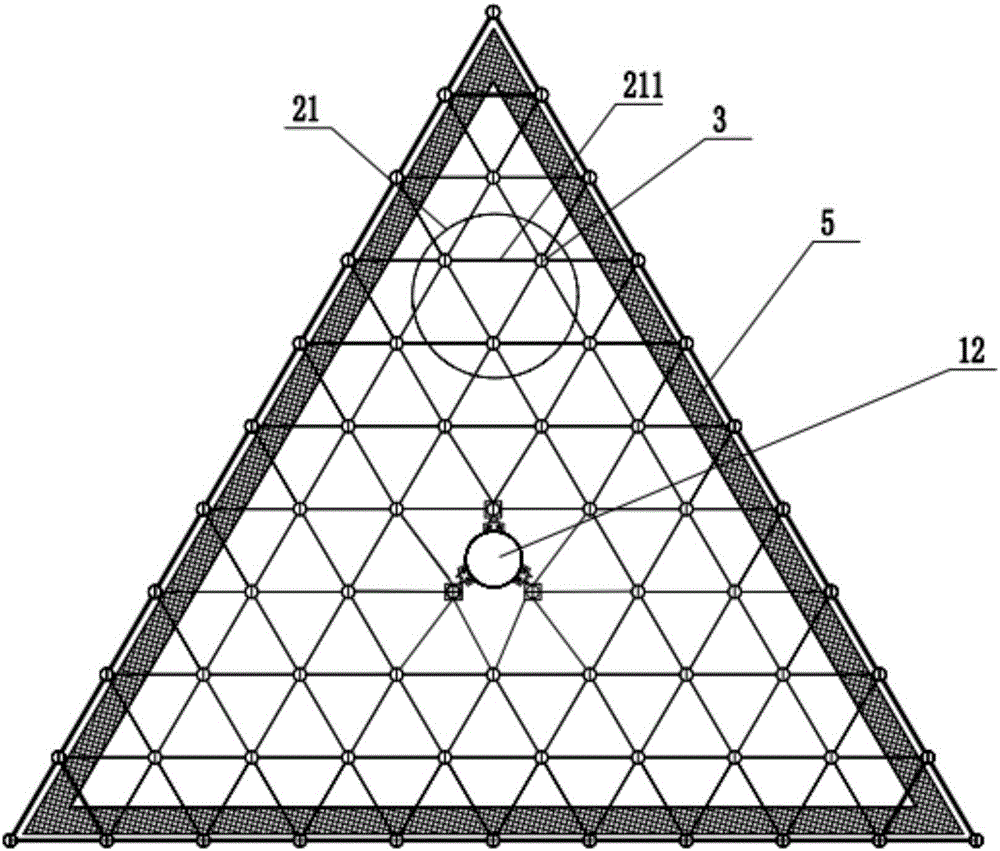

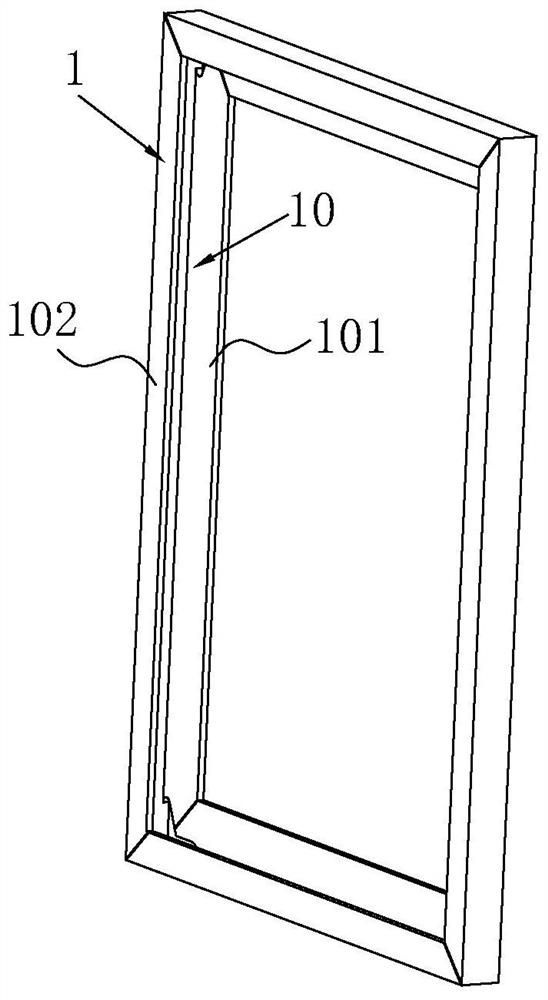

Advertising board

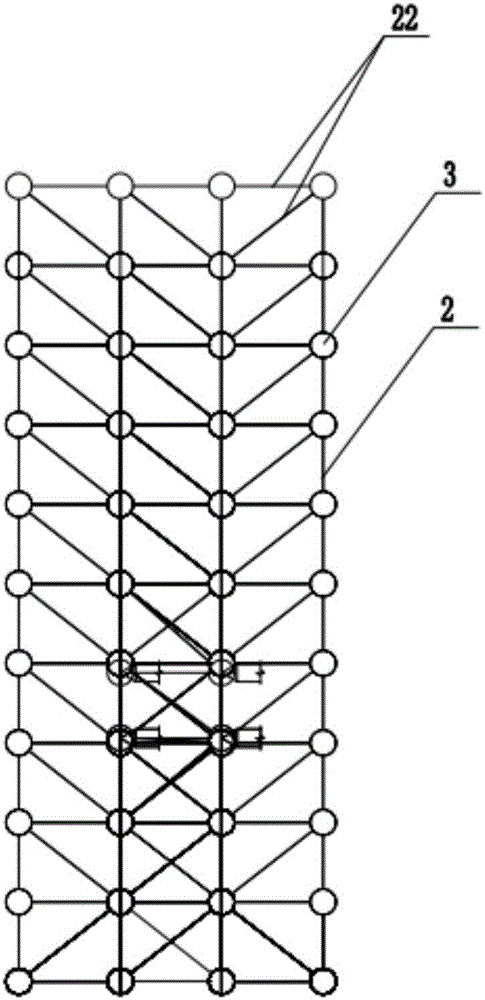

PendingCN106504674AImprove construction efficiencyShorten the construction periodBoardsArchitectural engineeringTriangular grid

The invention relates to an advertising board which comprises an advertising board body. An advertising plate and the advertising board body are fixed by arranging multiple supports on the advertising board body, accordingly the mode that the advertising plate is needed to be welded in a traditional construction method is omitted, each support consists of multiple triangular grid frameworks, and the adjacent grid frameworks are connected through connecting bodies. Therefore, assembly and disassembly can be rapidly performed in a construction field, the construction efficiency is improved, and a construction period is shortened. In addition, the triangular grid frameworks are stable in structure during stress, weak links formed after welding are eliminated, and the safety of the advertising board is improved.

Owner:贵州斌一亨广告(集团)有限公司

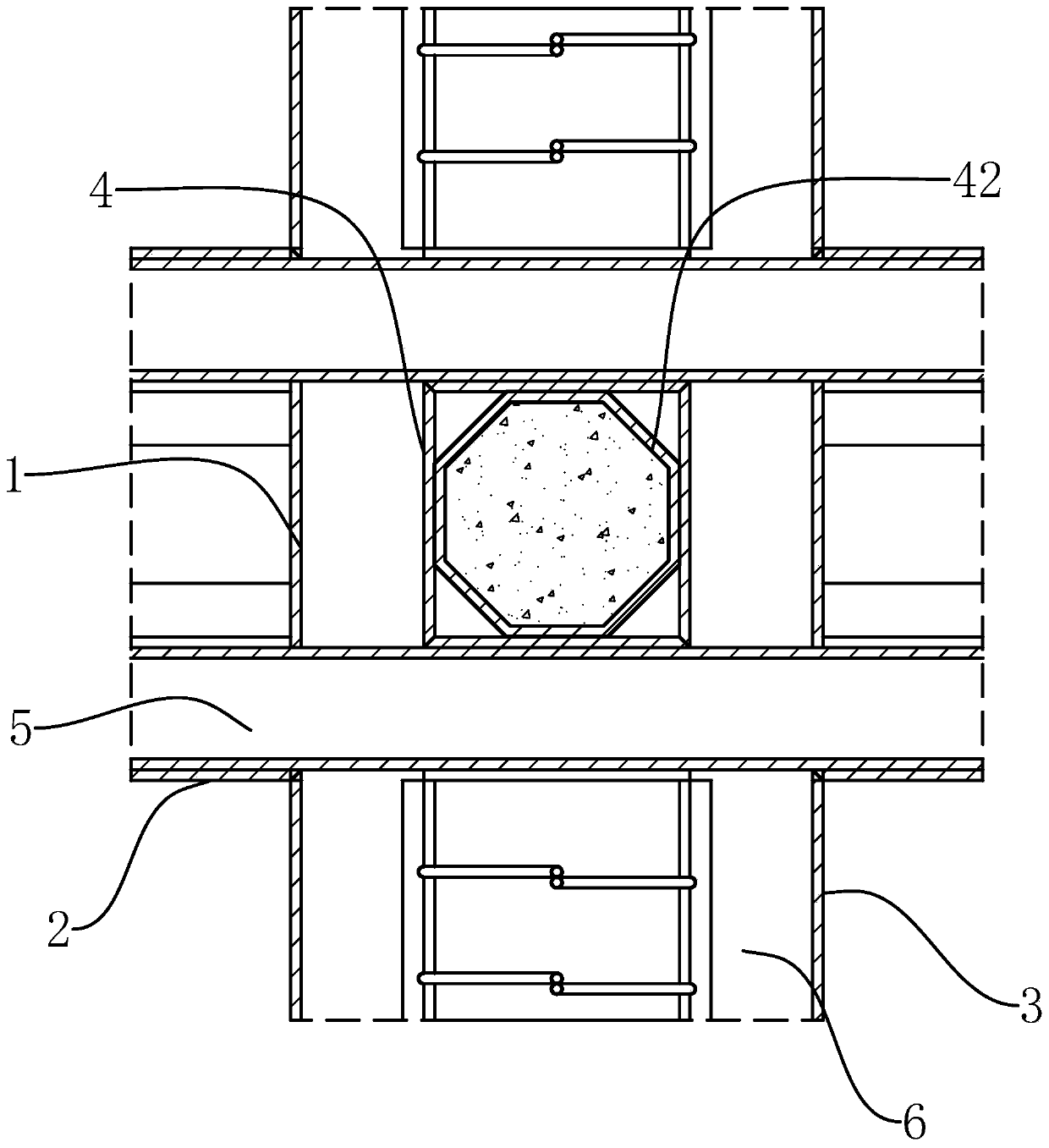

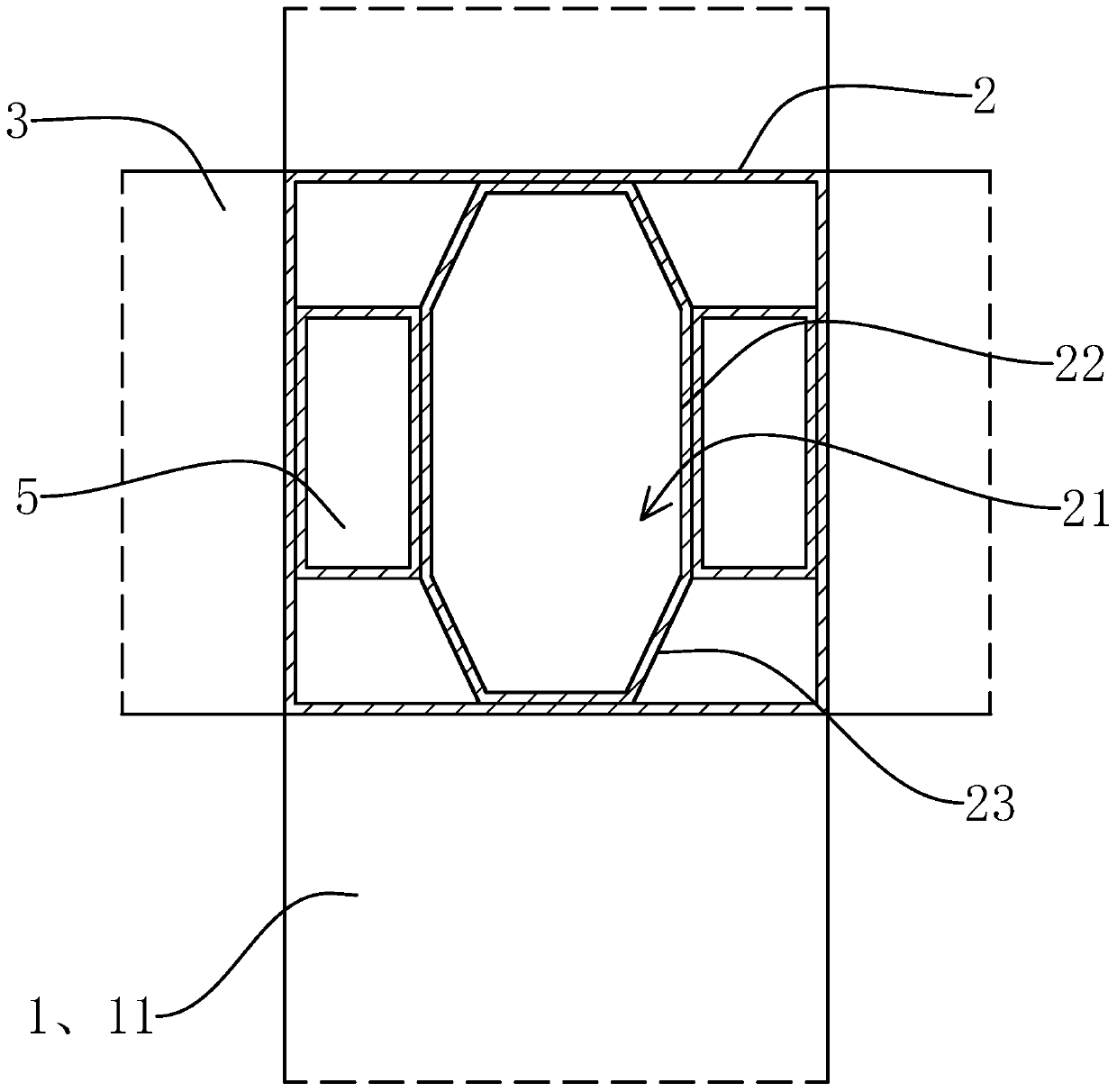

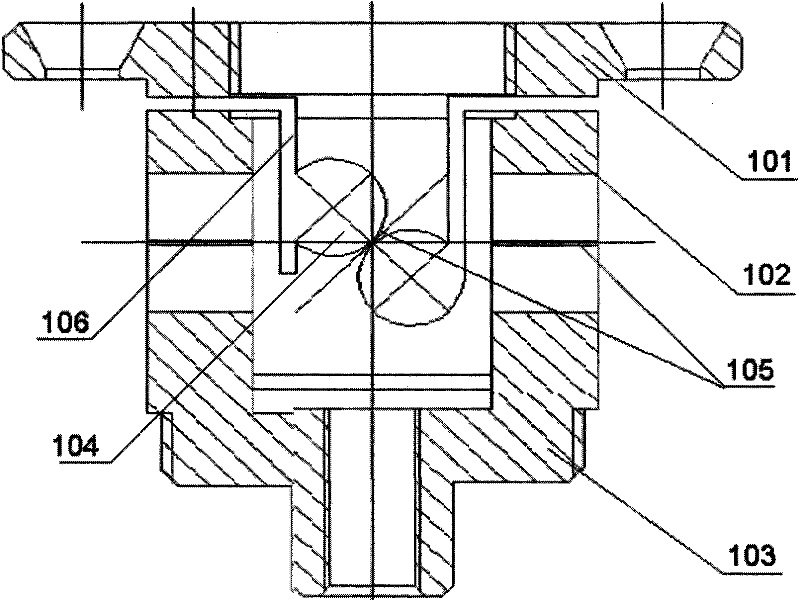

Beam and column connecting structure

The invention provides a beam and column connecting structure, and belongs to the field of steel structures. The problem that an existing beam and column connection strength is low is solved. The beamand column connecting structure comprises a column body and a beam body. The column body comprises a stand column; the beam body comprises cross beams and longitudinal beams; the stand column comprises four column plates; two cross beams and two longitudinal beams are fixed to the stand column. The column body also comprises a central pipe; the central pipe comprises is connected into the columnbody; and the central pipe comprises four central plates. The column body also comprises two transverse pipes and four longitudinal pipes. the two transverse pipes are fixed to the outer side surfacesof the two central plates at the front and rear; the four longitudinal pipes are fixed to the outer side surfaces of the two central plates on the left and right; the two longitudinal pipes are positioned above the two transverse pipes; transverse holes are formed in the two column plates on the left and right, the two ends of the transverse pipe penetrate out of the transverse holes and are located in the two transverse beams, the two transverse pipes are fixed to the inner walls of the left and right sides of the transverse beams, longitudinal holes are formed in the two column plates on the front and back, the longitudinal pipes penetrate out of the longitudinal holes and are located in the longitudinal beams, and the four longitudinal pipes are fixed to four corners of the inner wallsof the longitudinal beams. The connecting structure is higher in strength and better in stability.

Owner:台州航权机械科技有限公司

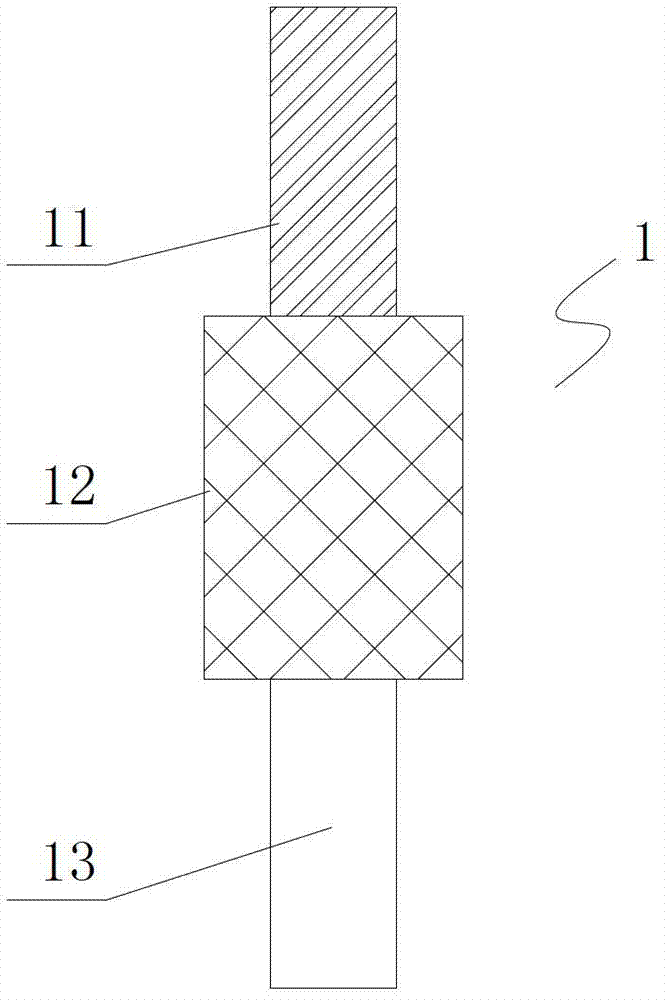

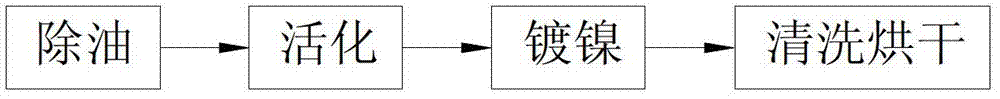

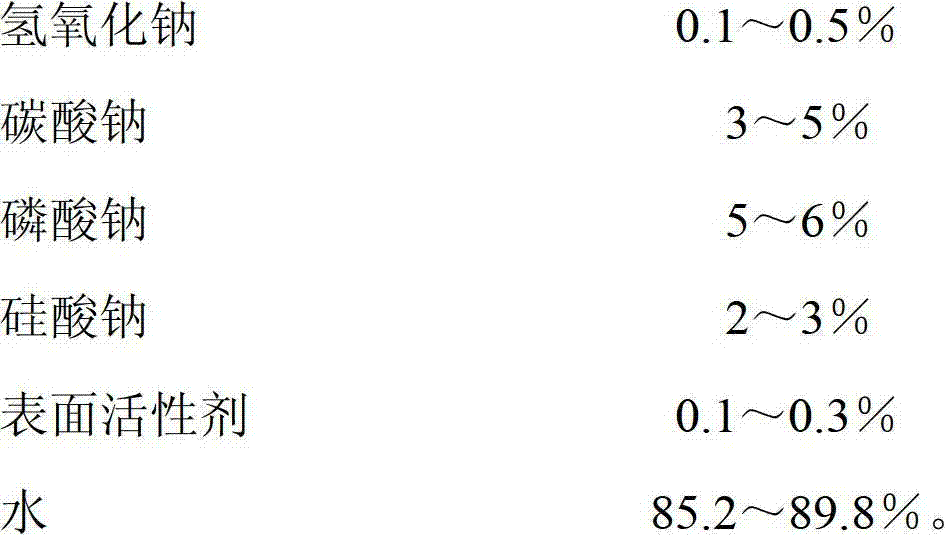

Lithium ion battery anode tab and manufacture method thereof

InactiveCN102790199AReduce high temperature soldering processAvoid WeldingCell component detailsElectrical batteryEngineering

The invention belongs to the technical field of lithium ion battery manufacture, and particularly discloses a lithium ion battery anode tab and a manufacture method thereof. The lithium ion battery anode tab comprises an aluminum strip, a nickel plating layer is arranged at the tail end of the aluminum strip, and a tab-film for adhesion is arranged in the middle of the aluminum strip. The manufacture method of the lithium ion battery anode tab specifically includes the steps of (1) oil removal; (2) activation; (3) nickel plating; and (4) cleaning and drying. The nickel plating layer plated at the tail end of the lithium ion battery anode tab substitutes for existing soldering nickel strips, a high-temperature soldering process after battery charging is decreased, and the easily appeared problems of pseudo soldering, burn-in, short circuit and even explosion during soldering of a battery are avoided, and the quality of the battery is ensured. Additionally, by the manufacture method, consumption of nickel is greatly reduced, precious resources are saved, production efficiency is improved, and production cost is lowered. The lithium ion battery anode tab prepared by the manufacture method is smaller in resistance, higher in voltage and larger in capacity.

Owner:广东新庙科技有限公司

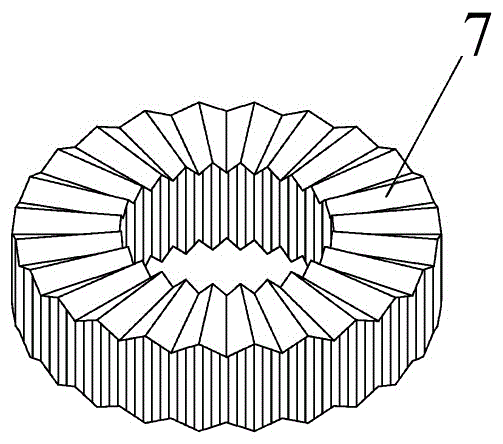

Multi-angle purline connecting assembly for metal roof

The invention relates to a metal roof multi-angle purlin connector, which aims to solve the technical problems of realizing multi-angle purlin connection by cold treatment and convenient on-site installation, and belongs to the technical field of metal roof construction. It is characterized in that, the first hinge piece, the cylindrical fixing clip and the second hinge are connected in series on the pin shaft, between the first hinge piece and the fixed clip, and between the fixed clip and the second hinge. The connecting surfaces between the sheets are provided with the same annular rib, which can be engaged and connected with each other. The positive effects of the present invention are: the present invention optimizes the design of the hinge-like profile member, and after being fastened by the pin spring nut, the annular rib is meshed and fastened with each other without rotation; not only can the welding process be avoided, but also During on-site installation, the purlin can be connected with various angles to meet the installation of special-shaped and complex building shapes. The invention has simple and reasonable structure, convenient installation, very firm connection and good overall safety.

Owner:SHANGHAI JINGRUI METAL BUILDING SYST

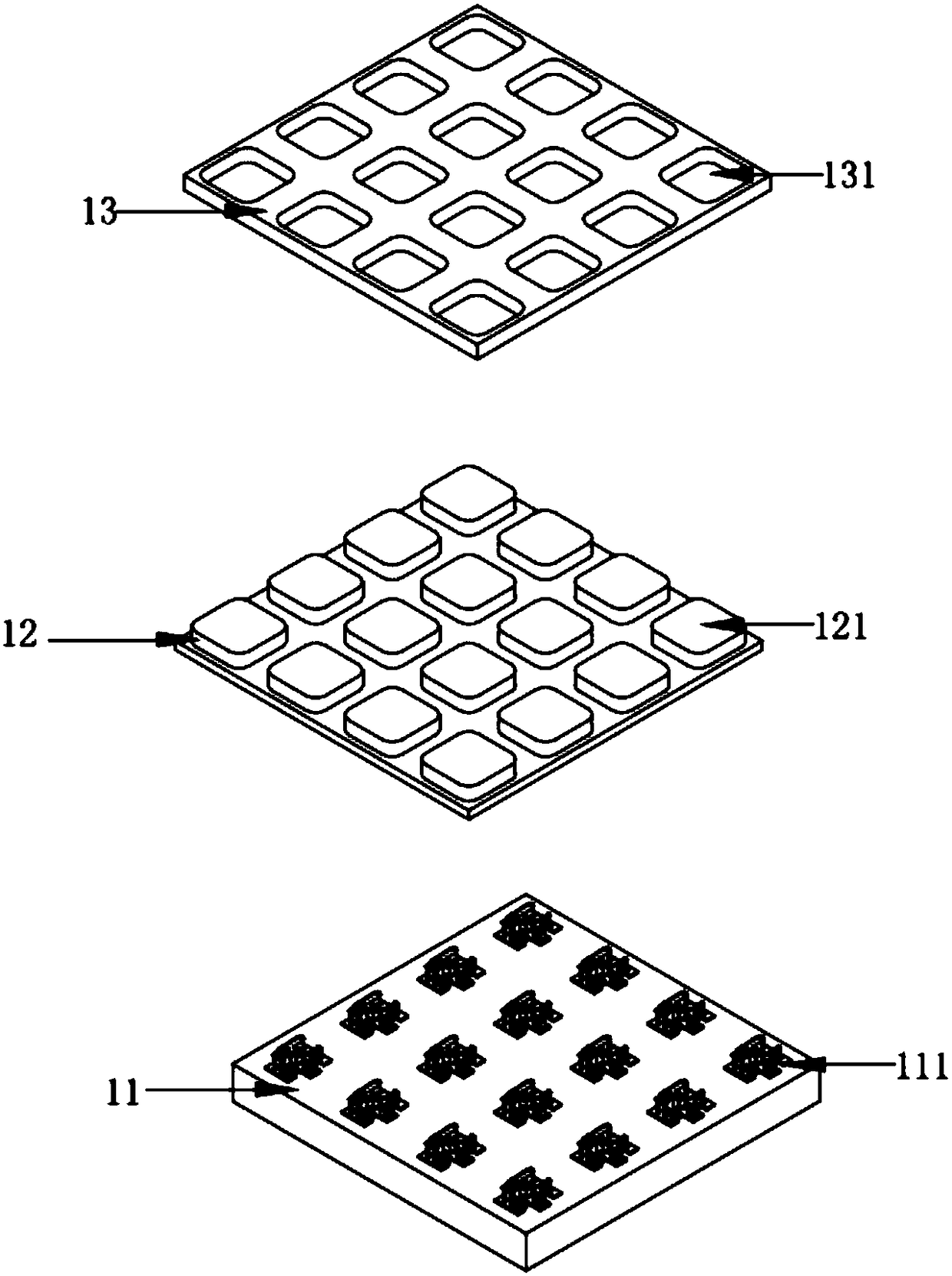

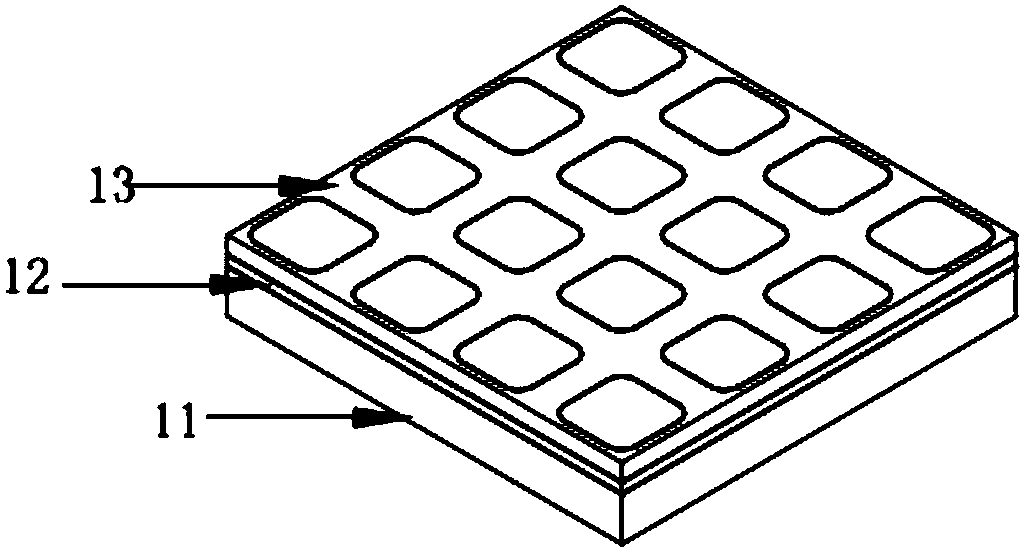

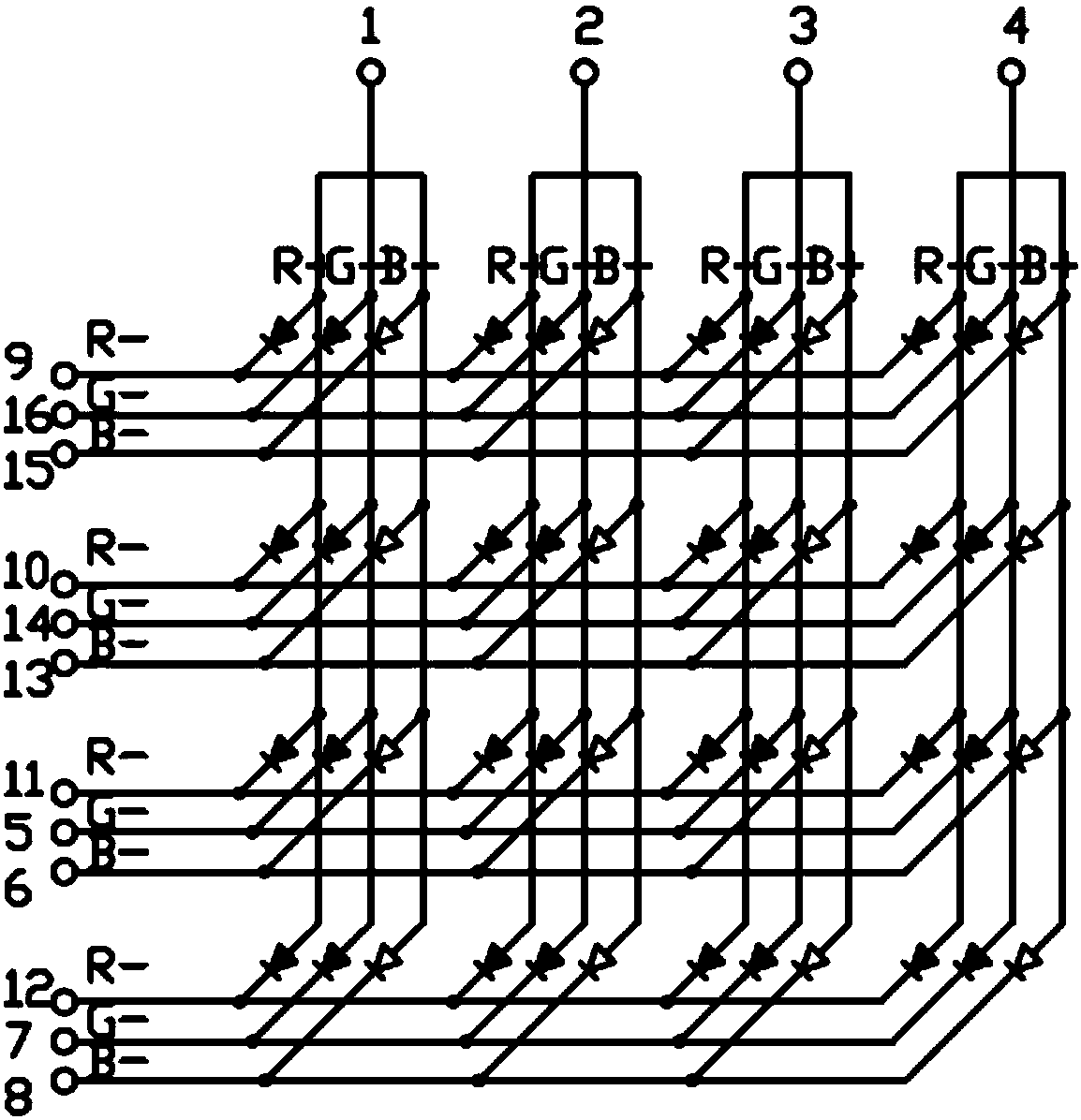

LED display screen and matrix type LED module

PendingCN108336078AAvoid solderingAdd black screen effectSolid-state devicesIdentification meansHigh densityLED display

The invention is applicable to the field of light emitting diodes, and provides an LED display screen and a matrix type LED module. The matrix type LED module comprises a circuit board and a light emitting layer, a plurality of LED units forming a matrix is fixed on the front face of the circuit board, each LED unit comprises a red LED chip, a green LED chip and a blue LED chip, positive electrodes of red LED chips, green LED chips and blue LED chips of each column of the LED units are in conduction with the same bonding pad located on the bottom surface of the circuit board, negative electrodes of red LED chips of each row of the LED units are in conduction with the same bonding pad located on the bottom surface of the circuit board, negative electrodes of green LED chips of each row of the LED units are in conduction with the same bonding pad located on the bottom surface of the circuit board, and negative electrodes of blue LED chips of each row of the LED units are in conduction with the same bonding pad located on the bottom surface of the circuit board. According to the LED display screen and the matrix type LED module, welding points when the LED display screen is made are reduced, the production efficiency is improved, and the yield is high when the high density LED display screen is made.

Owner:厦门市信达光电科技有限公司

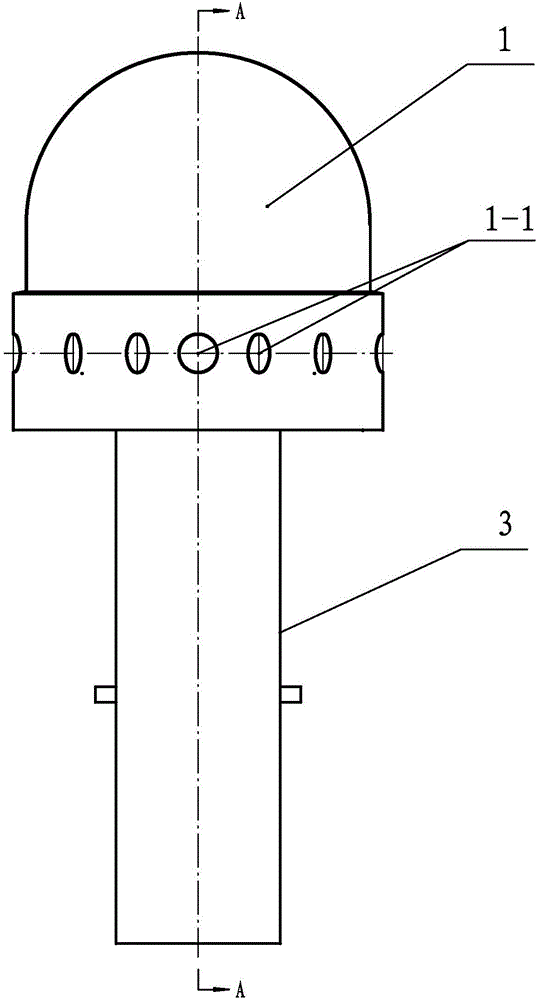

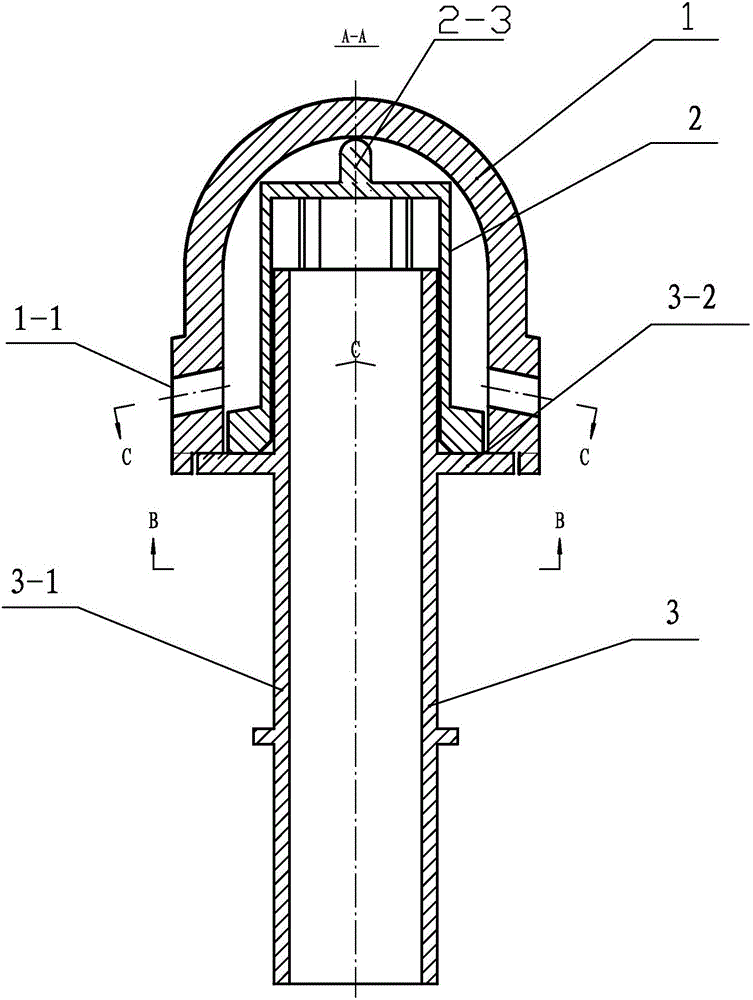

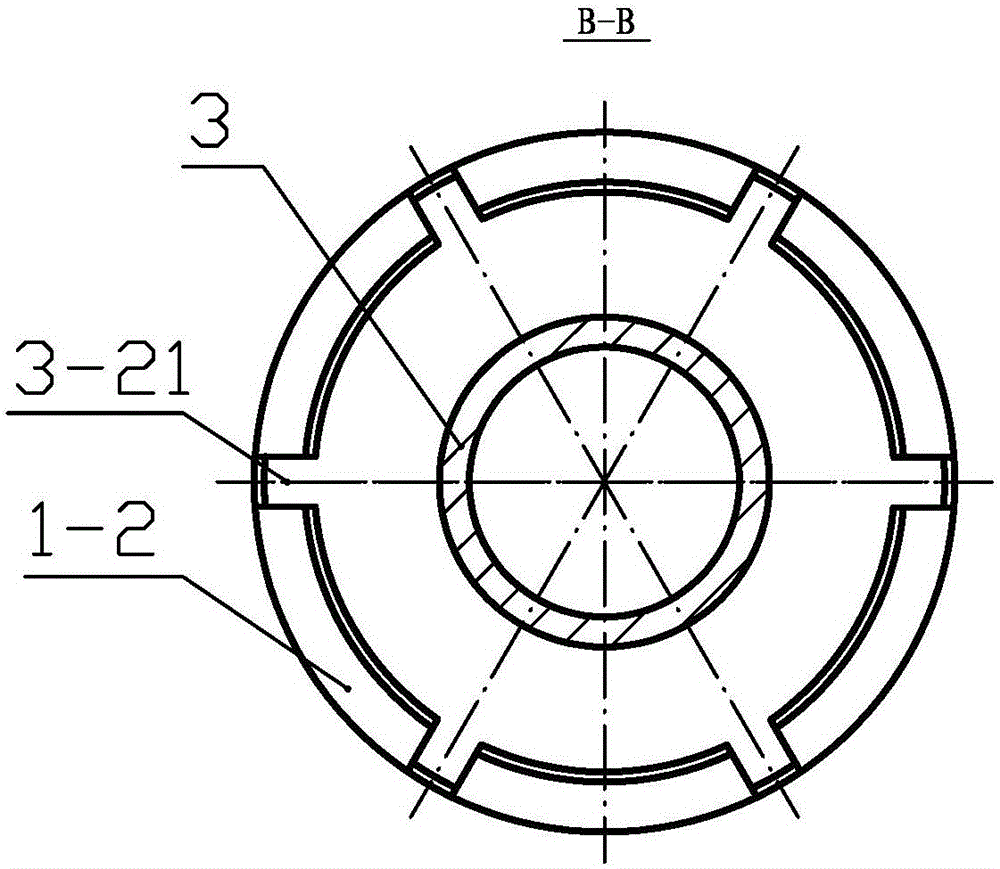

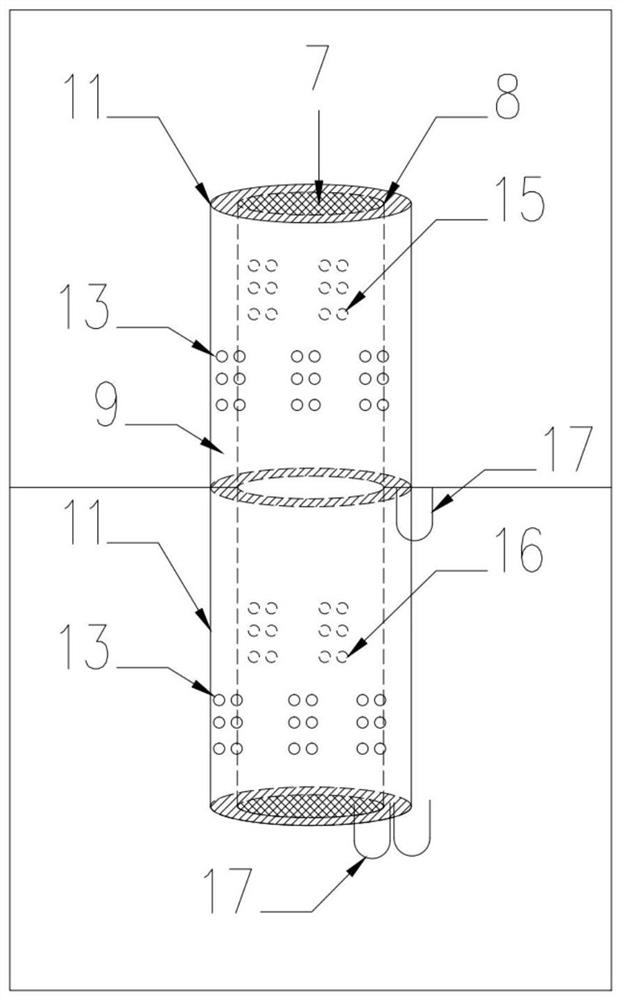

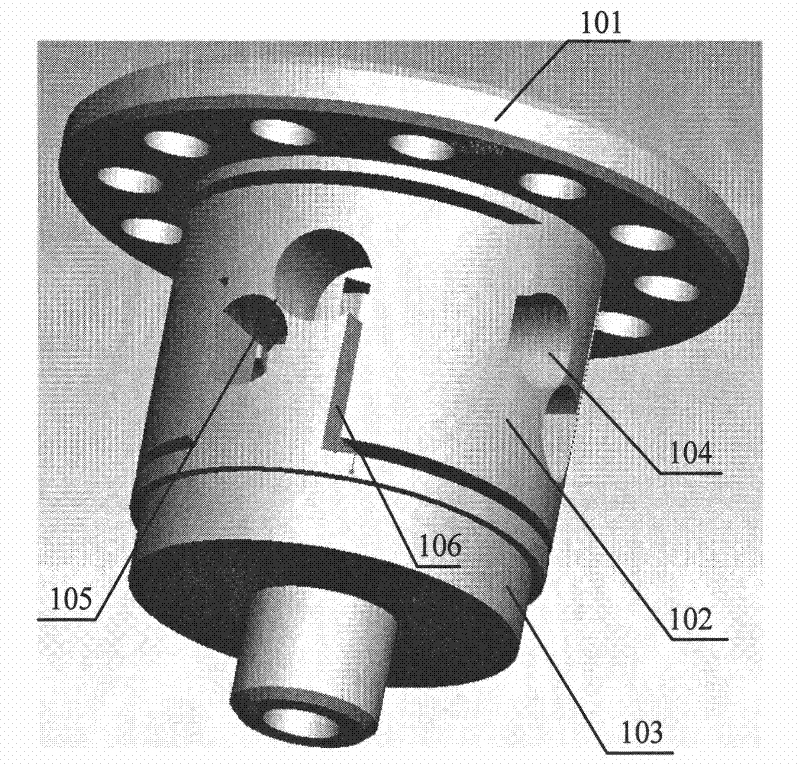

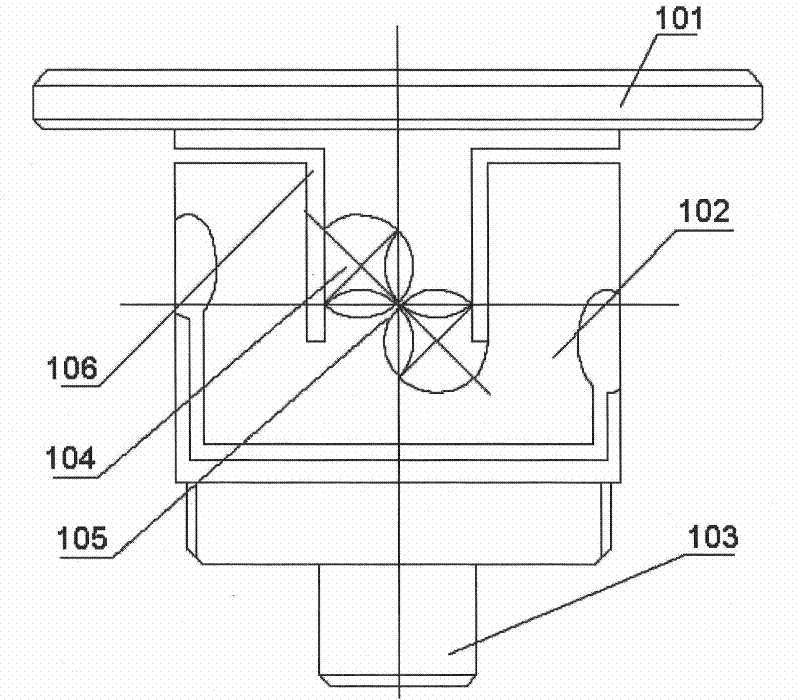

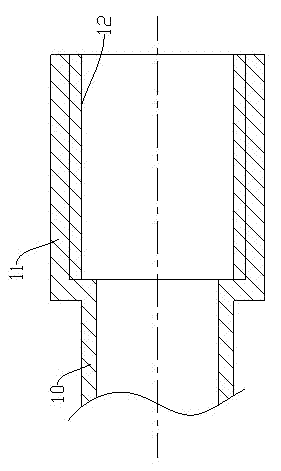

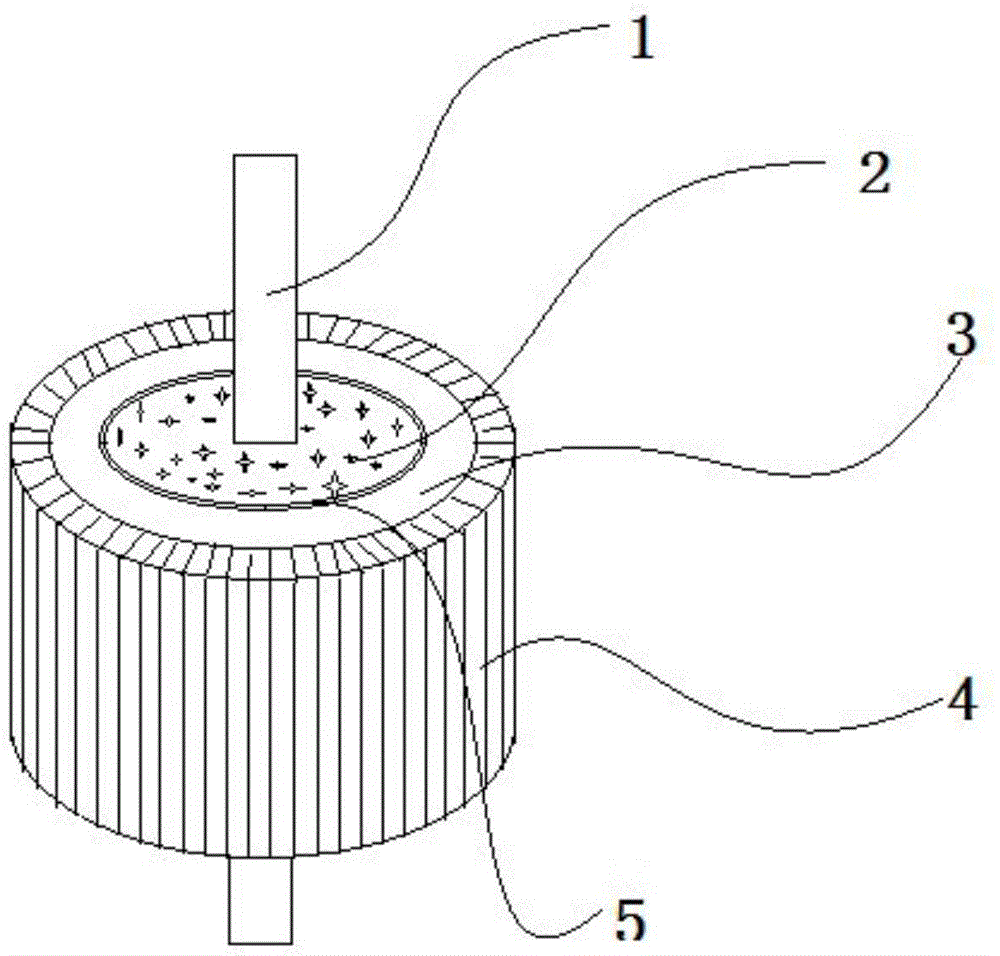

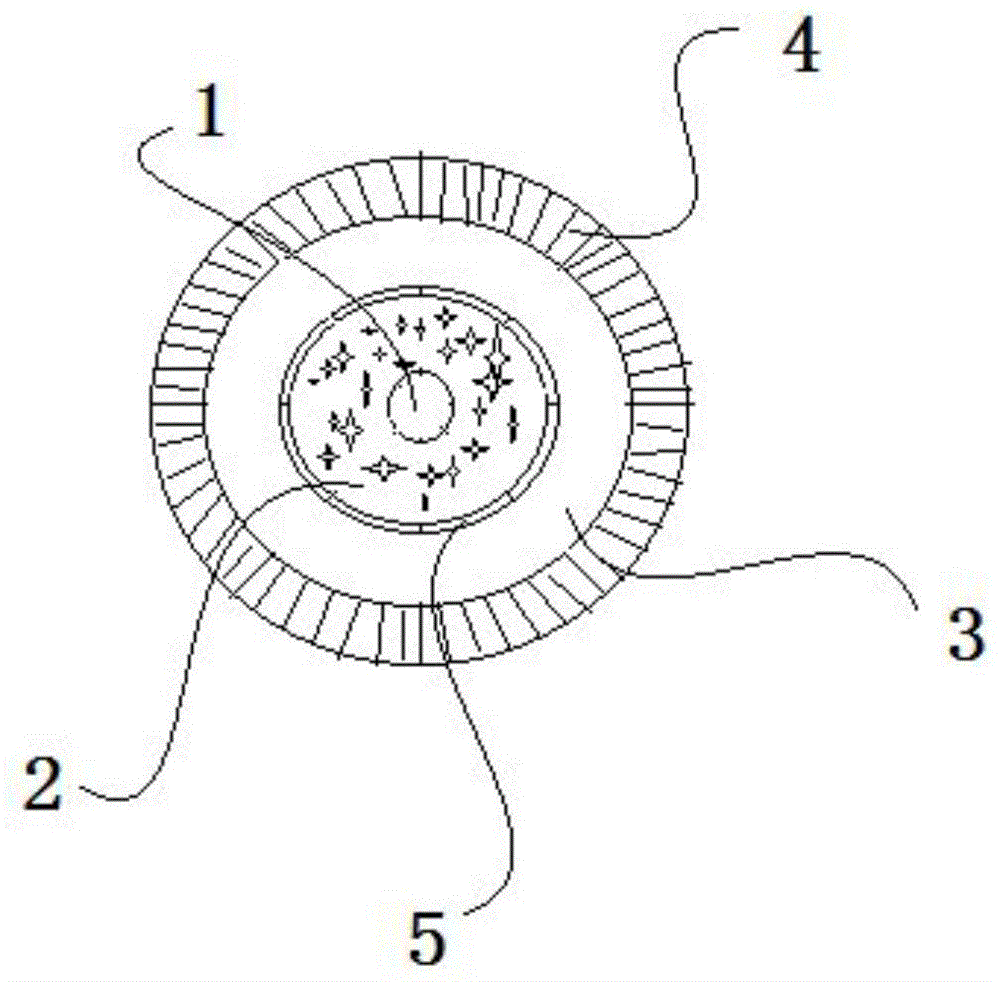

Bell jar type wind cap for environment-friendly energy-saving circulating fluidized bed boiler

InactiveCN106678786AReduce wearRealize self-coolingFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

The invention discloses a bell jar type wind cap for an environment-friendly energy-saving circulating fluidized bed boiler, belongs to the technical field of boiler structures, and solves the problems that a conventional wind cap is liable to slag leakage, a wind cap head and a wind cap seat are severely abraded, and the cost is high and economy is poor due to the fact that the wind cap is uneasy to change after abrasion. The bell jar type wind cap comprises the wind cap head, a protective sleeve and the wind cap seat, wherein the wind cap seat comprises a cylinder and a support plate; the support plate is mounted at the upper part of the cylinder in a sleeving manner; the protective sleeve comprises a barrel body and a locating ring fixedly connected on the outer edge of an open end of the barrel body; a plurality of first through holes are uniformly formed in the side wall of the upper part of the barrel body; a plurality of second through holes are uniformly formed in the top of the barrel body; the wind cap head and the protective sleeve are mounted on the support plate in a buckle manner; the wind cap head is fixedly connected with the support plate; the protective sleeve is positioned between the wind cap head and the wind cap seat; the outer side wall and the top outer edge of the locating ring are in tight contact with the inner wall of the wind cap head; and the wind cap head, the protective sleeve and the cylinder are coaxially arranged. The bell jar type wind cap is used for an air distribute device of the circulating fluidized bed boiler.

Owner:哈尔滨红光锅炉总厂有限责任公司

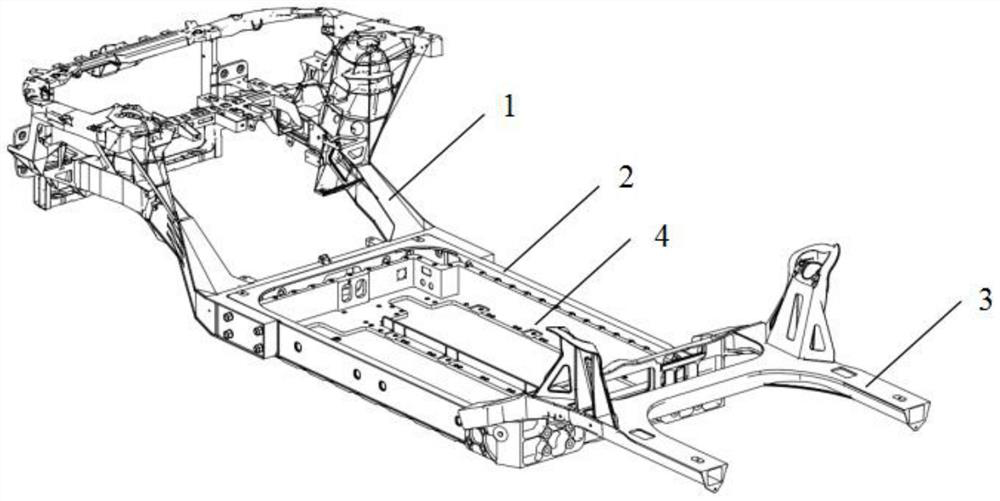

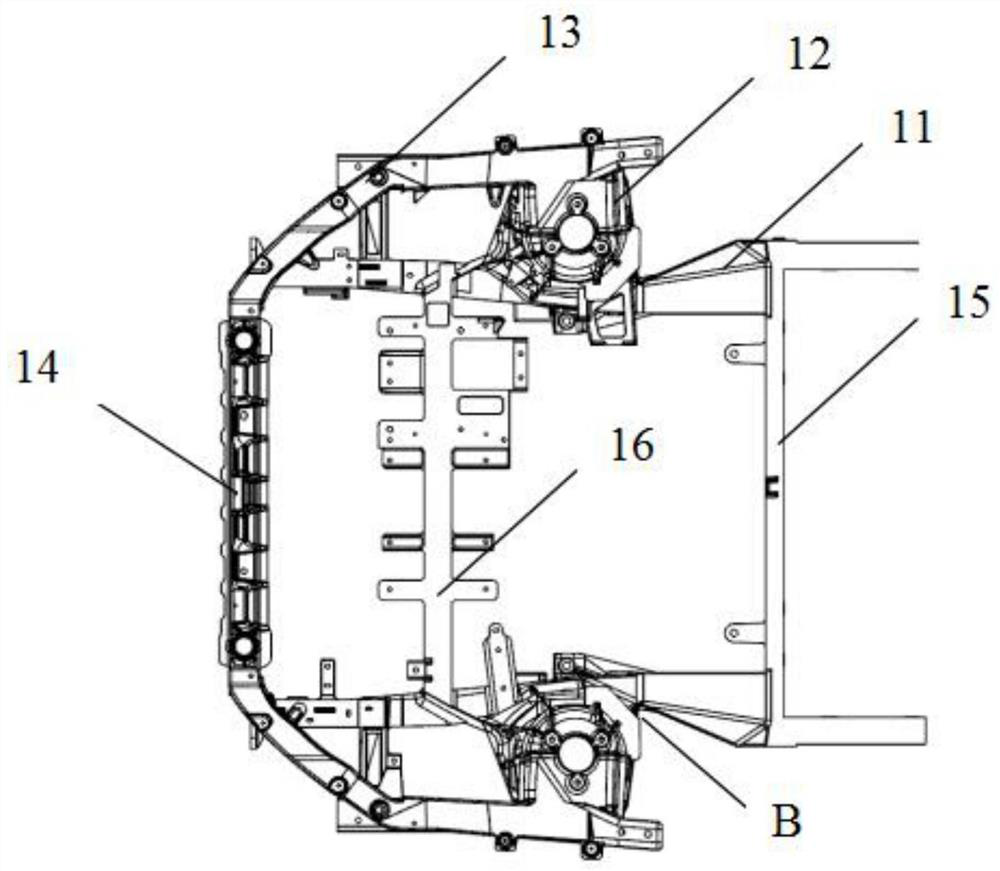

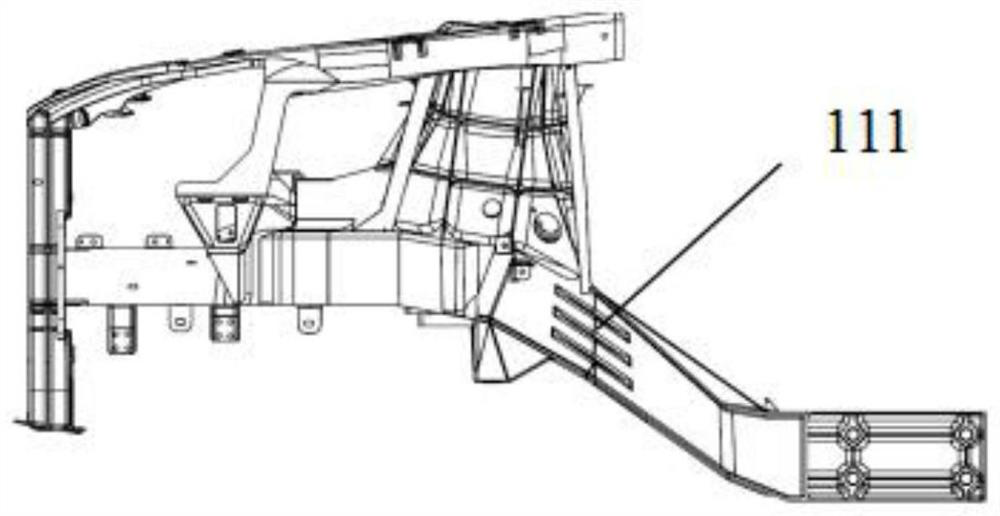

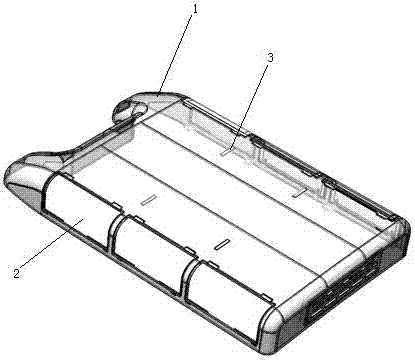

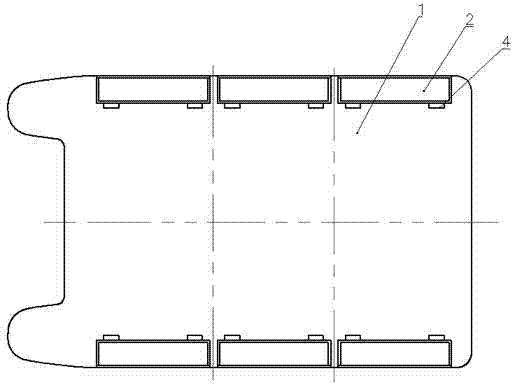

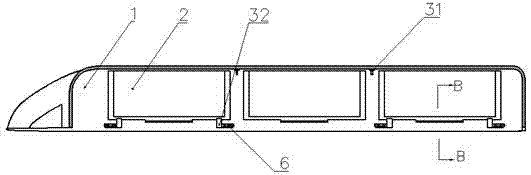

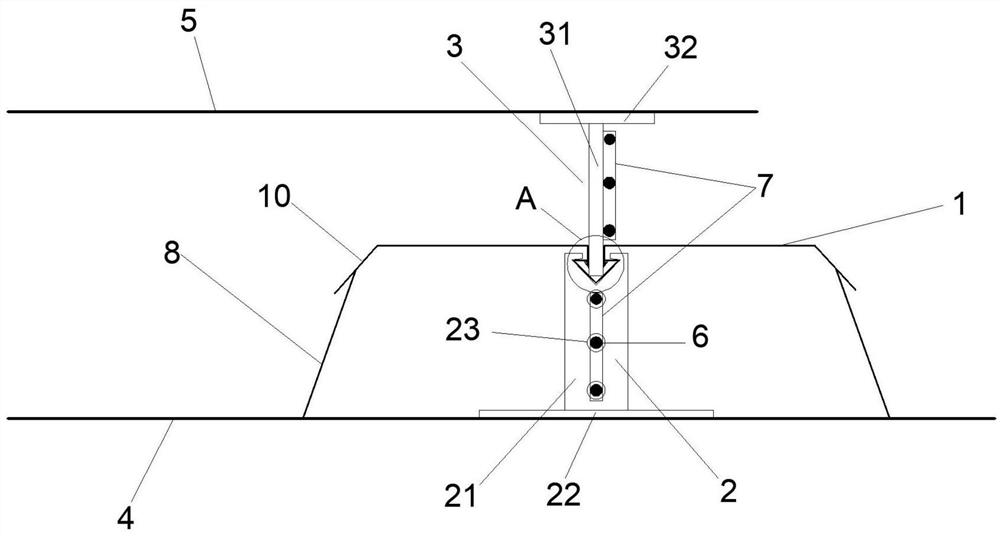

Lower frame of electric vehicle and chassis

PendingCN111746649AAchieve lightweightAchieve integrationElectric propulsion mountingUnderstructuresVehicle frameElectrical battery

The invention discloses a lower frame of an electric vehicle and a chassis using the frame, and relates to the technical field of new energy vehicles. The lower frame comprises a front-end frame, a battery box fixing frame, a rear-end frame and a battery box lower shell, wherein the front-end frame, the battery box fixing frame, the rear-end frame and the battery box lower shell are all thin-wallaluminum alloy pieces; the front-end frame is positioned in front of the battery box fixing frame; the front-end frame is in threaded connection with the front end and the front side edge of the battery box frame through four bolt sets; the rear-end frame is located behind the battery box fixing frame, the rear-end frame is in threaded connection with the rear end and the rear side edge of the battery box frame through four bolt sets, the battery box lower shell is located in the battery box fixing frame, and the battery box lower shell is connected with the battery box frame through a circleof screws at the bottom. The lower frame has the characteristics of no need of welding, simple process, high precision, light weight, high structural strength and modular assembly, and can adapt to small-batch or customized production of electric vehicles.

Owner:SUSHI PRECISION MFG TECH BEIJING CO LTD

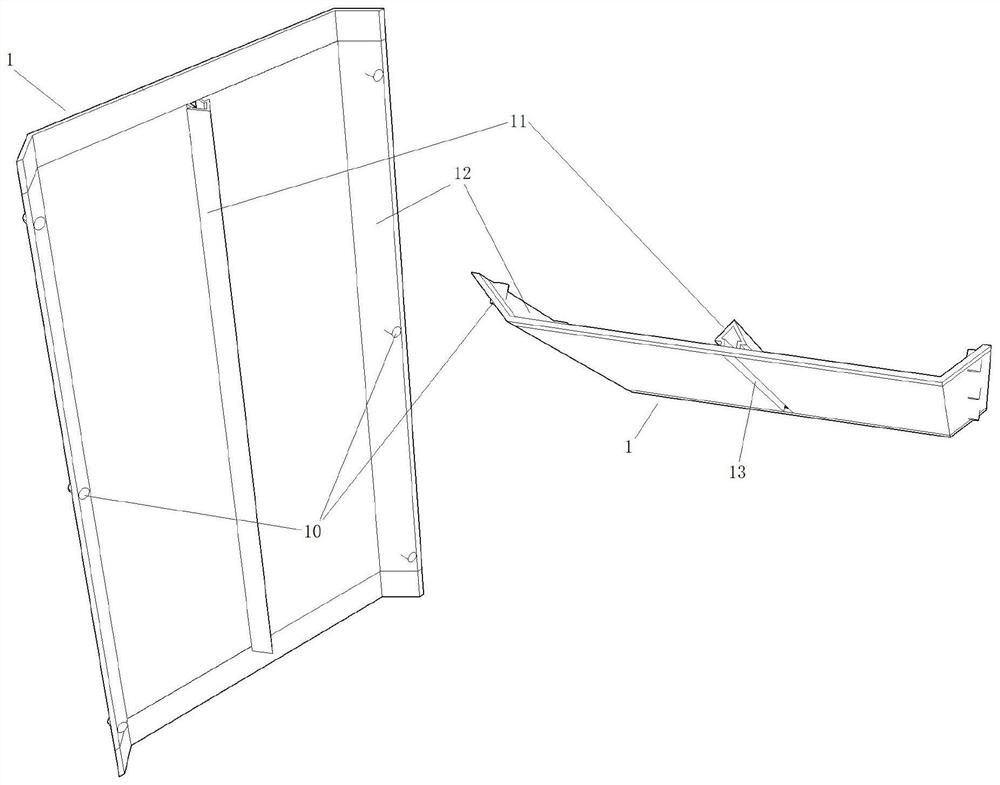

Lightening method of battery protective cover for electric buses and battery protective cover

InactiveCN107284217AReduce weightReduce manufacturing costElectric propulsion mountingSecondary cellsPolyvinyl chlorideElectrical and Electronics engineering

A lightening method of a battery protective cover for electric buses is provided. The battery protective cover includes a protective cover body, a maintenance door mounted on the protective cover body, and a connector for mounting and connecting the battery protective cover. The battery protective cover is characterized in that both the protective cover body and the maintenance door are made of a heat-insulating sandwich material, the heat-insulating sandwich material is composed of two fiber-reinforced plastic layers and a PVC (polyvinyl chloride) foam layer pasted between the two fiber-reinforced plastic layers, and the connector is embedded in the protective cover body. The lightening method of the invention has the advantages that the weight and manufacture cost of the battery protective cover for electric buses are effectively decreased, the lightening requirement of electric buses is met, and the overall appearance effect of the battery protective cover is improved. The invention also provides a battery protective cover.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Water stopping steel plate structure and installation method

ActiveCN111677016AAvoid welding operationsImprove waterproof performanceArtificial islandsProtective foundationMortise and tenonRebar

The invention proposes a water stopping steel plate structure. The structure comprises a water stopping steel plate, a supporting seat, and a bayonet pin; flange plates are arranged on the edges of two opposite sides of the water stopping steel plate; a connecting hump is formed in the middle part of a first side surface of the water stopping steel plate; a connecting groove is formed in the middle part of a second side surface of the water stopping steel plate; a clamping groove is formed in a first end of the supporting seat; the connecting hump is connected with the clamping groove via a mortise and tenon structure; a second end of the supporting seat is connected with a bottom layer steel bar so the water stopping steel plate is connected with the bottom layer steel bar; a first end ofthe bayonet pin is arranged in the connecting groove in a clamped mode; and a second end of the bayonet pin is connected with a face layer steel bar of a bottom plate. The water stopping steel platestructure has the beneficial effects that through the arrangement of the water stopping steel plate, the supporting seat used for installing the water stopping steel plate, and the bayonet pin used for fixing the water stopping steel plate, the water stopping steel plate structure of a novel structure is formed by using the principles of mortises and tenons, spring limiting and the like and in combination of a suitable number of steel wires and waterproof materials, welding operation in the process of installing the water stopping steel plate can be effectively avoided, and the waterproof effect is greatly improved.

Owner:CHINA FIRST METALLURGICAL GROUP

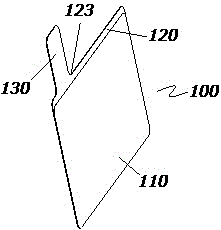

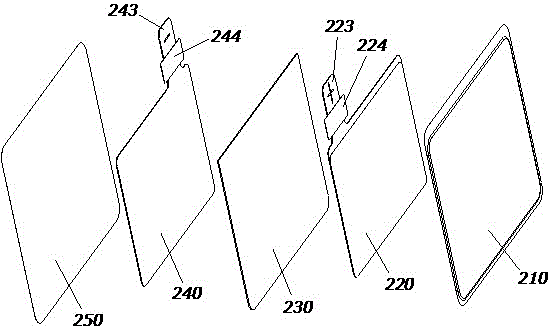

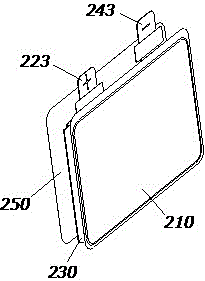

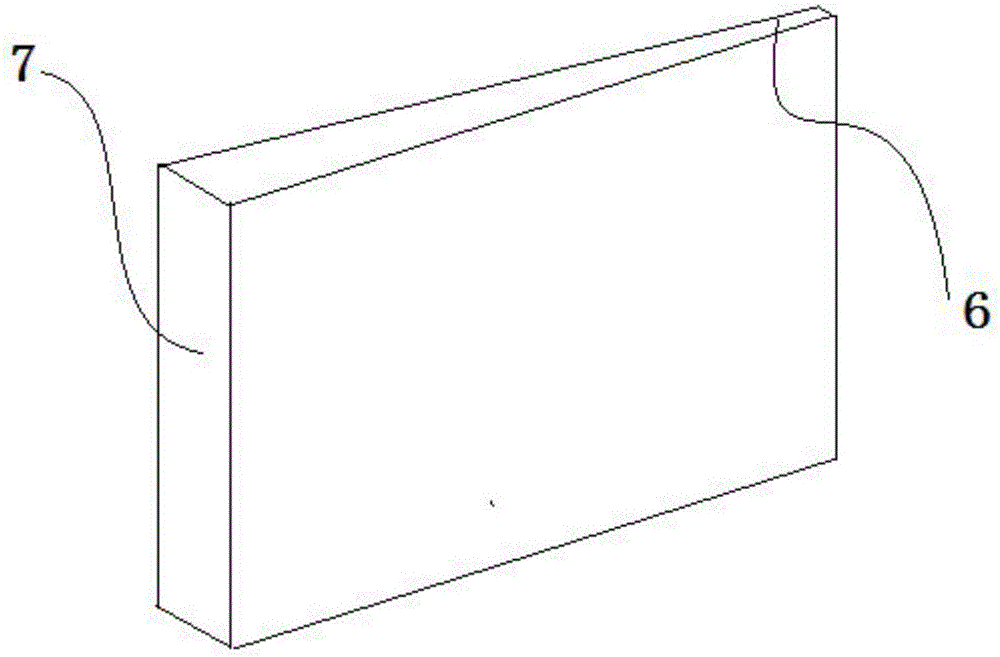

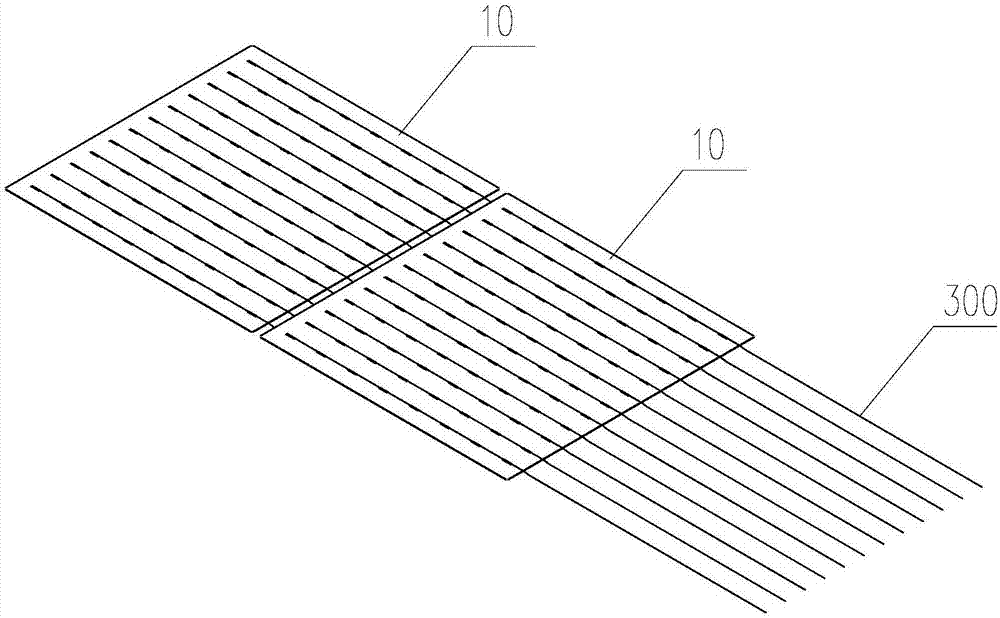

Intelligent IC card, ultrathin battery and pole piece with tab of ultrathin battery

PendingCN106531951AReduce thicknessAvoid solderingCell component detailsRecord carriers used with machinesElectrical batteryCurrent collector

The invention discloses an intelligent IC card, an ultrathin battery and a pole piece with a tab of the ultrathin battery. The pole piece comprises a current collector piece, wherein the current collector piece is provided with connected dressing area and blank area; an integrally connected tab area extends on local edge of the blank area; and the tab area and the dressing area are located at two sides of the blank area. Due to the adoption of the tab which is integrally connected with the current collector piece, the welding mode of superposing a tab piece on the current collector piece is creatively avoided, the thickness of the pole piece is obviously reduced, the bottleneck that a polymer ultrathin soft package secondary battery cannot be easily improved towards a smaller thickness direction is broken through, and the pole piece has important practical value and significance in popularization and development of the intelligent IC card with the battery.

Owner:东莞市科睿思美新能源科技有限公司

Heat radiator and manufacturing method thereof

InactiveCN105043135AImprove cooling effectGuaranteed cooling effectStationary conduit assembliesHeat exchanger casingsEngineeringHeat spreader

The invention relates to the technical field of heat radiation, in particular to a heat radiator and a manufacturing method thereof. The heat radiator is composed of cooling fins, a fixed medium cavity fixedly connected with the cooling fins, a heat transfer contact base body movably connected with the fixed medium cavity and a connecting piece arranged on the upper surface and the lower surface of the heat transfer contact base body. Then, the fixed medium cavity is included in the heat radiator, and media in the fixed medium cavity are defined as heat conduction oil. Then, a large amount of heat can be transmitted out of the heat transfer contact base body through the performance of the heat conduction oil. Then, heat exchange is achieved, the heat radiation effect is improved through rotation and large-area treatment of the cooling fins, and the heat radiation effect on equipment needing heat radiation treatment is guaranteed. In the manufacturing process, the cooling fins and the fixed medium cavity are formed in an ultrasonic welding manner or a manner of being squeezed into a whole; then the character that heat radiation of welding blocks is uneven due to a tradition welding manner is reduced; and then the heat radiation performance of the heat radiator is improved.

Owner:贵州凯宏汇达冷却系统有限公司

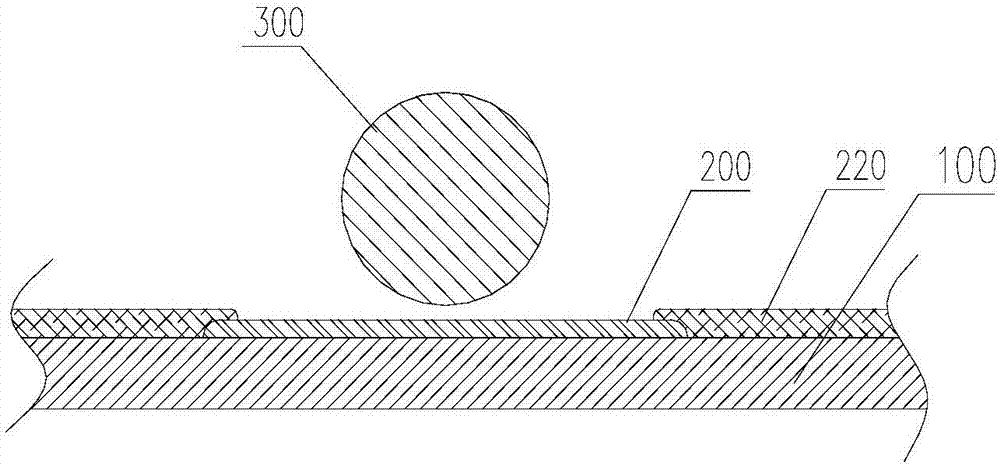

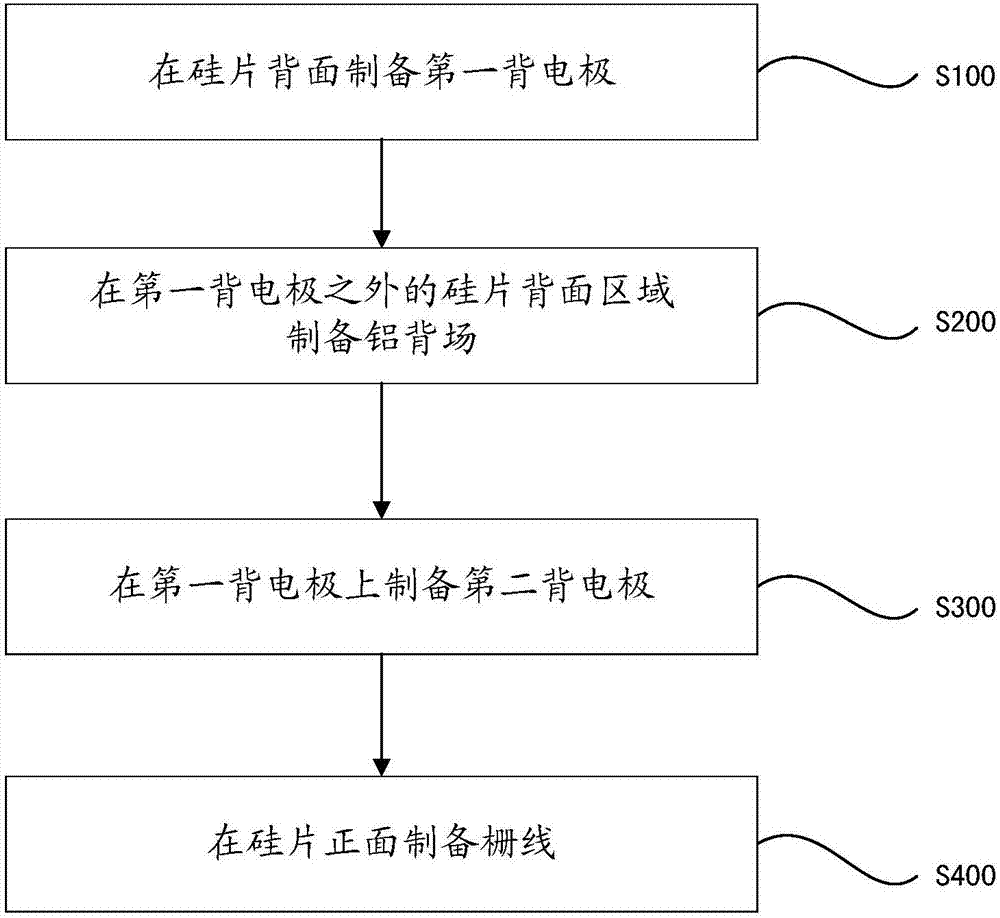

Solar cell piece and preparation method thereof

InactiveCN107394011AEliminate hard-to-reach defectsAvoid solderingFinal product manufacturePhotovoltaic energy generationSolderingSolar cell

The invention provides a solar cell piece and a preparation method thereof. The preparation method comprises: a first back electrode is prepared on the back of a silicon wafer; an aluminum back field is prepared at the back, beyond the first back electrode, of the silicon wafer, wherein the n aluminum back field is in conduction with the first back electrode; a second back electrode is prepared on the first back electrode and the first back electrode and the second back electrode are combined to form a back electrode, so that the thickness of the back electrode is not less than that of the aluminum back field; and a front electrode is prepared on the front side of the silicon wafer. According to the solar cell piece prepared based on the preparation method, because the thickness of the back electrode is not less than that of the aluminum back field, the back electrode and a solder strip are in full contact during cell piece series welding, so that a problem that the back electrode can not be welded with the solder strip or insufficient soldering exists is solved; and a technical bottleneck of volume production of the solar photovoltaic assembly is solved and the industrialization target of the products is realized.

Owner:ZHANGJIAGANG GCL INTEGRATION TECH CO LTD

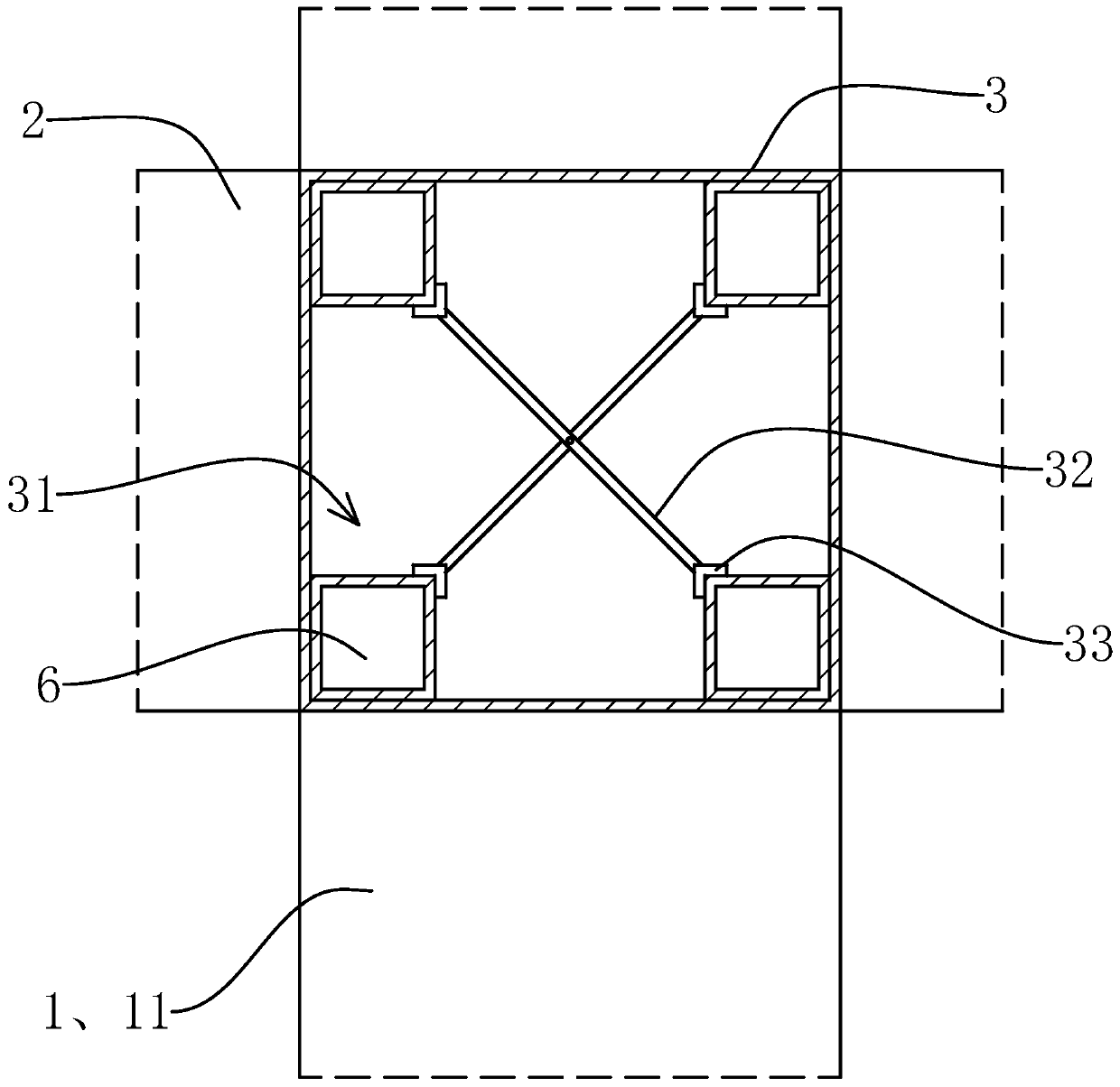

Anchor-ear node plate and construction method of ceiling joist

A construction method of hoop gusset plate and its suspended ceiling keel. The main body of the upper hoop plate is an inverted channel-shaped flat steel. The bolt holes, the structure of the lower half hoop plate and the upper half hoop plate are symmetrical, the bottom surface of the lower half hoop plate is connected with the joint plate, the bottom surface of the joint plate is connected with the vertical joint plate and the joint longitudinal plate, and the joint transverse plate and There are main keel connecting holes and auxiliary keel connecting holes respectively opened on the node longitudinal plates. Enclose the upper half hoop plate and the lower half hoop plate to the steel truss, fix the upper half hoop plate, the lower half hoop plate and the steel truss with bolts, connect the main keel connection hole with the main keel with bolts, and The auxiliary keel connecting hole is connected with the auxiliary keel. The prefabricated building product and construction method avoid excessive welding methods, reduce building energy consumption, and speed up construction, and can be widely used in the construction of suspended ceilings for various steel structure buildings.

Owner:BEIJING CONSTR ENG GRP CO LTD +1

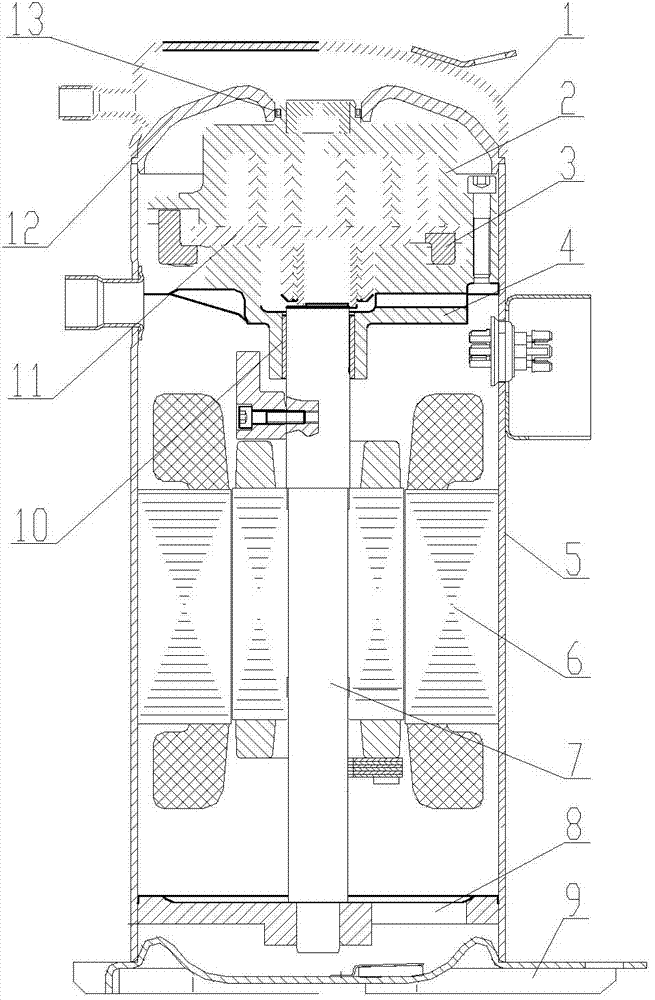

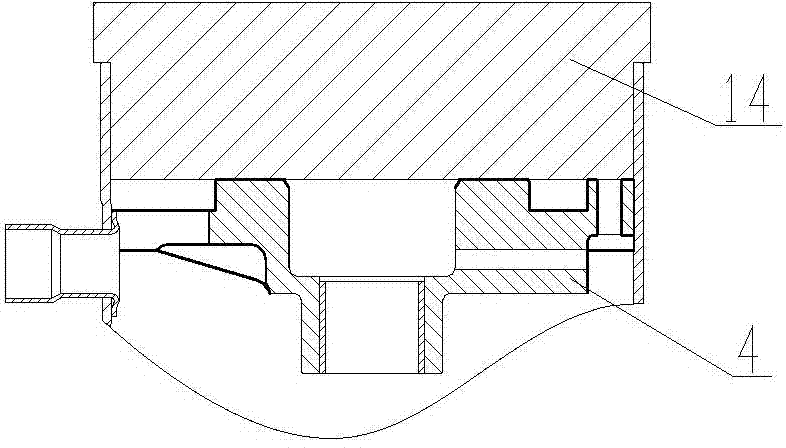

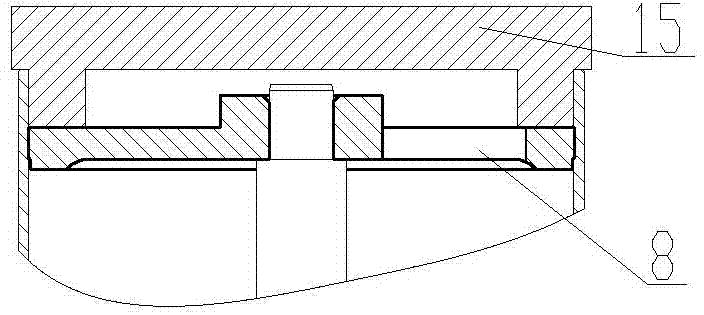

Fully-sealed scroll compressor and assembly method thereof

InactiveCN104295495AReduce distortionLow costAssembly machinesRotary piston pumpsEngineeringCrankshaft

The invention discloses a fully-sealed scroll compressor and an assembly method thereof and relates to the field of scroll compressors. The scroll compressor comprises an upper cover, a static scroll, a crossed ring, a main bearing support, a shell, a motor stator with a motor rotor, an auxiliary bearing, a lower cover, a main bearing, a movable scroll, a high-low-pressure isolation board and a seal ring, wherein the motor stator is used for driving a crankshaft to rotate; the lower cover is fixed at the lower end of the shell; the moveable and static scrolls are matched with each other so as to form at least one compressing cavity; the main bearing support is fixed at the upper end in the shell in an interference manner; an auxiliary bearing support is fixed at the lower end in the shell in an interference manner and acts as an auxiliary bearing; the main and auxiliary bearings are coaxial. The fully-sealed scroll compressor is compact in structure; the main and auxiliary bearing supports are fixed in the interference manner, not in a normal welding manner; on the premise that the deformation of the supports is alleviated, assembly devices are simplified and the assembly cost of the compressor is lowered.

Owner:HEFEI SANSONG HOT & COLD TECH

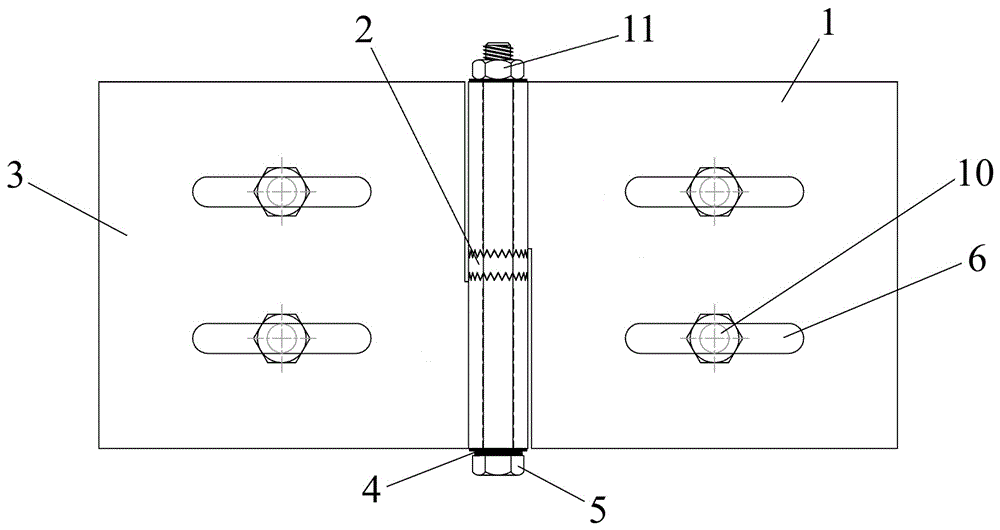

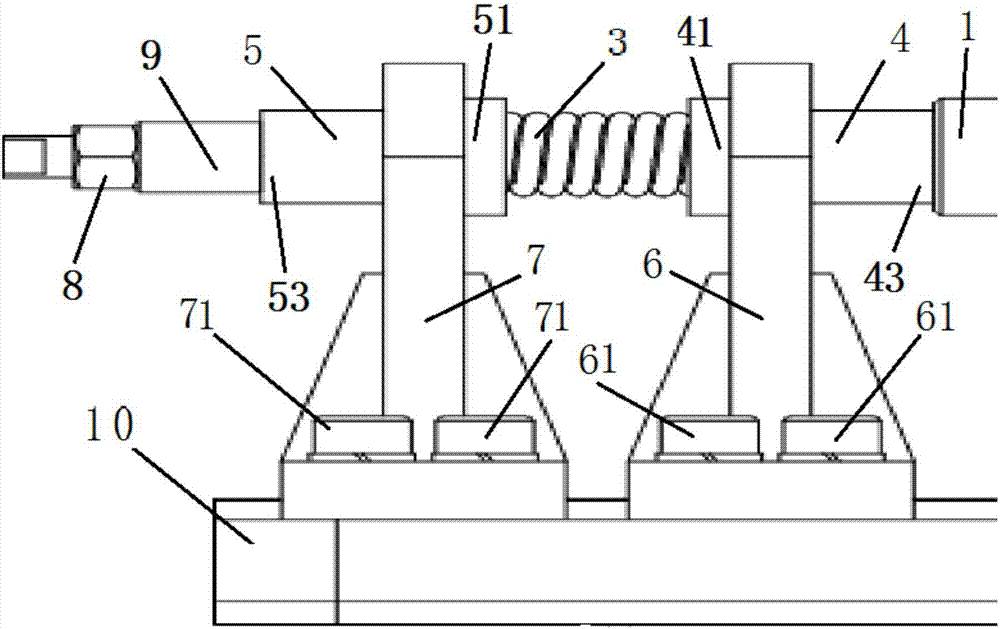

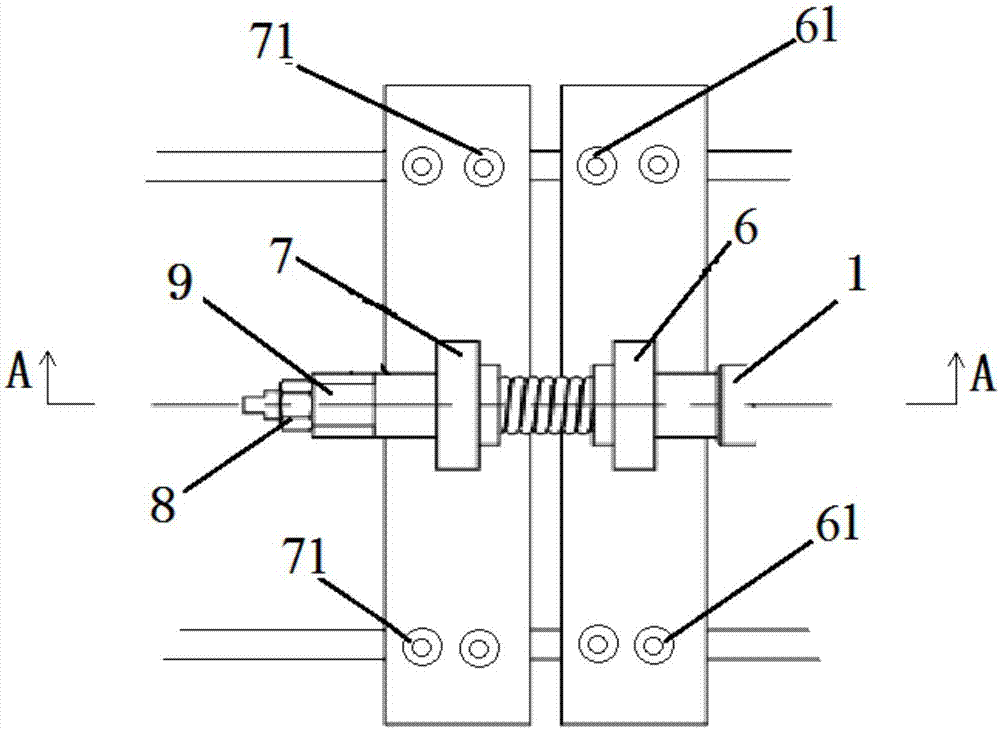

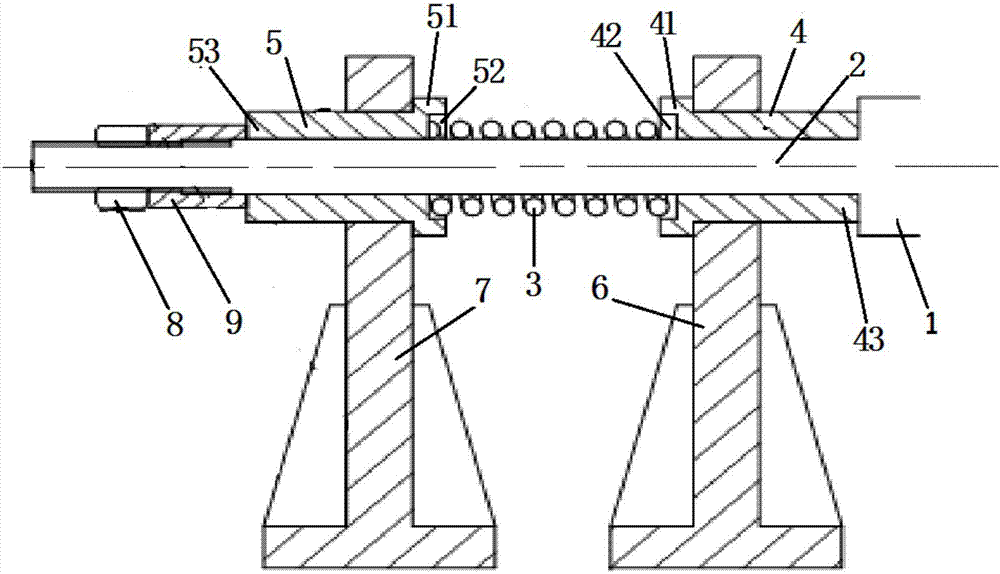

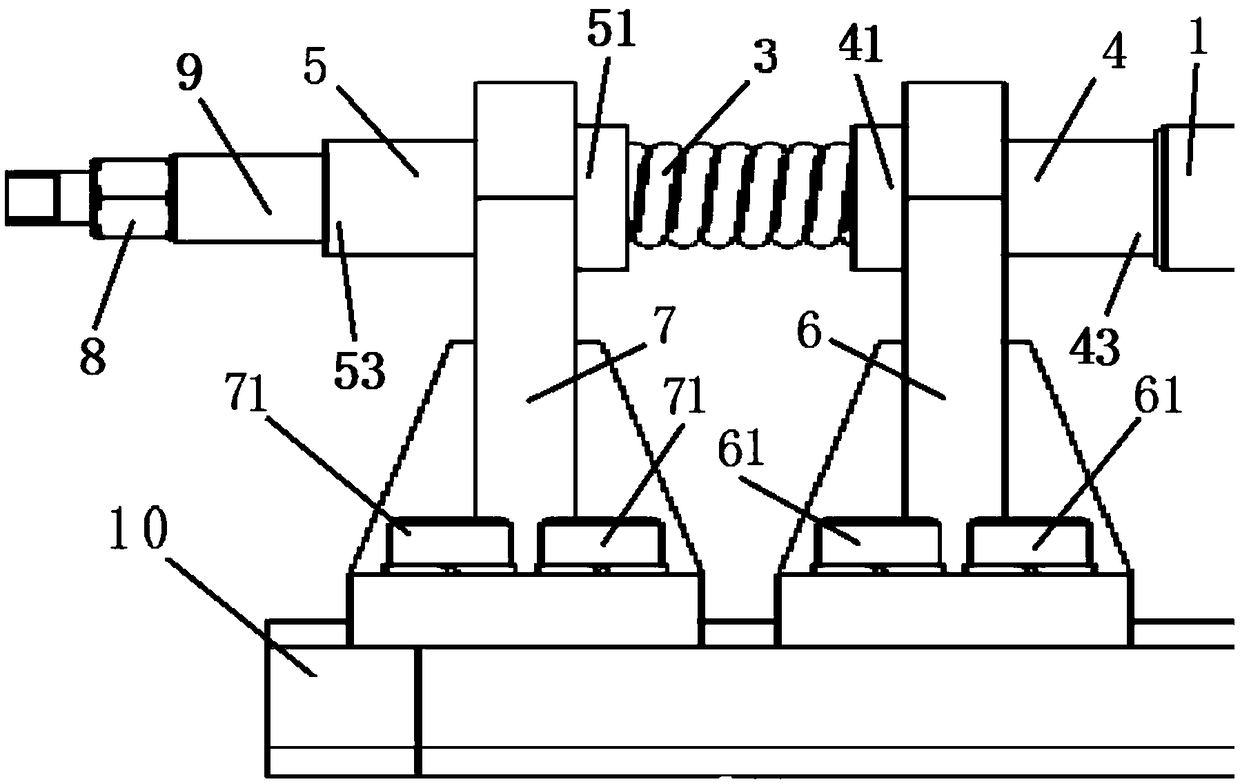

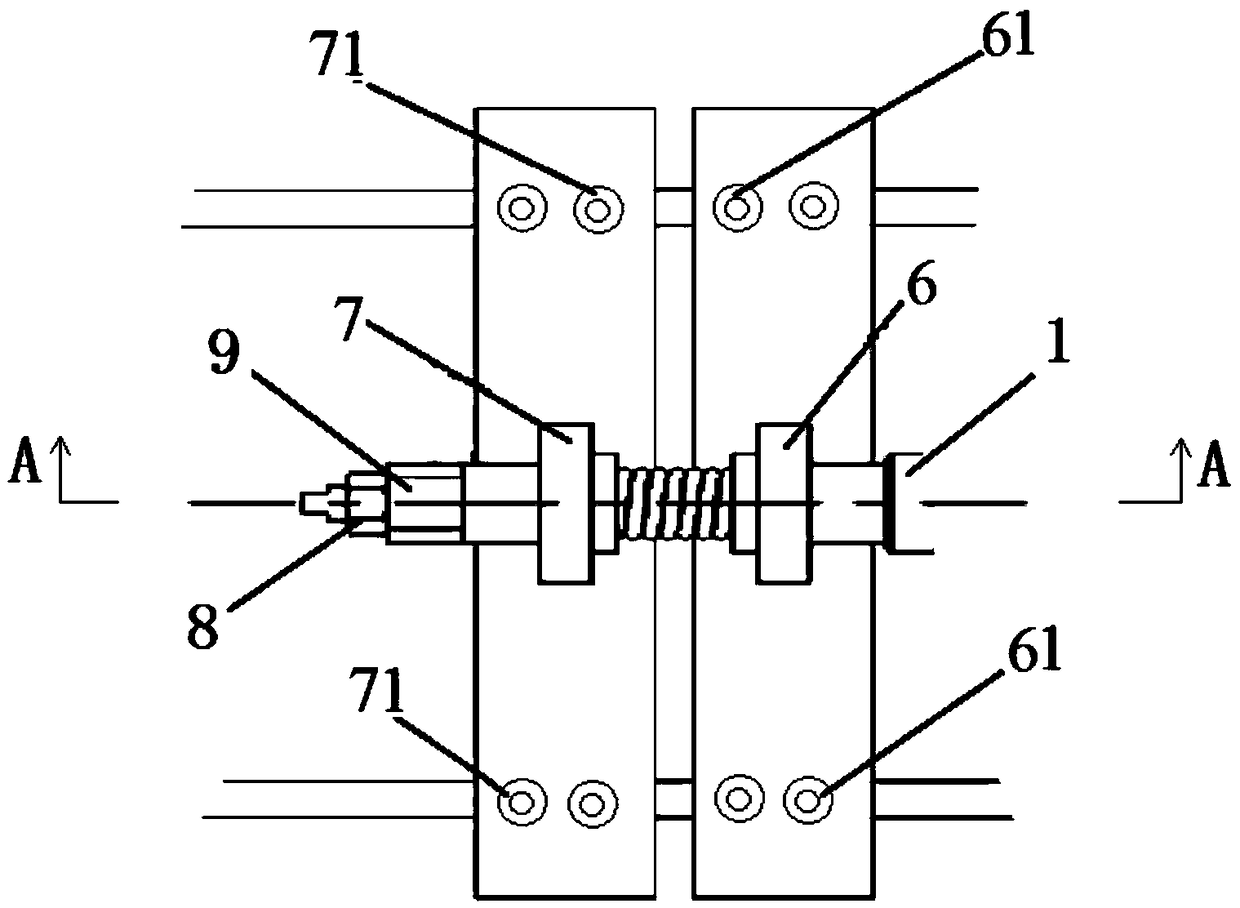

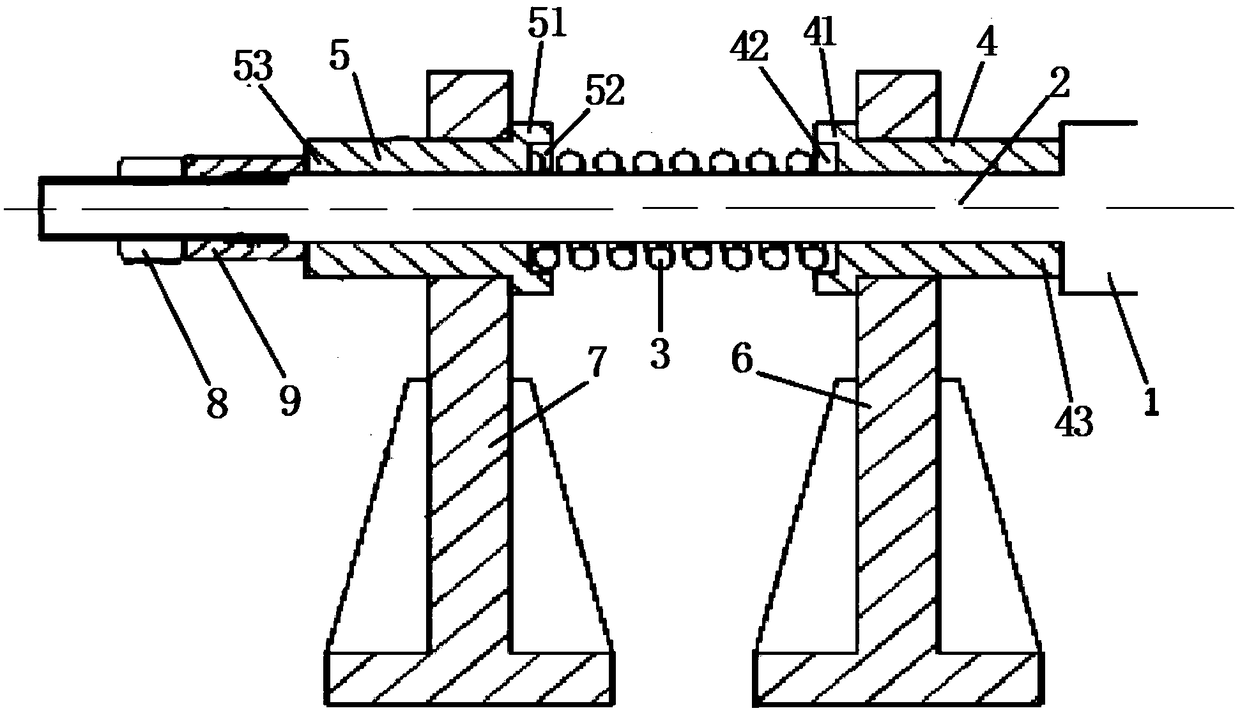

Elastic load mechanism and method for measuring elastic load

InactiveCN106932183AStable structureAdjust the initial elastic loadMachine part testingEngineeringMechanical engineering

Owner:BEIJING JIAOTONG UNIV

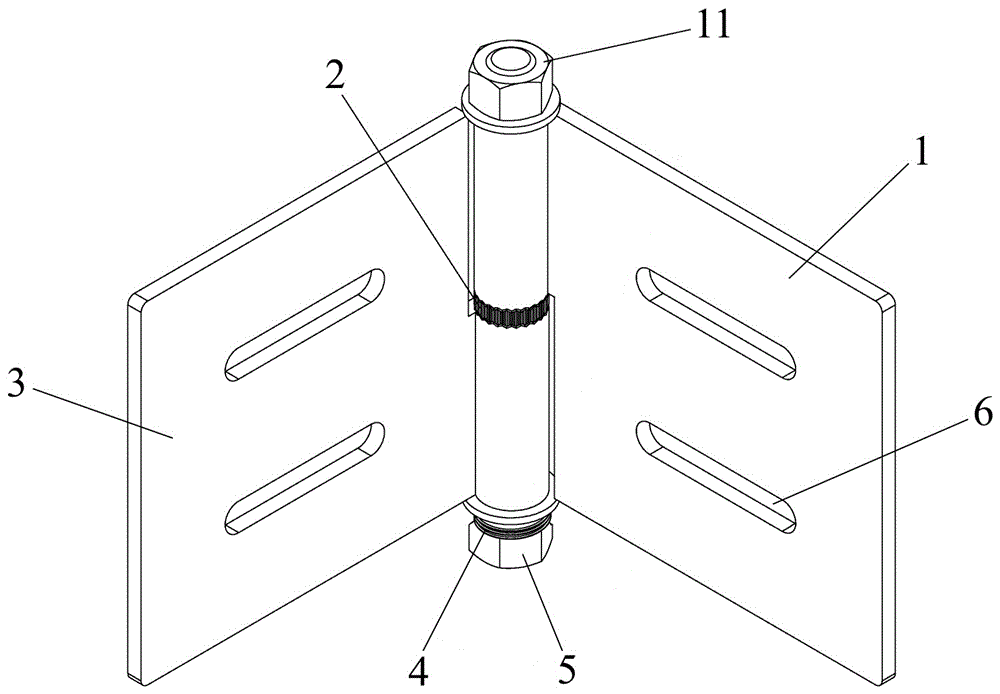

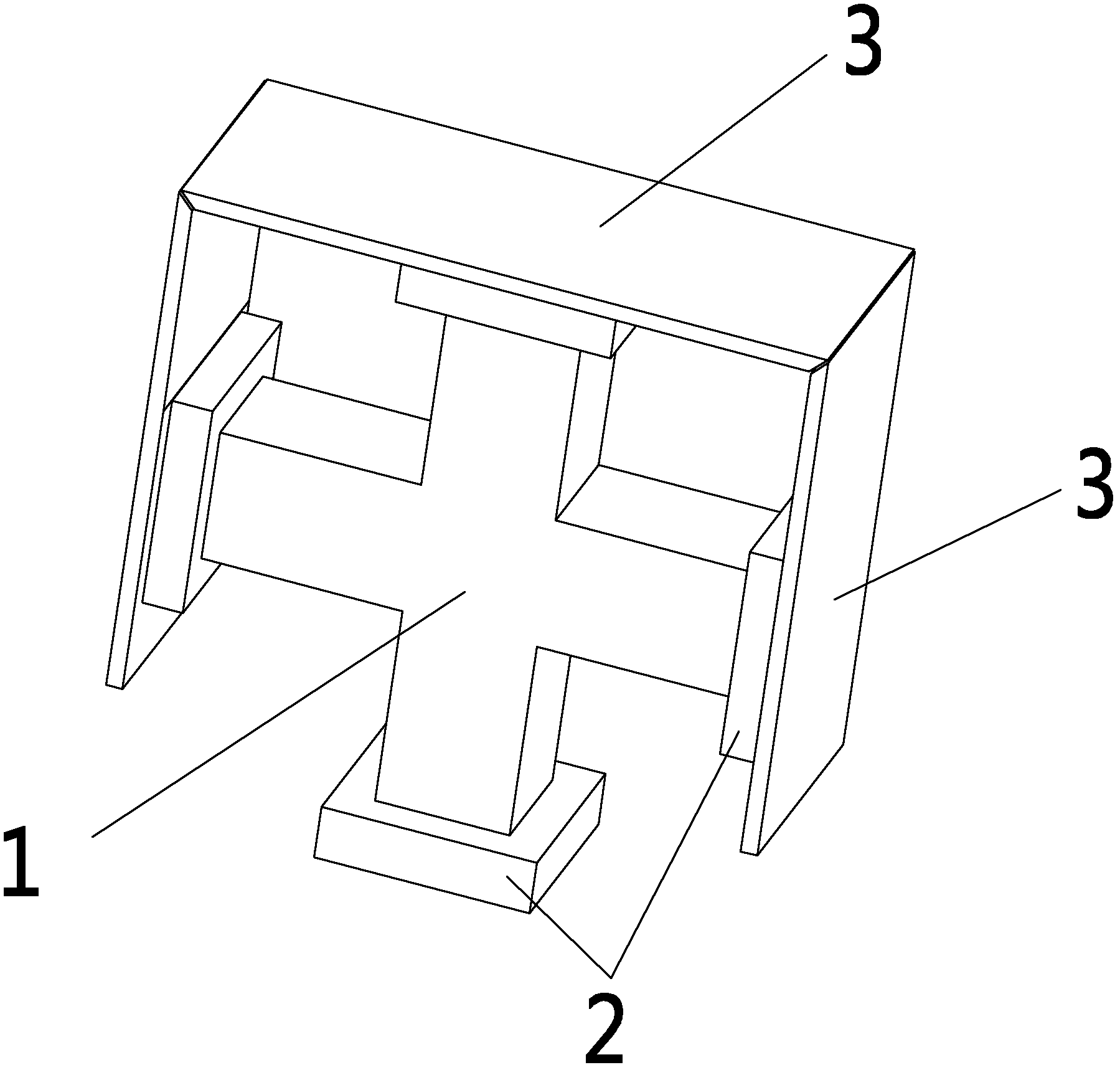

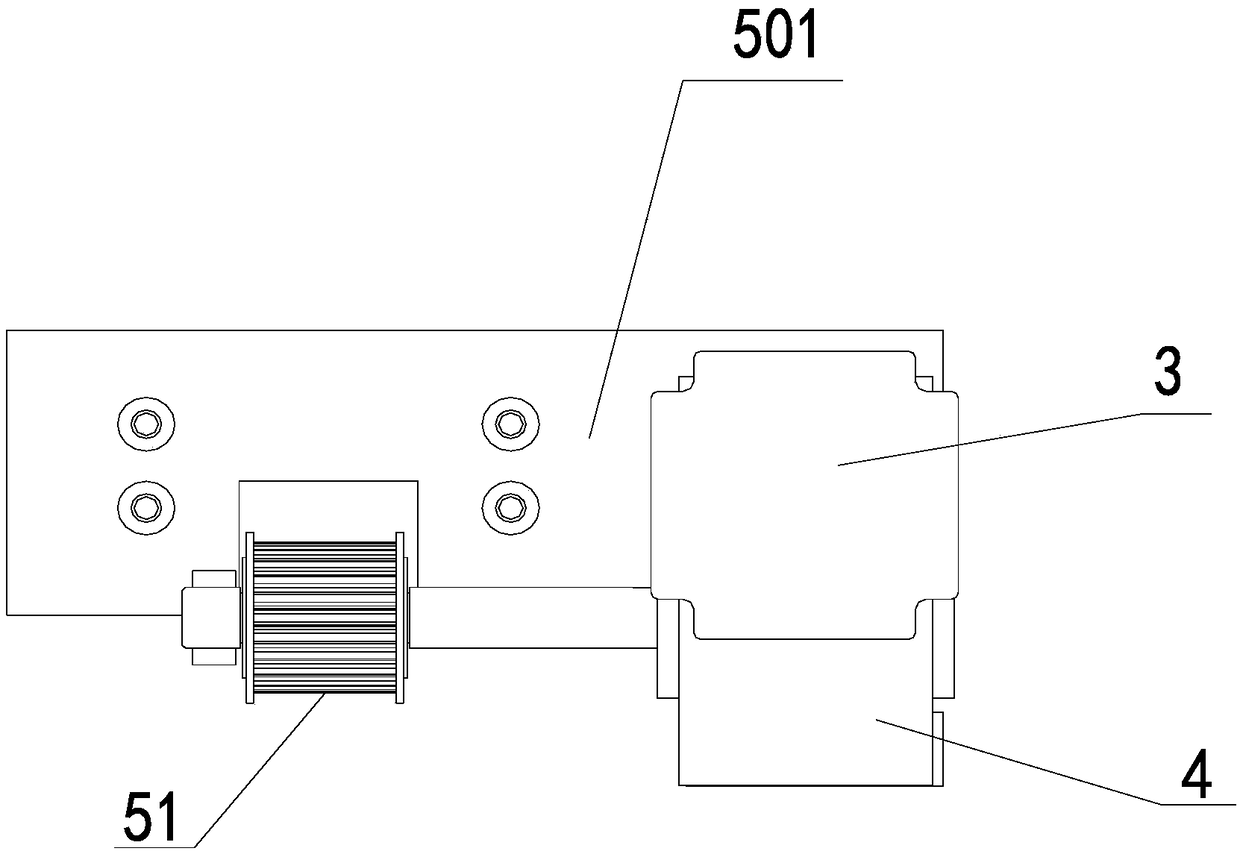

Welding fixture

InactiveCN102615462AImprove welding efficiencyReduce rework rateWelding/cutting auxillary devicesAuxillary welding devicesWeldingEngineering

The invention discloses a welding fixture which comprises a fixture body and fastening components, wherein the fixture body is cross-shaped, and the fastening components are four in number and are fixed at four top ends of the fixture body respectively. According to the welding fixture provided by the invention, workpieces can be fixed at the top ends of the fixture body through the fastening components, and a plurality of workpieces can be welded in one attempt, so that the welding efficiency of the workpieces is improved; moreover, the two sides of a welding part are empty, so that other objects are prevented from being welded when the workpieces are welded, and the rework rate of welding of the workpieces is lowered.

Owner:SUZHOU TANGFENG ELECTRICAL APPLIANCE

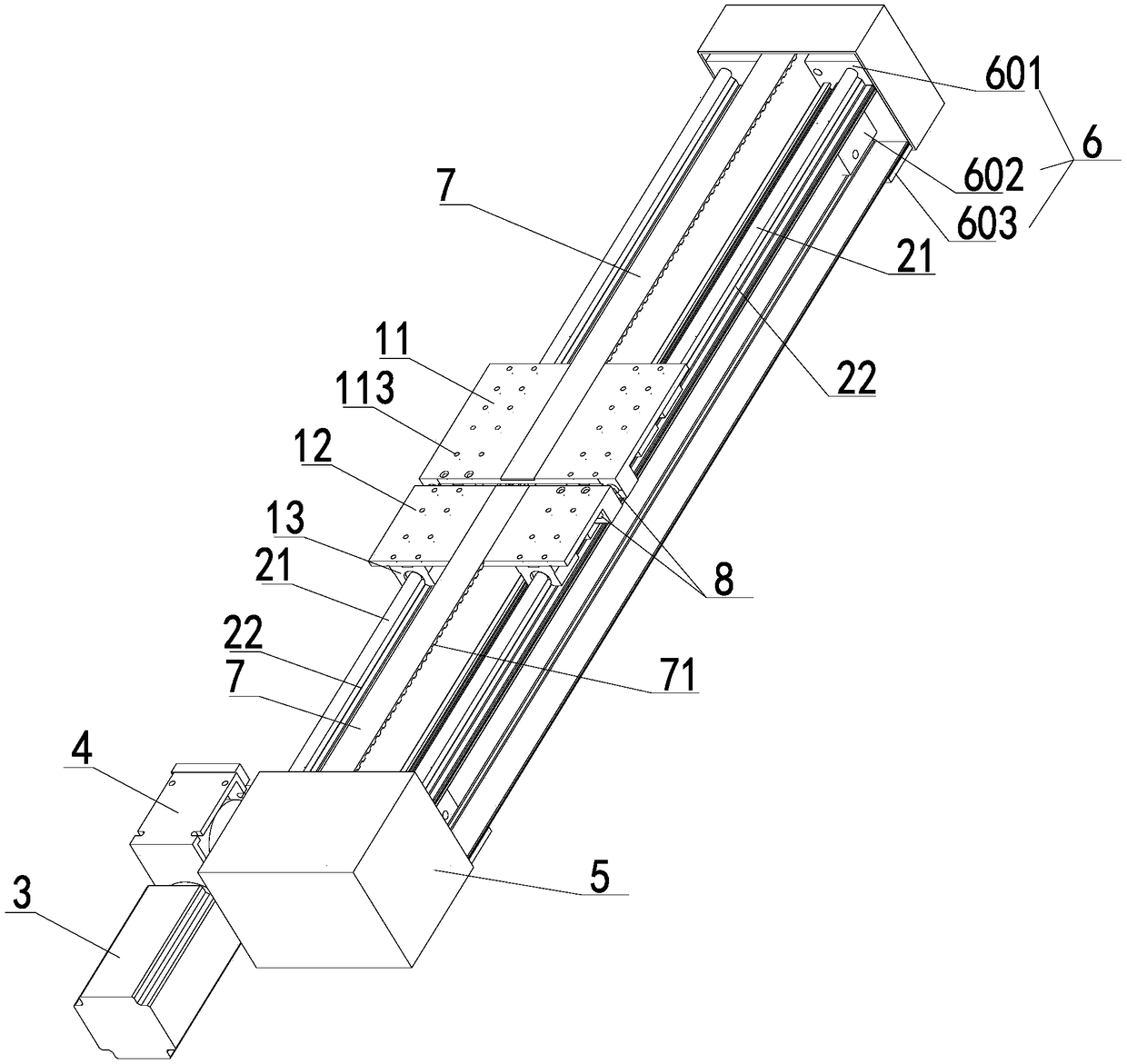

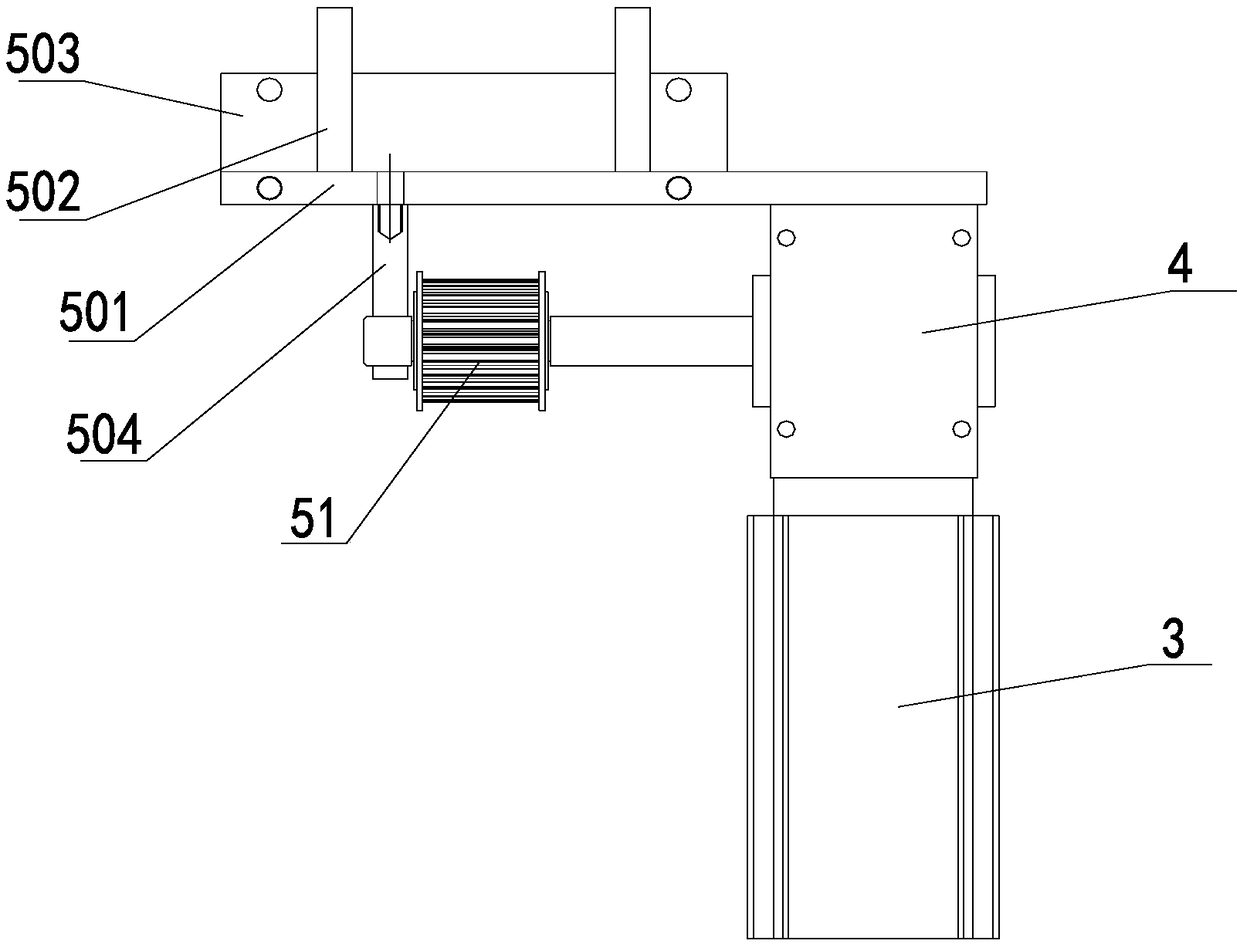

Movement track

PendingCN109502259AEasy to installAdjust the tightnessMechanical conveyorsEngineeringMechanical engineering

Owner:合肥瑞堡科技发展有限公司

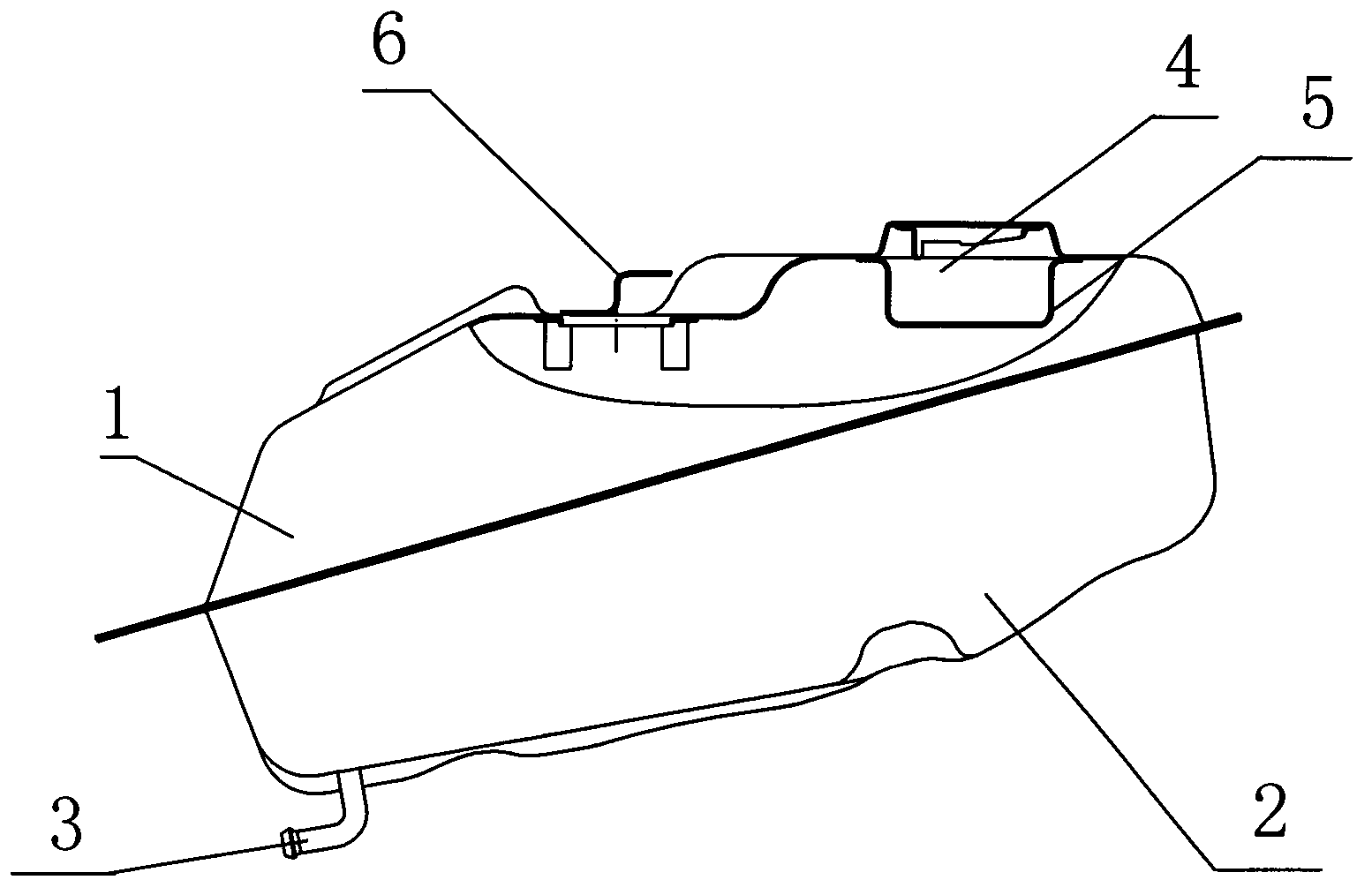

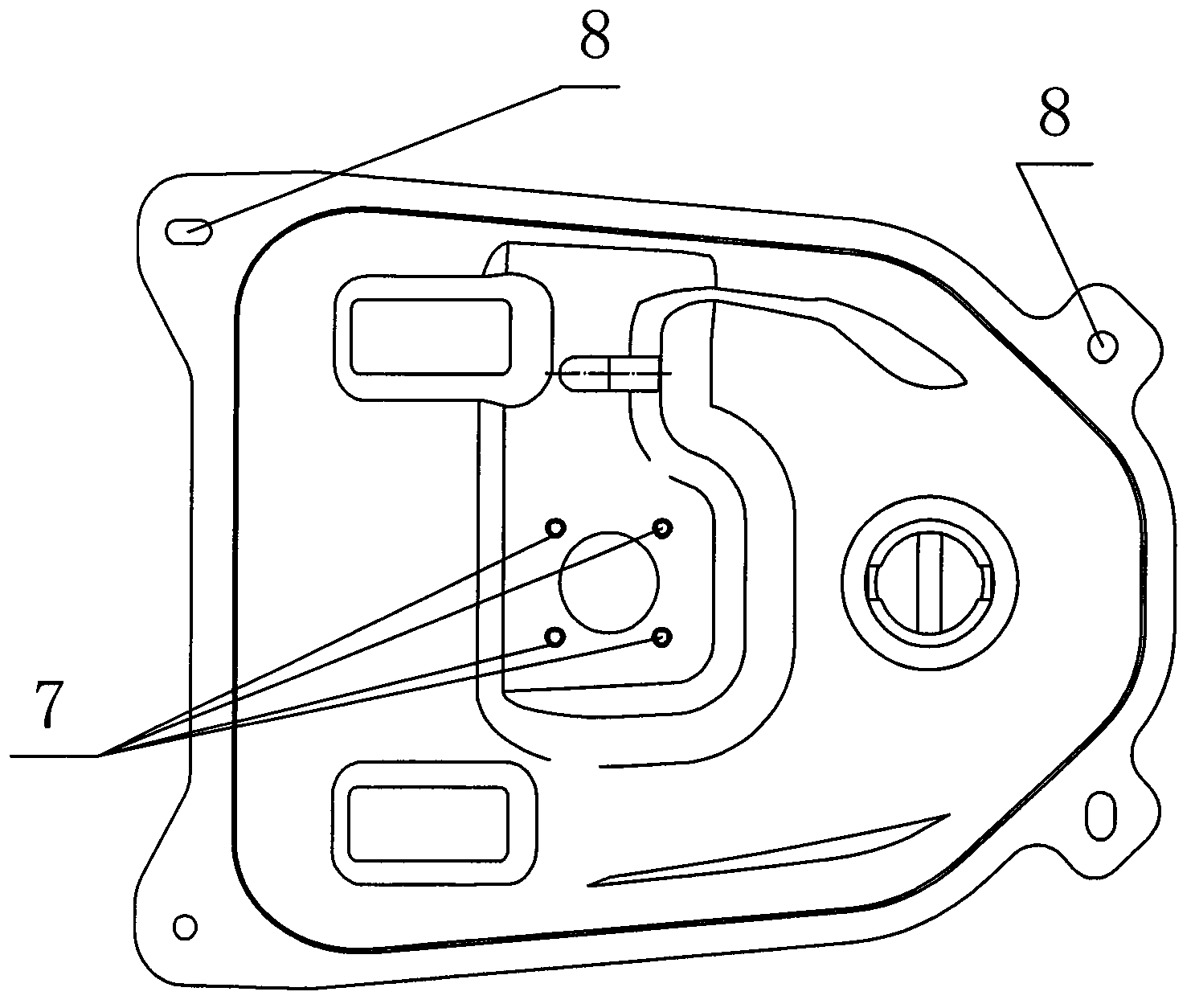

Fuel tank structure of motorcycle

The invention discloses a fuel tank structure of a motorcycle. The fuel tank structure of the motorcycle comprises an upper fuel tank shell and a lower fuel tank shell. A fuel filler is formed in one end of the upper fuel tank shell. The lower portion of the fuel filler is communicated with the lower fuel tank shell. A fuel deflector used for preventing fuel from overflowing is arranged between the fuel filler and the lower fuel tank shell. A fuel outlet nozzle is arranged on the lower portion of the lower fuel tank shell. The fuel outlet nozzle and the lower fuel tank shell are fixed in a welded mode. An overflowing pipeline clamp is further arranged on the upper fuel tank shell and is used for fixing an overflowing pipe. The overflowing pipeline clamp is located on one side of the fuel filler. The contact surface where the upper fuel tank shell and the lower fuel tank shell are connected is of a plane structure. The upper fuel tank shell and the lower fuel tank shell are fixed in an electric resistance welding mode. Four installation holes where a motorcycle frame is installed are formed in the four corners of the upper fuel tank shell respectively and comprise two round holes and two strip-shaped holes. The two round holes are arranged in a diagonal mode. The fuel tank structure of the motorcycle has the advantages of being simple in mold joint, more suitable for welding fixation, capable of relieving aging of a seal ring, easy to install, firm in installation, capable of saving materials and the like.

Owner:聂绍彬

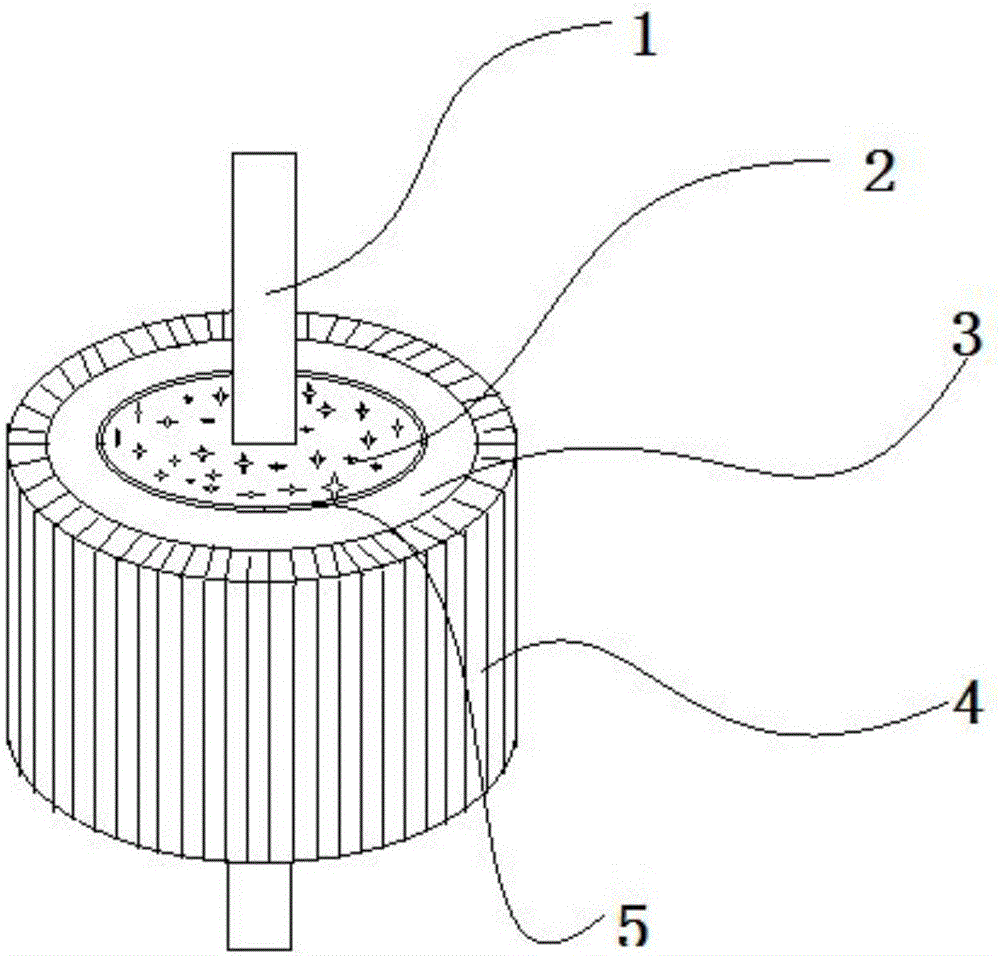

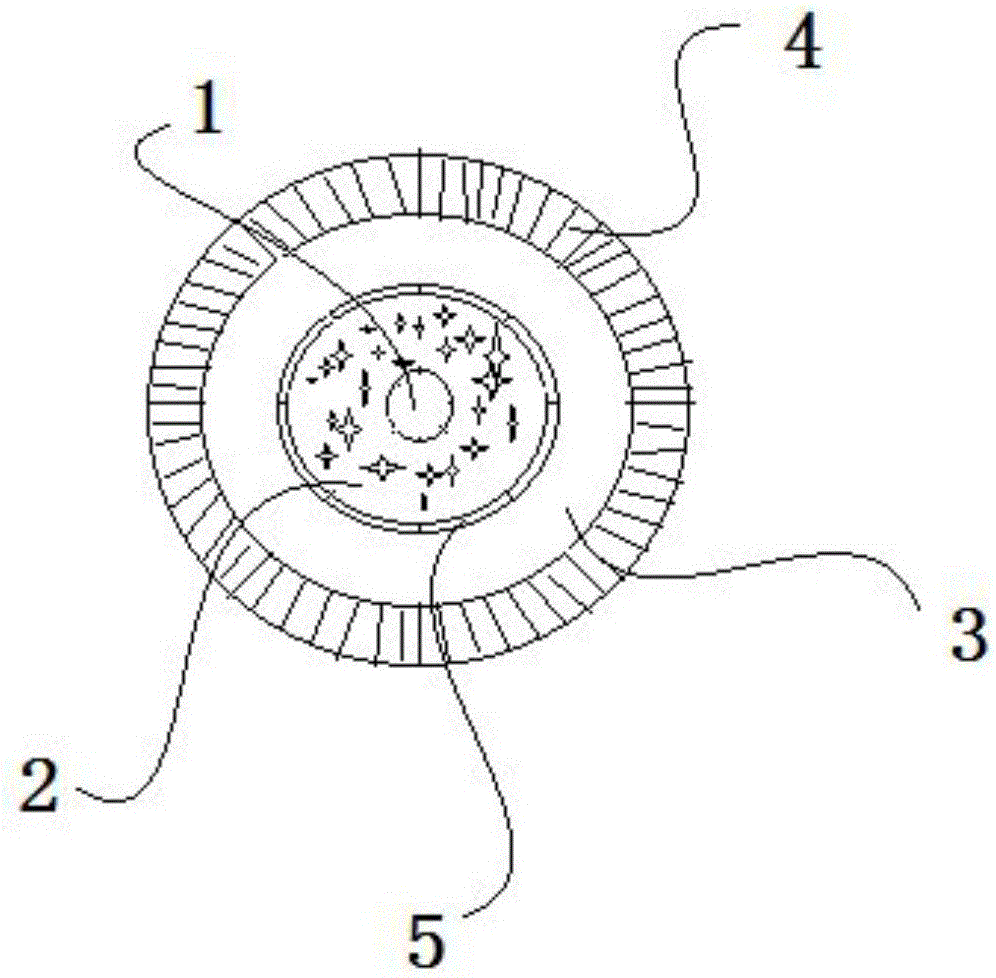

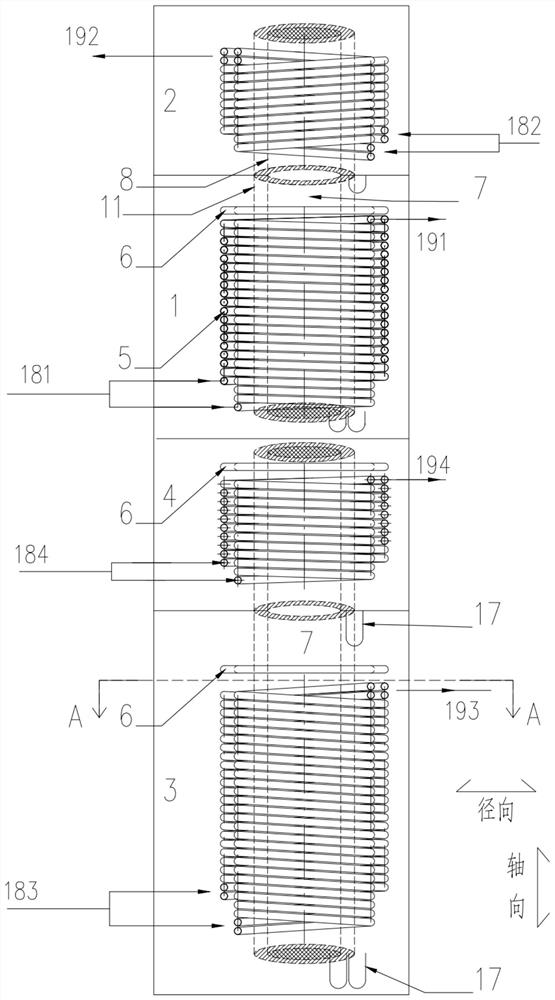

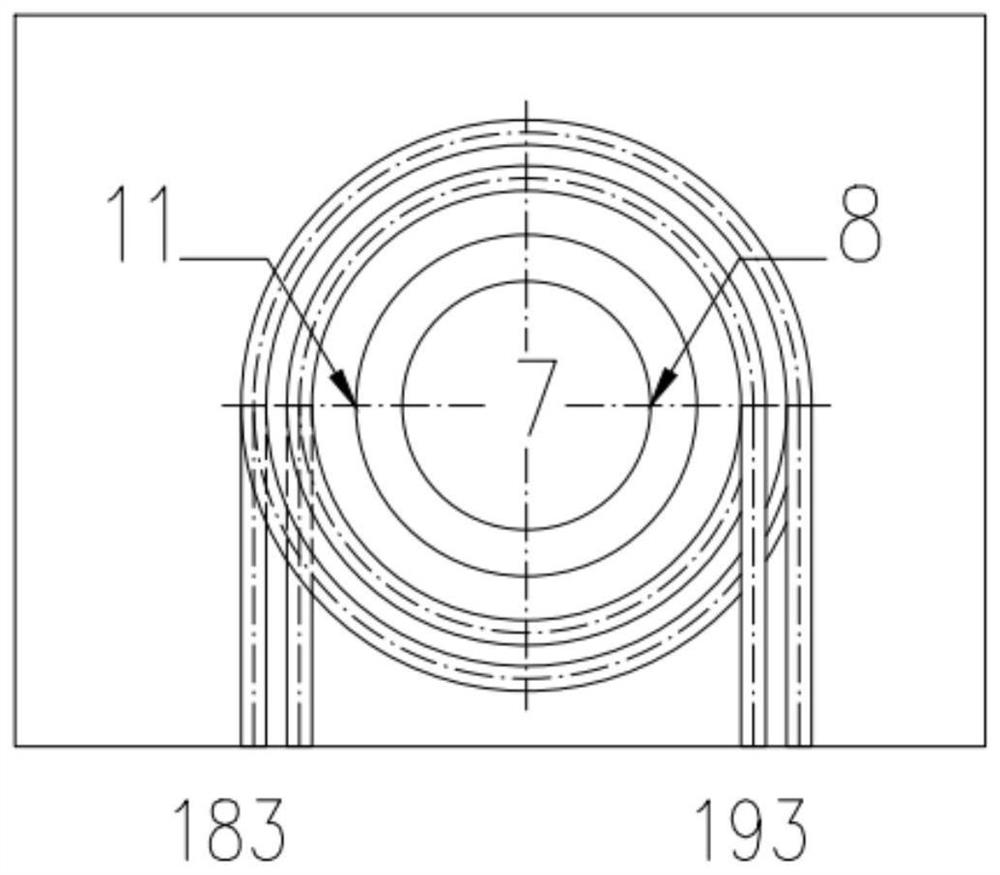

A multi-layer multi-head spiral tube type absorption heat exchange unit

ActiveCN113175763BReduce the number of weldsReduce processing difficultyEnergy efficient heating/coolingClimate change adaptationThermodynamicsEngineering

The invention discloses a multi-layer multi-head spiral tube type absorption heat exchange unit belonging to the field of energy saving; wherein the condenser is located above the generator, the condenser and the generator are connected through a cylindrical steam channel arranged in the center, and the evaporator Located above the absorber, the evaporator and the absorber are connected by a cylindrical steam channel inside; an auxiliary cylinder orifice baffle is installed outside the cylindrical steam channel, and at least one layer of spiral heat exchange tubes is arranged in the auxiliary cylinder Outside the orifice baffle, the inlet and outlet pipes of the spiral heat exchange tube group are fixedly connected to the shell of the absorption heat exchange unit; the liquid distribution pipes with small holes evenly opened at the upper end or lower end are installed directly above the spiral heat exchange tube group. The number of welding seams in the invention is greatly reduced, and at the same time, the welding link between each layer of the mosquito-repellent coil tube is avoided, and the vacuum airtightness is improved. There are multiple degrees of freedom in the design of the coil, and the design value of the flow rate in the tube and the density of the liquid distributed outside the tube can be met through changes in the number of groups, layers, and heads.

Owner:TSINGHUA UNIV

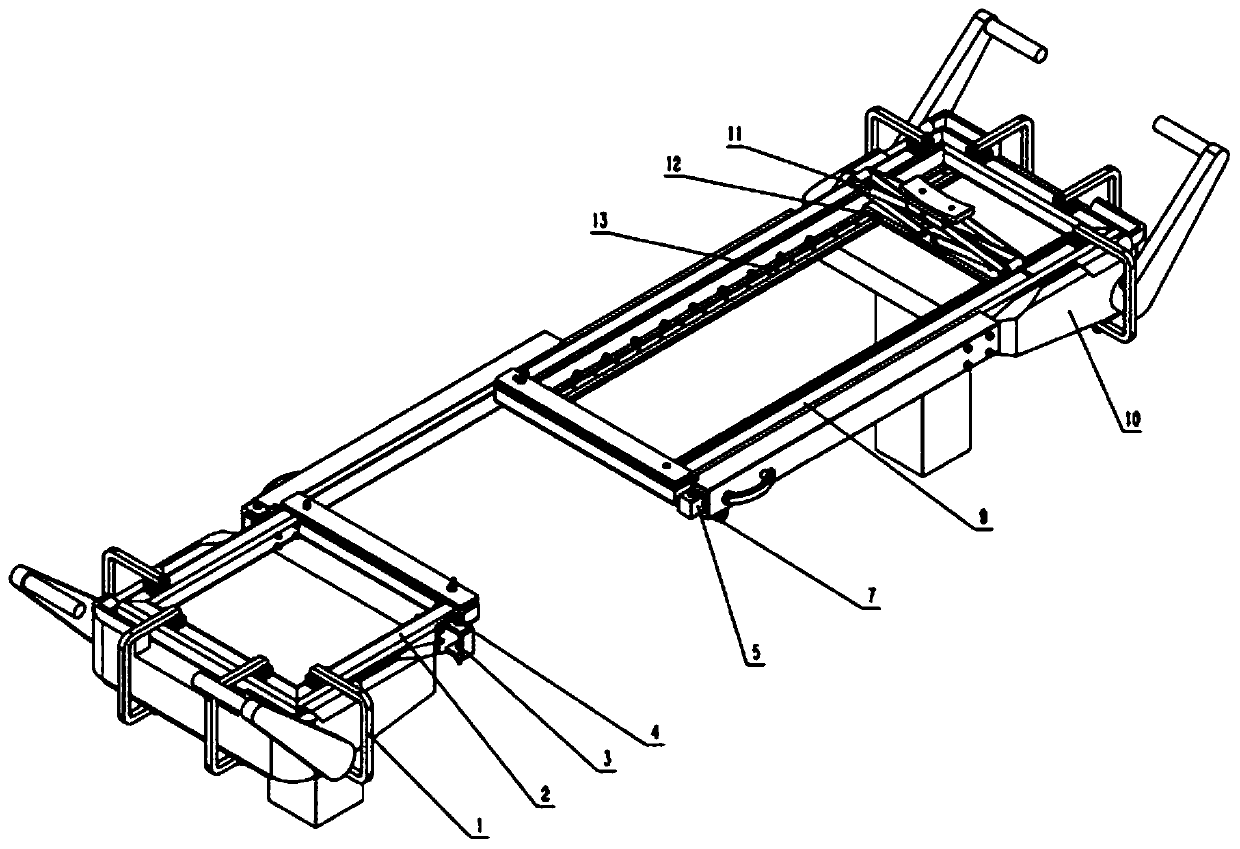

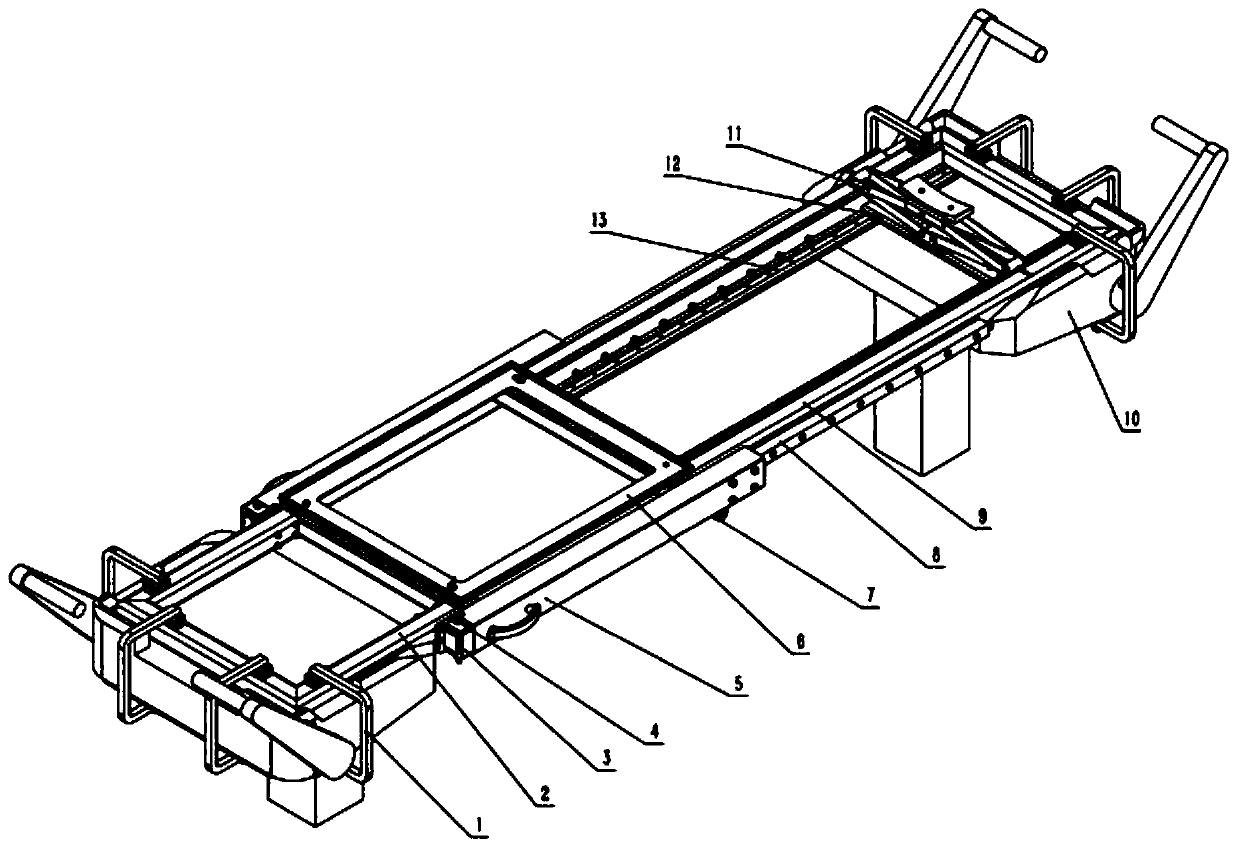

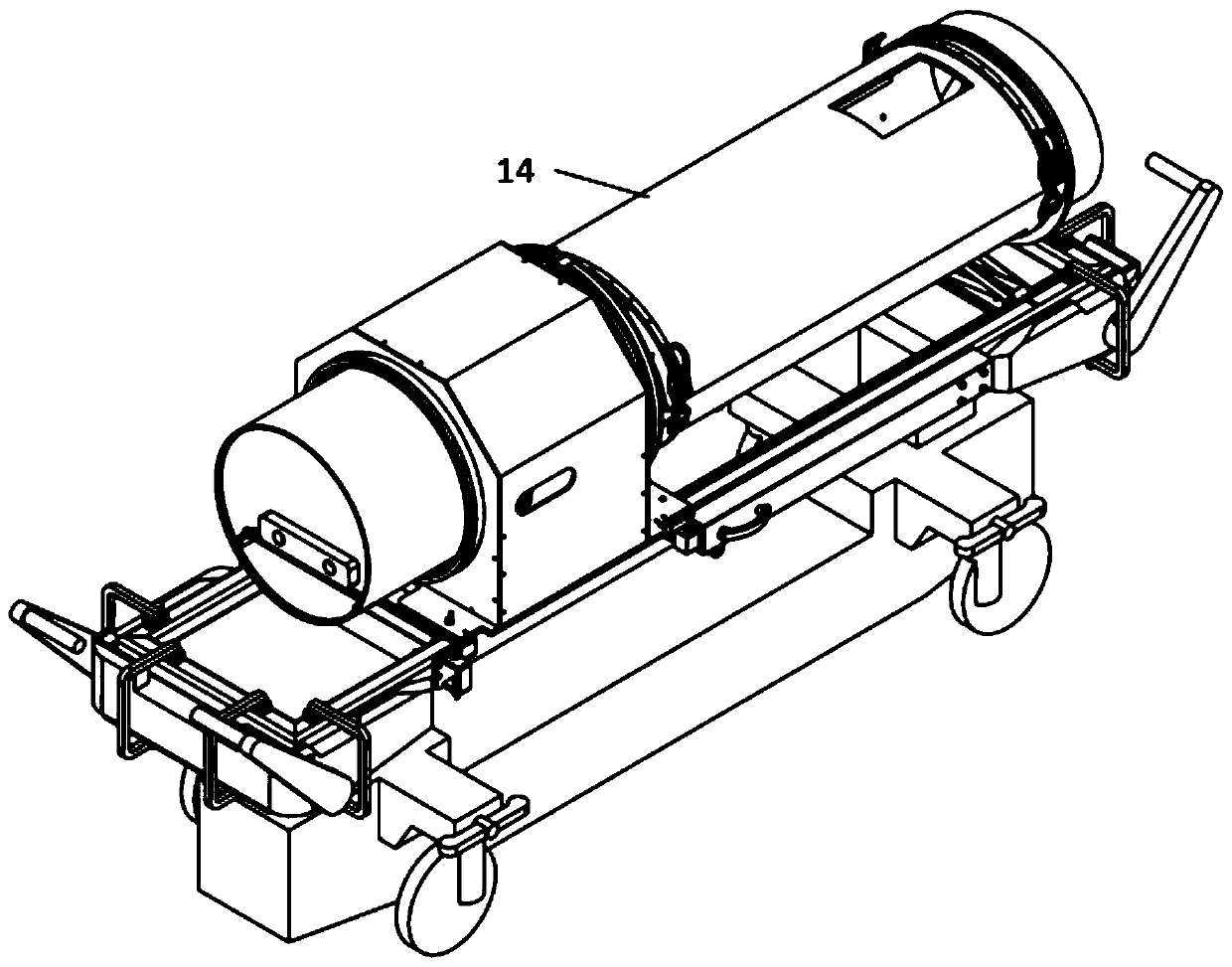

Cabin carrying frame

InactiveCN110498181ADoes not affect lifting strokeEasy to operateConveyorsManual conveyance devicesMirror imageTransport engineering

The invention discloses a cabin carrying frame comprising a first transportation frame and a second transportation frame which are horizontally and oppositely placed. The two transportation frames areeach of a rectangular frame structure. Corresponding lateral side frames of the two transportation frames are connected through two connection rods. A connection rod linear guide rail is arranged onthe outer side of each of the two lateral side frames of the second transportation frame. Two fixed structure corresponding to the two connection rods are arranged at the end, close to the second transportation frame, of the first transportation frame. The two connection rods slide along the two connection rod linear guide rails correspondingly and can be stretched to be inserted in the corresponding fixed structures, and the two transportation frames are connected into a whole. The cabin carrying frame is simple in structure, mirror image installation can be achieved, the space occupied by the sliding connection rod structure is small, the rising and falling stroke of a platform, capable of rising and falling, of a transportation vehicle is not influenced, and operation of a rotation treatment device is facilitated.

Owner:SHANGHAI ELECTRICGROUP CORP

Elastic load mechanism and method for measuring elastic load

InactiveCN106932183BStable structureAdjust the initial elastic loadMachine valve testingMechanical engineeringEngineering

Owner:BEIJING JIAOTONG UNIV

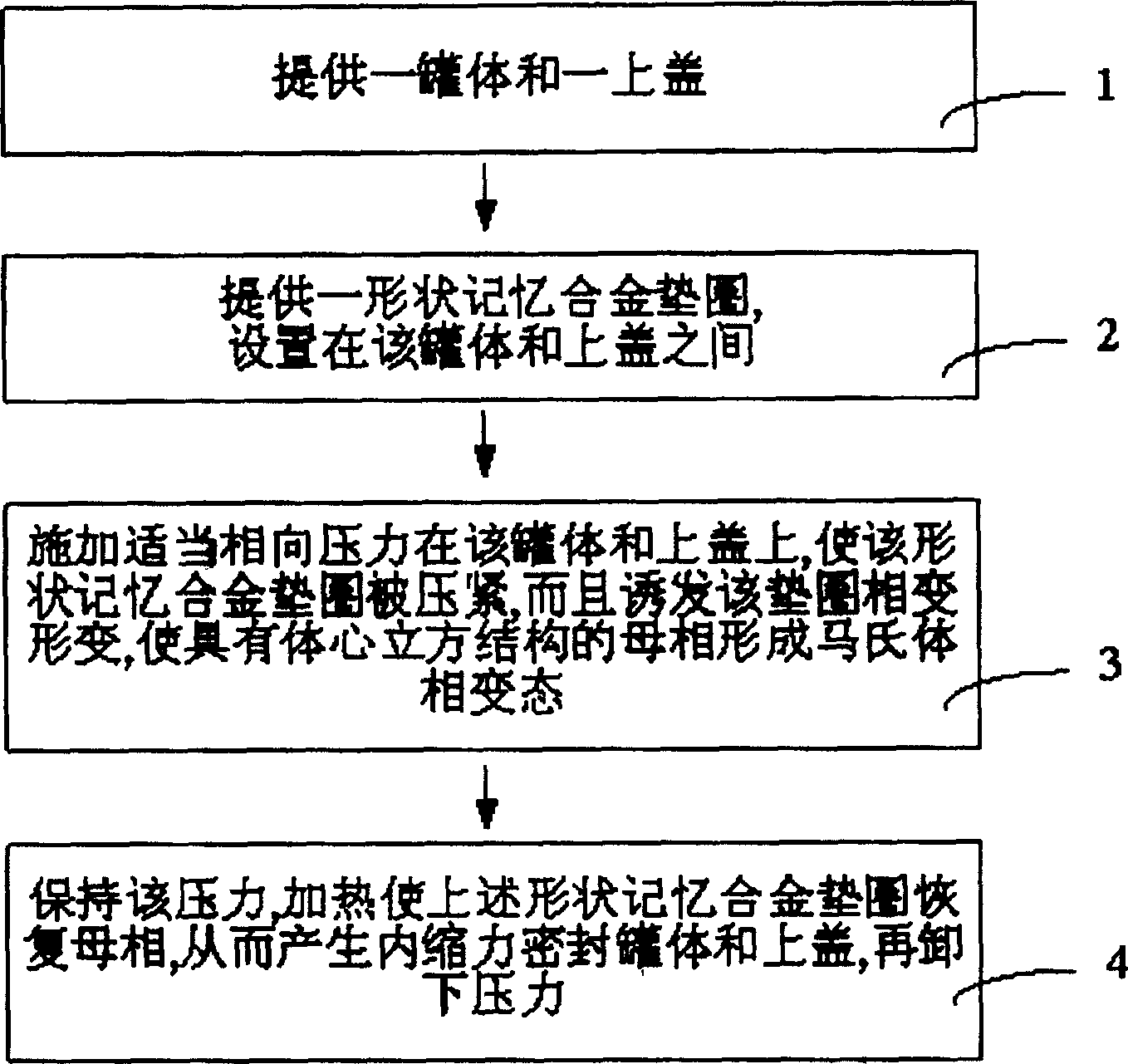

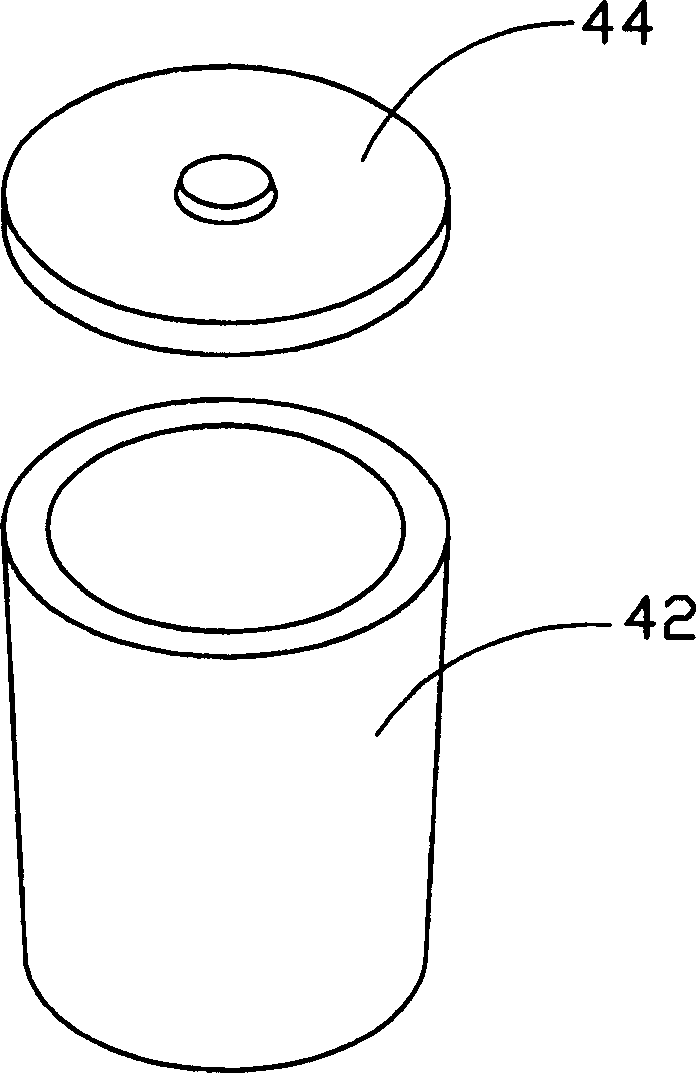

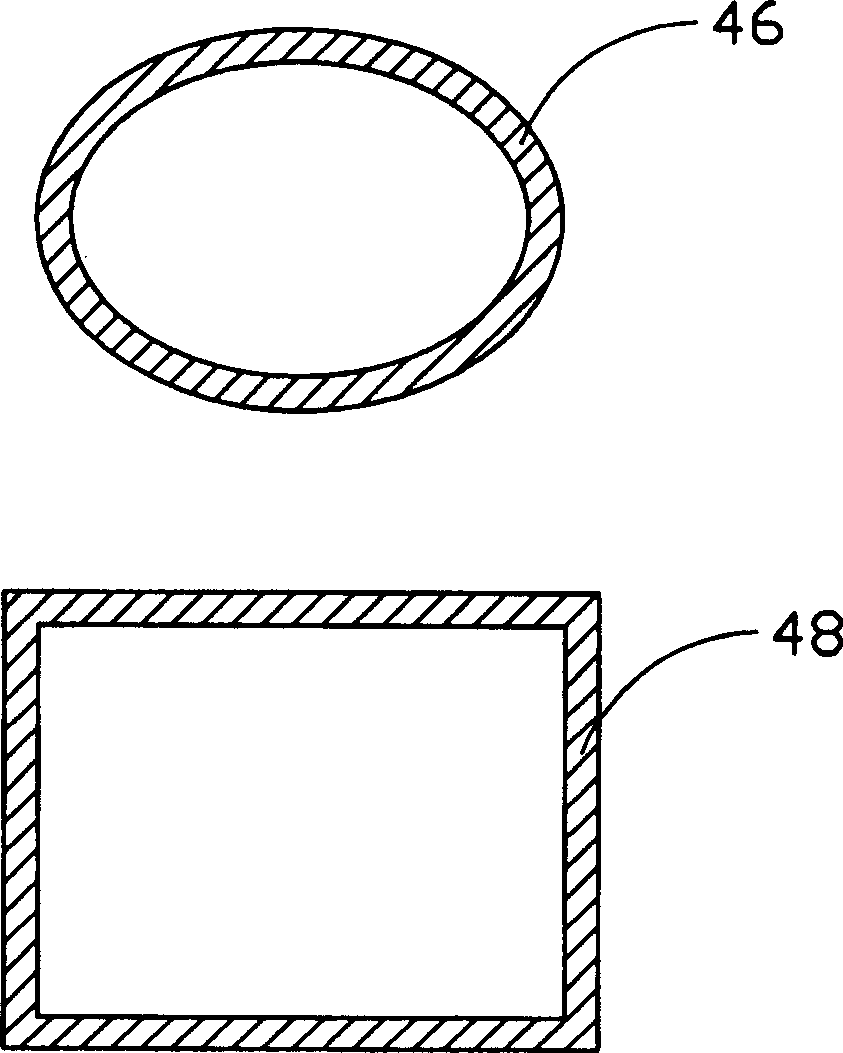

Method for capping lithium ion battery

InactiveCN1291505CLow costImprove securityFinal product manufactureSecondary cellsShape-memory alloyAlloy

The invention relates to a lithium ion battery capping method, including the following steps: providing a cylinder and a top cap; providing a shape memory alloy washer, arranged between the cylinder and the top cap; applying a proper opposite pressure on the cylinder and the top cap to tightly press the said washer and causing phase vibration and shape vibration of the said washer to make a mother phase with central cubic structure form Martensite phase-varying state; keeping this pressure, and heating to above Austenite Final (Af) phase terminating temperature to make the wafer return to the mother phase, and thus the washer generates internal shrinking force to seal the cylinder and top cover and then removes the said pressure. The invention has the advantages of good safety, high sealing degree, low failure ratio, etc.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Small-sized integral type flexible joint and minitype high-speed dynamic tuned gyroscope

The invention relates to a small-sized integral type flexible joint and a minitype high-speed dynamic tuned gyroscope. The small-sized integral type flexible joint is made of an elastic material, has small volume and simple structure, prevents a welding link of an inner flexible joint and an outer flexible joint and enhances the processing precision of the flexible joint. The minitype high-speed dynamic tuned gyroscope formed by the small-sized integral type flexible joint is in a dumbbell type symmetrical structure, one end of the minitype high-speed dynamic tuned gyroscope is a gyroscope rotation part, the other end of the same is a driving motor part, the gyroscope rotation part is connected with the driving motor part by the small-sized integral type flexible joint, thereby reducing the volume of the dynamic tuned gyroscope and enhancing resistance of the gyroscope against mechanical environment and improving the measuring precision of the gyroscope.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

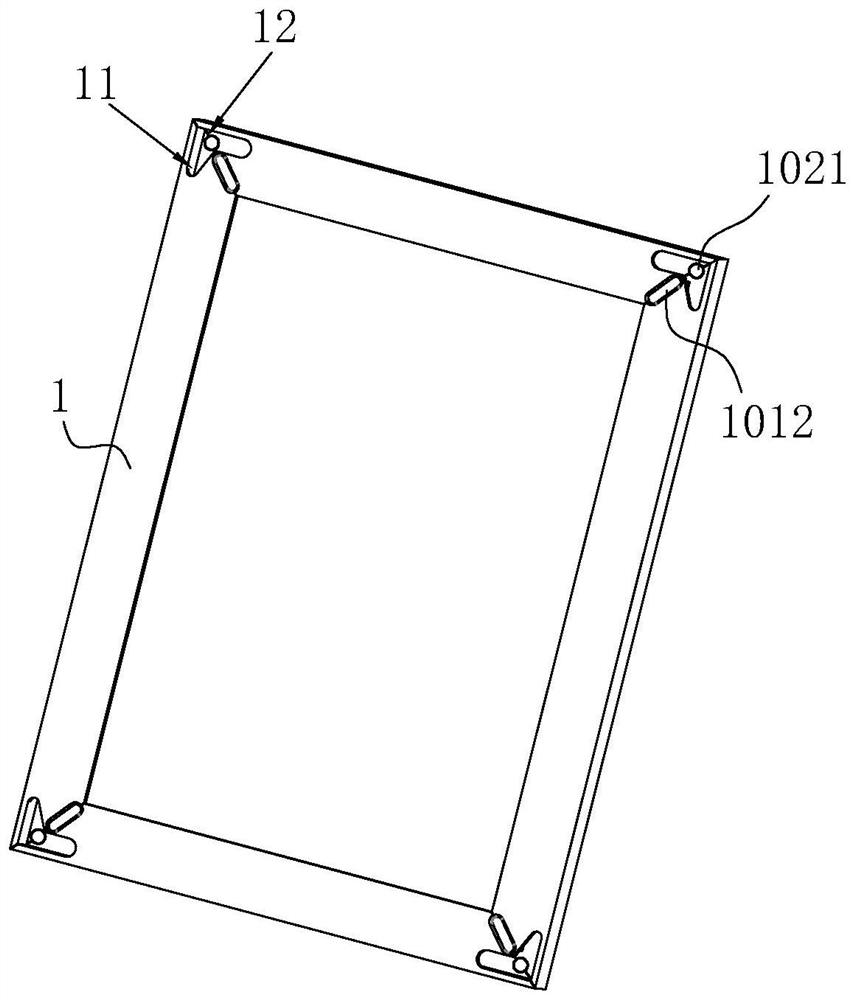

Advertising frame welding process

ActiveCN110788451BAvoid weld scarsGuaranteed welding strengthWelding accessoriesStructural engineeringWeld seam

The invention relates to the field of advertising frame production, and in particular discloses an advertising frame welding process. The method includes the following steps: S1. Opening a plurality of through grooves at the seam position of the back layer of the support frame of the advertising frame, the through grooves penetrate the back layer from the thickness direction of the back layer, and after the two frames are butted, the through grooves form through holes one by one ; S2, butt two support frames, extend the welding torch into the support frame chamber from the through hole, and weld the surface layers of the two pairs of support frames from the inner wall of the surface layer; S3, repeat S2, and weld the remaining support frames to form an advertising frame; S4, in turn Weld the weld between the back layers of each support frame of the advertising frame. By opening a through slot at the seam position of the back layer of the support frame, the welding torch can penetrate into the chamber and weld the back of the support frame surface layer from the inside of the chamber. Therefore, even if traditional argon arc welding or MIG gas shielded welding is used Welding can be done on the back of the finish to avoid welding scars on the front of the finish.

Owner:上海裕纪金属制品有限公司

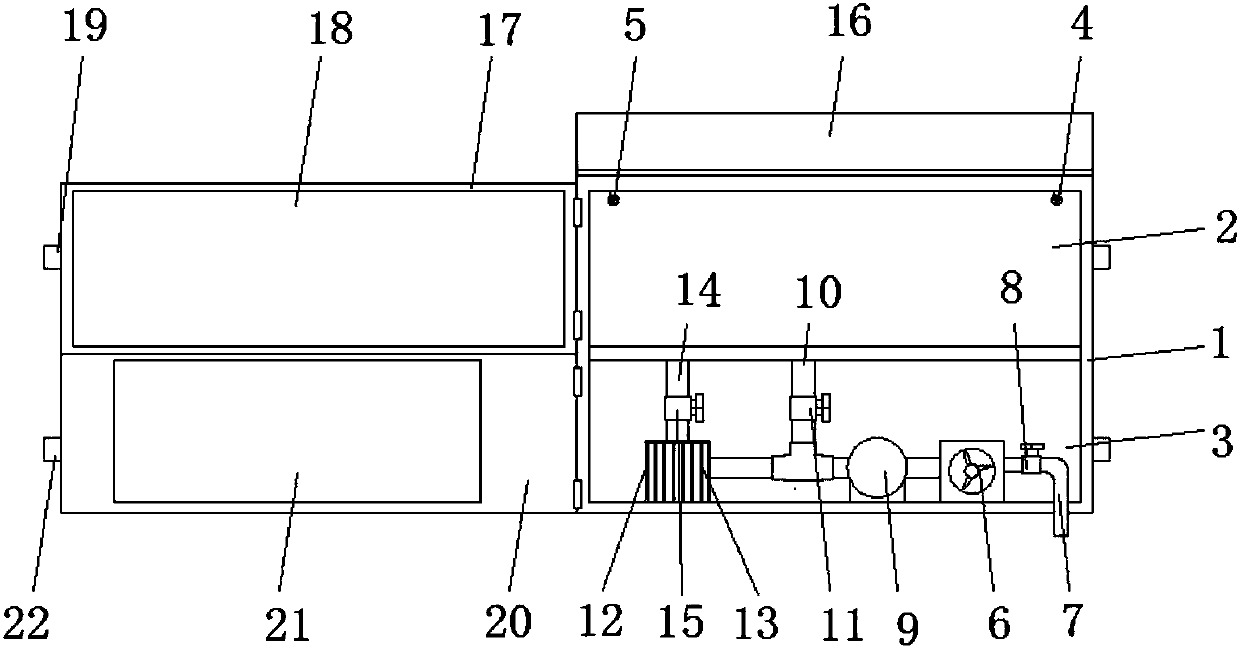

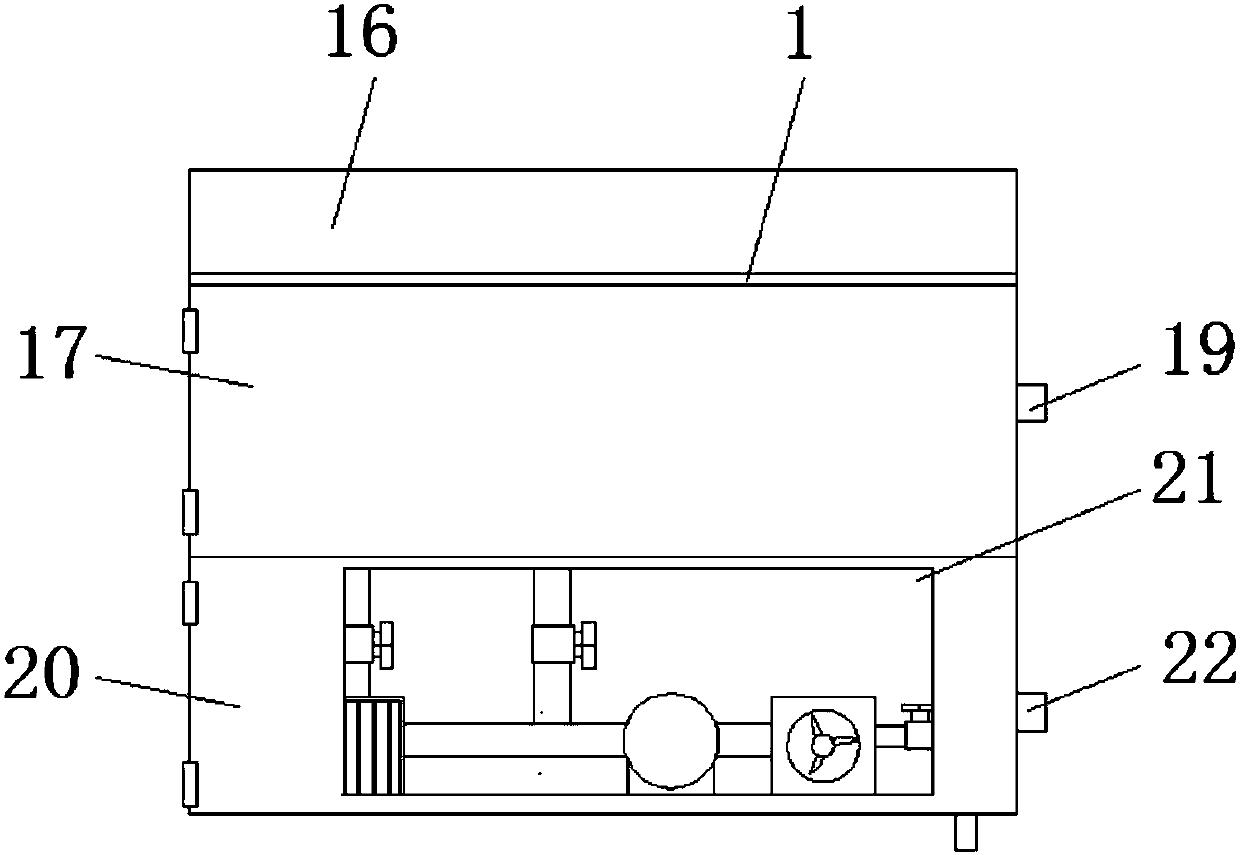

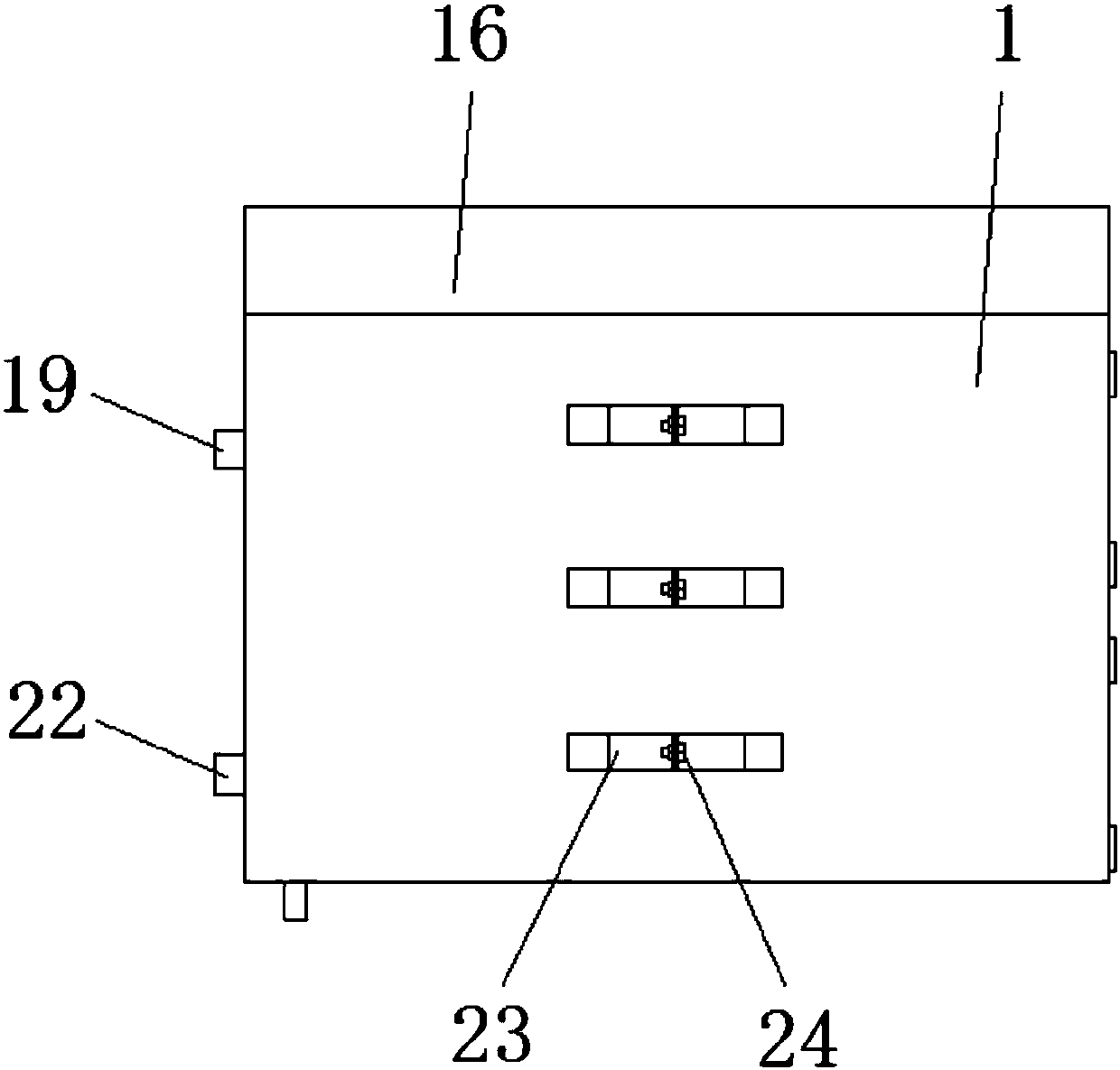

Intelligent temperature-control protective box for outdoor electricity transmission monitoring equipment

InactiveCN107613708AAvoid influenceGuaranteed tightnessCasings/cabinets/drawers detailsHermetically-sealed casingsElectricityTemperature control

The invention provides an intelligent temperature-control protective box for outdoor electricity transmission monitoring equipment. The box includes a box body, a storage chamber and a temperature control chamber; the box body is internally provided with the storage chamber and the temperature control chamber, the temperature control chamber is arranged below the storage chamber, the top of the interior of the storage chamber is provided with a temperature detector and a humidity detector, the temperature detector is arranged at the right side of the humidity detector, the temperature controlchamber is internally provided with a fan and a drying tank, the drying tank is arranged at the left side of the fan, and an inlet of the drying tank is communicated with an outlet of the fan througha conduit; the temperature control chamber is further internally provided with a heating tank, and a heating pipe is installed in the heating tank. The intelligent temperature-control protective box for the outdoor electricity transmission monitoring equipment changes the traditional structural layout and prevents temperature control equipment from being placed with a main machine and the like; byseparately arranging the storage chamber and the temperature control chamber, the influences of the equipment to the environment of the storage chamber is avoided during adjustment of the temperaturecontrol equipment, and therefore the temperature control of the storage chamber can satisfy the required standard.

Owner:刘和来

Inward recess preventing capillary tube capable of being fast installed

Owner:泰州市海陵区欧菱自动化设备有限公司

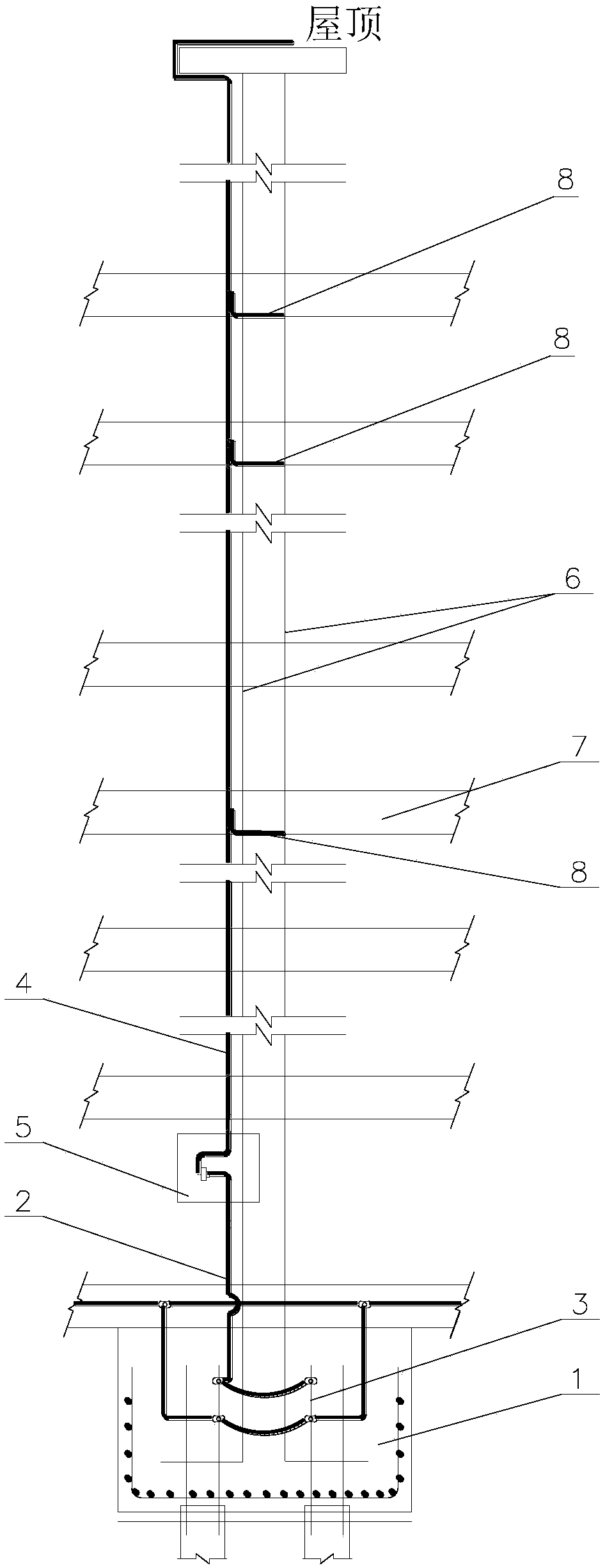

Lightning-proof ground structure for high-rise building and construction method

PendingCN109510003AEasy to bendSimple structureConnection contact member materialArchitectural engineeringRebar

The invention relates to a lightning-proof ground structure for a high-rise building. The lightning-proof ground structure includes a copper sheet conduction belt, an aluminium sheet conduction belt,a switching device, and copper sheet switching belts. The copper sheet conduction belt and the aluminium sheet conduction belt are pre-embedded inside a building from bottom to top. The copper sheet conduction belt is fixedly connected to a reinforcing steel bar mesh in the foundation of the building. The copper sheet conduction belt extends upwardly and passes through the switching device to be fixedly connected to the aluminium sheet conduction belt. The aluminium sheet conduction belt reaches the roof directly, and the external surface of the aluminium sheet conduction belt outside the switching device is wrapped in an insulator. The building is provided with a plurality of conduction assisting layers, the aluminium sheet conduction belt of the conduction assisting layers is connected by the switching device, the switching device is also connected to the copper sheet switching belts, and the copper sheet switching belts are fixedly connected to reinforcing steel bars in the building. The lightning-proof ground structure is simple, is easy to manufacture and install, and is easy to carry since aluminum sheets can be easily bent. The current conduction efficiency is achieved, thestandard conduction effect is achieved, the problem of welding of each layer is avoided, and the construction speed of a site is effectively accelerated. The high process is satisfied, and the cost isreduced.

Owner:CHINA THIRD METALLURGICAL GRP

A kind of radiator and preparation method thereof

InactiveCN105043135BReduced non-uniform heat dissipation propertiesImprove cooling effectStationary conduit assembliesHeat exchanger casingsUltrasonic weldingEngineering

The invention relates to the technical field of heat radiation, in particular to a heat radiator and a manufacturing method thereof. The heat radiator is composed of cooling fins, a fixed medium cavity fixedly connected with the cooling fins, a heat transfer contact base body movably connected with the fixed medium cavity and a connecting piece arranged on the upper surface and the lower surface of the heat transfer contact base body. Then, the fixed medium cavity is included in the heat radiator, and media in the fixed medium cavity are defined as heat conduction oil. Then, a large amount of heat can be transmitted out of the heat transfer contact base body through the performance of the heat conduction oil. Then, heat exchange is achieved, the heat radiation effect is improved through rotation and large-area treatment of the cooling fins, and the heat radiation effect on equipment needing heat radiation treatment is guaranteed. In the manufacturing process, the cooling fins and the fixed medium cavity are formed in an ultrasonic welding manner or a manner of being squeezed into a whole; then the character that heat radiation of welding blocks is uneven due to a tradition welding manner is reduced; and then the heat radiation performance of the heat radiator is improved.

Owner:贵州凯宏汇达冷却系统有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com