Rotating transferring mechanism and lifting transferring machine with same

A technology of rotating mechanism and transfer machine, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as manual operation, and achieve the effect of good adaptability and good practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

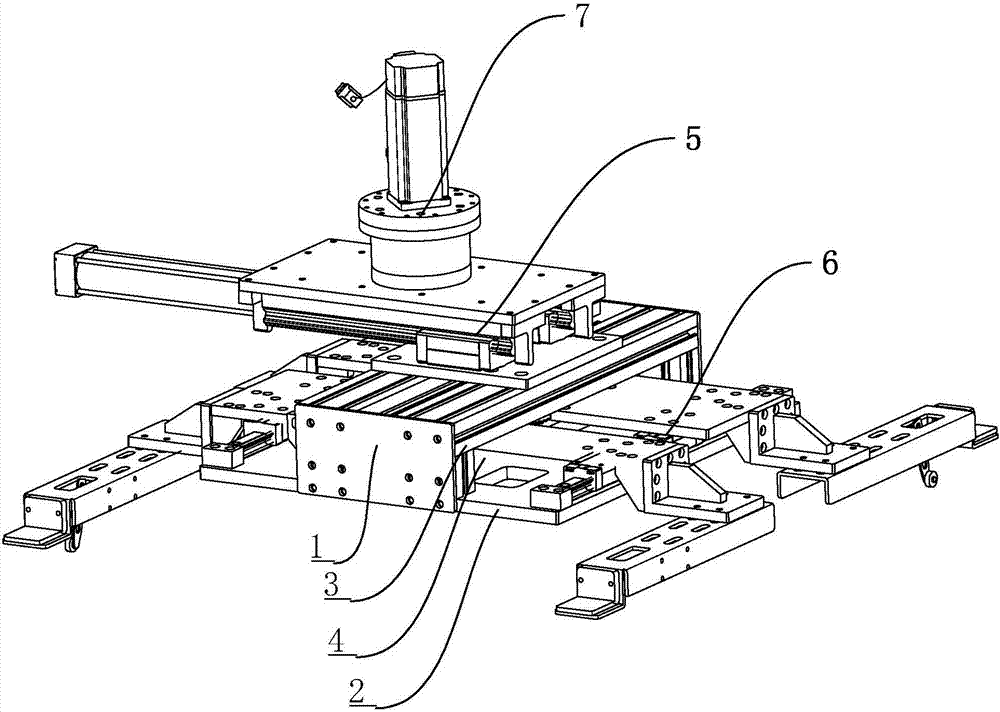

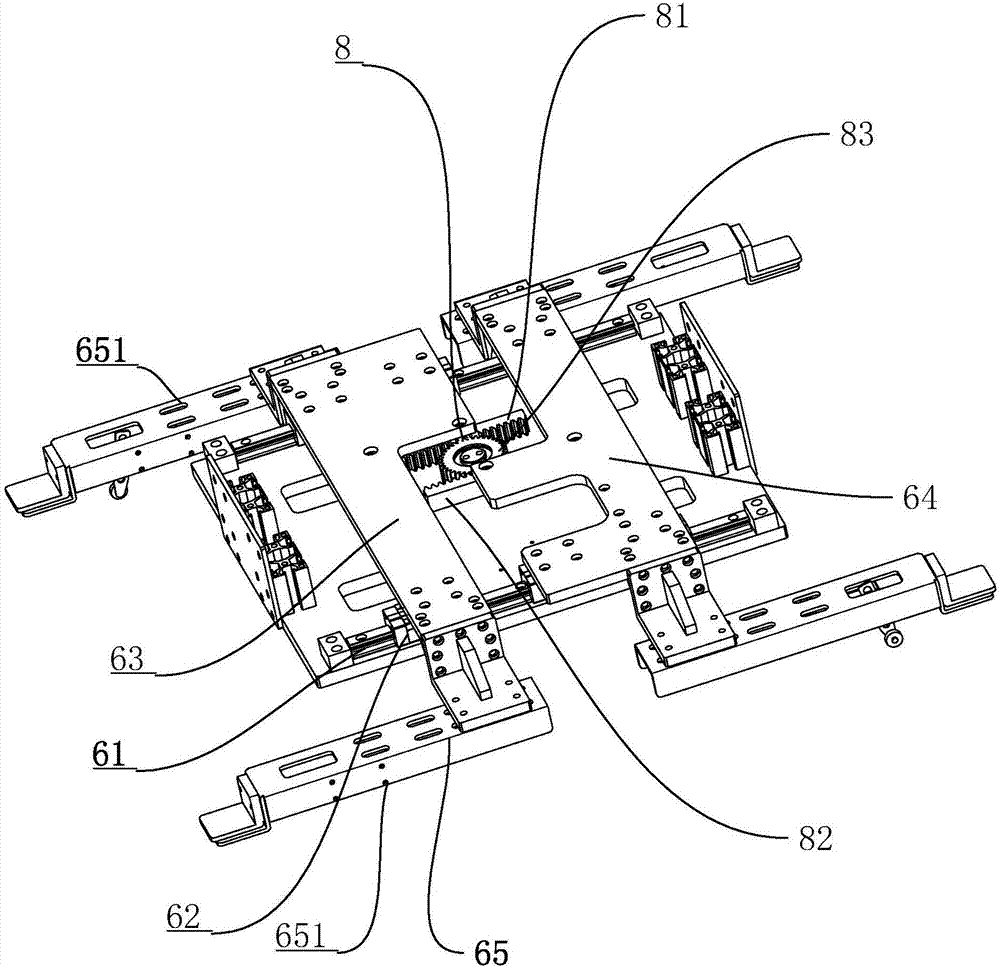

[0039] Embodiment 1: a kind of rotary transfer mechanism, such as figure 1 As shown, a mounting frame 1 is included, and the mounting frame 1 is composed of a base plate 2 and a "п" profile 3 arranged on the base plate 2, and a storage space 4 is formed between the "п" profile 3 and the base plate 2. An X-axis reciprocating mechanism 5 is provided above the "п" profile 3 of the mounting frame 1, and a Y-axis reciprocating mechanism 6 is provided in the storage space 4 of the mounting frame 1. The Y-axis reciprocating mechanism 6 passes through the "п" profile 3 and the X-axis The reciprocating mechanisms 5 are separated from each other, and a rotating mechanism 7 for interlocking the rotation of the X-axis reciprocating mechanisms 5 is provided on the upper side.

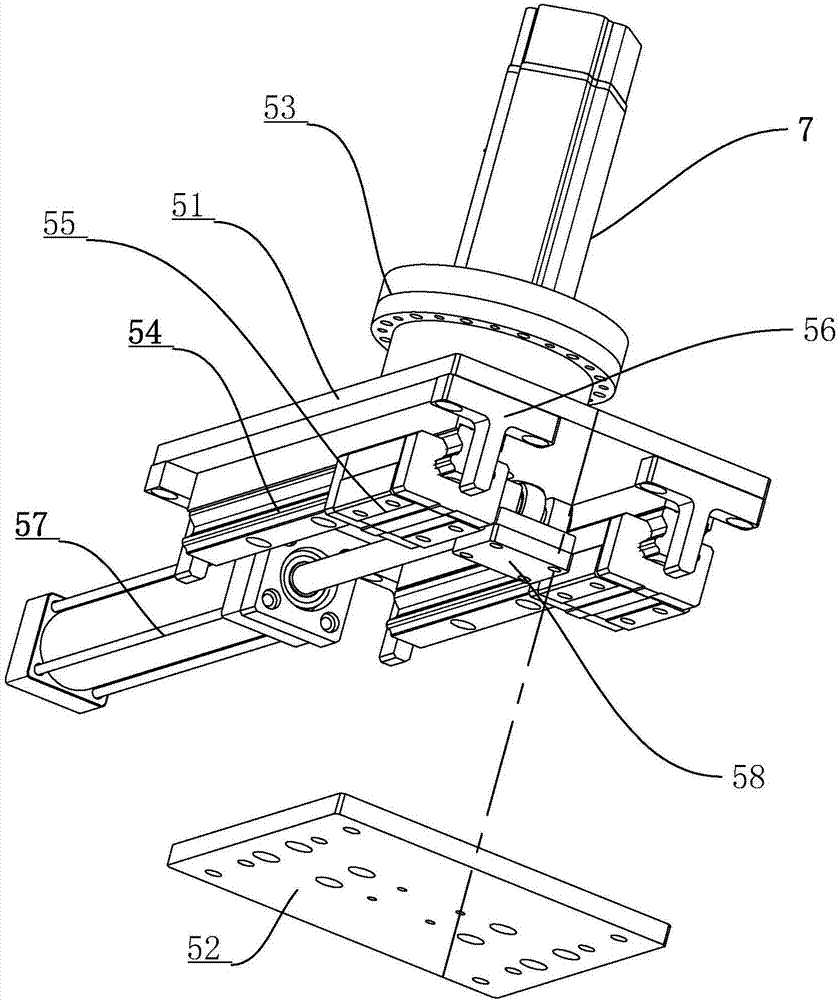

[0040] like figure 1 , figure 2As shown, the X-axis reciprocating mechanism 5 includes an upper support plate 51 linked with the rotation mechanism 7 and a lower support plate 52 fixed with the installation frame...

Embodiment 2

[0045] Embodiment 2: a kind of lifting transfer machine, such as Figure 5 As shown, it includes the installation arm 9 in the X direction, the lifting device 10 that the linkage installation arm 9 lifts along the Z axis, the rotating assembly 11 that the linkage lifting device 10 rotates, and the crawling device 12 that moves in the Y direction together with the linkage rotation assembly 11 and the lifting device 10 , the end of the mounting arm 9 is installed with the rotation transfer mechanism 13 in Embodiment 1, the rotation mechanism 7 is mounted on the mounting arm 9 and the rotation axis is the same as the Z axis.

[0046] like Figure 5 , Image 6 As shown, the crawling device 12 includes a casing 121 laid on the ground, a third linear slide rail 122 disposed on the casing 121 and a third slider 123 slidingly connected to the third linear slide rail 122, the third slide Block 123 is provided with seat plate 124, and rotating assembly 11 ( Image 6 has been disassem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com