Processing method for welding supports on irregular plate

A processing method and special-shaped plate technology, applied in the field of mechanical processing, can solve the problems of large size error of the motor protective shell, increase the difficulty of welding the support, affect the welding production efficiency, etc., and achieve fast and accurate control of the welding position and adjustability Strong and reasonable support structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

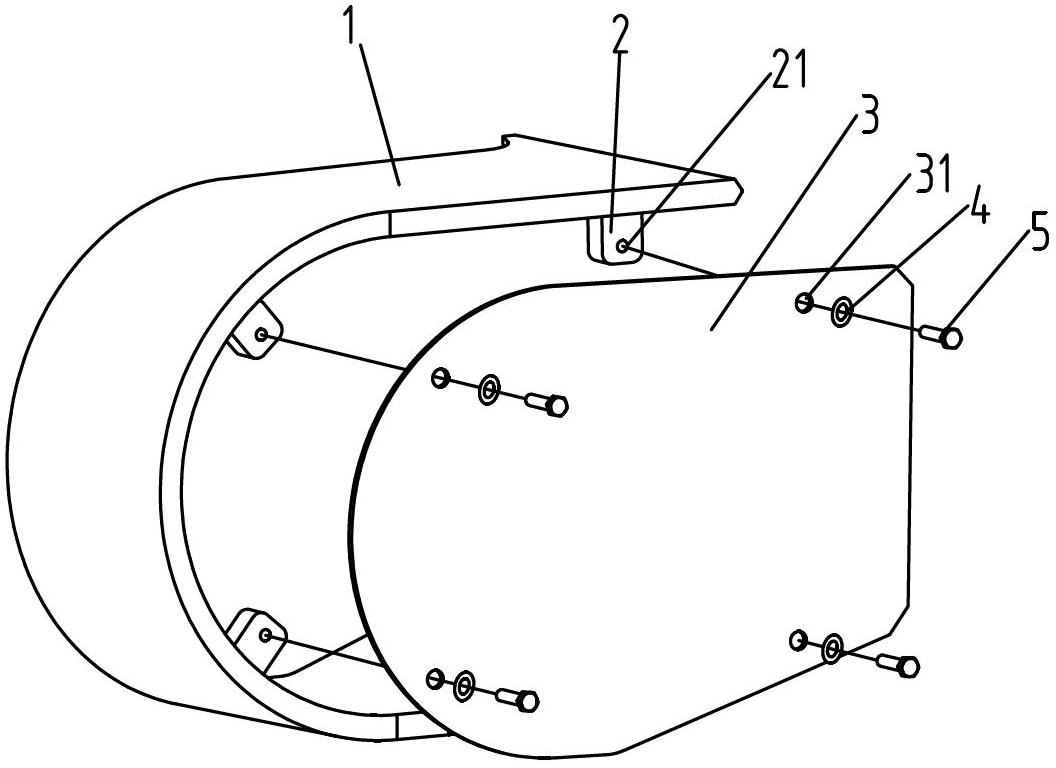

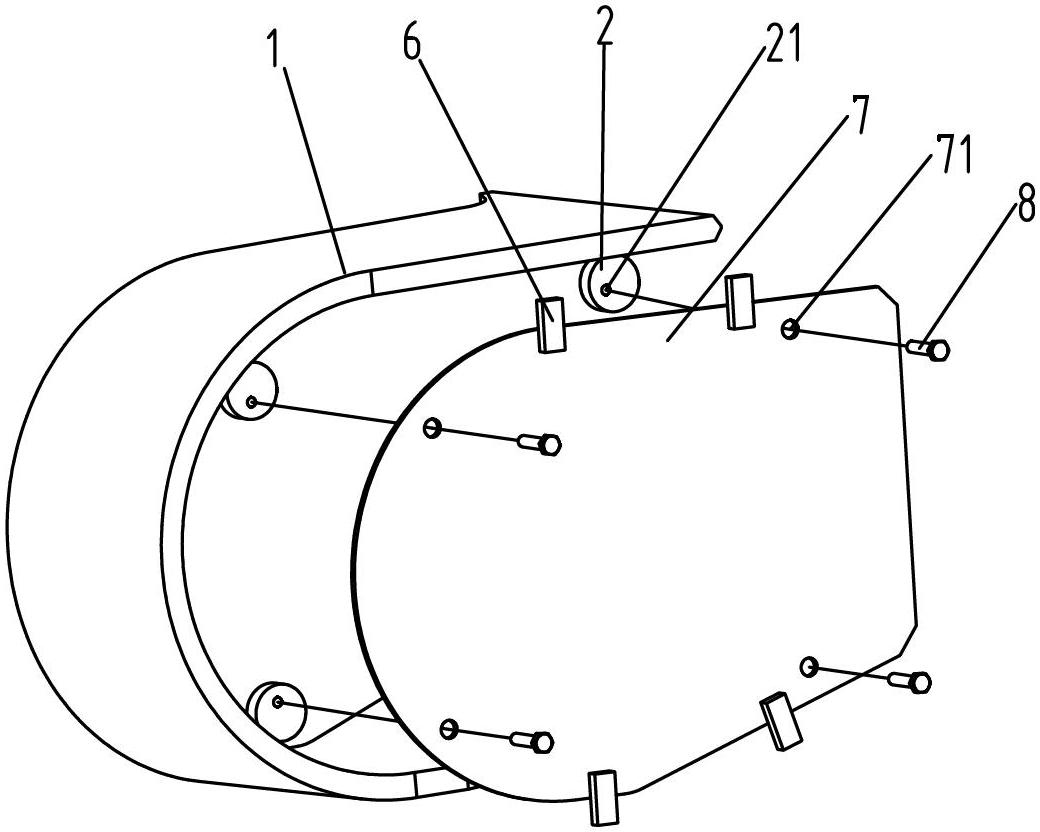

[0023] See Figure 3-5 Shown, the present invention welds the processing method of bearing on the special-shaped plate, carries out according to the following steps,

[0024] ⑴. First, bend the special-shaped plate 1 into the desired shape, and it can be bent according to the design requirements. See image 3 As shown, the traveling motor protection shell of the hydraulic excavator walking frame is used as a special-shaped plate 1. One end of the motor protection shell is a closed arc end and the other end is open, and the upper and lower side plates are connected to the arc end. The special-shaped plate 1 It can also be a curved panel or a composite panel, and it can also be a flat panel.

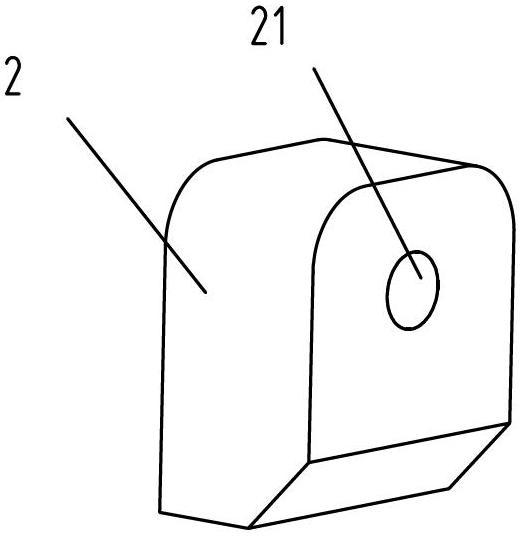

[0025] (2) The template 7 is installed on the side of the special-shaped board 1. The present invention is to quickly install the template 7 on the side of the special-shaped board 1. The template 7 is provided with more than two decks 6, and the end faces of the deck 6 and the special-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com