Method and system for regulating feeding wire speed

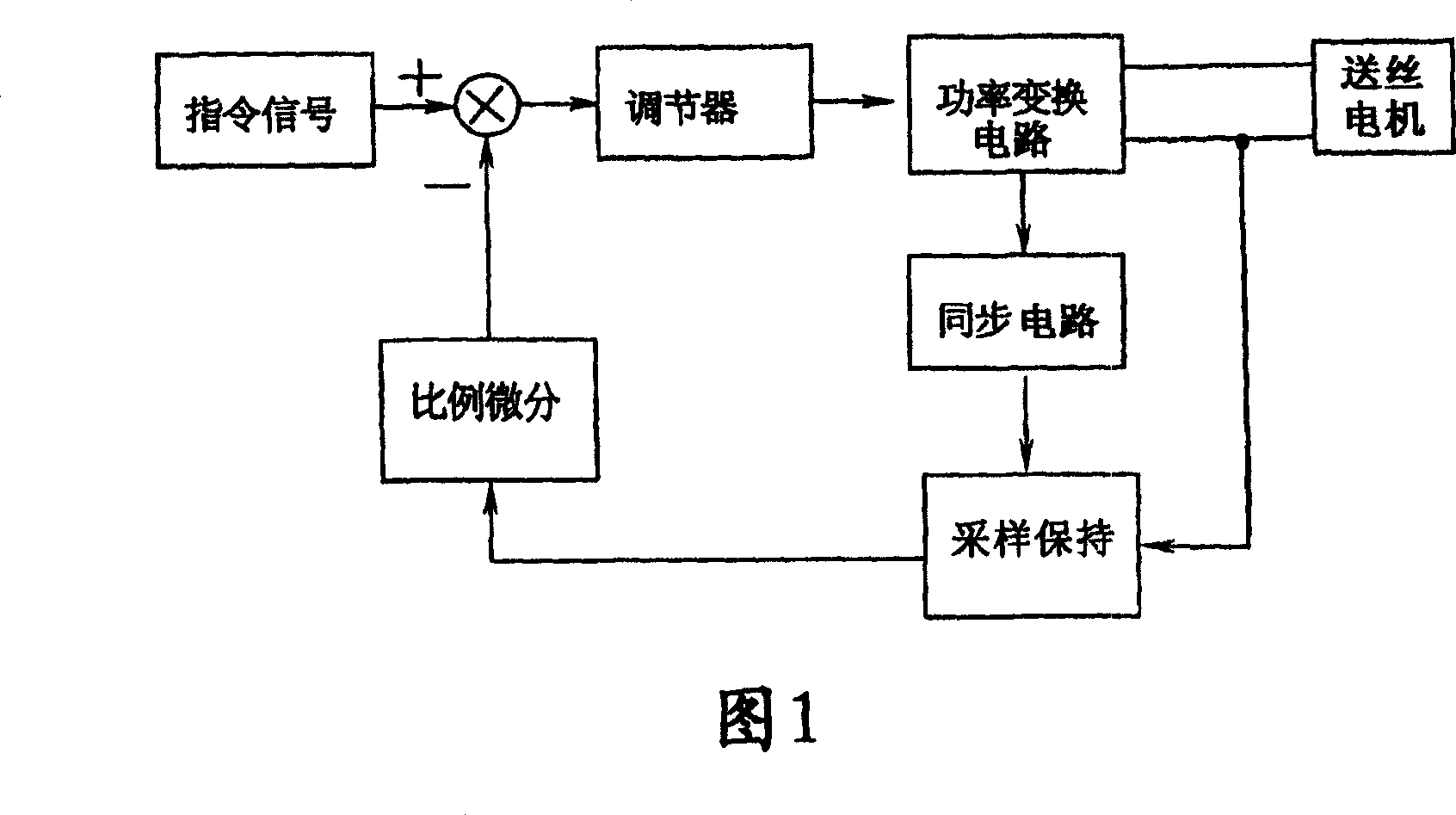

A technology for speed regulation system and wire feeding, which is applied in the direction of control system, DC motor speed/torque control, excitation or armature current control, etc. Accurate sampling of electromotive force and other issues to achieve the effect of stable rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

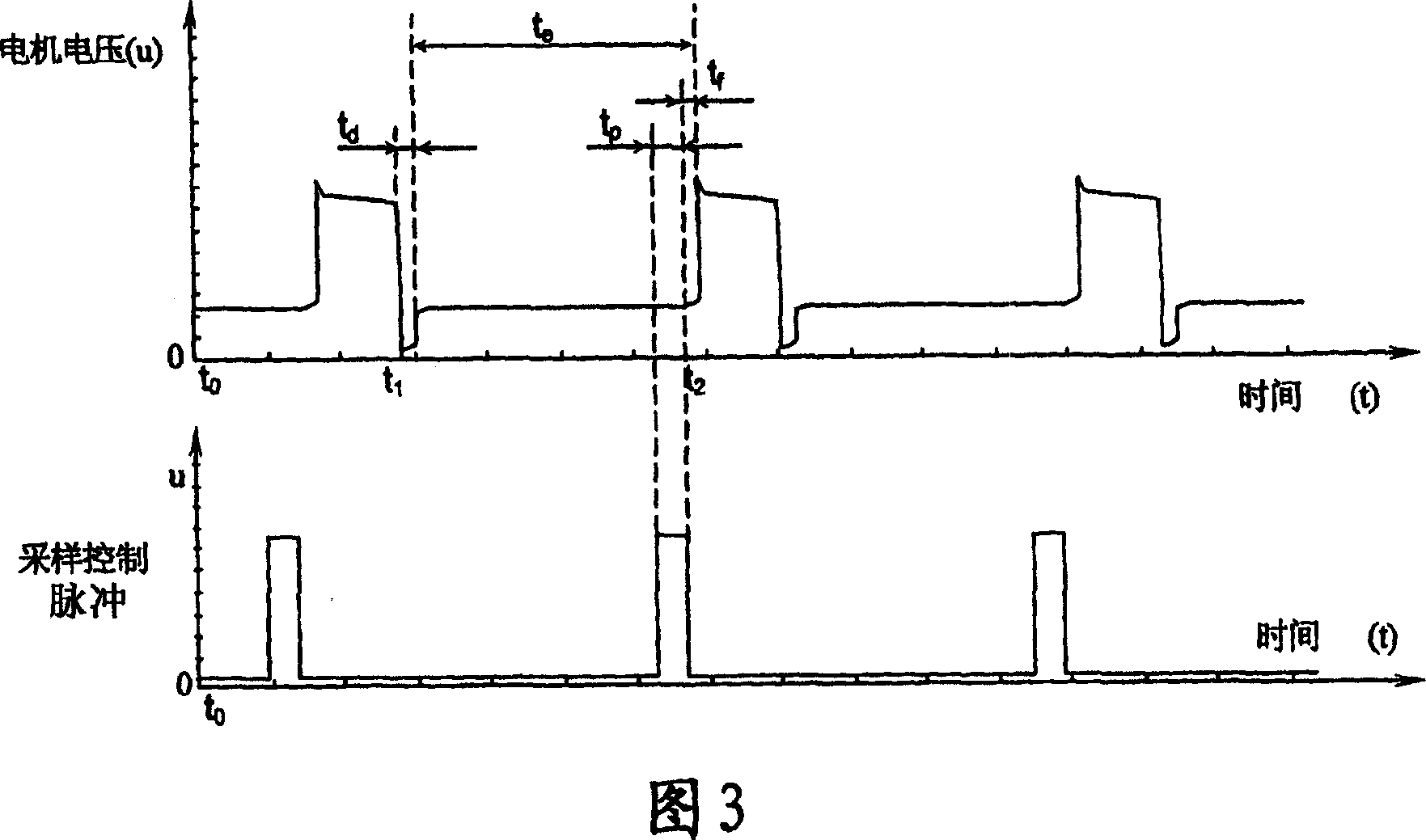

[0020] Firstly, the wire feeding sampling method of the present invention will be described with reference to the time sequence of the induction electromotive force feedback sampling control of the speed control of the wire feeding motor in FIG. 3 .

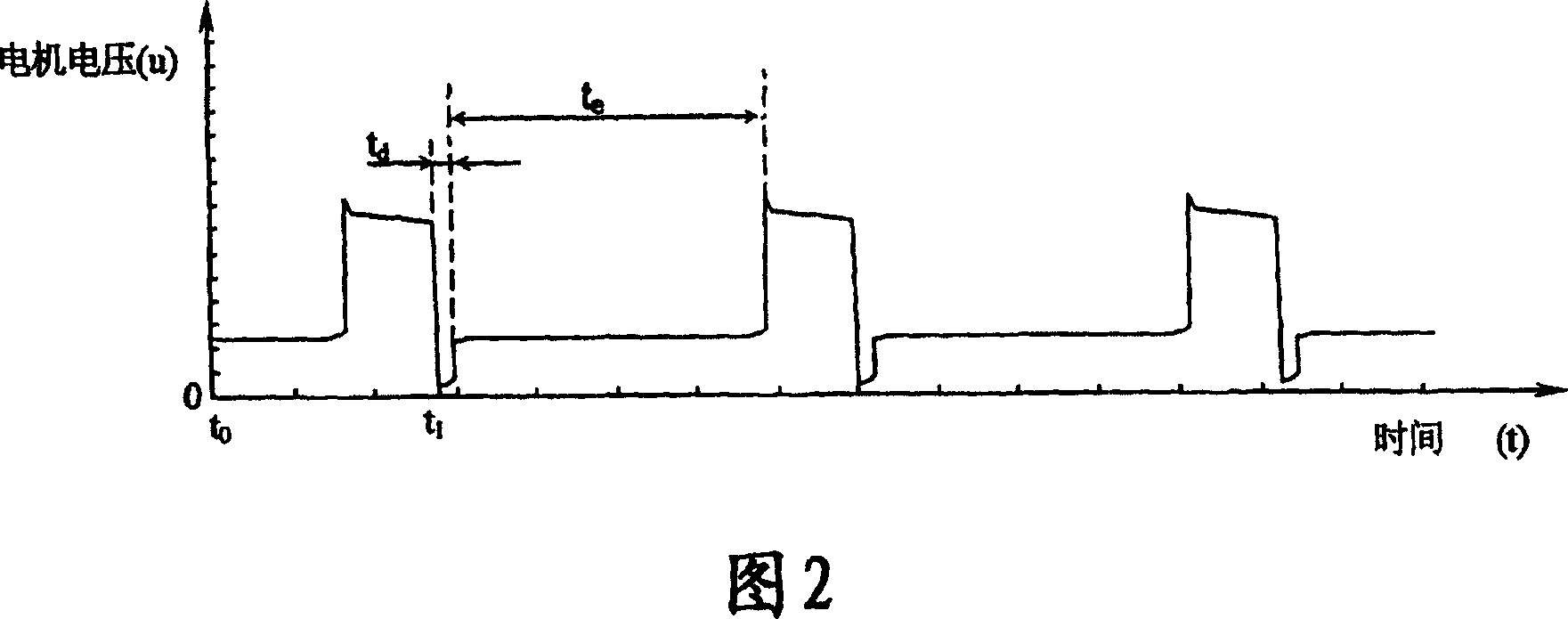

[0021] When the wire-feeding motor is working, an induced electromotive force will be generated when the power supply is cut off, and the induced electromotive force of the wire-feeding motor has a linear relationship with its speed. Therefore, accurate sampling of the induced electromotive force of the motor can accurately reflect the rotational speed of the motor. The voltage waveform at both ends of the wire feeding motor is shown in Figure 2. There is a t in the wire feed motor voltage waveform d and t e period. t d The time period is the release time of the energy stored in the armature winding of the wire-feeding motor. During this time period, the voltage at both ends of the wire-feeding motor is close to zero. During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com