Connection method for titanium plate and stainless steel plate

A technology of stainless steel plate and connection method, which is used in the connection of titanium plate and stainless steel plate during production switching, and in the field of co-linear equipment between titanium plate and stainless steel, can solve the problems of easily scratched rollers and easily broken belts, and can not be welded. , The production process is simple, and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

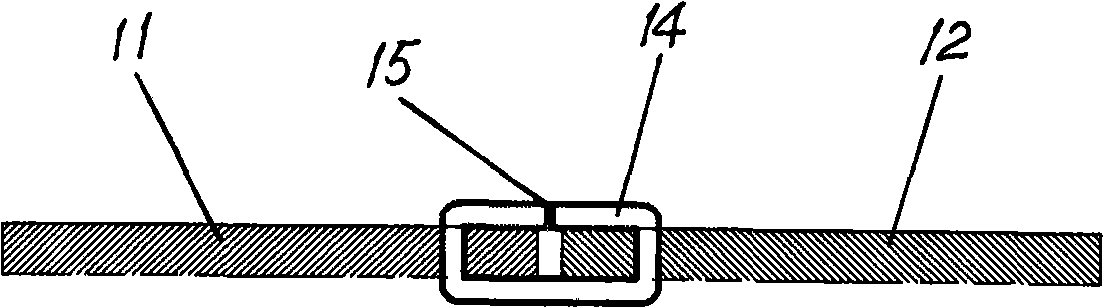

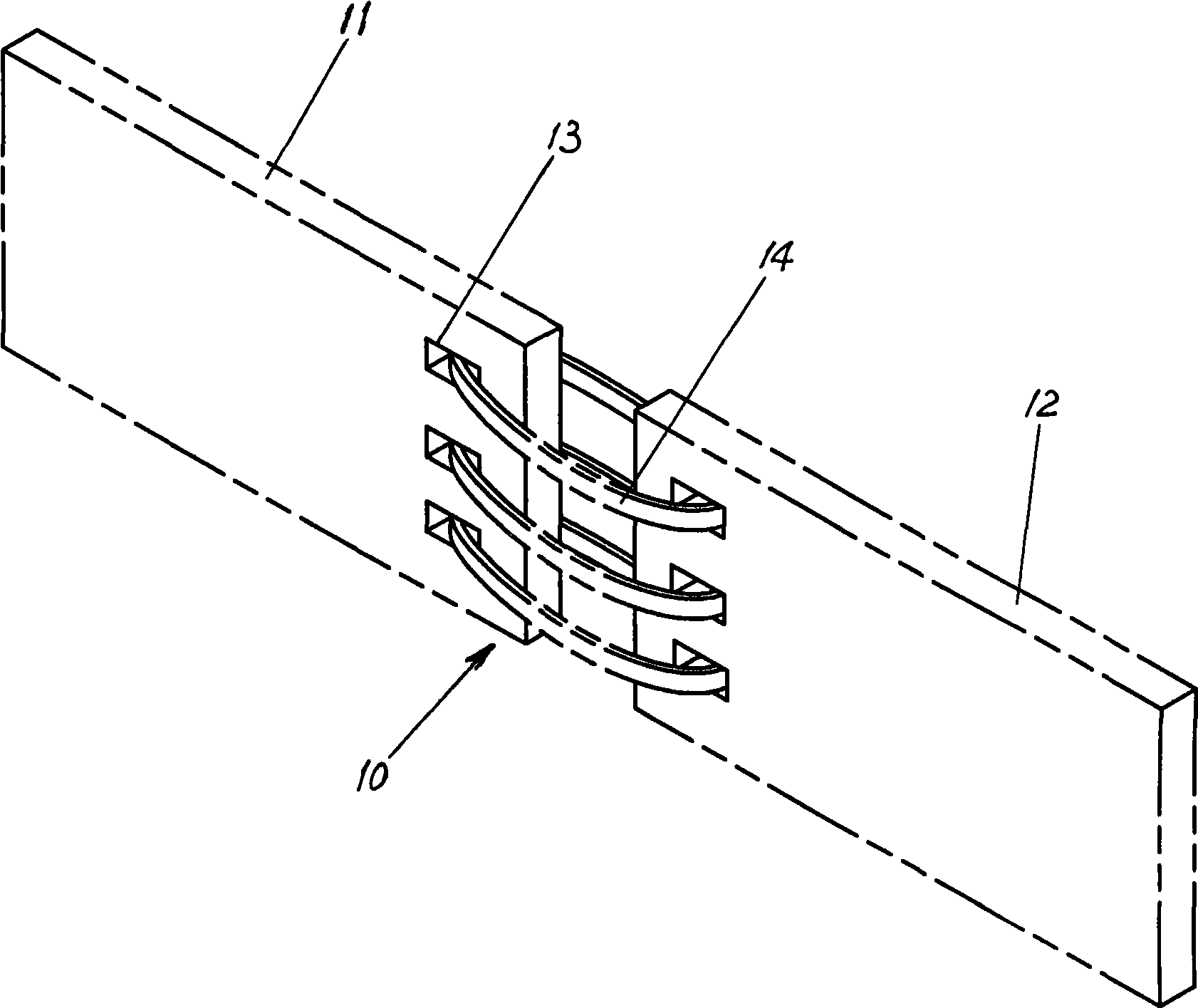

[0026] see figure 2 with image 3 , according to a kind of titanium plate and stainless steel plate connection method of the present invention, use titanium plate or titanium strip, stainless steel plate or stainless steel strip and welding material, adopt following steps:

[0027] First punch several small holes 13 at the end of the titanium plate 11 and the end of the stainless steel plate 12 respectively, and insert several connecting narrow strips 14 prepared in advance into the small holes 13 at the ends of the titanium plate 11 and the end of the stainless steel plate 12 Inside, the titanium plate 11 and the stainless steel plate 12 are flexibly connected. The stainless steel plate 12 is made of annealed material. Connect narrow band 14 and connect narrow band for stainless steel.

[0028] Then weld 15 with welding material at the gap between the end of the titanium plate 11 and the end of the stainless steel plate 12 and between the connecting narrow strips 14, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com