A method for through-hole reflow soldering

A reflow soldering and reflow soldering technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of thermal damage of plug-in components, insufficient tin penetration in holes, and insufficient tin penetration, so as to improve reliability and soldering quality and high reliability, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

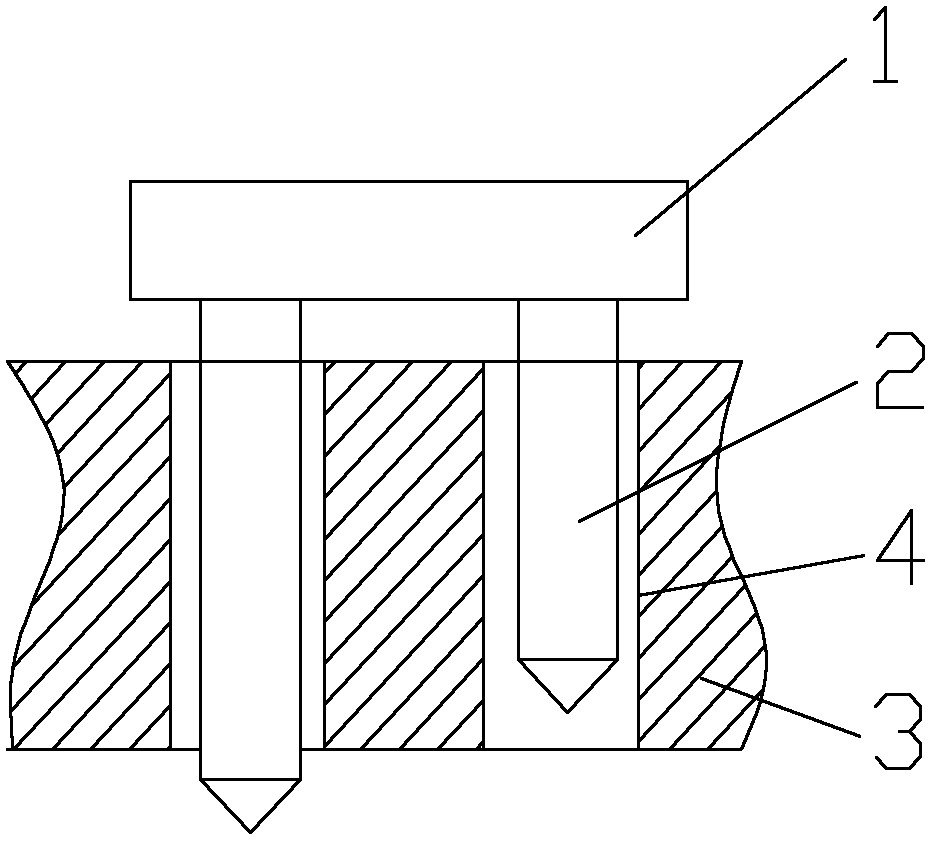

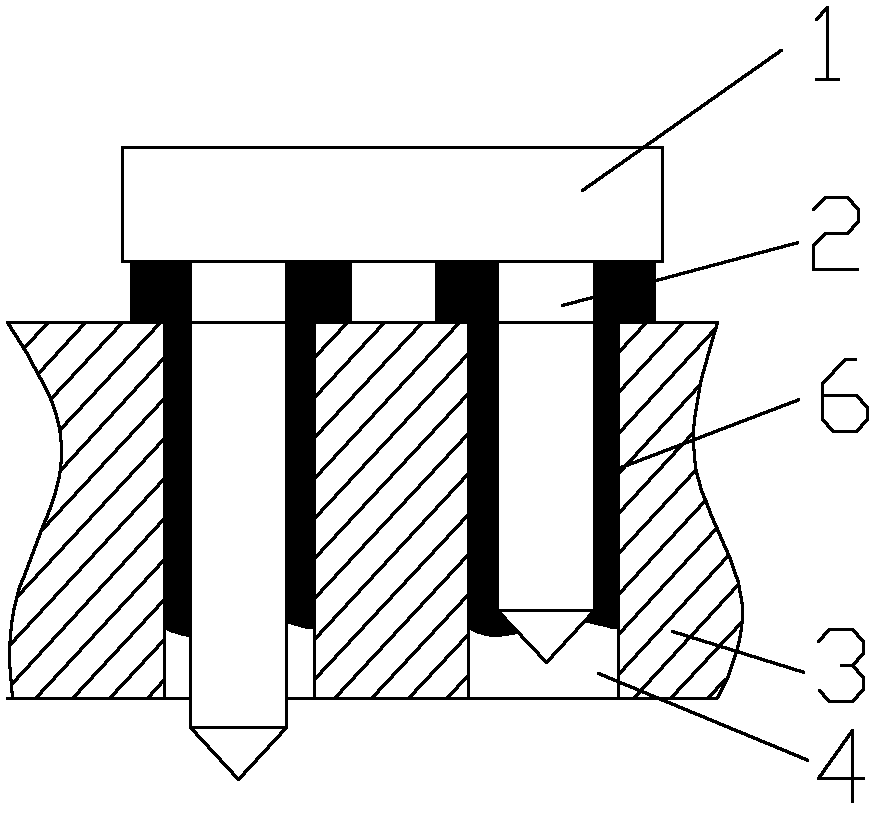

[0018] The PCB board 3 is provided with an HDMI plug-in component 1 which is a patch connector with four pins 2. Among them, the length of pin 2 is 1.8 mm and 2.2 mm, and the thickness of PCB board 3 is 2.0 mm. After inserting this plug-in component 1 into the corresponding plug-in hole 4 on PCB board 3, pin 2 with a length of 1.8 mm is not The pin 2 with a length of 2.2 mm has a pin 2 of 0.2 mm, which does not meet the pin requirement of 0.8 mm to 1.5 mm, such as figure 1 Shown.

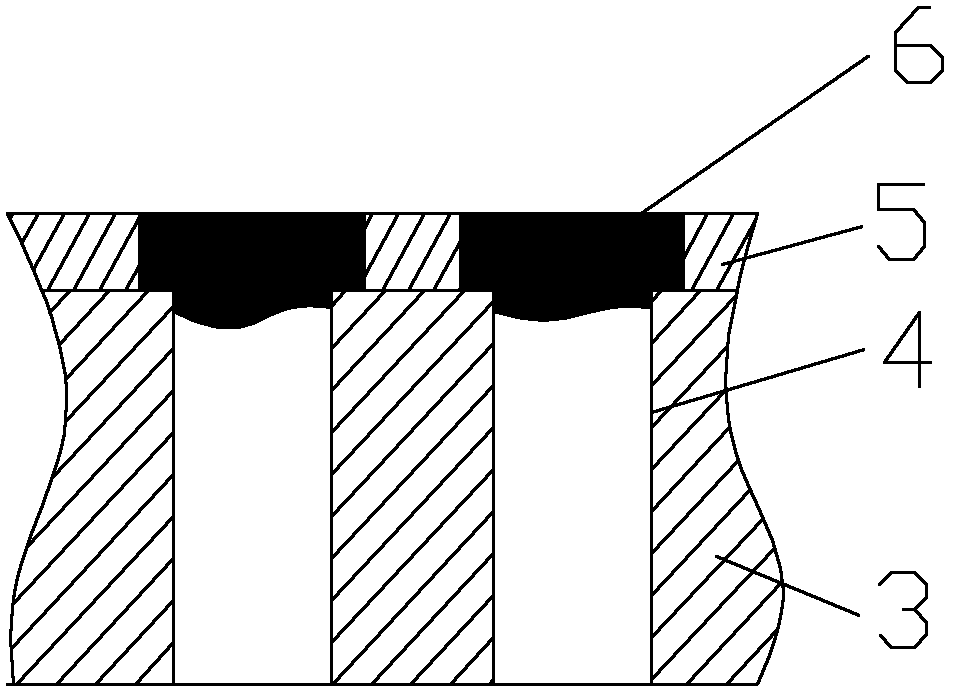

[0019] When using traditional methods, namely wave soldering and manual repair soldering, the front side cannot penetrate the tin, and the amount of solder filling in the plug-in hole 4 does not meet the 75% filling requirement of the plug-in hole 4 of IPC610D (Electronic Industry Solder Joint Inspection Standard). The reliability of the component is poor. At the same time, the plug-in hole 4 places tin piles, the surrounding large copper skin absorbs heat, and the solder joints are easy to cause cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com