Movement track

A technology for moving rails and guide rails, applied in the field of rails, can solve problems such as difficulty, waste of manpower, waste of material resources, etc., and achieve the effect of preventing slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

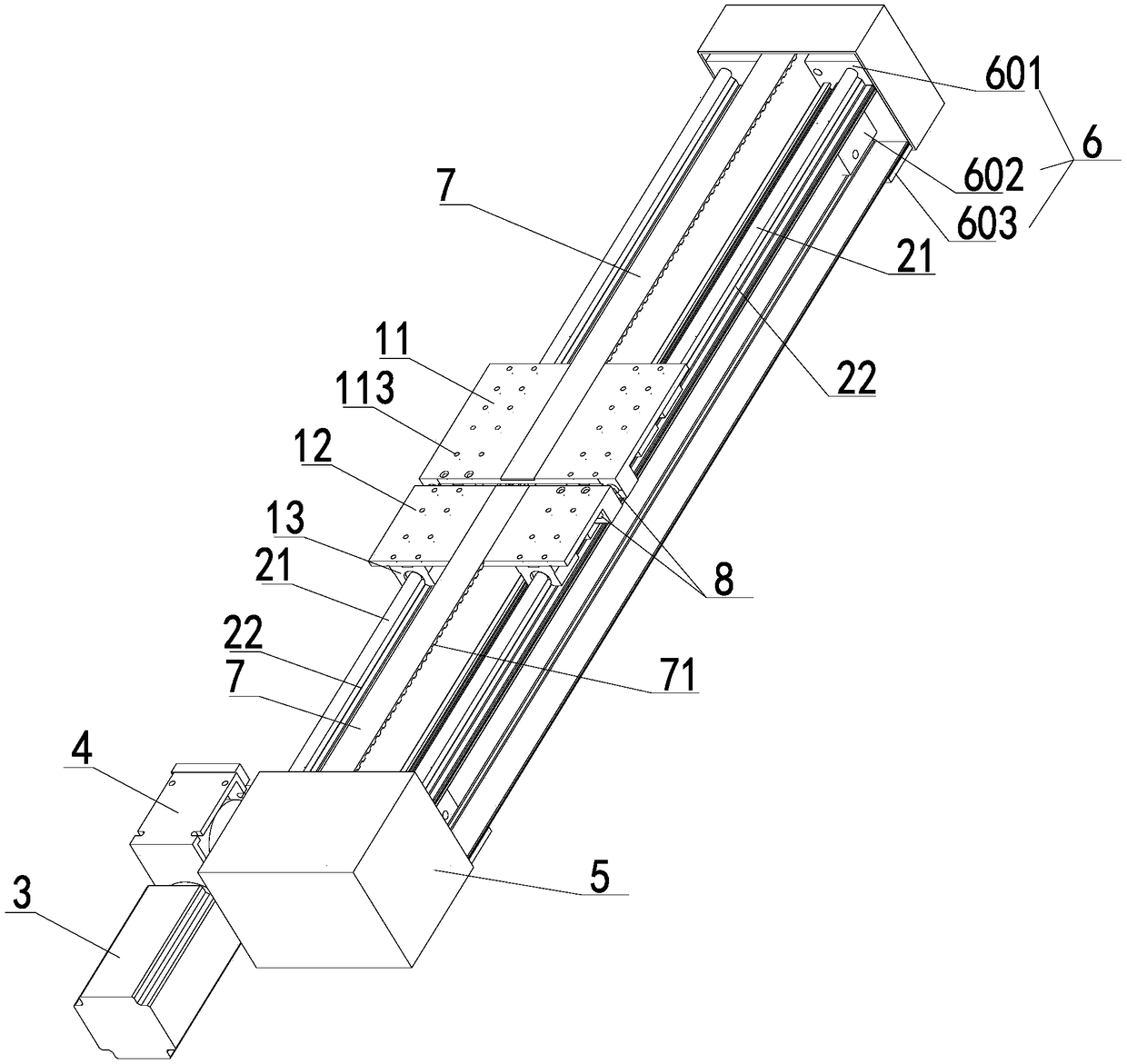

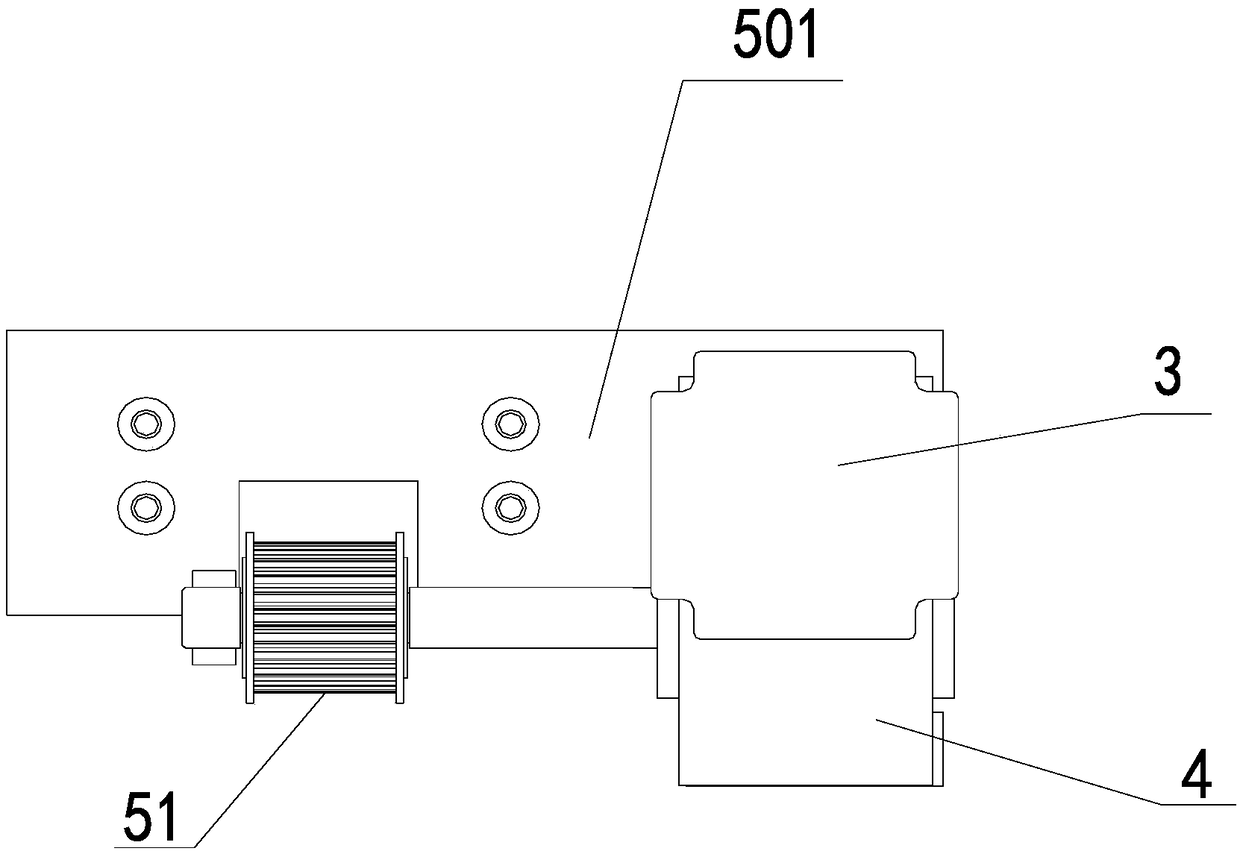

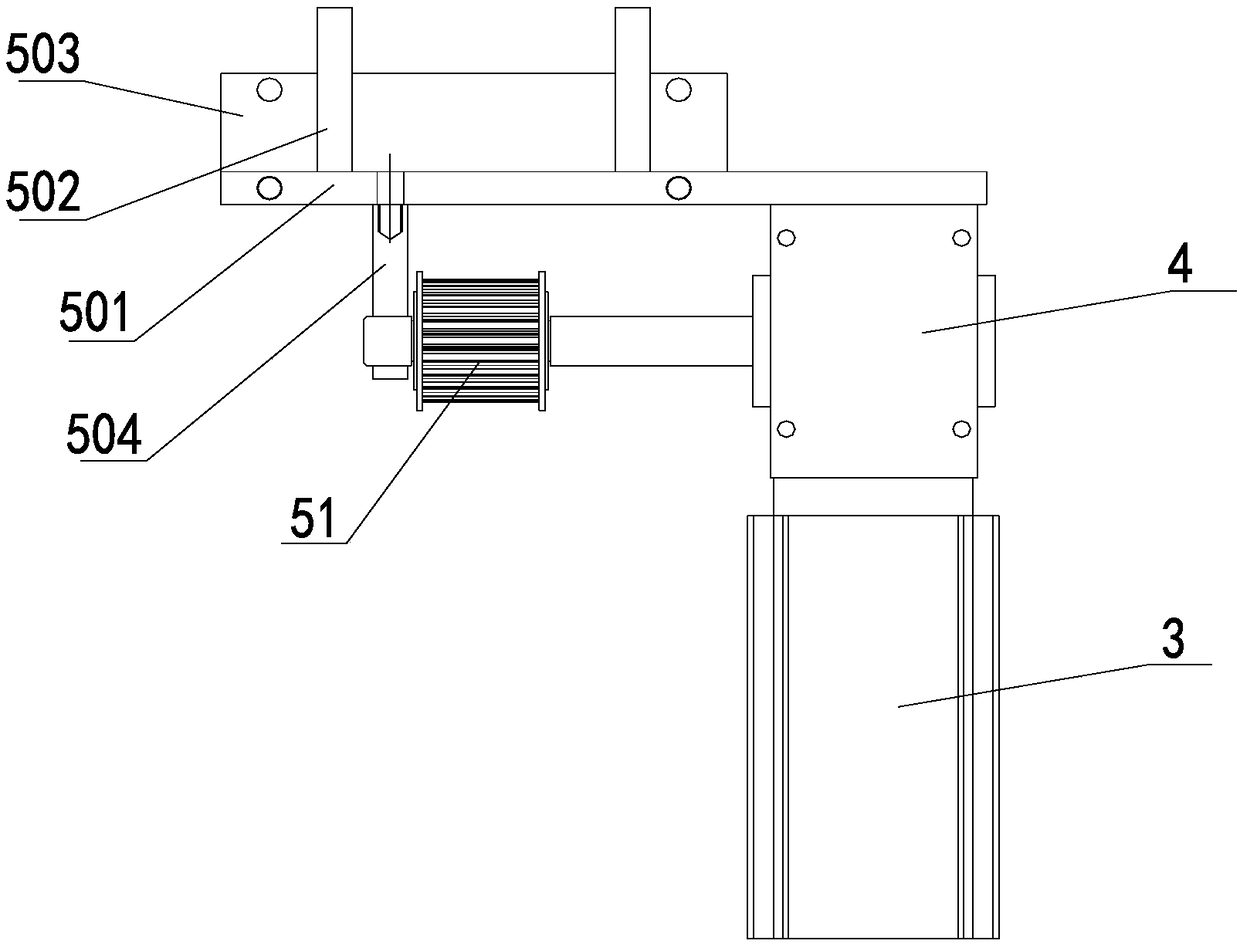

[0035] like Figure 1-4 As shown, a moving track includes a base, a conveyor belt, a power mechanism, a first mounting plate 11 and a second mounting plate 12 , and connectors. The power mechanism includes a motor 3 and a reduction box 4 . The base is arranged vertically. In order to save cost, the base is fixed and formed by two parallel I-beams in the length direction. The conveyor belt can be a chain, a timing belt 7, or a conveyor belt, and the timing belt 7 is taken as an example here.

[0036] The synchronous belt 7 is supported in a ring shape by the first support member 5 and the second support member 6, the upper surface of the ring shape is disconnected, and the two ends of the disconnection are respectively fixed on the first mounting plate 11 and the second mounting plate 12, the first mounting plate 11 and the second mounting plate 12 are provided with screw positioning holes 8, the screw positioning holes 8 on the first mounting plate 11 and the second mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com