Calculation method of grinding force on spherical base surface of tapered roller

A technology of tapered roller and calculation method, which is applied to the parts, calculation, grinding/polishing equipment of grinding machine tools, etc., can solve the lack of understanding of grinding principle, affect the machining accuracy of the ball base surface of tapered roller, and cannot effectively establish Problems of Calculation Method of Grinding Force of Tapered Roller Ball Base Surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The calculation method of the grinding force of the tapered roller ball base surface of the present invention comprises the following steps:

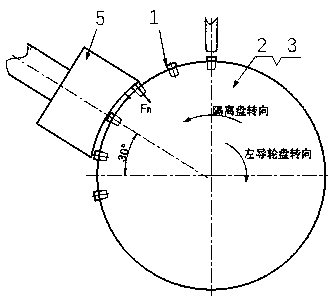

[0077] Step 1. When grinding the base surface of the tapered roller, set the tapered roller to be in rigid contact with the two guide wheels. The tapered roller and the two guide wheels have no slippage and the rotation speed is stable. The speed of the isolation disc is equal to that of the two guide wheels. One-half of the disc rotation speed difference, the tapered roller rotation linear speed is equal to the difference between the right guide wheel disc linear speed and the isolation disc linear speed;

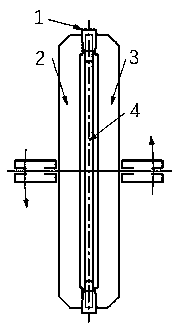

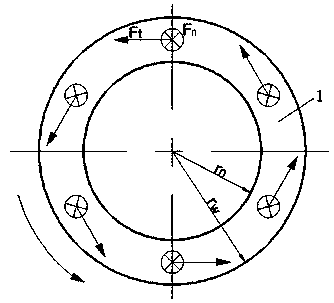

[0078] Step two, such as image 3 As shown, according to the processing principle of the tapered roller 1 spherical base surface, the grinding of the tapered roller spherical base surface adopts the concave spherical surface forming grinding wheel with the same curvature radius, and the grinding force during the grinding of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com