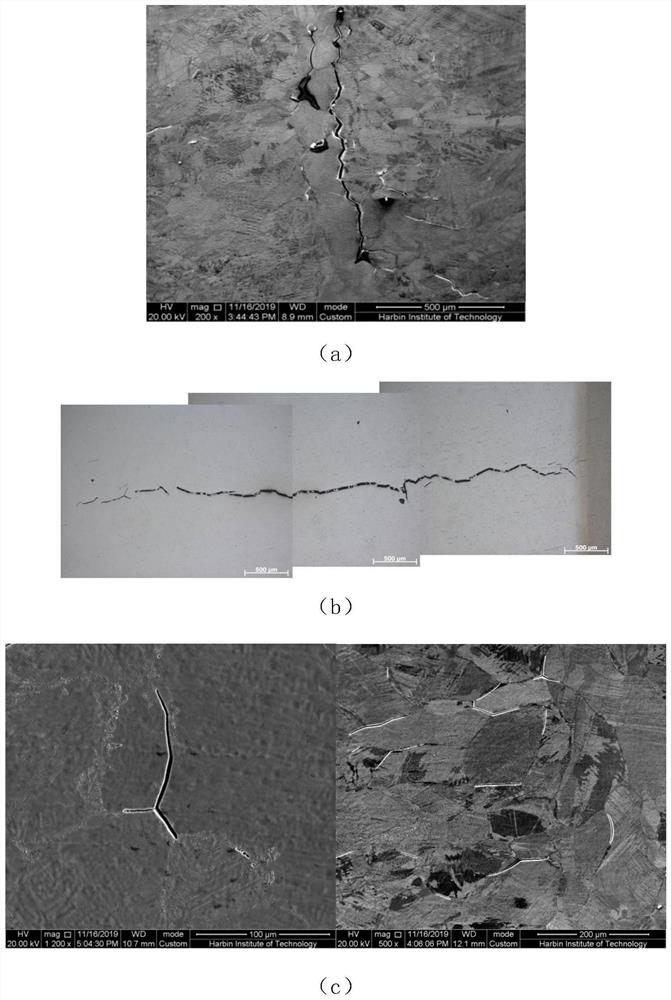

Electron beam weld joint micro-crack control method for Ti2AlNb material

A technology of electron beam welding seam and control method, which is applied in electron beam welding equipment, welding equipment, manufacturing tools, etc., can solve the problem of cracks that cannot be welded, and achieves high machining cost, expanded application scope, and reliable electron beam welding seam. effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

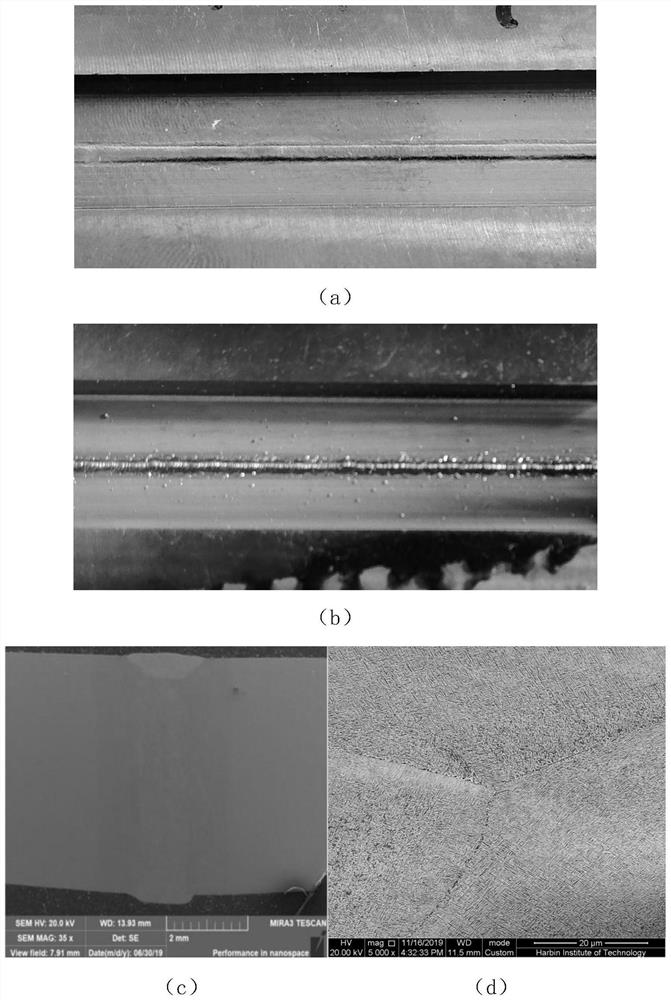

Embodiment 1

[0032] The object of welding in this embodiment is two Ti 2 For parts of AlNb material, the welding surface is flat. The welding process steps are as follows:

[0033] Step 1: Weld cleaning

[0034] Clean Ti with a scraper or wire wheel 2 AlNb welding surface and joint surface, expose the fresh surface, and then use a white cloth to dip alcohol or acetone to clean the welding joint to ensure that there is no dirt, impurities or other oxides. After cleaning, the weld should be welded within 120 hours.

[0035] Step 2: Soldering Assembly

[0036] For Ti to be welded 2 AlNb parts are welded and assembled to ensure that the maximum fit gap of the weld seam is ≤0.1m and the maximum misalignment is ≤0.5mn.

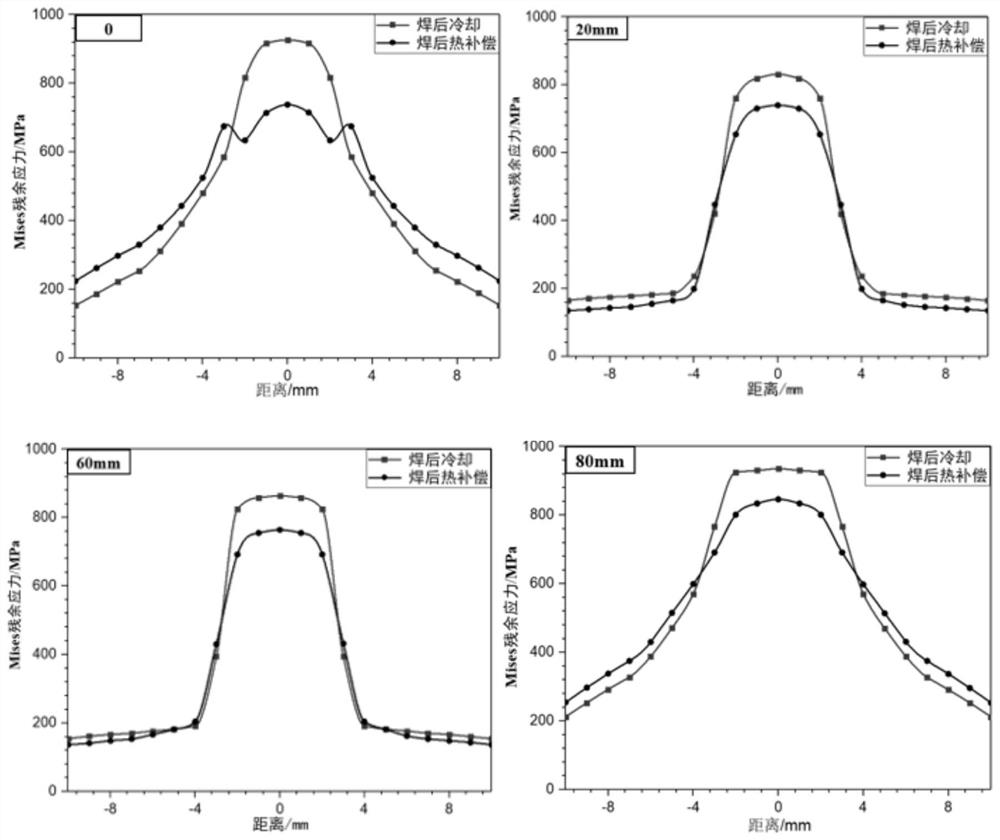

[0037] Step 3: Weld Preheating

[0038] The electron beam defocusing method is used to scan and preheat the electron beam weld. The parameters are shown in Table 1. The temperature before welding is increased, and the temperature gradient and stress during the weld heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com