Welding-free film frame

A welding-free, membrane frame technology is applied in the field of MBR membrane frame, which can solve the problems of short processing time, inability to weld, and low production cost, and achieve the effects of short processing time, less dosage and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

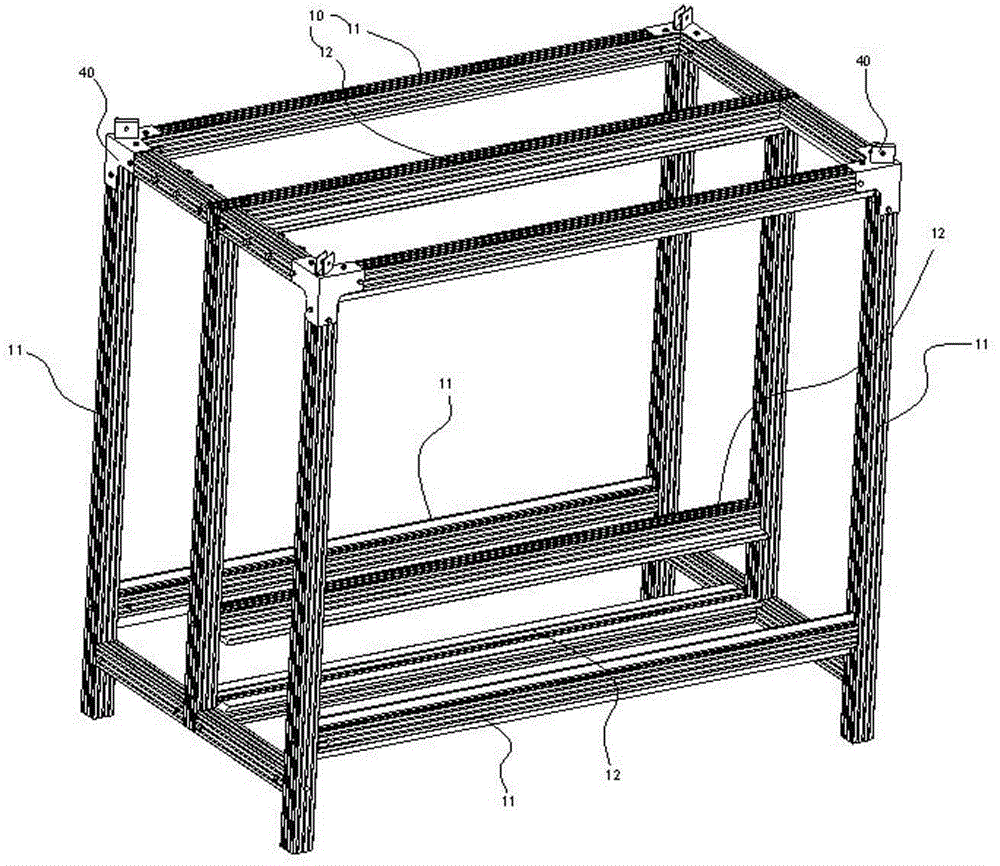

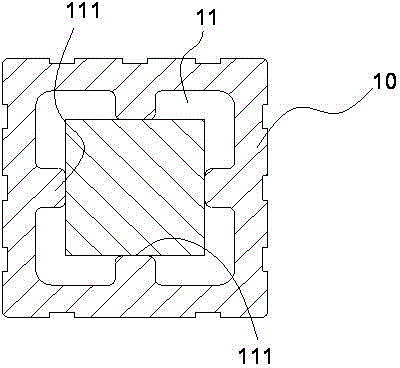

[0017] Such as Figure 1 to Figure 4 Shown is a kind of preferred specific implementation example of the present invention, a kind of welding-free membrane frame, such as figure 1 , figure 2 As shown, it includes a plurality of elongated frame members 10, and each frame member 10 is provided with an accommodating groove 111 inside;

[0018] A plurality of connectors 20, the plurality of connectors 20 are inserted into the accommodation grooves 111 of the plurality of frame members 10, so that the plurality of frame members 10 are butted with each other to form a rectangular frame; and,

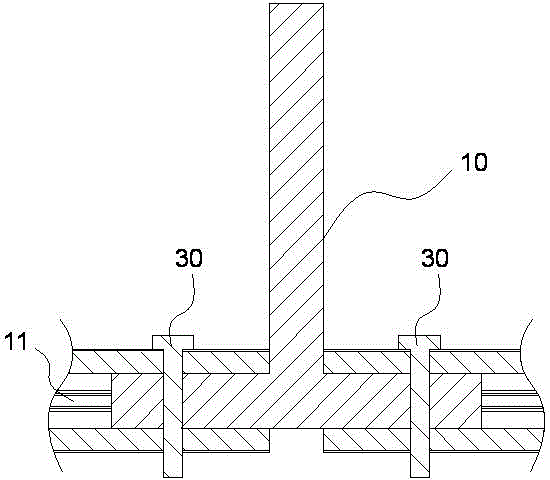

[0019] A plurality of locking elements 30 pass through the plurality of frame components 10 and the plurality of connecting elements 20 respectively, so as to secure them to each other.

[0020] further, such as image 3 As shown, on the groove wall of the accommodation groove 111 of each frame member 10, a resistance block 112 protrudes toward the center of the member. When the connector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com