Peristaltic pump control system for purifying blood and method thereof

A blood purification and control system technology, applied in pump control, dialysis systems, machines/engines, etc., can solve problems such as the inability to adjust the angular velocity of the peristaltic pump, affecting the pressure and flow stability in the pump tube, and affecting the comfort of patients during treatment. , to achieve the effect of good sealing, improved life and stable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings and embodiments:

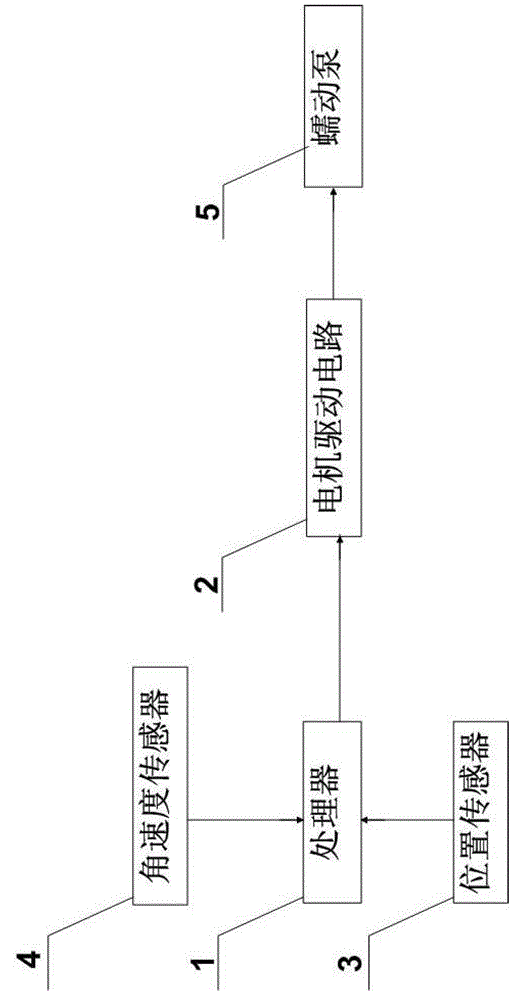

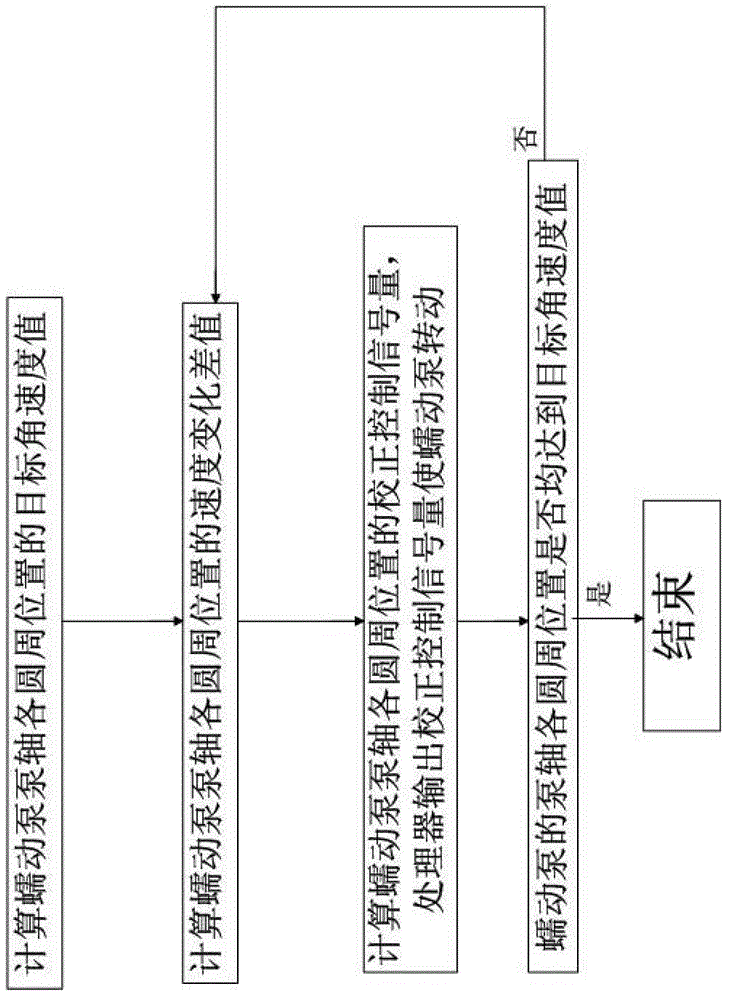

[0016] Such as figure 1 As shown, a peristaltic pump control system for blood purification includes a control circuit 1 and a motor drive circuit 2; the output end of the control circuit 1 is connected to the input end of the motor drive circuit 2; the first of the control circuit 1 The input terminal is connected to the signal output terminal of the position sensor 3; the second input terminal of the control circuit 1 is connected to the signal output terminal of the angular velocity sensor 4.

[0017] The control circuit 1 is implemented by a single-chip microcomputer. Of course, it can also be implemented by a programmable logic controller or other control circuits, which should be included in the scope of protection determined by the claims.

[0018] When in use, the position sensor 3 and the angular velocity sensor 4 transmit the detected signals to the control circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com