Coiled tubing flash butt welding method capable of being used for on-site production

A technology of flash butt welding and coiled tubing, which is applied in applications, household appliances, welding equipment, etc., and can solve problems such as restricting the application of flash butt welding technology and inability to complete welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with accompanying drawing.

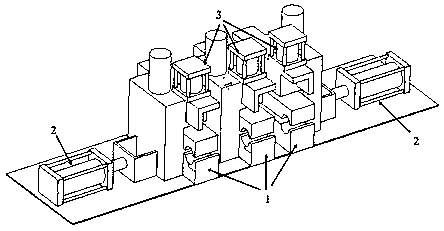

[0022] Such as figure 1 As shown, a coiled tube flash butt welding method that can be used in on-site production includes electrode clamp 1, electrode clamp 1 connects horizontal cylinder 2 and longitudinal cylinder 3, horizontal cylinder 2 and longitudinal cylinder 3 are controlled by the control cabinet, electrode clamp 1 is controlled by Electrical system power transmission, the coiled tube flash butt welding method includes the following steps:

[0023] 1) Turn on the equipment in the control cabinet, put the coiled tube into the electrode holder 1, and install it stably;

[0024] 2) Press the electrode clamp 1 button in the control cabinet, the longitudinal cylinder 3 starts, and the electrode clamp 1 is clamped;

[0025] 3) Start the electrical system and send power to the electrode clip 1, the electrode clip 1 in the middle is positive, and the electrode clips on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com