Thin type flat rectilinear vibration motor

A linear vibration, flat technology, applied in electrical components, electromechanical devices, etc., can solve the problems of complex design, inconvenient replacement, poor universality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

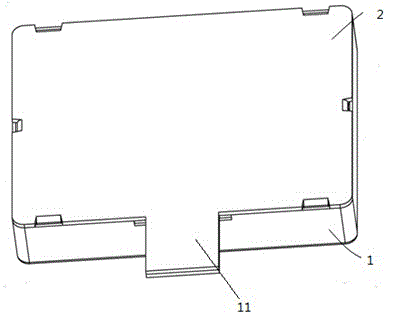

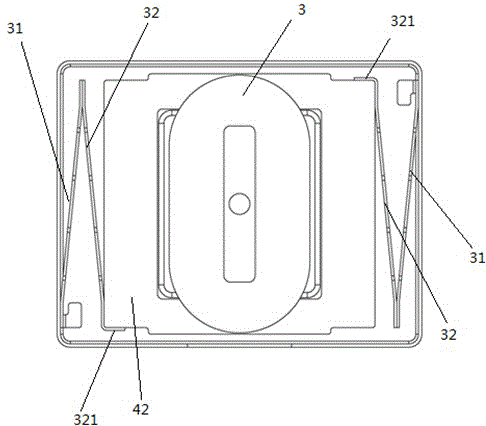

[0038] such as 1 and figure 2 As shown, this embodiment provides a vibration motor, including a casing 1 and a cover plate 2 mounted on the casing 1, the casing 1 has a bottom surface 14, and a first side wall 12 connected to the bottom surface 14 , the second side wall 13, the front wall 15 and the rear wall (not shown in the figure), the bottom surface 14 and the above-mentioned side wall of the casing 1 enclose a cavity with a specific height, and the front wall 15 is provided with The concave mounting groove 11, the cover plate 2 has an outwardly protruding cover plate protrusion 21, and the cover plate protrusion 21 is inserted into the concave mounting groove 11, so that the cover plate 2 and the The casings 1 are assembled together to form an installation space.

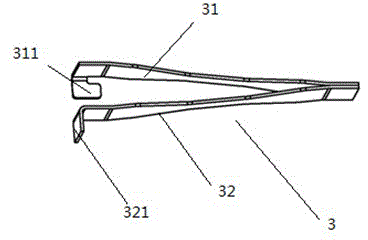

[0039] In the installation space, a vibration block 41, a permanent magnet 42, a coil 5, and an insulating support plate 6 are sequentially installed from the casing 1 toward the cover plate 2, and the vibra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com