S-shaped through type solar thermal-collecting tube

A solar heat collection tube and through-type technology, which is applied in the field of solar energy utilization, can solve the problems of differences in expansion coefficients, etc., and achieve the effects of improving thermal energy utilization, efficient utilization and protection of the ecological environment, and not easy to scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

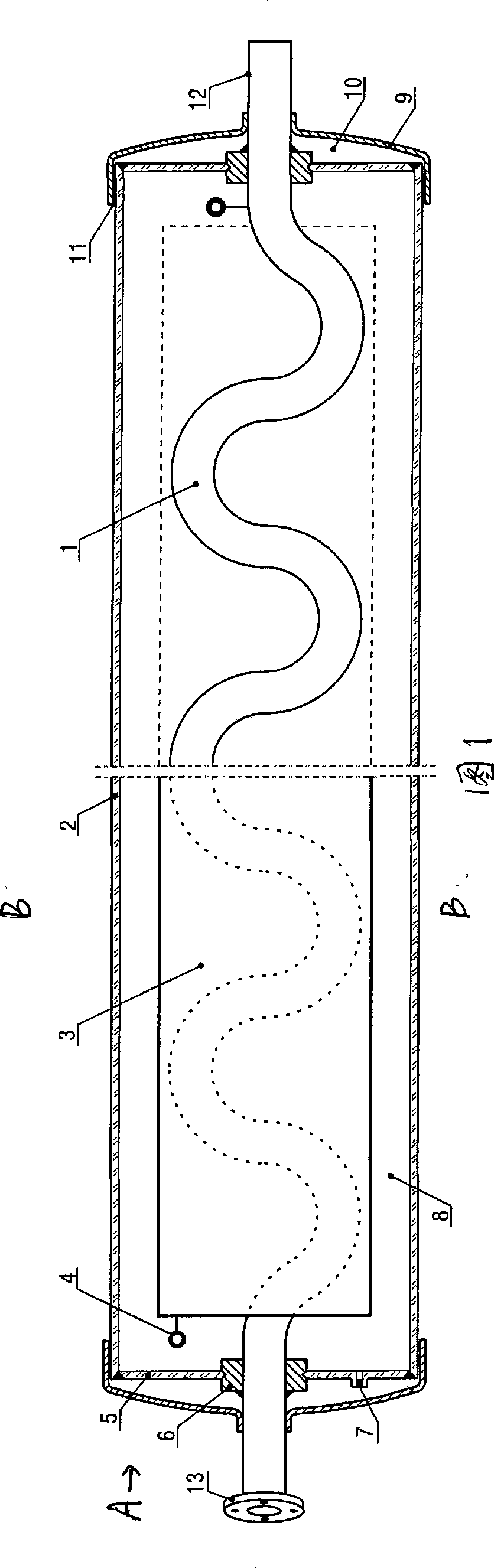

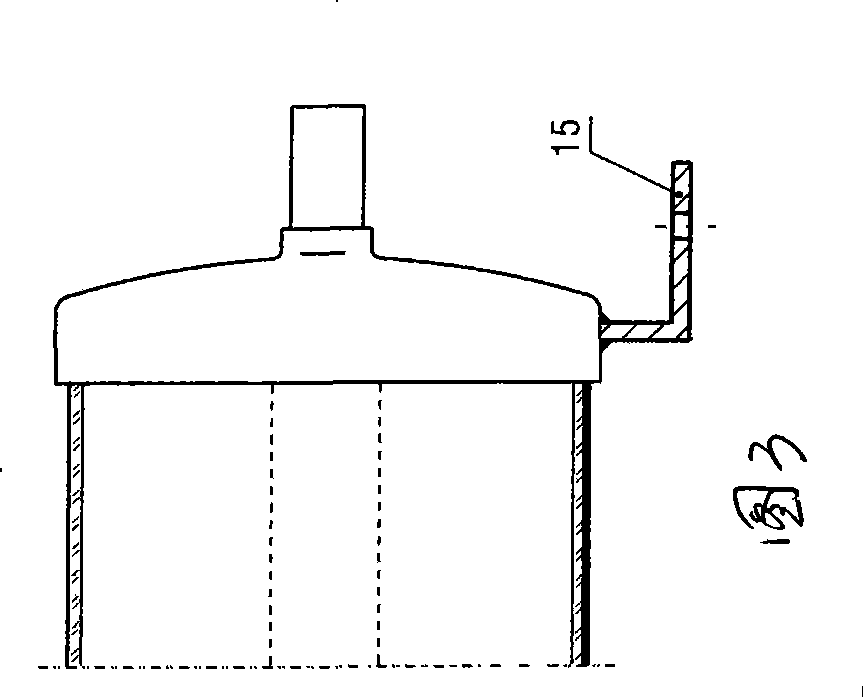

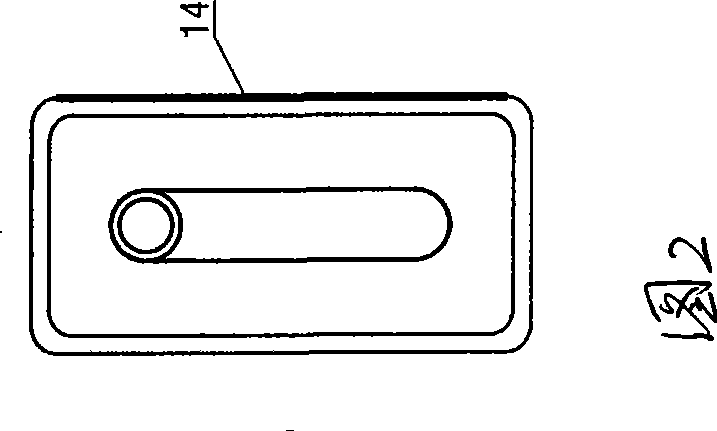

[0024] The present invention will be described in detail below in conjunction with accompanying drawing: Fig. 1,2, shown in 3, the present invention is made up of inner metal tube 1, outer glass tube 2, glass end cap 5, alloy material 6 and metal cover 9. The inner metal tube 1 is an S-shaped curved metal tube; the two ends of the outer glass tube 2 are at least sealed with glass end caps 5 to form a vacuum between the inner and outer tubes.

[0025] The middle of the glass end cap 5 is pressed or fused with an alloy material 6, which is a conventional material; the inner metal tube 1 protrudes from the alloy material 6, and the alloy material 6 and the inner metal tube 1 welding and sealing; the glass end cap 5 is fixedly connected with the outer glass tube 2 by welding or bonding.

[0026] The outermost sides of the two ends of the outer glass tube 2 are provided with a metal cover 9 filled with heat insulating material 10 , and the outer glass tube 2 and the metal cover 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com