Method for capping lithium ion battery

A technology of lithium-ion batteries and memory alloys, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of high cost of laser welding equipment, high flatness requirements, and increased cost burden, and achieve low cost , good safety and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The production process of general batteries: First, the electrodes, including positive and negative materials and separators, are wound together and put into the tank body, then the tank body and the upper cover are sealed and welded, and then the electrolyte is injected, and the liquid injection port is closed. Sealing, the liquid injection port is usually sealed by spot welding, or the liquid injection hole is directly blocked by a small steel ball, that is, the entire preparation process is completed.

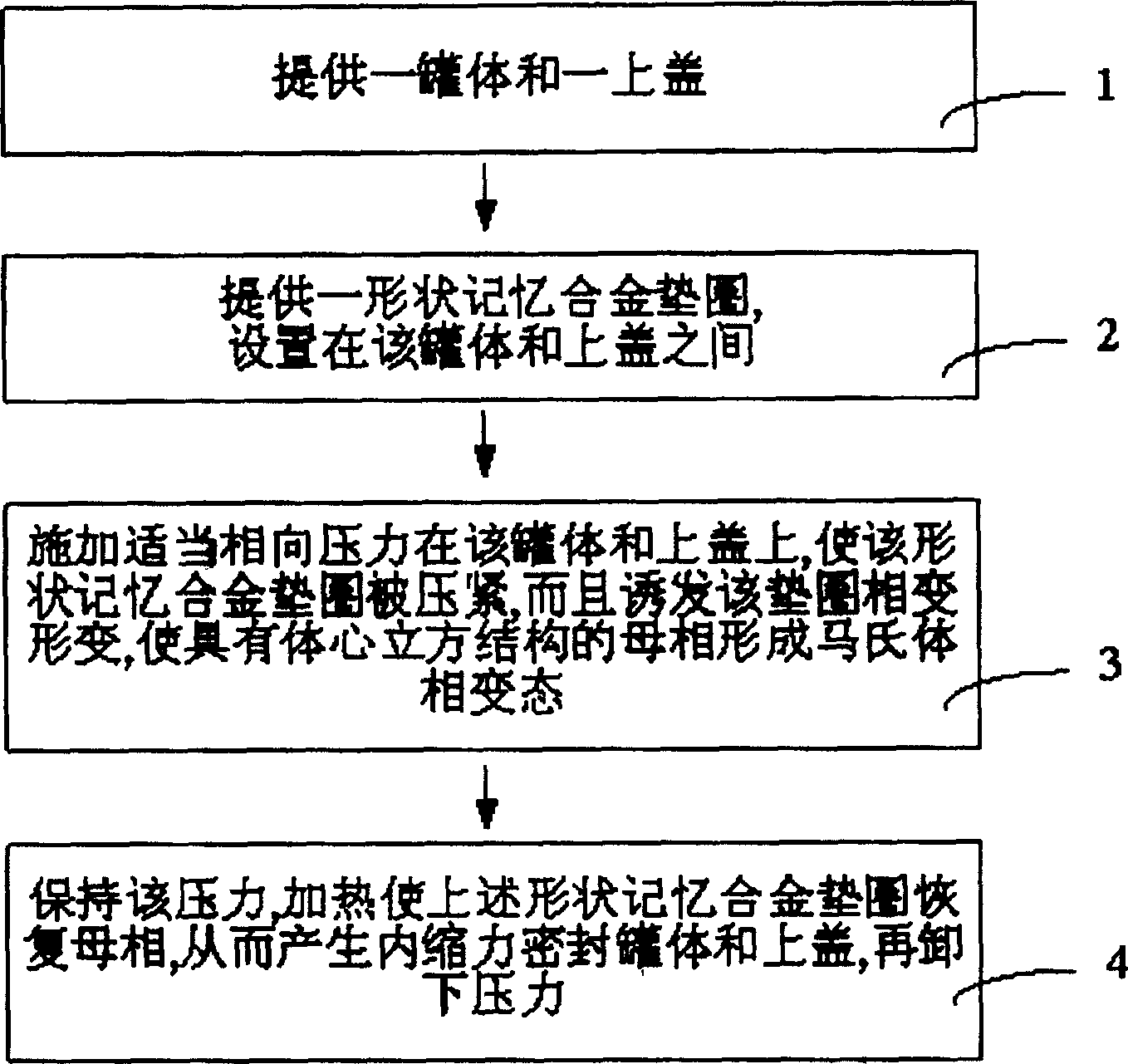

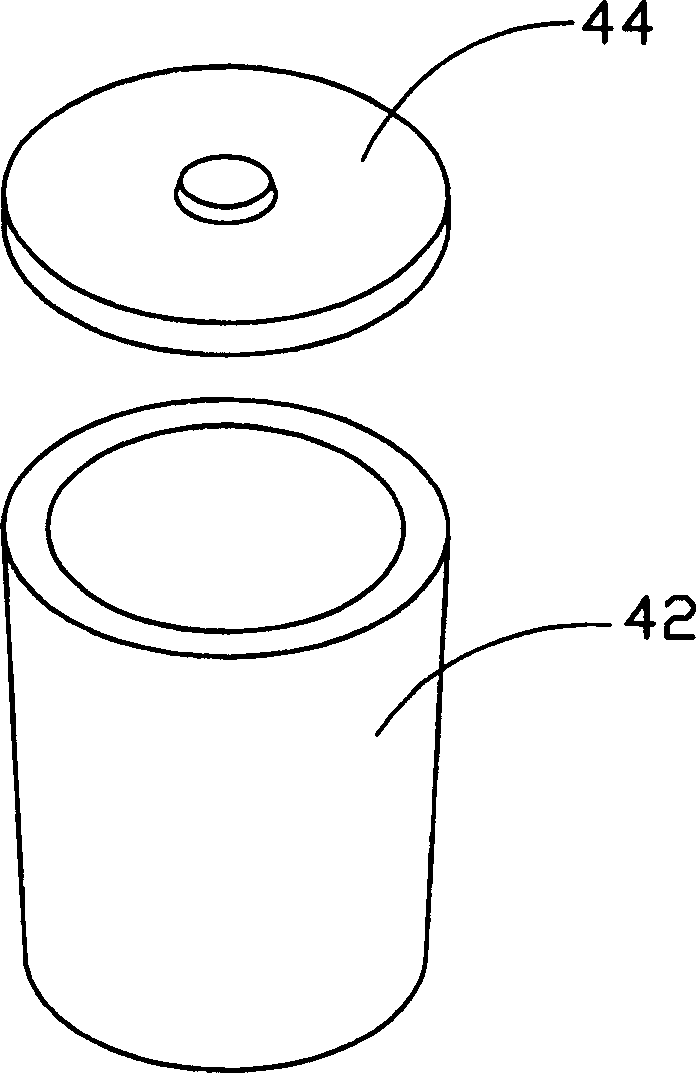

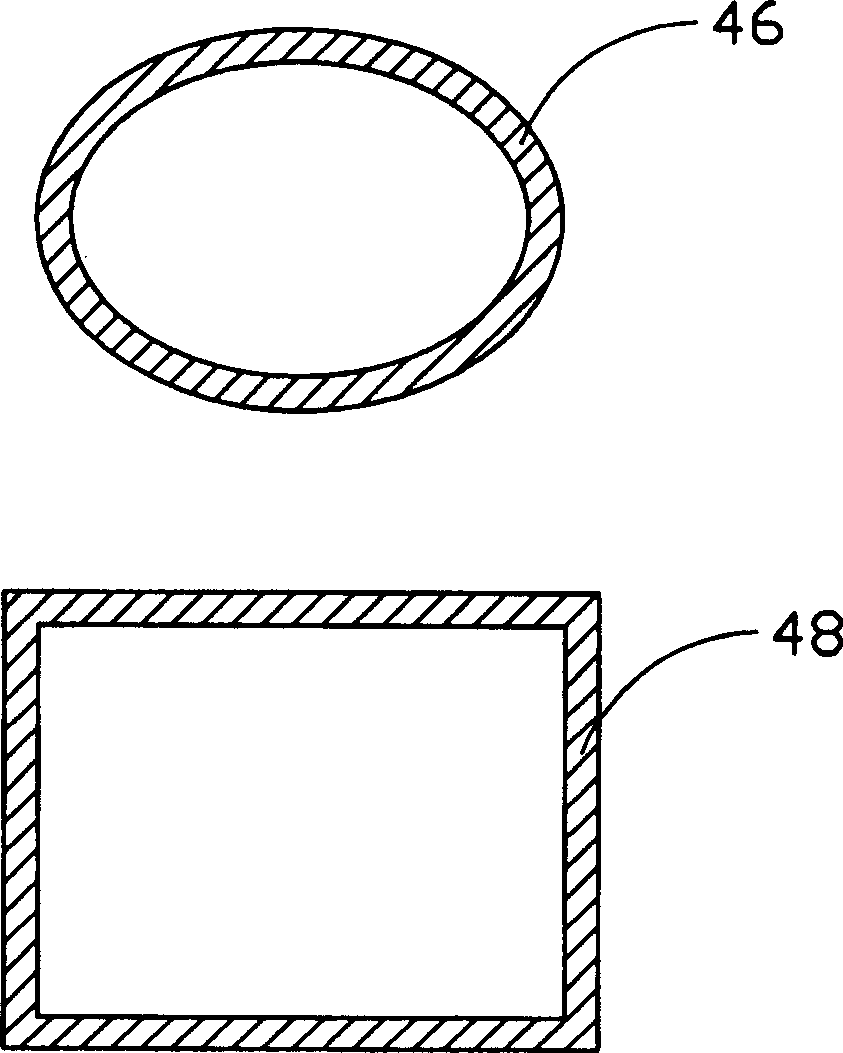

[0024] The present invention is to improve the process of sealing and welding the tank body and the upper cover. The battery sealing method of the present invention is to use the shape memory alloy gasket to induce phase deformation under the applied pressure, and to maintain the pressure and heat to Austrian. Above the astenite termination temperature (Af), it restores the parent phase with a body-centered cubic structure in a limited space, thereby generating a retra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com