Current extraction device for aluminium base flexible conductive backboard

A conductive backplane, aluminum-based flexible technology, applied in the field of solar cells, can solve the problems of inability to weld on the surface of aluminum foil, reduce the manufacturing cost of solar back contact components, reduce the manufacturing cost of solar back contact components, etc., so as to improve market competitiveness, The effect of convenient implementation and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

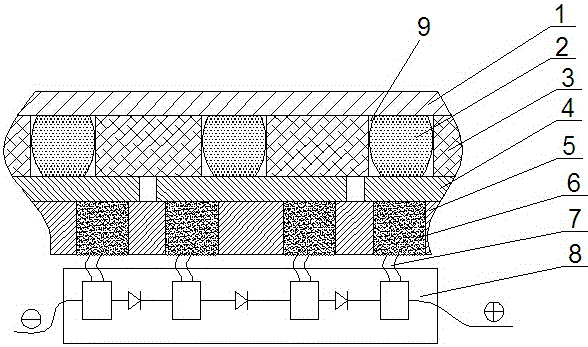

[0015] Such as figure 1 Shown is a specific embodiment of the present invention, including a solar cell sheet layer 1, an insulating adhesive film layer 3, an aluminum foil conductive layer 4 and a solar cell backplane film layer 5 that are sequentially laminated in a high-temperature vacuum pressurized manner. A plurality of conductive through holes 9 are provided on the insulating adhesive film layer 3, and conductive silver glue 2 is injected into each conductive through hole 9, and the conductive silver glue 2 conducts the current generated by the solar cell layer 1 to the aluminum foil conductive layer 4. The film layer 5 of the back plate of the solar cell is provided with a number of receiving through holes, and in each of the receiving through holes, electrode lead-out clusters 6 with a rough surface are deposited by supersonic cold spraying tec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com