Flow control valve for test of electric submersible centrifugal oil pump units

A technology for flow control valves and centrifugal pumps, which is applied in the direction of engine components, valve details, valve devices, etc., can solve the problems of difficult flow control, economic loss, and affecting the performance of electric submersible centrifugal pump units, etc., to achieve slow rotation speed and high flow rate Easy and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

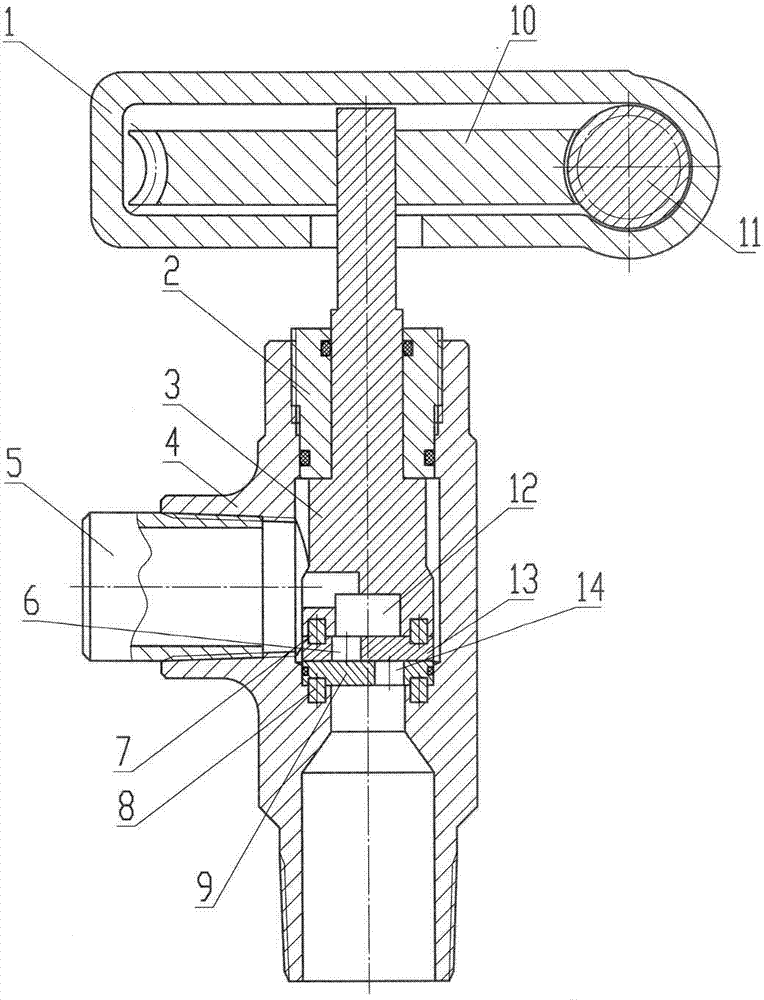

[0008] As can be seen from the figure, the embodiment of the present invention includes a wheel housing 1, a sealing pressure piece 2, a flow regulating rod 3, a valve body 4, a connecting pipe 5, a connecting shaft 7, a positioning shaft 8, a lower valve plate 9, a turbine 10, and a worm rod 11. The upper valve plate 13 and the positioning shaft 8 position the lower valve plate 9 at the bottom of the inner hole of the valve body 4, so that the lower valve plate 9 cannot rotate, and the outer circumference of the lower valve plate 9 is sealed with the valve body 4, which is realized by a sealing ring. The upper valve plate 13 is press-fitted on the lower valve plate 9, the upper valve plate 13 is fixed on the lower end surface of the flow regulating rod 3 by the connecting shaft 7, the outer thread of the sealing pressing part 2 is connected with the inner thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com