Bell jar type wind cap for environment-friendly energy-saving circulating fluidized bed boiler

A circulating fluidized bed, energy-saving technology, applied in fluidized bed combustion equipment, combustion type, fuel burning in a molten state, etc., can solve the problems of wear of the hood head and hood seat, difficult to replace the hood, and easy slag leakage from the hood. , to achieve significant economic and social benefits, save power consumption, reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

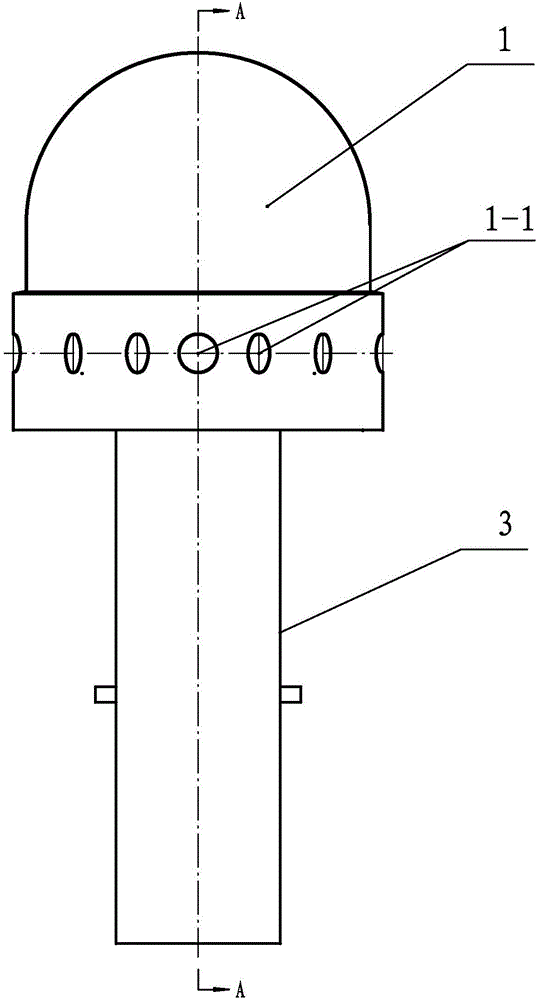

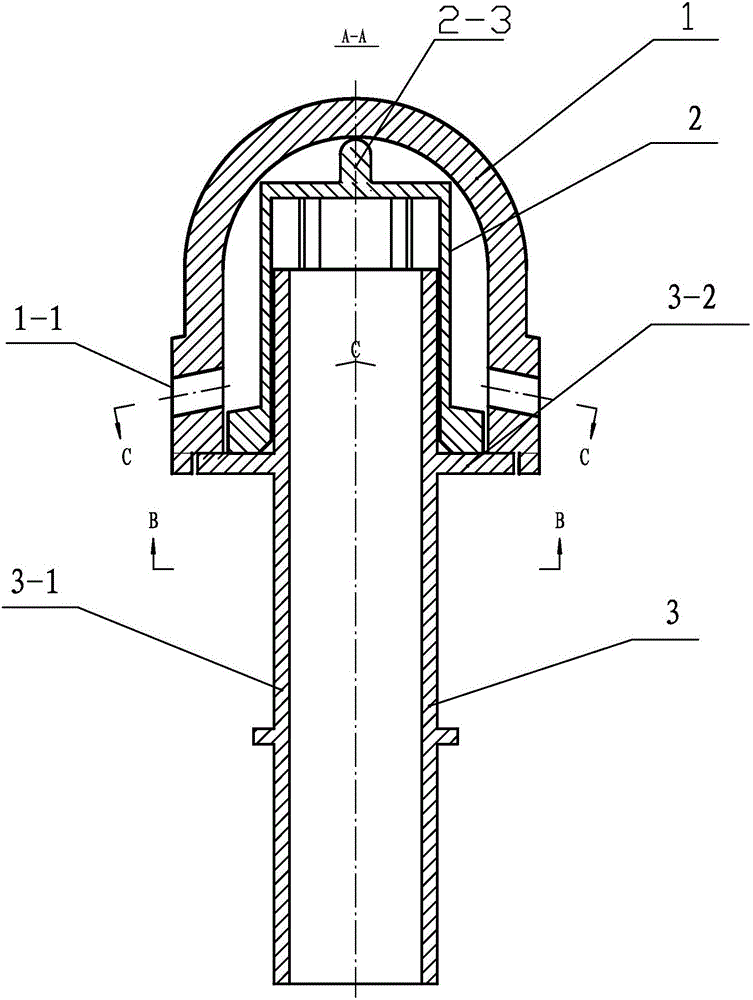

[0035] Specific implementation mode one: combine Figure 1 to Figure 12 Description of this embodiment, a bell-type hood for an environment-friendly and energy-saving circulating fluidized bed boiler, which includes a hood head 1, the hood head 1 is bell-type, and the lower side walls of the hood head 1 are evenly distributed along its circumferential direction There are several air outlets 1-1, and each air outlet 1-1 on the hood head 1 is arranged obliquely from inside to outside,

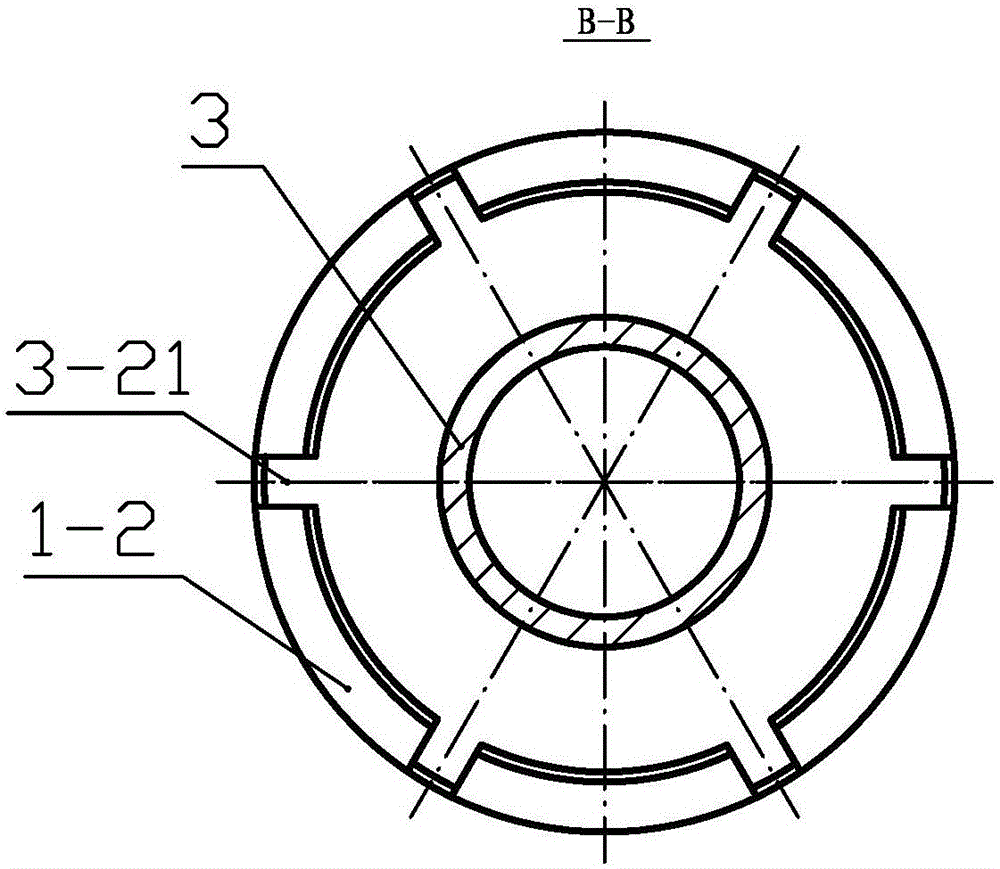

[0036] It also includes a protective cover 2 and a hood seat 3, the hood seat 3 includes a cylinder 3-1 and a support plate 3-2, the support plate 3-2 is set on the top of the cylinder 3-1 and is connected with the cylinder 3-1 The outer side wall of the barrel body 2-1 is fixed as a whole, and the protective cover 2 includes a barrel body 2-1 and a positioning ring 2-2 fixedly connected to the outer edge of the barrel body 2-1 opening end, and the barrel body 2-1 opening end is the lower end, T...

specific Embodiment approach 2

[0042] Specific implementation mode two: combination figure 2 , 3, 6, 11, 12 illustrate the present embodiment, the circumferential direction of the support plate 3-2 is evenly distributed with some first positioning blocks 3-21, and the bottom end of the hood head 1 is uniformly distributed with some second positioning blocks 1 along its circumferential direction -2, several first positioning blocks 3-21 are cross-fitted with several second positioning blocks 1-2, and the first positioning blocks 3-21 are welded to the second positioning blocks 1-2. With such a design, the hood head 1 and the support plate 3-2 are connected by spot welding, which facilitates the replacement operation of the hood head 1 . Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0043] Specific implementation mode three: combination figure 1 , 2 , 4, 5 illustrate this embodiment, the air outlet 1-1 is a circular air outlet, the number is twelve, and the angle between the central axis of each air outlet 1-1 and the horizontal direction is 10-12 Spend. With such a design, the included angle is preferably 10 degrees, which can make the air flow out of the hood uniform and meet the needs of different air volumes, and the inclined air outlet 1-1 can effectively prevent the bed material from entering the hood and prevent slag leakage. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com