Connector and connection method of graphite composite grounding bodies

A technology of composite grounding and connection method, applied in the field of power system, can solve the problems of inapplicability of electric welding, gas welding and exothermic welding, and achieve the effect of meeting the actual grounding construction requirements, low connection resistance and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

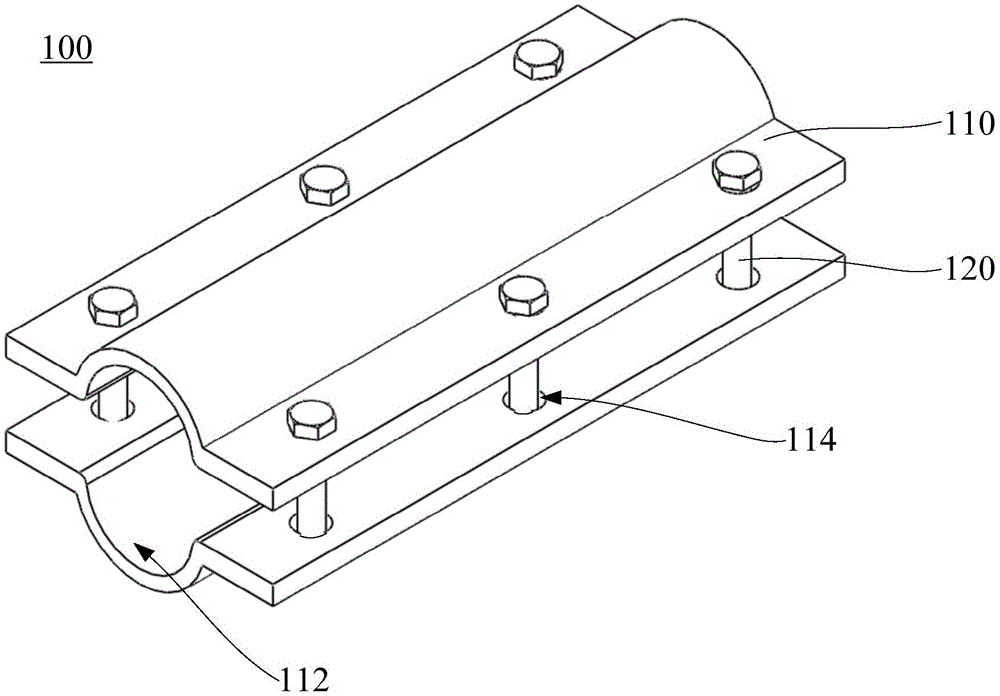

[0027] The connector 100 of the graphite composite grounding body of the first embodiment includes a conductive splint 110 , a bolt 120 , a nut (not shown in the figure) and a washer (not shown in the figure). The graphite composite grounding body of this embodiment can be used to connect graphite composite grounding materials with a diameter of 28mm, such as the connection of flexible graphite composite grounding materials disclosed in the patent CN203521649U "New Graphite Composite Grounding Material".

[0028] There are two conductive splints 110 . The length of the two conductive splints 110 is 150mm, the width is 70mm, and the thickness is 5mm. The middle parts of the two conductive splints 110 are provided with arc-shaped arches 112 . The interior of the arch 112 forms a slot for accommodating the graphite composite grounding body. The diameter of the arch 112 is consistent with the diameter of the graphite composite grounding body to be connected, which is also 28mm. ...

Embodiment 2

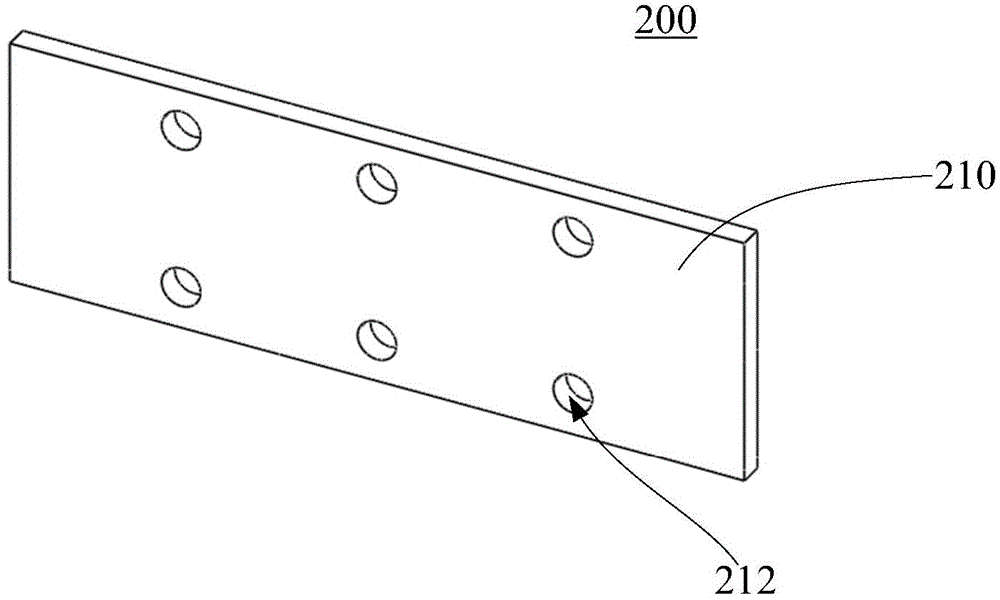

[0031] The connector 200 of the graphite composite grounding body of the second embodiment includes a conductive splint 210 , bolts (not shown), nuts (not shown) and washers (not shown). The graphite composite grounding body of this embodiment can be used to connect low-skin effect graphite composite grounding materials with a diameter of 40mm, such as the connection of low skin effect graphite composite grounding materials disclosed in the patent CN203521648U "Low Skin Effect Graphite Composite Grounding Material".

[0032] There are two conductive splints 210 . The conductive splint 210 is a flat structure. The length of the two conductive splints 210 is 150mm, the width is 70mm, and the thickness is 5mm. Three pairs of fixing holes 212 are provided on two sides of each conductive clip 210 . The diameter of each fixing hole 212 is 10.2mm.

[0033] The conductive splint 210 is made of stainless steel. Bolts, nuts and gaskets are made of fiberglass. There can be two nuts,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com