Traveling device of automatic welding tractor

An automatic welding and walking device technology, which is applied in the field of welding manufacturing, can solve problems such as increased labor and material costs, failure to work normally, deviation, etc., to improve welding quality and efficiency, save labor costs and time, and ensure construction quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

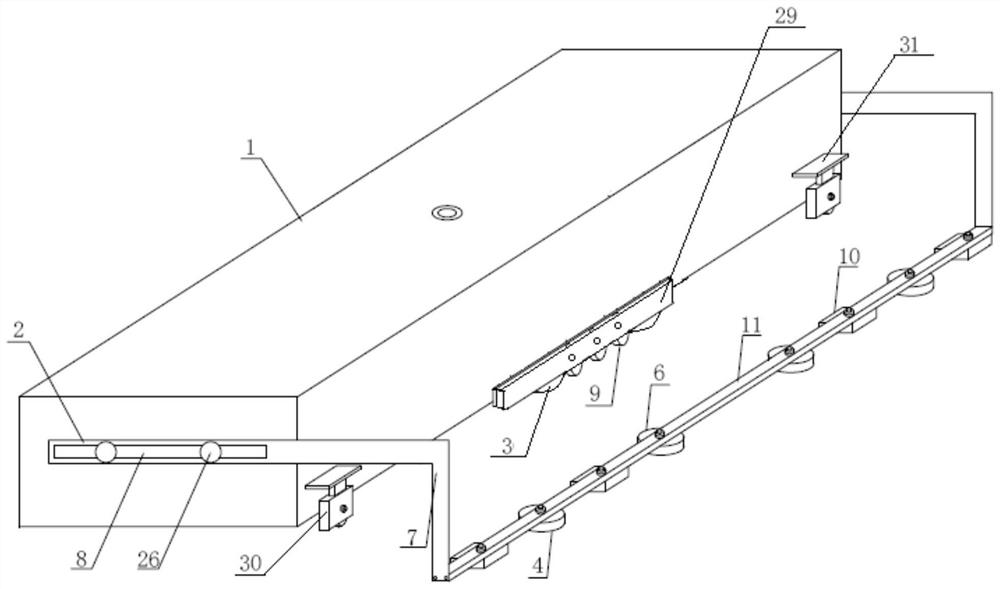

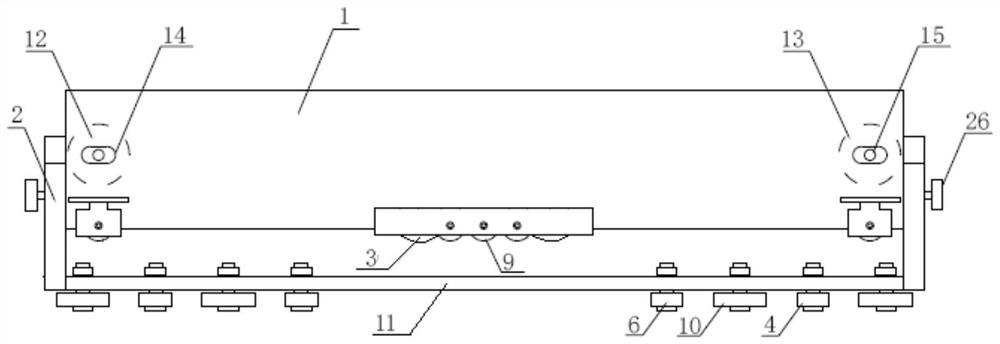

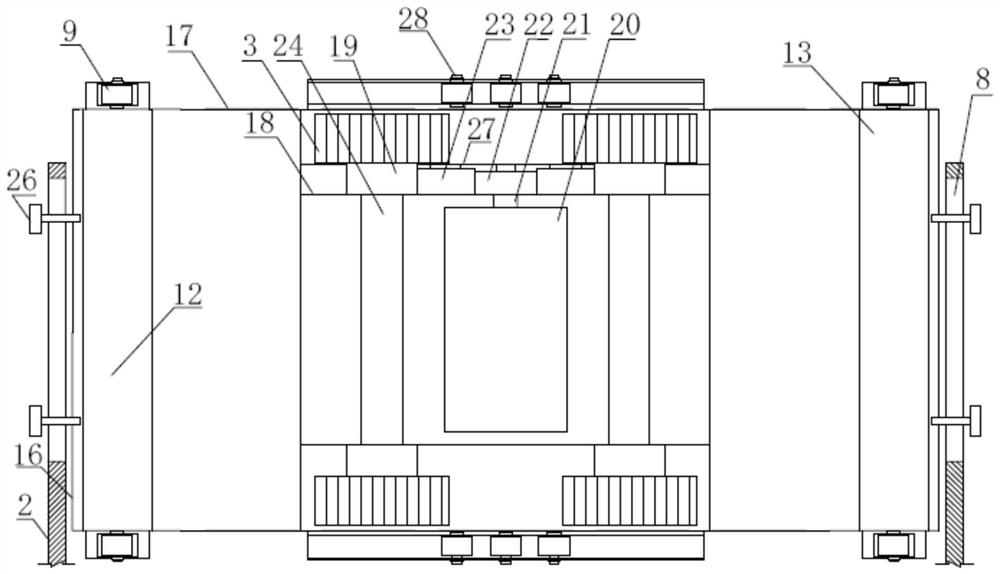

[0032] Such as figure 1 , 2 , 3, the walking device of the automatic welding trolley of the present invention comprises an automatic welding trolley body 1, the bottom of the car body 1 is open, and a first magnetic base 12 and a second magnetic base 13 are respectively installed at both ends of the interior of the vehicle body 1 , the first magnetic base switch 14 and the second magnetic base switch 15 are all arranged on the left side of the vehicle body.

[0033] Such as figure 1 , 3 , 4, on the end plate 16 at both ends of the car body 1, a guide arm 2 is installed horizontally, and the surface of one end of the guide arm 2 is provided with a notch 8, and the screw 26 passes through the notch 8 to fix one end of the guide arm 2 on the end plate 16; the other end of the guide arm 2 stretches out to the right side of the car body 1 and is equipped with a straight bar 7 vertically downward. A guide rod 11 is installed between the two straight rods 7 at the two ends of the...

Embodiment 2

[0042] In this embodiment, on the basis of Embodiment 1, the walking drive mechanism has been improved, as follows:

[0043] Such as Figure 5 , 6 As shown, crawler belt 25 is installed on the driving wheel 3 of the traveling drive mechanism, and the inner surface of driving wheel 3 coincides with the inner surface of crawler belt 25; .

[0044] The crawler belt 25 is made of metal or non-metallic material; when metal material is used to make the crawler belt 25, a pattern structure is arranged on the outer surface of the crawler belt 25, which can effectively increase the friction between it and the workpiece 5; When crawler belt 25, present embodiment is preferred to make crawler belt 25 with steel wire and high-temperature-resistant rubber as the material of filling molding with internal reinforcement, and a layer of gravel grain is evenly embedded in the outer layer of crawler belt 25, can strengthen crawler belt 25 surface anti-high temperature ability and with Frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com