Method and system for automatically compensating torque

A torque compensation and automatic compensation technology, applied in the control system, vector control system, motor generator control and other directions, can solve the problem of rotation speed fluctuation, achieve the effect of stable rotation speed and prevent vibration and noise problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

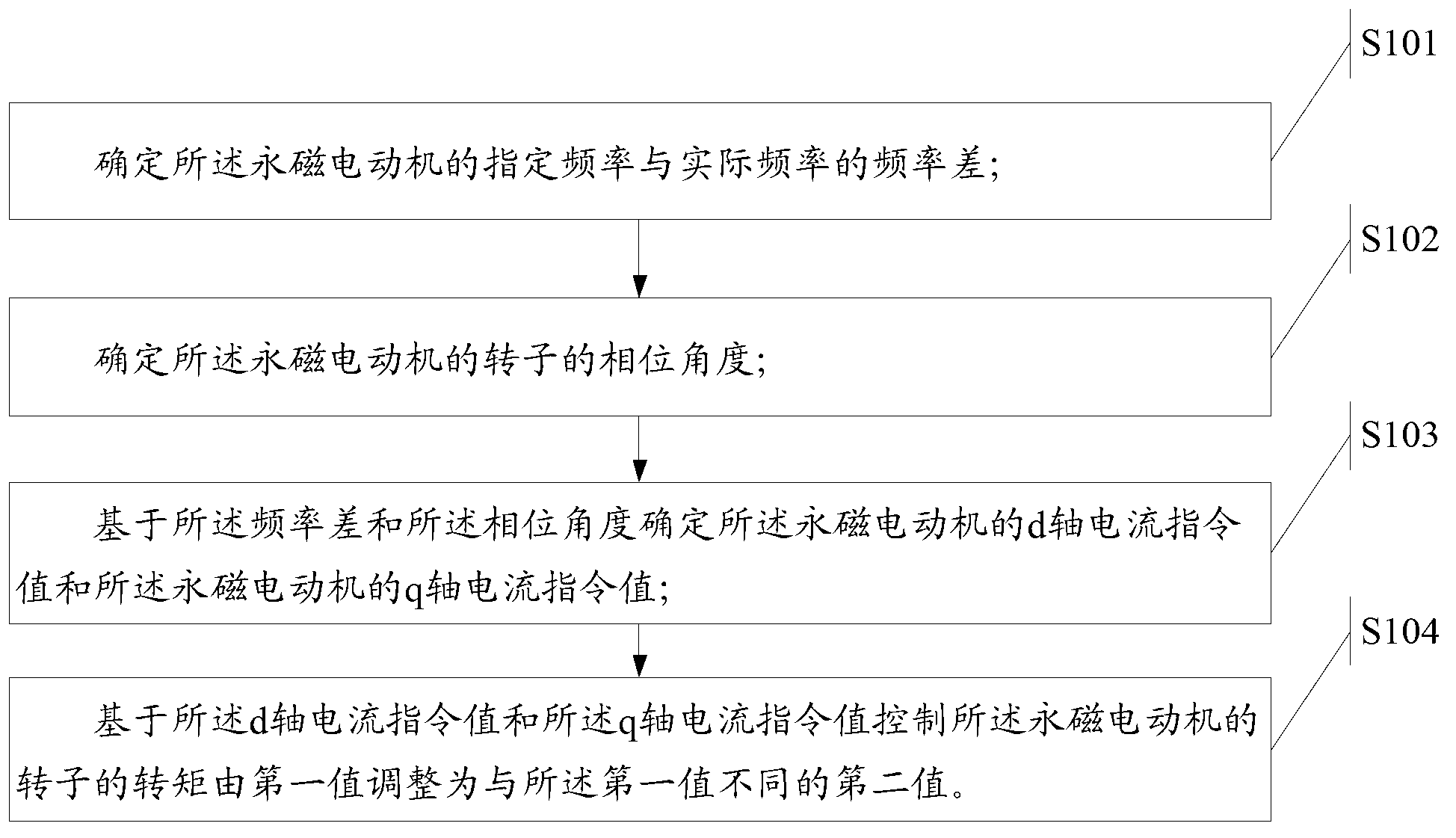

[0051] Embodiments of the present invention provide an automatic torque compensation method and an automatic torque compensation system, which are used to solve the technical problem of fluctuations in the rotational speed of a rotor of a permanent magnet motor in the prior art.

[0052] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

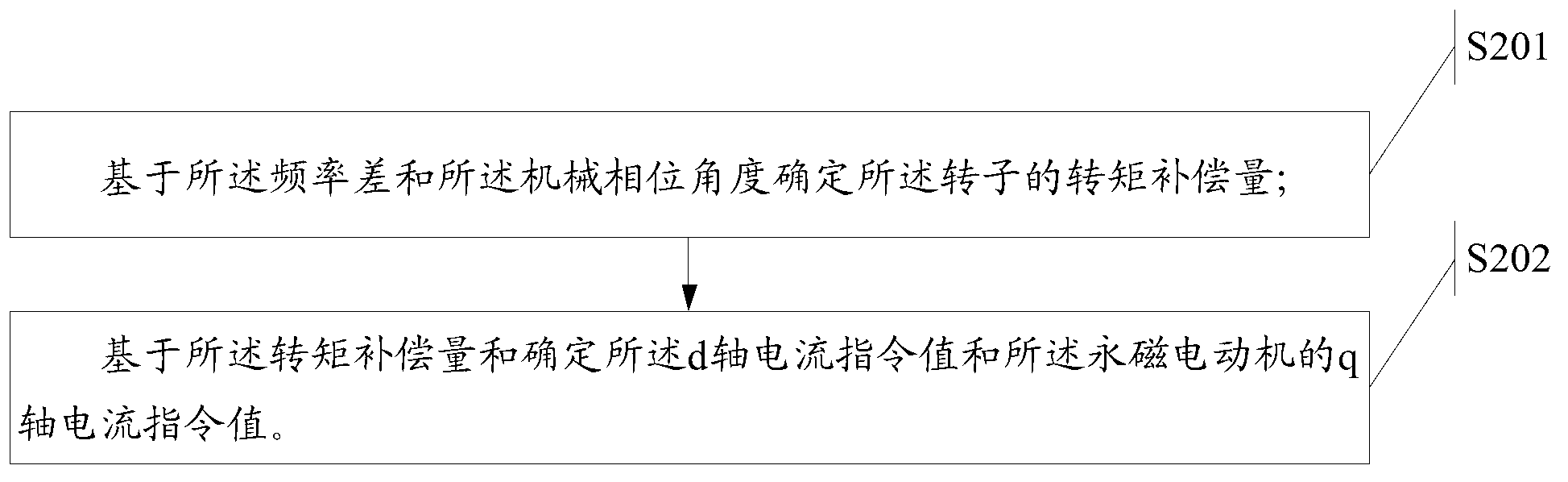

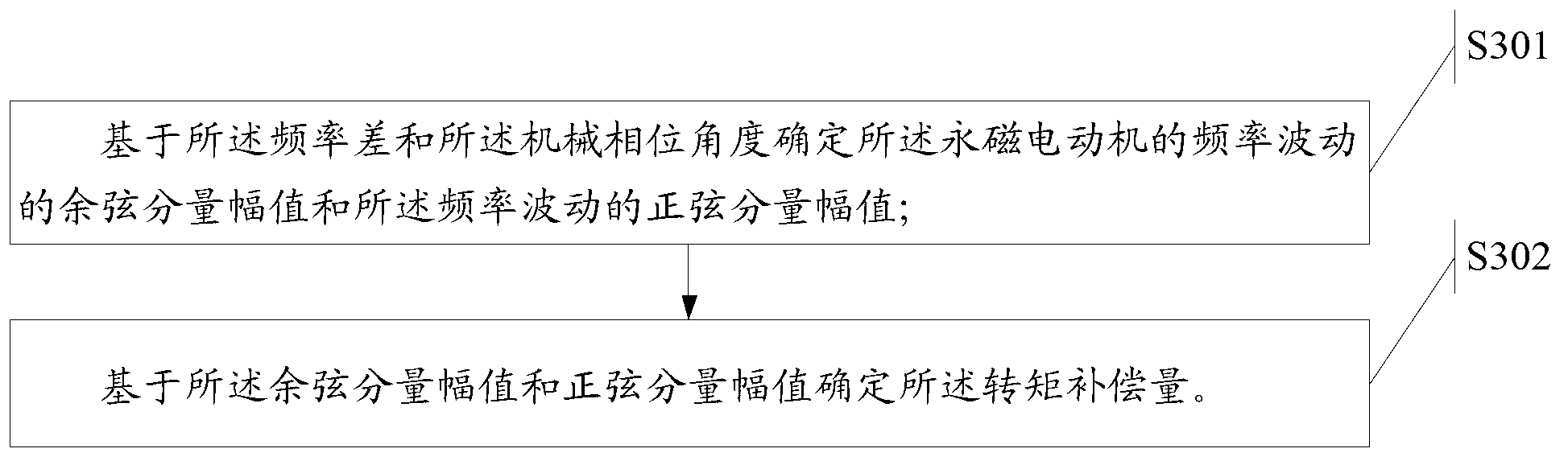

[0053] Determining the specified frequency f of the permanent magnet motor * A frequency difference Δf from an actual frequency f; determining a phase angle θ of a rotor of the permanent magnet motor; determining a d-axis current command value I of the permanent magnet motor based on the frequency difference Δf and the phase angle θ d * and the q-axis current command value of the permanent magnet motor I q * ; Based on the d-axis current command value I d * and the q-axis current command value I q * The torque controlling the rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com