Three-dimensional linkage pipe beveling device

A pipeline and linkage technology, used in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve problems such as re-cutting, and achieve the effect of improving cutting accuracy, improving moving accuracy, and improving angular deflection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

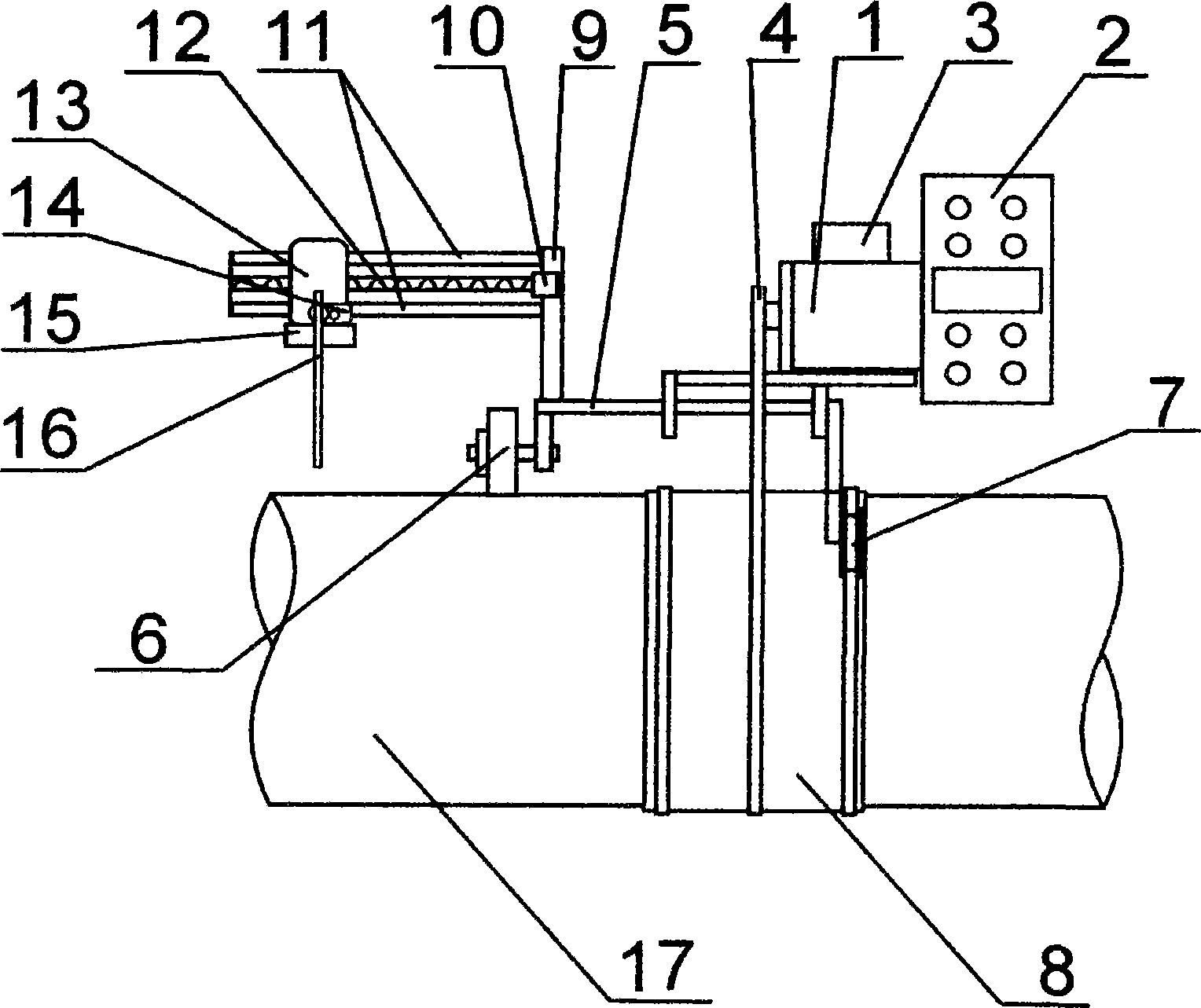

[0018] The present invention will be further described below in conjunction with accompanying drawing:

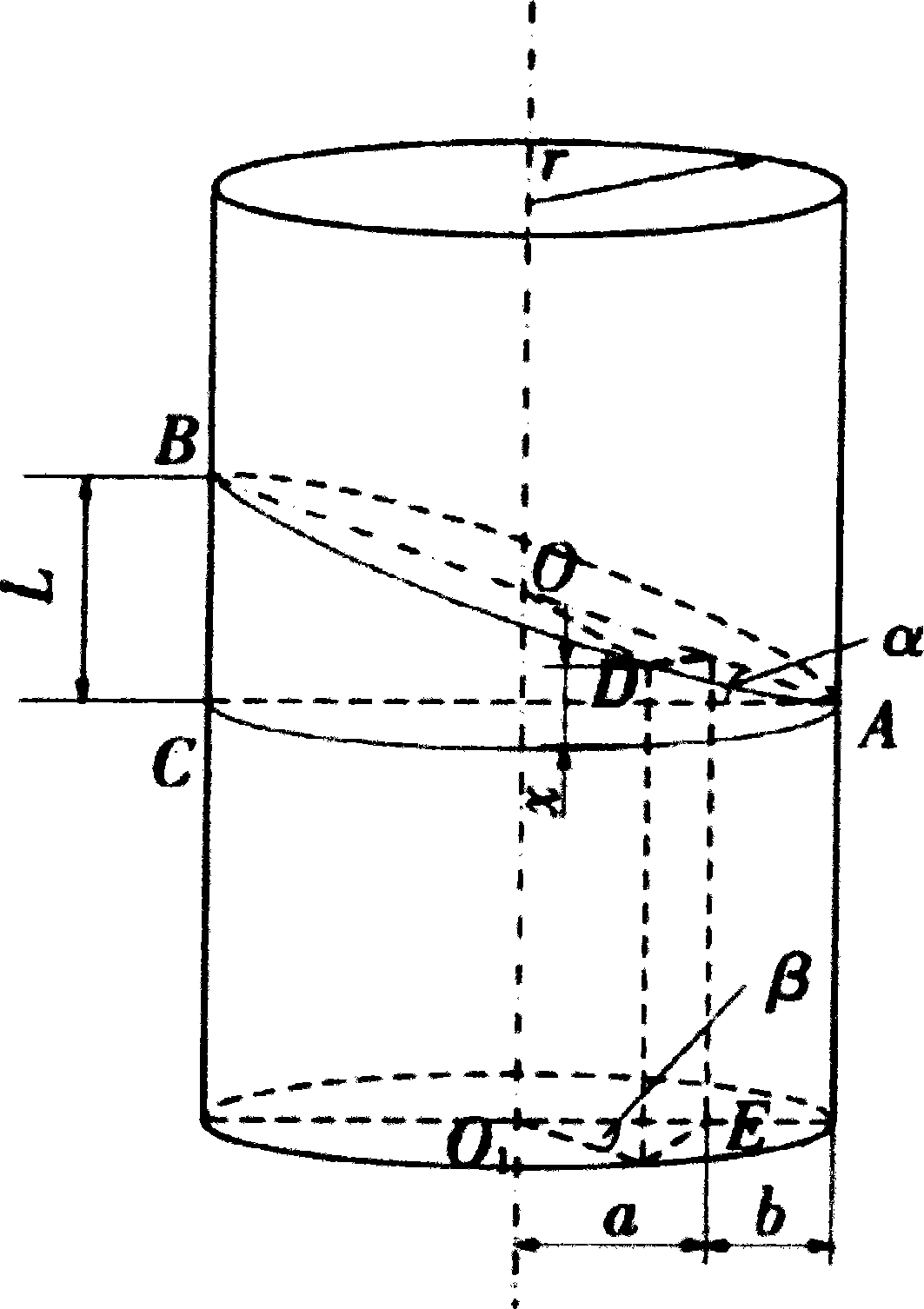

[0019] Such as figure 1 As shown, tgα=L / 2r, cosβ=a / r, a=r·cosβ, b=r-a, x=b·tgα, so a mathematical model tgθ=r / (L / 2-x)=r / [L / 2-L / 2(1-cosβ)]=2r / (Lcosβ)=1 / (tgαcosβ), where r is the radius of the steel pipe, a is the cutting angle, and l is the cutting length. The axial displacement of the cutting torch is x when the cutting torch starts to rotate through the circumferential angle β from point A. It can be seen that the position of the cutting torch at any time is only related to the oblique cutting length of the steel pipe and the central angle of the cutting torch turning along the steel pipe surface , and has nothing to do with the tube radius r.

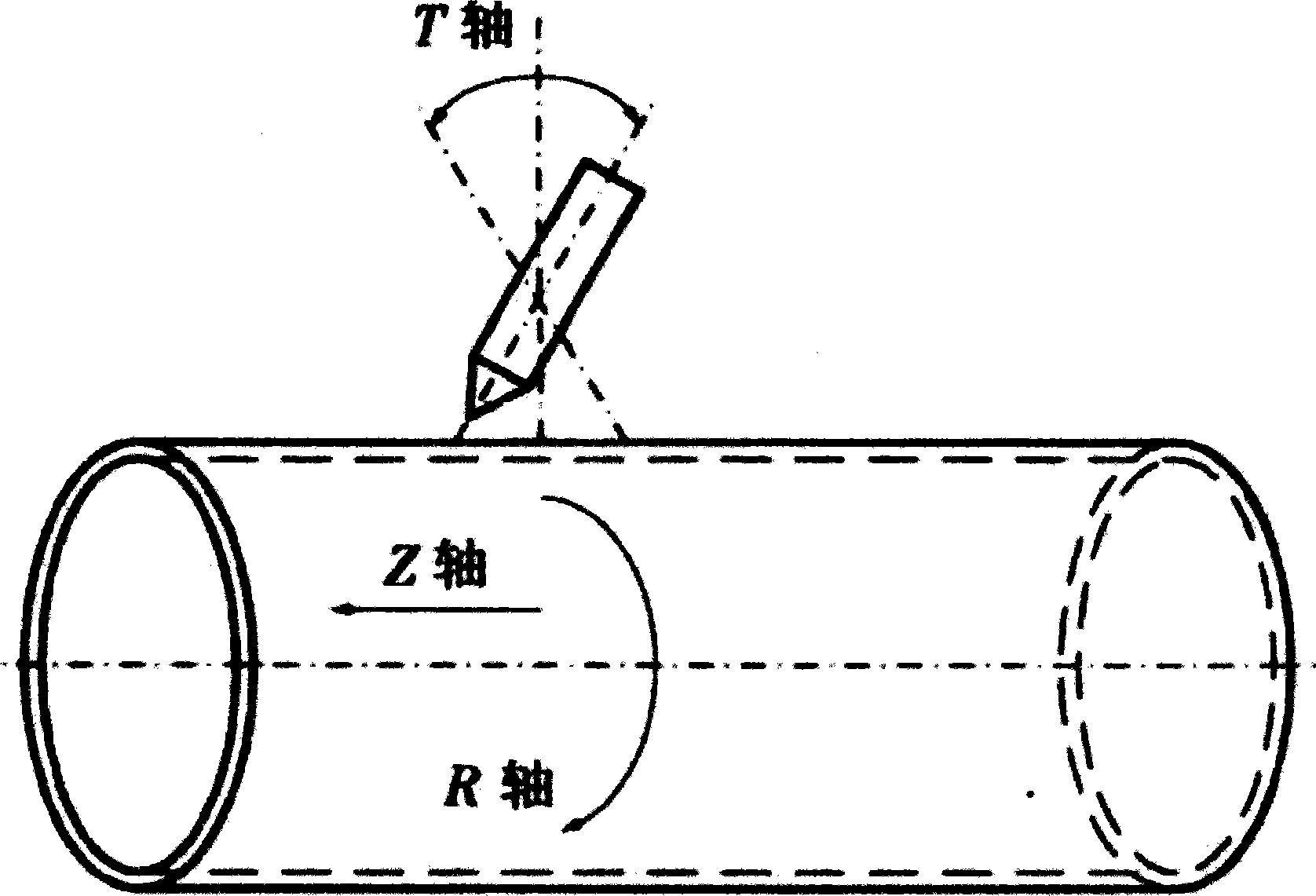

[0020] Such as figure 2 As shown, during the cutting process, the cutting torch has three degrees of freedom. The rotational movement along the circumferential direction of the cut pipe is recorded as the R axis, and the axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com