Vibration suppressing method and vibration suppressing device for use in machine tool

A vibration suppression and machine tool technology, which is applied in the direction of automatic control devices, feeding devices, program control, etc., can solve problems such as inability to suppress chatter, and achieve the effect of suppressing chatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Next, a vibration suppressing method and a vibration suppressing device as one embodiment of the present invention will be described in detail with reference to the drawings.

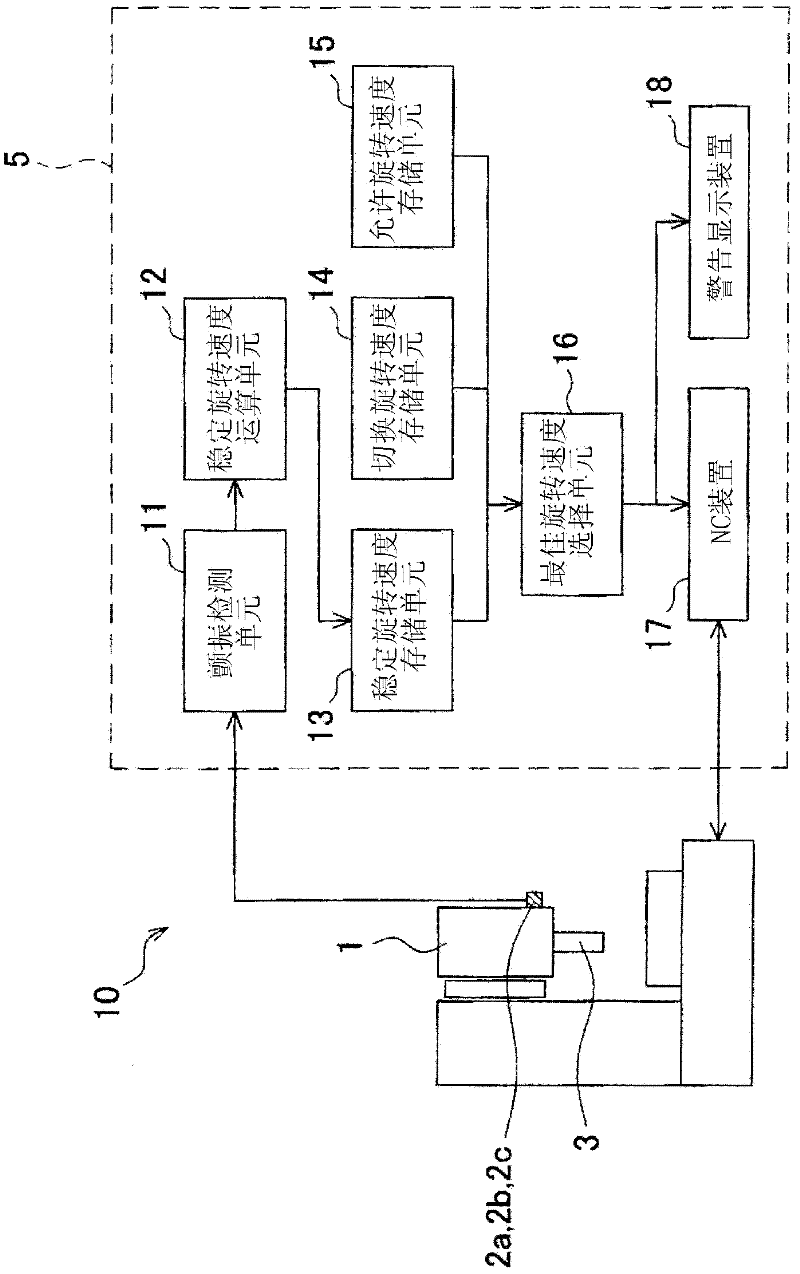

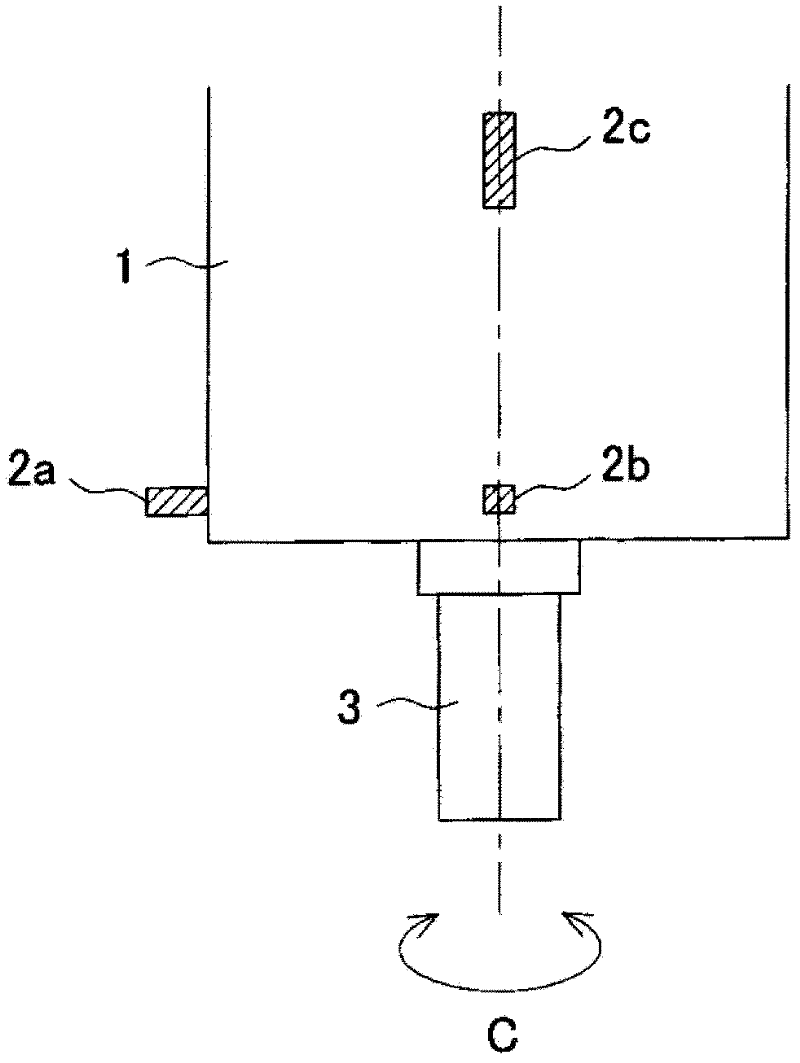

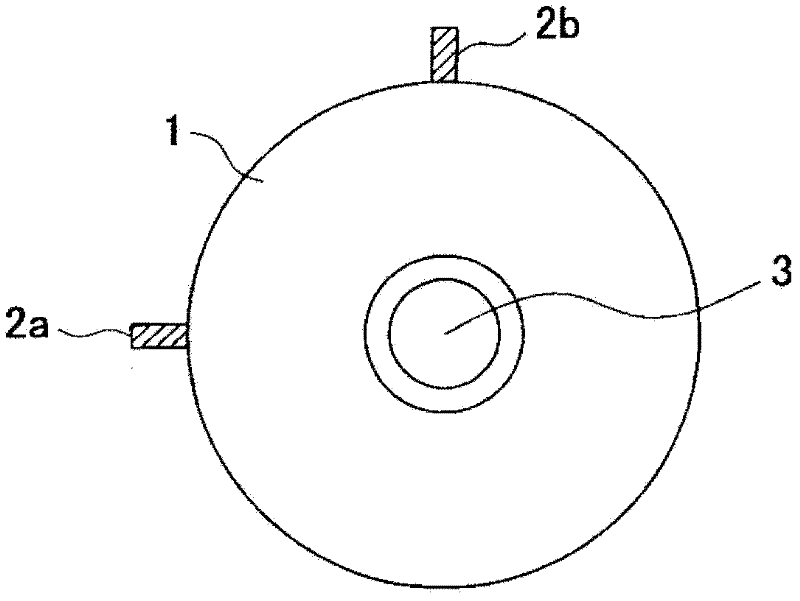

[0023] figure 1 It is an explanatory diagram showing a block configuration of the vibration suppressing device 10 . figure 2 It is an explanatory diagram showing the rotating shaft housing 1 as the object of vibration suppression from the side, image 3 It is an explanatory diagram showing the rotating shaft housing 1 from the axial direction.

[0024] The vibration suppression device 10 is used to suppress "chatter" generated by the main shaft (rotation shaft) 3, which is mounted on the main shaft housing 1 so as to be rotatable around the C-axis. The vibration suppression device 10 includes: vibration sensors 2a- 2c for detecting time-domain vibration acceleration (representing vibration acceleration on the time axis) as a characteristic value accompanying the vibration generated by the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com