Multi-angle purline connecting assembly for metal roof

A metal roof, multi-angle technology, applied in the fields of metal roof purlin connectors and multi-angle purlin connections, can solve the problems of blanking and on-site construction and installation difficulties, and achieve the effects of avoiding welding processing, firm connection, and reasonable and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

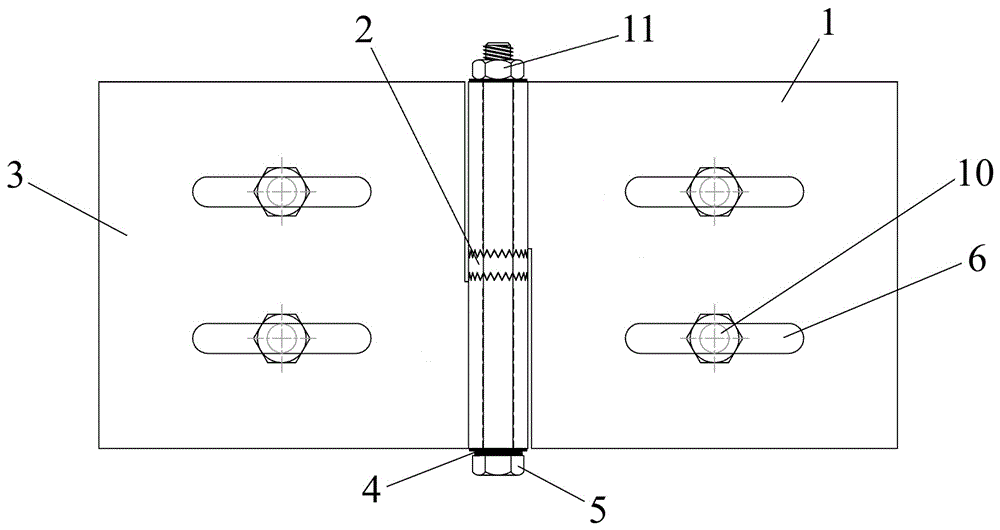

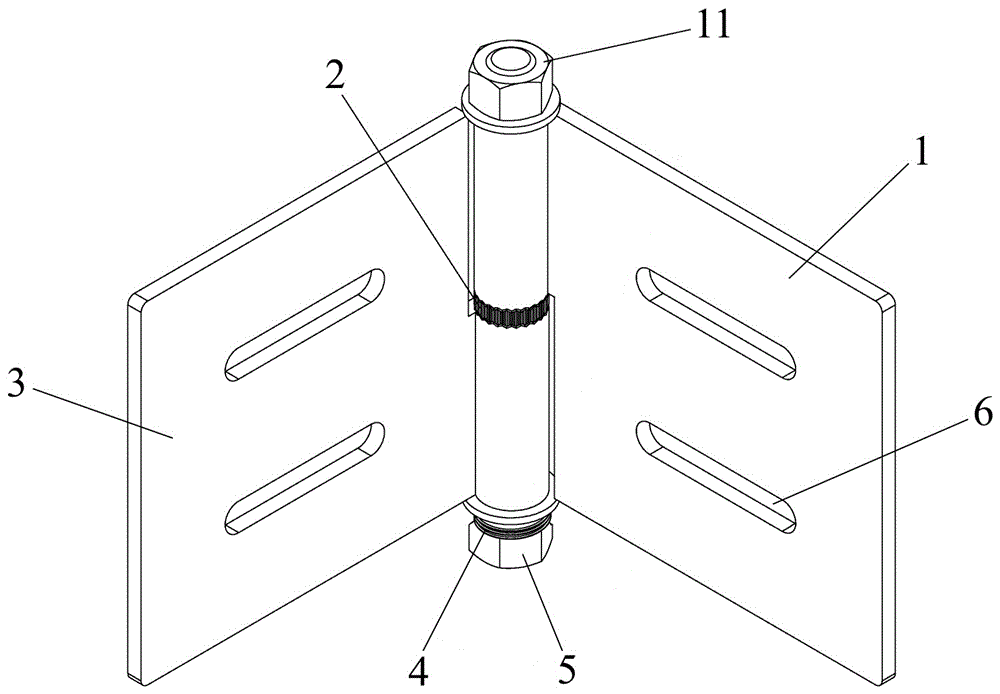

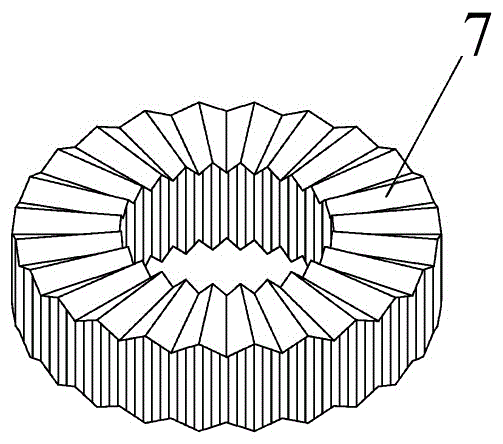

[0014] The overall structure schematic diagram of the present invention is as figure 1 , figure 2 shown. image 3 For the enlarged three-view structural diagram of the fixing clip 2, the upper and lower ends of the fixing clip are shown with the same circumferential ribs 7.

[0015] It can be seen from the figure that a metal roof multi-angle purlin connector includes two hinge pieces 1 / 3 that can be rotated and separated around the pin shaft 5 and the pin shaft 5 connecting the two hinge pieces. It is characterized in that: the pin Between the first hinge piece 1 and the second hinge piece 3 connected in series on the shaft 5, there is also a cylindrical fixing clip 2 connected in series; between the first hinge piece 1 and the fixing clip 2 , and the joint surface between the fixed clip 2 and the second hinge 3 are provided with the same circumferential ribs; the lower surface of the first hinge 1 is provided with circumferential ribs The ribs 7 and the circumferential r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com