Welding fixture

A welding jig and clamp body technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of rework rate, waste of time, and low work efficiency, so as to reduce rework rate, ensure welding quality, The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

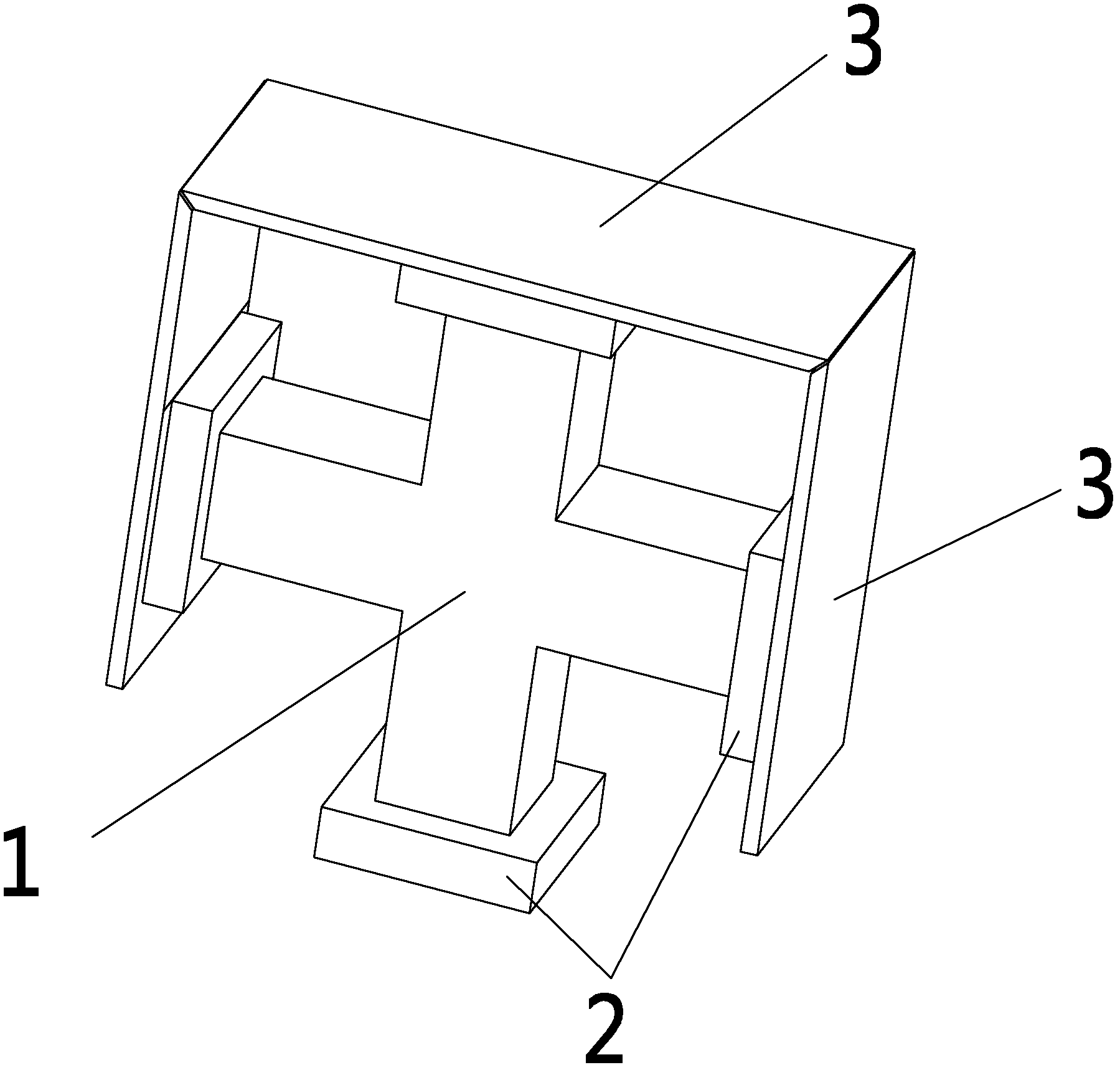

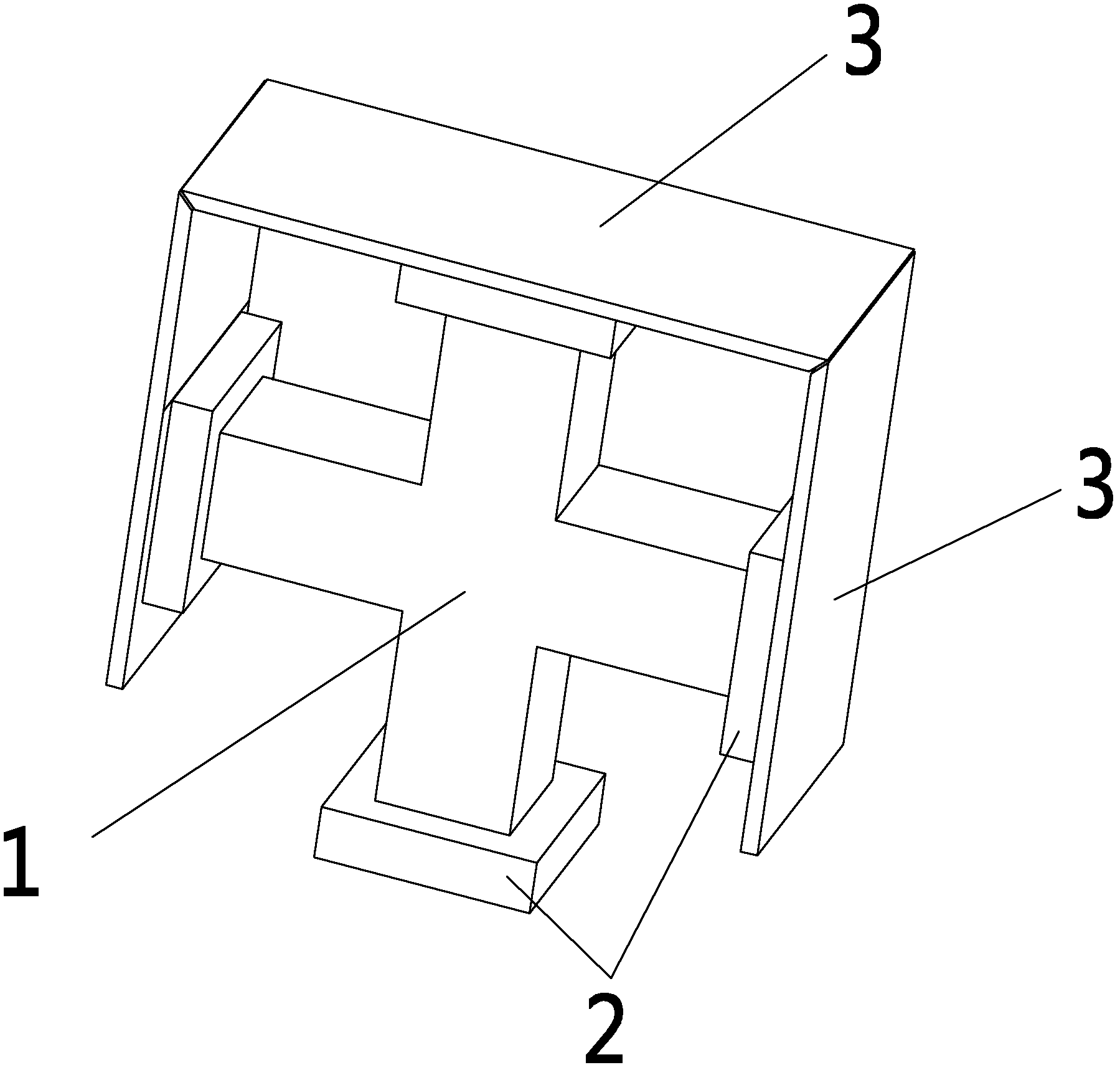

[0013] attached figure 1 It is a welding fixture according to the present invention, which includes a clamp body 1 and a magnet block 2; the clamp body 1 is in the shape of a "ten"; there are four magnet blocks 2, and they are respectively fixed on four top.

[0014] When in use, the three workpieces 3 are fixed on the three top ends of the clamp body 1 through the magnet block 2, and can be welded and processed after being fixed. Wherein the magnet block can also be replaced by a pressing plate and a bolt; the bolts are all fixed on the top of the clamp body; the pressing plate is fixed on the top of the bolt, and the pressing plate and the bolt compress the workpiece. Using the welding jig of the present invention, several workpieces can be welded at one time, which improves the welding efficiency of the workpieces; moreover, both sides of the welding place are empty, which prevents...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com