Horizontal gravity casting hub dedicated riser cutting machine

A technology of gravity casting and hub, applied in the field of pouring riser equipment, can solve the problems of smashing the operator, cutting hands, and poor placement of the tool protection cover, and achieving the effect of avoiding hand injury and small inertia.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

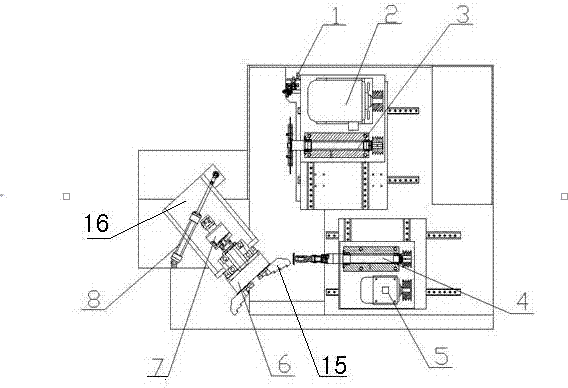

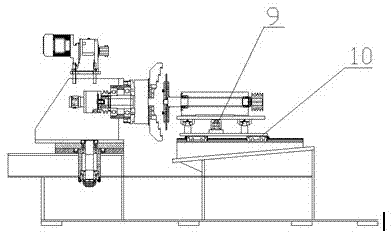

[0019] Depend on figure 2 It is known that the horizontal gravity casting hub special-purpose cutting riser machine includes a fixture part, a large tool spindle part and a small tool spindle part. The large tool spindle part and the small tool spindle part are arranged horizontally in the machine tool, and the fixture part is set There is a wheel hub, and after the fixture part clamps, swings or rotates the wheel hub on it, the cutting tools on the main shaft part of the large tool and the small tool tool respectively complete the cutting of the wheel hub according to the settings.

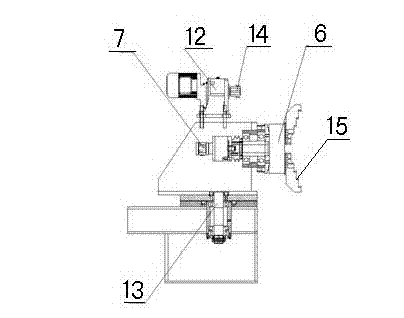

[0020] Depend on figure 2 , image 3 It is a schematic diagram of the fixture part; the fixture part is composed of a clamping wedge chuck 6, a clamping rotary cylinder 7, a fixture swing cylinder 8, a fixture rotation deceleration motor 12, a fixture swing spindle 13, a fixture rotation transmission sprocket 14, and jaws 15 , the main shaft of clamping wedge-shaped chuck 6 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com