Lower frame of electric vehicle and chassis

A technology for electric vehicles and frames, which is applied in the substructure, vehicle components, electric power devices, etc., can solve the problems that hinder the lightweight design of the frame, reduce the structural safety and reliability, and the difficulty of aluminum welding, etc., to achieve adaptability Effects of small batch production and customized requirements, improving structural safety and reliability, and improving structural strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

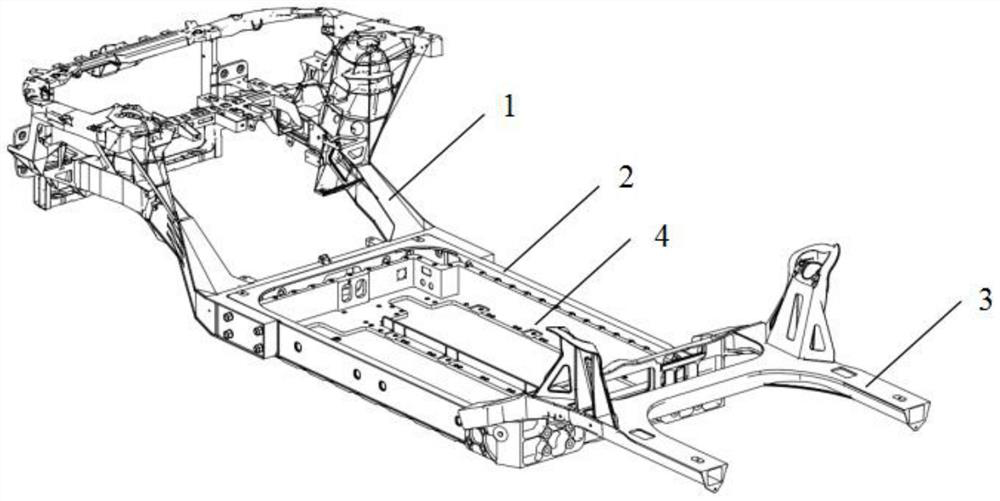

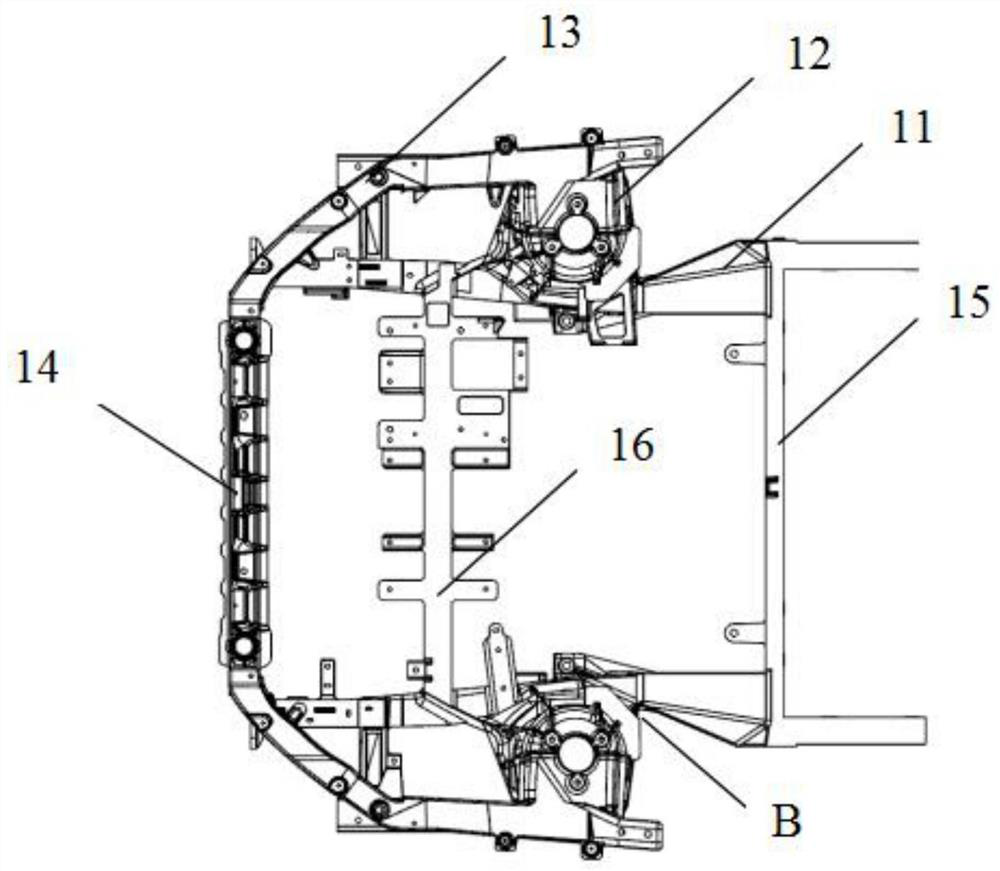

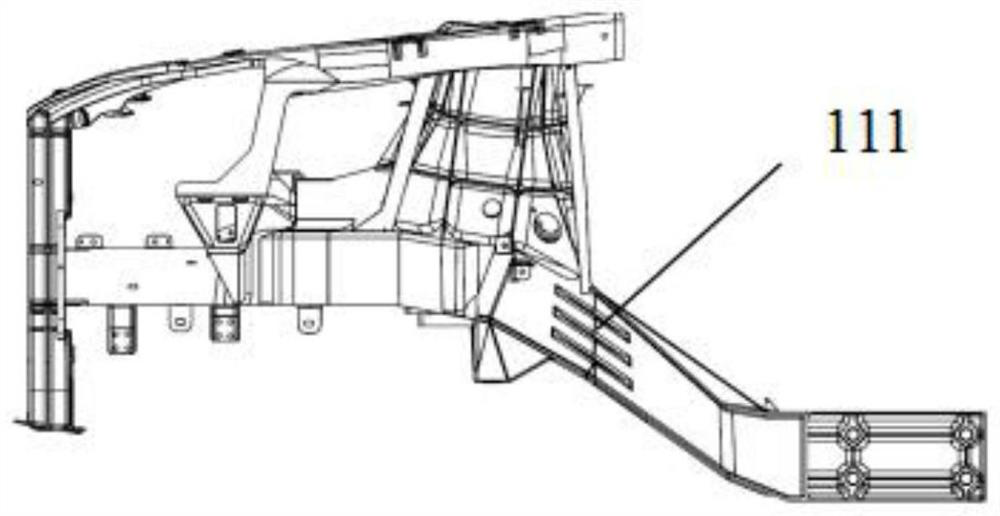

[0048] refer to Figure 1 to Figure 12 , Embodiment 1 provides a lower frame of an electric vehicle and a chassis to which the frame is applied.

[0049] refer to figure 1 , The lower frame is composed of four parts: the front frame 1, the battery box fixed frame 2, the rear frame 3 and the battery box lower case 4. The front-end vehicle frame 1, the battery box fixed frame 2, the rear-end vehicle frame 3, and the battery box lower shell 4 are all thin-walled aluminum alloy parts. The front frame 1 is screwed to the front end and the front side of the battery box frame 2 through four bolt groups; the rear frame 3 is screwed to the rear end and the rear side of the battery box frame 2 through four bolt groups; The lower case 4 of the battery box is connected to the frame 2 of the battery box by screws around the bottom. This minimizes the number of parts, reduces connection links, and greatly reduces machining and assembly workloads. The four major parts all have the charac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com