Adipose transplantation material containing highly concentrated adipose-derived stem cells and extracellular matrix, and pure physical preparation method and application thereof

A fat-derived, highly concentrated technology, applied in the field of fat transplantation and stem cell therapy, can solve the problems of high cost, complicated separation process, limited capacity, etc., and achieve the effect of low cost, rich source, and no rejection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Process the obtained fat particles by Coleman technology: centrifuge at 1200g / min for 3 minutes, recover the upper layer of fat after centrifugation, discard the bottom liquid, and transfer the high-density fat tissue in the middle layer to a needle-free syringe, and use scissors The adipose tissue is further shredded.

[0046] The above-mentioned granular fat is obtained by wet liposuction technology, using a liposuction needle to suck fat tissue from the patient's abdomen or thigh.

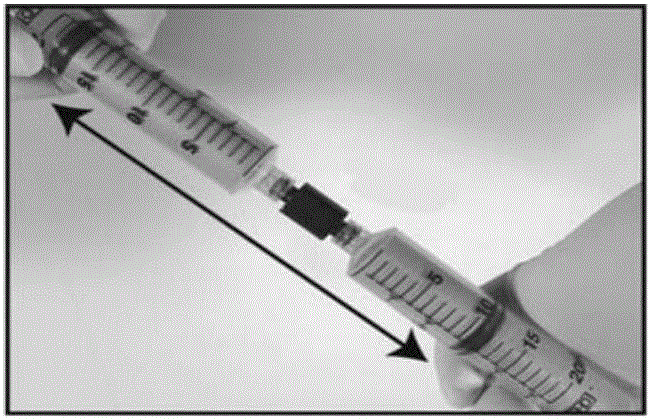

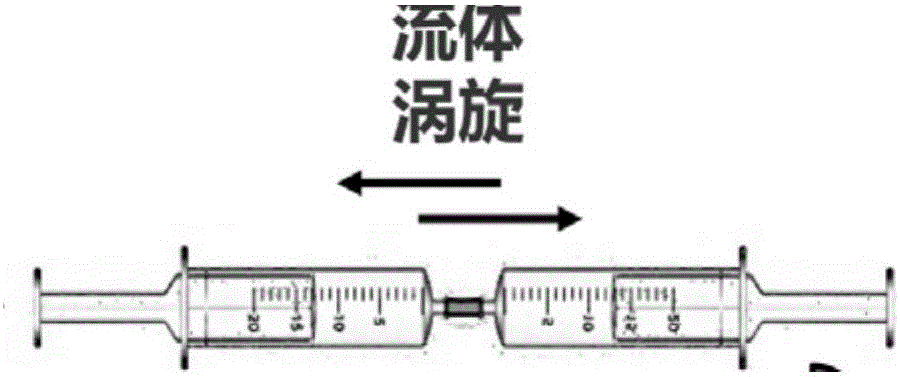

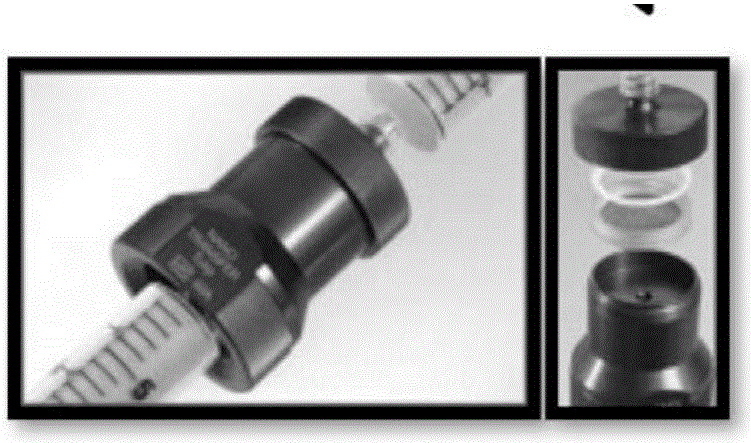

[0047] 2) Connect the syringe filled with fat in the previous step with a new syringe through the Luer connector (such as figure 1 As shown) Connect the injection ports of the two syringes to achieve a sealed butt joint, push the plunger of the syringe containing adipose tissue, and inject the adipose tissue into the opposite syringe through the connector at a speed of 20ml / s. Note 2min (eg figure 2 shown).

[0048] 3) Take the oil retained in step 1) and mix it into the adipose ti...

Embodiment 2

[0054] 1) Process the obtained granular fat with Coleman technology: centrifuge at 800g / min for 5 minutes, recover the upper layer of fat after centrifugation, discard the bottom liquid, and transfer the high-density fat tissue in the middle layer to a needle-free syringe, and use scissors The adipose tissue is further shredded.

[0055] The above-mentioned granular fat is obtained by wet liposuction technology, using a liposuction needle to suck fat tissue from the patient's abdomen or thigh.

[0056] 2) Connect the syringe filled with fat in the previous step and a new syringe through the luer connector to connect the two syringe injection ports to achieve a sealed connection, push the syringe piston containing fat tissue, and push the fat tissue through the connector to the In the contralateral syringe, the bolus injection speed is 10ml / s, and the back-and-forth bolus injection is continued for 1min.

[0057] 3) Take the oil retained in step 1) and mix it into the adipose ...

Embodiment 3

[0063] 1) Process the obtained granular fat with Coleman technology: centrifuge at 1200g / min for 5 minutes, recover the upper layer of fat after centrifugation, discard the bottom liquid, and transfer the high-density fat tissue in the middle layer to a needle-free syringe, and use scissors The adipose tissue is further shredded.

[0064] The above-mentioned granular fat is obtained by wet liposuction technology, using a liposuction needle to suck fat tissue from the patient's abdomen or thigh.

[0065] 2) Connect the syringe filled with fat in the previous step and a new syringe through the luer connector to connect the two syringe injection ports to achieve a sealed connection, push the syringe piston containing fat tissue, and push the fat tissue through the connector to the In the contralateral syringe, the bolus injection speed is 20ml / s, and the back-and-forth bolus injection is continued for 1min.

[0066] 3) Take the oil retained in step 1) and mix it into the adipose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com