Solar battery main grid mask plate

A solar cell and mask technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the conversion efficiency of solar cells, failing to achieve the mask effect, and increasing the manufacturing cost, so as to eliminate the inability to weld and be easy to industrialize. The effect of promotion and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

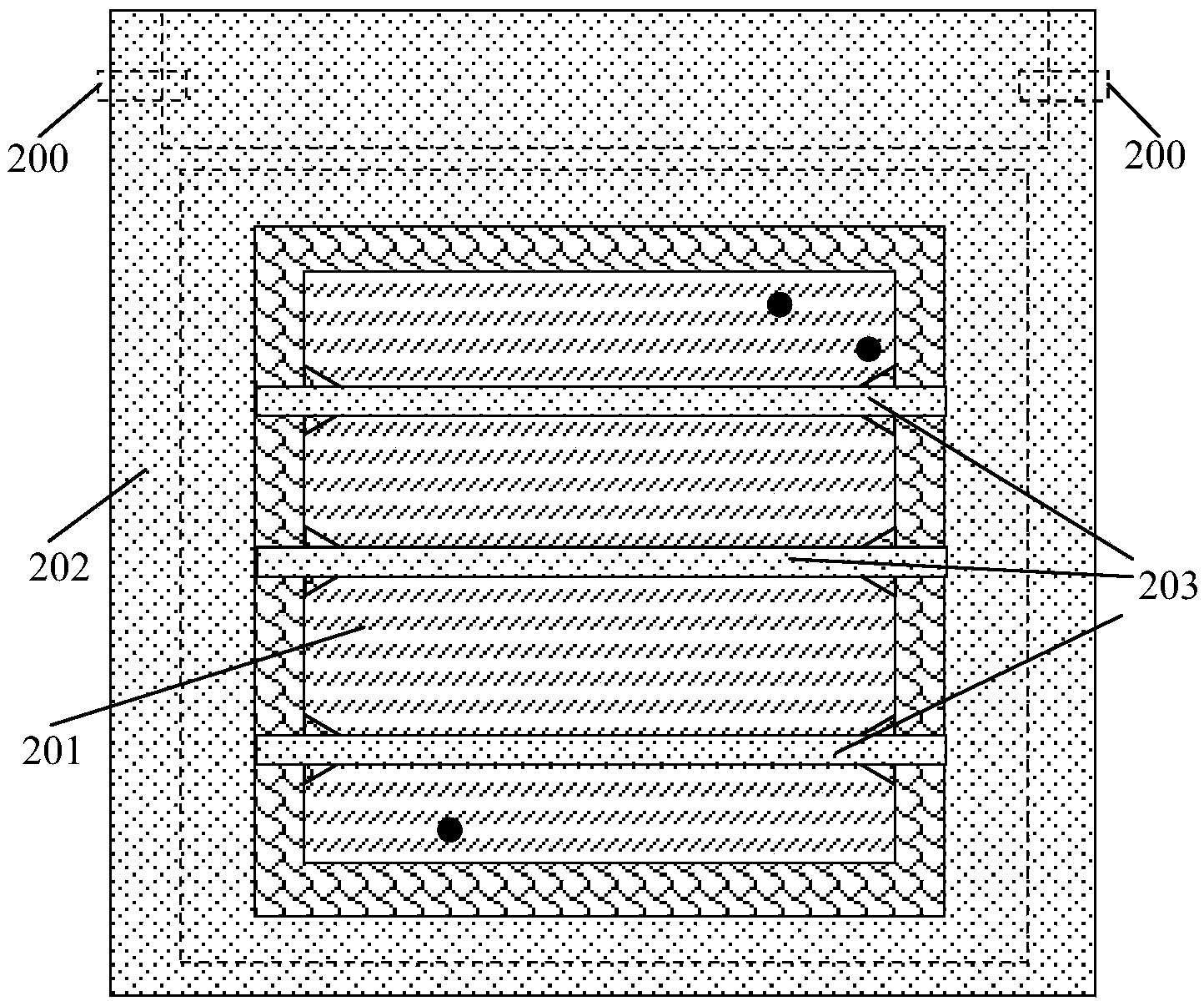

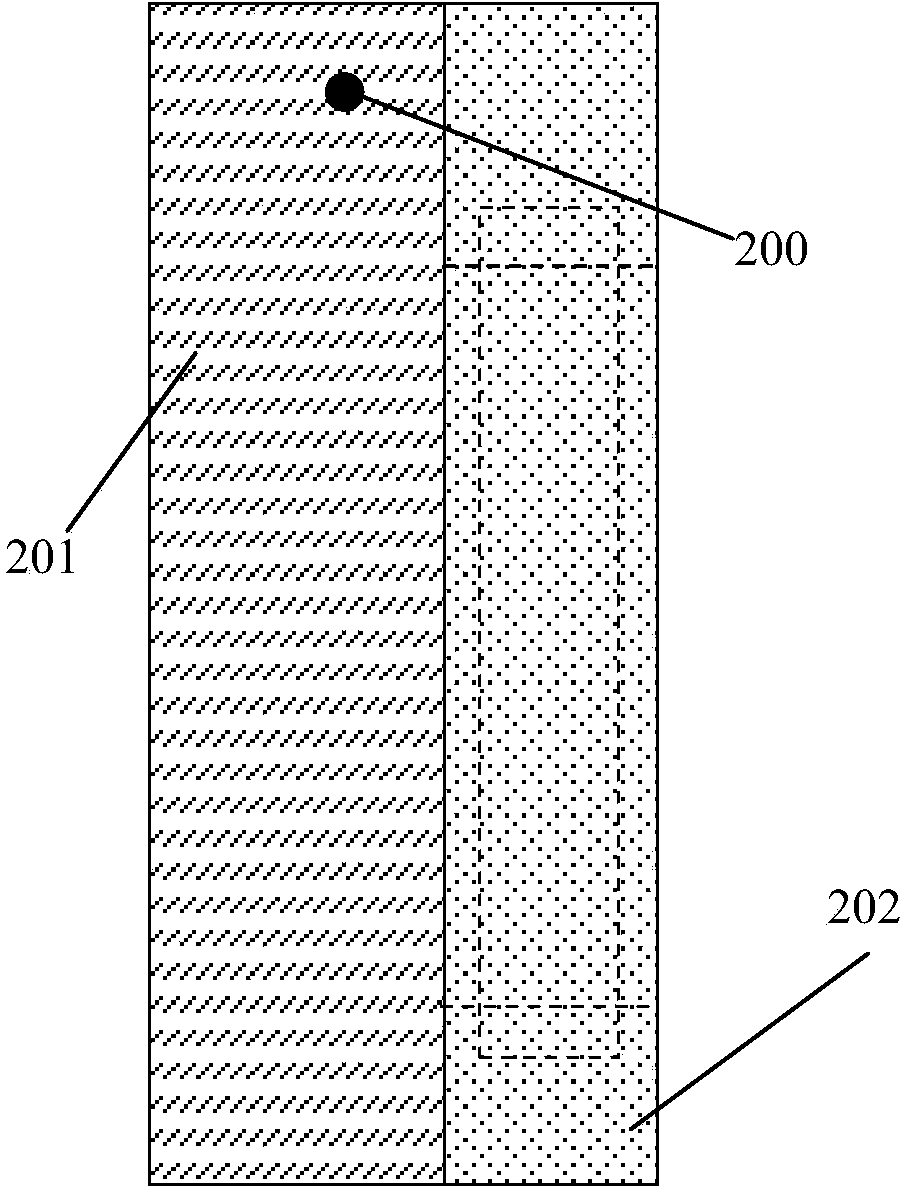

[0037] figure 2 , image 3 Shown is the solar cell busbar mask plate of the present invention. The busbar mask plate of the solar cell of the present invention is composed of an embolus 200 , a bottom plate 201 , a cover plate 202 and a mask strip 203 . The solar cell main grid mask plate is installed in a horizontal manner. The base plate 201 is arranged below, the cover plate 202 is placed on the base plate 201, and the plug 200 connects and fixes the base plate 201 and the cover plate 202 to form a loose-leaf hinge structure that can be opened and closed freely. The masking strips 203 are arranged in the middle area on the cover plate 202 , and the number of the masking strips 203 is the same as the number of busbars that need to be masked in the solar cell. figure 2 , image 3 The shown embodiment is used to realize the triple busbar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com