Heat radiator and manufacturing method thereof

A heat sink and heat sink technology, which is applied to heat exchange equipment, heat exchanger types, heat exchanger shells, etc., can solve problems affecting product quality, low heat dissipation performance of radiators, and low service life of heat dissipation equipment, so as to improve Heat dissipation effect, increase the area, reduce the effect of uneven heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

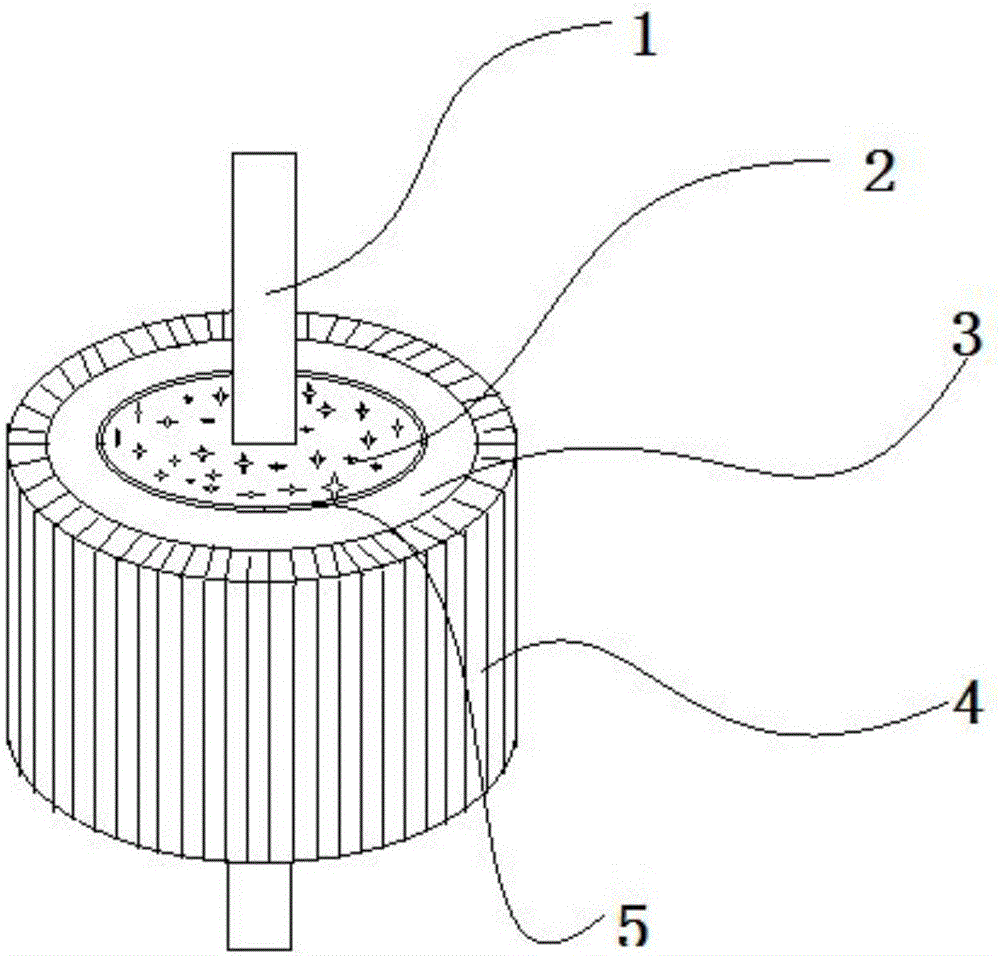

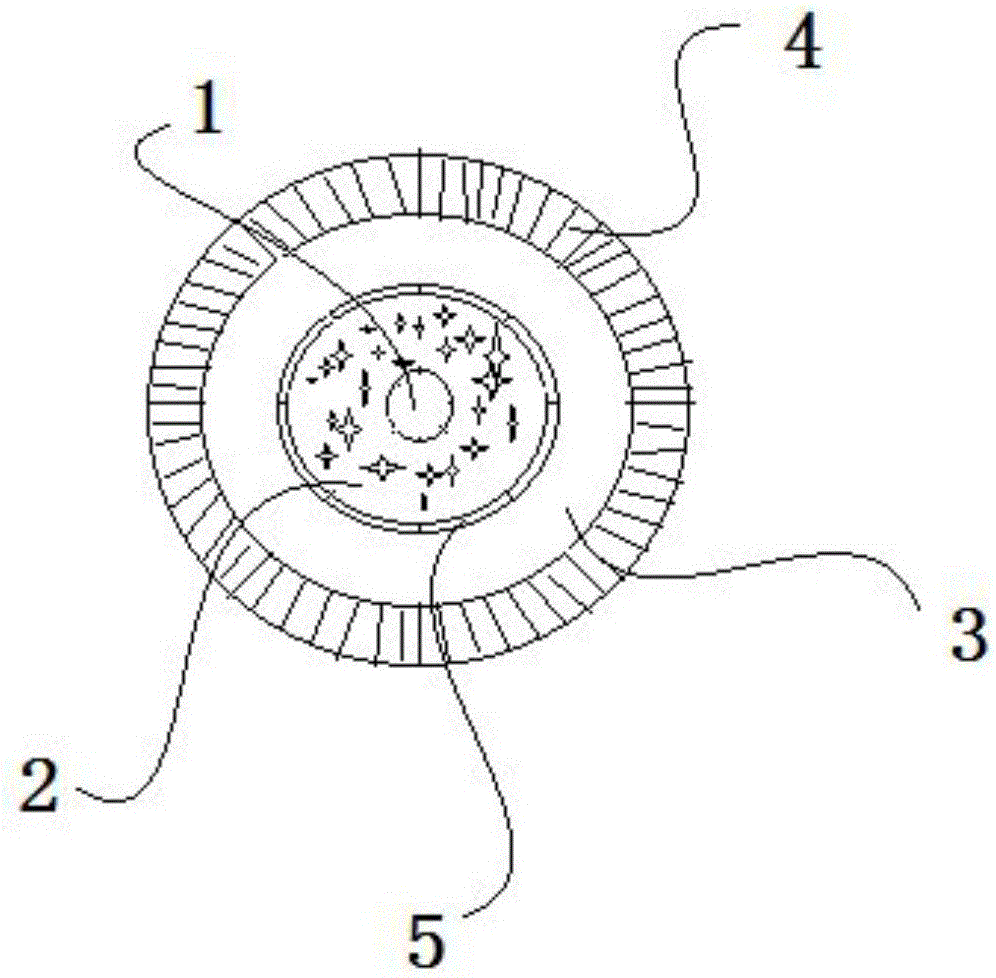

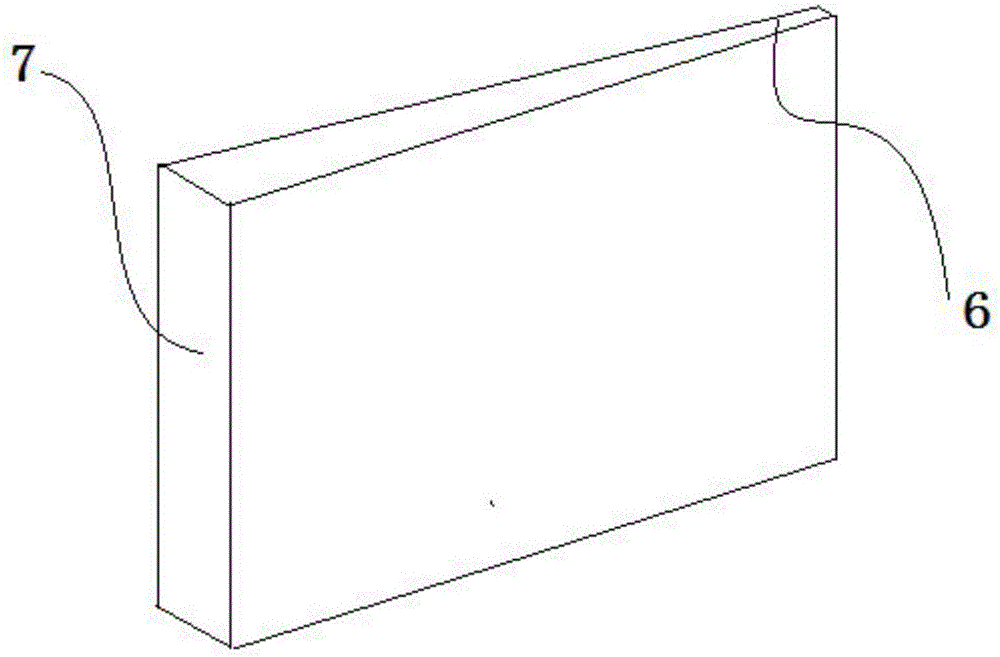

[0042] like Figure 1-4 Shown, a kind of radiator, its structural composition is by heat sink 4, the fixed medium chamber 3 that is fixedly connected with heat sink 4, the heat transfer contact base 2 that is movably connected with fixed medium cavity 3, and is arranged on the heat transfer contact base 2 The connecting piece 1 on the upper and lower surfaces is composed.

[0043] A rolling contact surface 5 is also provided between the fixed medium cavity 3 and the heat transfer contact base 2 .

[0044] The fixed medium cavity 3 and the heat transfer contact base 2 are provided with a rolling contact surface 5, wherein the rolling contact surface 5 is provided with grooves on the outer surface of the inner diameter of the fixed medium cavity 3, and on the outer diameter of the corresponding heat transfer contact base 2 A groove is also arranged on the surface, and a rolling shaft is arranged in the groove.

[0045] The rolling shaft is arranged in a groove on the outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com