Fully-sealed scroll compressor and assembly method thereof

A technology for scroll compressors and assembly methods, applied in the field of scroll compressors, can solve problems such as poor coaxiality of main and auxiliary bearings, increased production costs, expensive welding equipment, etc., to reduce deformation and reduce assembly and the cost of assembly equipment, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

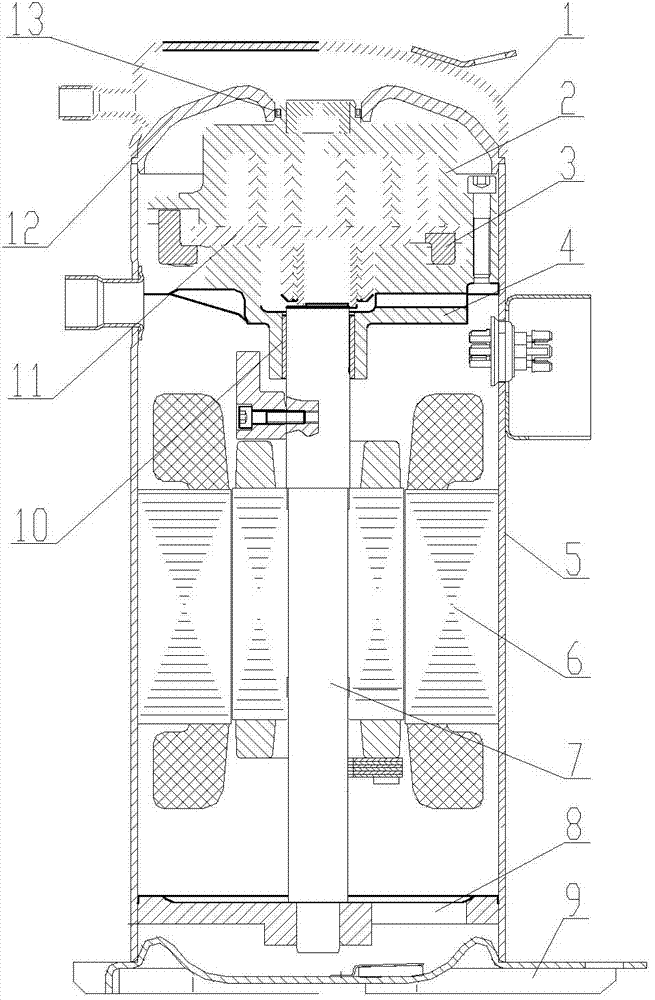

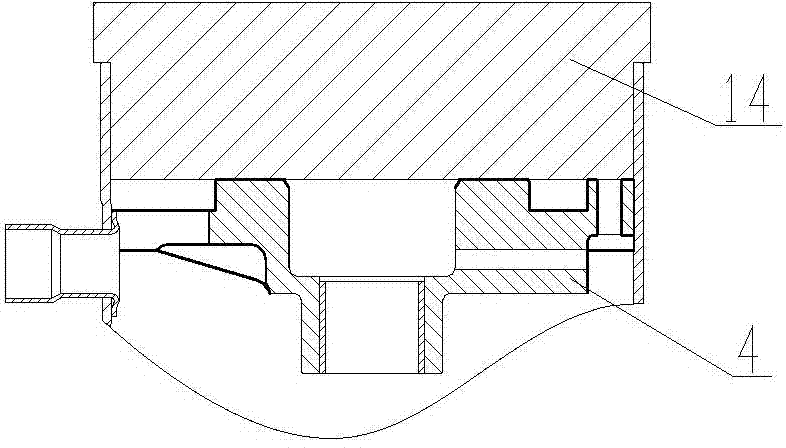

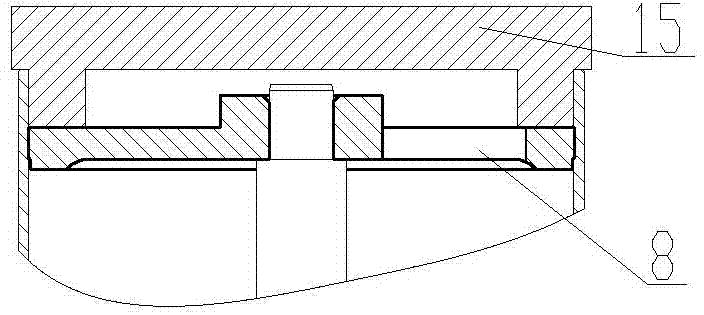

[0033] Such as figure 1 As shown, a fully enclosed scroll compressor includes an upper cover 1, a fixed scroll 2, an Oldham ring 3, a main bearing support 4, a casing 5, a driving crankshaft assembly 7, a rotating motor stator 6, and an auxiliary bearing 8 . The lower cover 9 fixed on the lower end of the housing 5, the main bearing 10, the movable scroll 11, the high and low pressure isolation plate 12, and the sealing ring 13 are characterized in that:

[0034] The movable scroll 11 driven by the crankshaft assembly 7 and the fixed scroll 2 cooperate with each other to form at least one compression chamber, the Oldham ring 3 is arranged between the fixed scroll 2 and the main bearing support 4, and the Oldham The ring 3 cooperates with the fixed scroll 2 and the movable scroll 11, so that the movable scroll 11 can only translate relative to the fixed scroll 2, and the crankshaft 7 drives the movable scroll 11 along the track Plane movement, so as to complete the suction, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com