Single two-way throttling capillary tube

A two-way throttling, capillary technology, applied in the direction of fluid circulation arrangement, refrigeration components, refrigerators, etc., can solve the problems of increasing the noise of the one-way valve of the welding joint and increasing the cost of materials, so as to reduce the hidden danger of leakage, reduce the welding joint, avoid the The effect of vibration noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

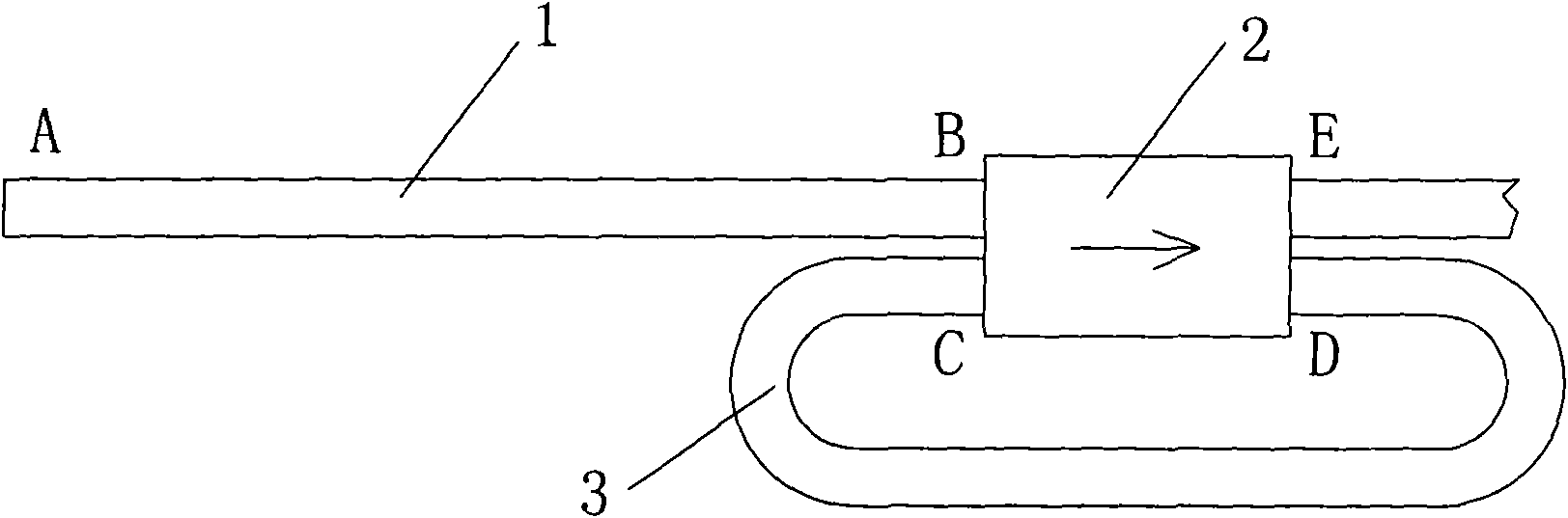

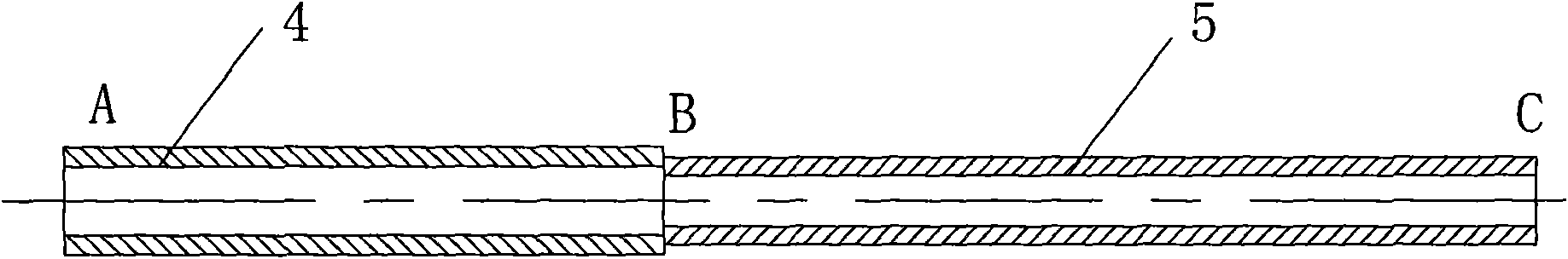

[0015] Such as figure 2 Shown, it is a kind of monomer two-way throttling capillary tube, the feature of the present invention is: comprise the capillary tube 4,5 of two section different tube inner diameters, two capillary tubes communicate with each other, the entrance A of capillary tube 4 with big tube inner diameter is for cooling when cooling The inlet of the refrigerant, the inlet C of the small capillary tube 5 is the inlet of the refrigerant during heating. It can also be capillary tubes with two or more sections of different inner diameters. Two adjacent capillary tubes are connected to each other to form a single capillary tube. When the refrigeration system is cooling, the refrigerant enters from the inlet A end with small resistance, and when heating, the refrigerant enters from the inlet C end with large resistance. Enter.

[0016] When in use, the single bidirectional throttling capillary is composed of a capillary 4 with a larger inner diameter and a capillar...

Embodiment approach 2

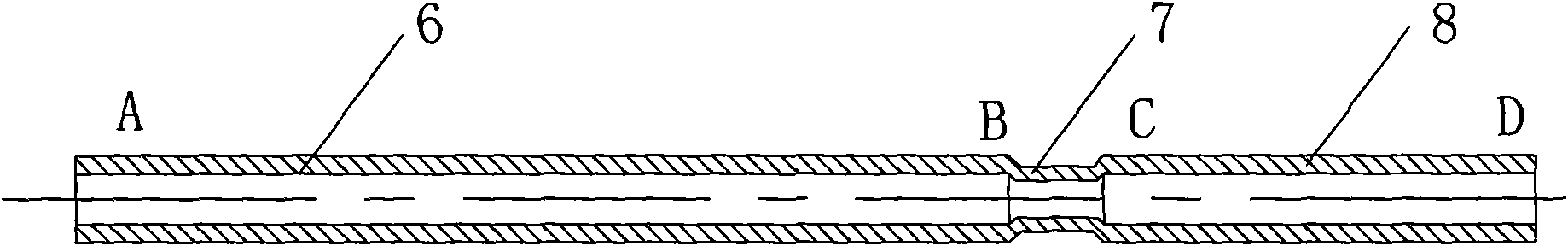

[0020] Such as image 3 As shown, the feature of a single bidirectional throttling capillary is that it includes three sections of capillaries 6, 7, and 8 with different inner diameters. The inner diameters of the capillaries 6 and 8 on both sides are different, and the lengths of the capillaries 6 and 8 on both sides are different. The inlet A of the long capillary 6 is the inlet of the refrigerant during cooling, and the inlet D of the short capillary 8 is the inlet of the refrigerant during heating.

[0021] When in use, when performing refrigeration operation, the refrigerant enters from the inlet A end of the long capillary tube 6, because the refrigerant in this section is in a liquid phase and a low dryness state, the flow rate is low, and the throttling pressure drops slowly. After being throttled by capillary tube 7 in the middle section, the dryness of refrigerant increases and the flow speed increases. It enters section 8 of capillary tube with short length and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com