Integrated permanent magnet speed regulating speed changer

A permanent magnet speed regulation and transmission technology, applied in electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve problems such as mechanical fatigue, friction loss, vibration noise, poor heat dissipation effect, and inability to discharge in time, to increase heat dissipation capacity, Various structural forms, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

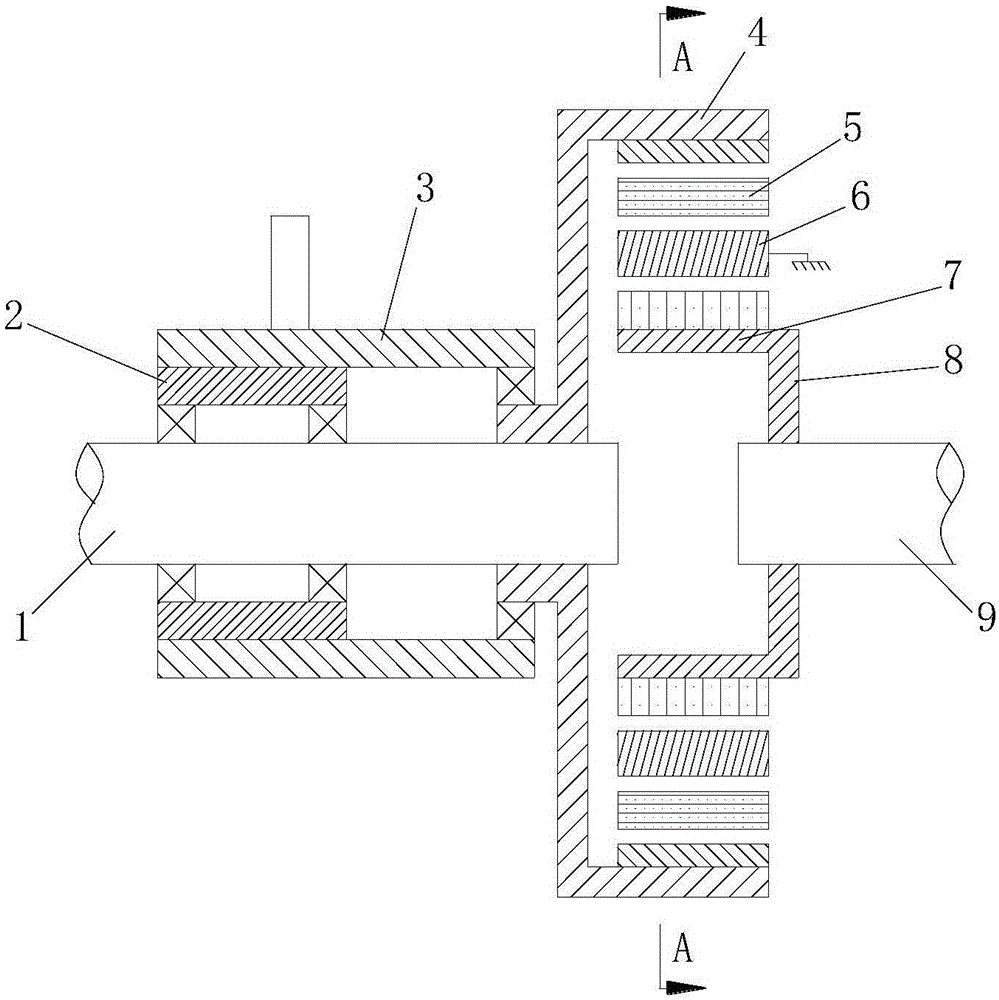

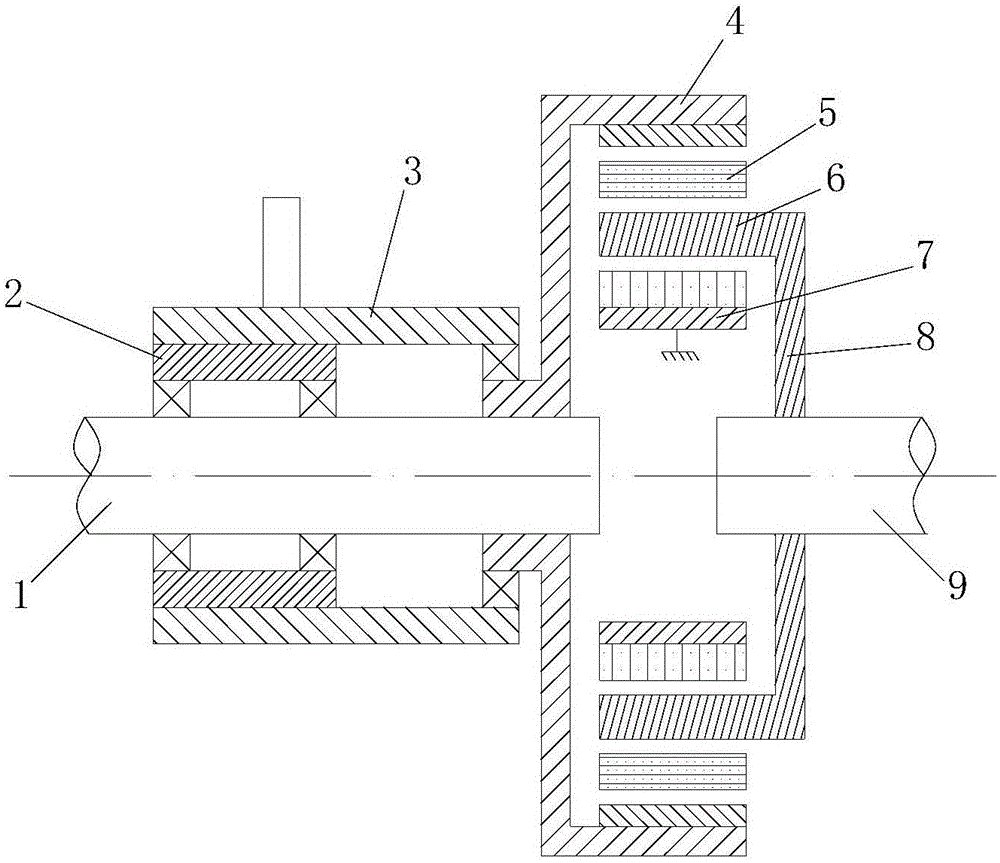

[0025] see figure 1 As shown, an integrated permanent magnet variable speed transmission includes an input shaft 1, a regulator 2, an adjusting rod 3, a conductor rotor 4, a first permanent magnet rotor 5, a modulation ring 6, a second permanent magnet rotor 7, and a flange 8. The output shaft 9 and the input shaft 1 are equipped with a conductor rotor 4 that rotates synchronously with the input shaft 1. The inner side of the conductor rotor 4 is sleeved with the first permanent magnet rotor 5, and the conductor rotor 4 drives the first permanent magnet rotor 5 to rotate through magnetic force. , the input shaft 1 is also provided with a regulator 2, the regulator 2 is connected with the conductor rotor 4 through the adjustment rod 3, by adjusting the regulator 2, the conductor rotor 4 is moved axially along the input shaft 1 to change the conductor rotor 4 and the first The relative area between the permanent magnet rotors 5, and then change the torque transmitted between the...

Embodiment 2

[0027] see figure 1As shown, an integrated permanent magnet variable speed transmission includes an input shaft 1, a regulator 2, an adjusting rod 3, a conductor rotor 4, a first permanent magnet rotor 5, a modulation ring 6, a second permanent magnet rotor 7, and a flange 8. The output shaft 9 and the input shaft 1 are equipped with a conductor rotor 4 that rotates synchronously with the input shaft 1. The inner side of the conductor rotor 4 is sleeved with the first permanent magnet rotor 5, and the conductor rotor 4 drives the first permanent magnet rotor 5 to rotate through magnetic force. , the input shaft 1 is also provided with a regulator 2, the regulator 2 is connected with the conductor rotor 4 through the adjustment rod 3, by adjusting the regulator 2, the conductor rotor 4 is moved axially along the input shaft 1 to change the conductor rotor 4 and the first The relative area between the permanent magnet rotors 5, and then change the torque transmitted between them...

Embodiment 3

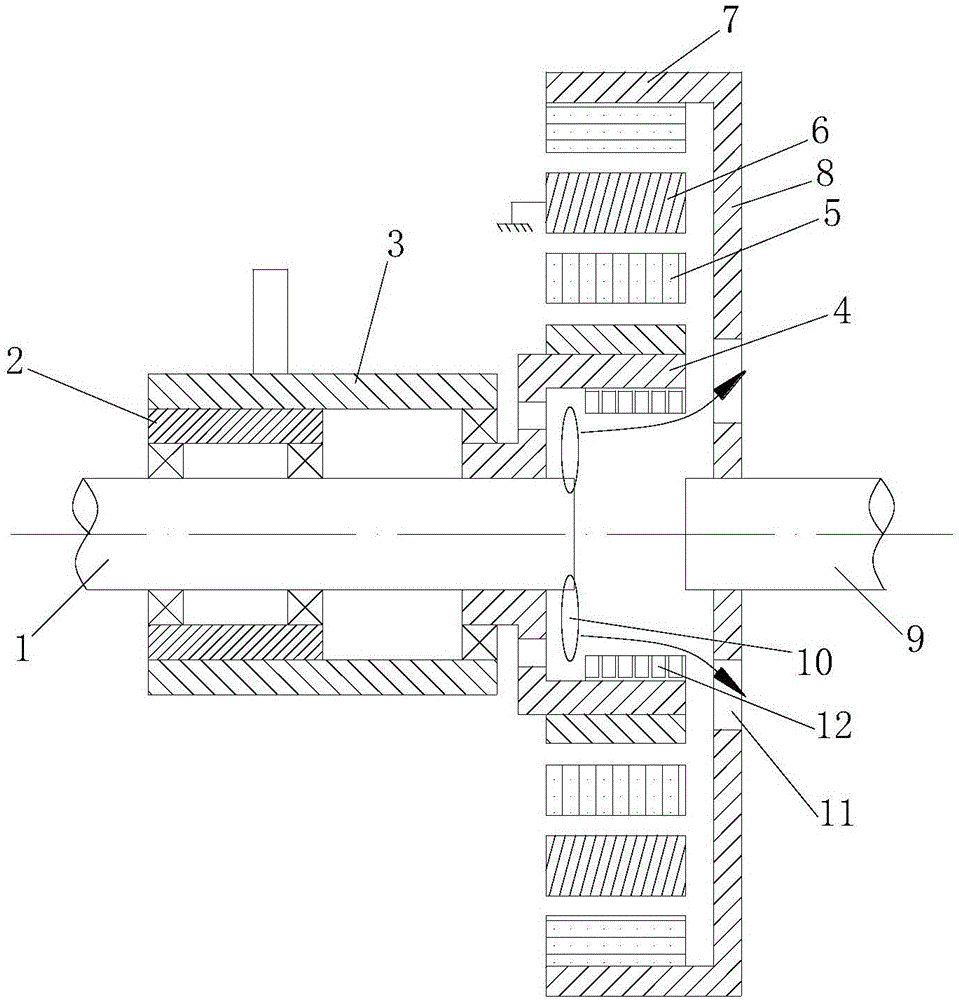

[0029] see image 3 As shown, an integrated permanent magnet variable speed transmission includes an input shaft 1, a regulator 2, an adjusting rod 3, a conductor rotor 4, a first permanent magnet rotor 5, a modulation ring 6, a second permanent magnet rotor 7, and a flange 8. The output shaft 9 and the input shaft 1 are equipped with a conductor rotor 4 that rotates synchronously with the input shaft 1. The outer side of the conductor rotor 4 is sleeved with a first permanent magnet rotor 5, and the conductor rotor 4 drives the first permanent magnet rotor 5 to rotate through magnetic force. , the input shaft 1 is also provided with a regulator 2, the regulator 2 is connected with the conductor rotor 4 through the adjustment rod 3, by adjusting the regulator 2, the conductor rotor 4 is moved axially along the input shaft 1 to change the conductor rotor 4 and the first The relative area between the permanent magnet rotors 5, and then change the torque transmitted between them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com