Anti-aging air-sterilization filter core

An air sterilization and anti-aging technology, which is applied in the direction of gasification substances, chemical instruments and methods, semi-permeable membrane separation, etc. Excellent steam sterilization performance, improved microbial retention rate, and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

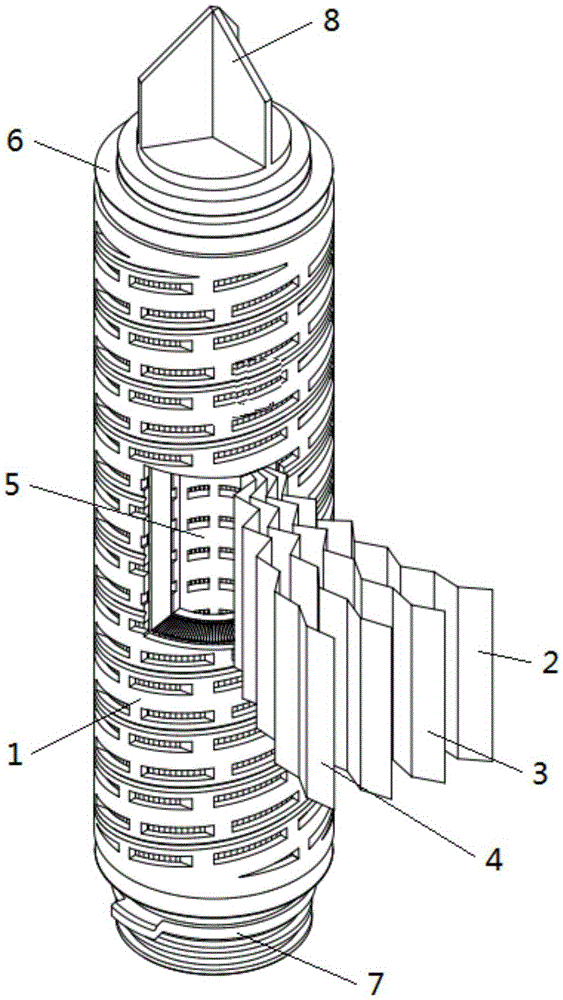

[0027] An anti-aging air sterilization filter element, such as figure 1 As shown, the filter element is composed of filter membrane 3, support layer 4, diversion layer 2, outer frame 1, end cap 6, center column 5, interface 7 and fins 8, diversion layer 2, filter membrane 3 and support layer 4 The W-shaped folding method is adopted, and the edges are sealed by hot melting, forming a whole barrel body, which is installed between the outer frame 1 and the central column 5, and the end faces are sealed by hot melting with end caps 6, and finally the joints are welded on both ends 7 and fins 8 form a complete filter element.

[0028] In this embodiment, the outer frame and the central column use polypropylene material with a glass fiber content of 25 wt% and an antioxidant content of 0.5 wt%. The thickness of the central column is 5mm, and the pressure resistance is >0.6MPa at 20°C. The end cap is made of pure polypropylene resin with a melting temperature of 164°C and an isotac...

Embodiment 2

[0031] The difference from Example 1 is that the outer frame and central column use polypropylene material with a glass fiber content of 28wt% and an antioxidant content of 0.5wt%. The thickness of the central column is 5.3mm, and the pressure resistance at 20°C is >0.6MPa. The end cap is made of pure polypropylene resin with a melting temperature of 166°C and an isotactic structure polypropylene content of 95.5wt%. Such a polypropylene end cap has good fluidity and is easy to seal the end face of the filter element. The penetration depth of the end cap is 1.1mm, and the filter membrane is completely wrapped by the slurry after melting the polypropylene. The filter element uses a PTFE membrane with a thickness of 50 μm, which passes through 10 7 CFU / cm 2 The ATCC19146 Liquid Bacteria Challenge, Downstream Liquid Sterility. Both the diversion layer and the support layer are made of 100wt% polyphenylene sulfide (PPS), and the weight is 100g / m 2 .

[0032] The filter element...

Embodiment 3

[0034] The difference from Example 1 is that the outer frame and central column use polypropylene material with a glass fiber content of 30wt% and an antioxidant content of 0.5wt%. The thickness of the central column is 5.5mm, and the pressure resistance at 20°C is >0.6MPa. The end cap is made of pure polypropylene resin with a melting temperature of 167°C and an isotactic structure polypropylene content of 96wt%. Such a polypropylene end cap has good fluidity and is easy to seal the end face of the filter element. The penetration depth of the end cap is 1.2mm, and the filter membrane is completely wrapped by the slurry after melting the polypropylene. The filter element uses a PTFE membrane with a thickness of 60 μm, which passes through 10 7 CFU / cm 2 The ATCC19146 Liquid Bacteria Challenge, Downstream Liquid Sterility. Both the diversion layer and the support layer are made of 100wt% polyphenylene sulfide (PPS), and the weight is 120g / m 2 .

[0035]The filter element of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com