Patents

Literature

59results about How to "Full contact time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing molecular sieve

ActiveCN103787352AFull residence timeFull contact timeCrystalline aluminosilicate zeolitesMolecular sieveGas phase

The invention relates to a method for preparing a molecular sieve, which comprises the following steps: the molecular sieve is introduced in a gas phase ultra-stable reactor, the gas phase ultra-stable reactor is capable of moving the molecular sieve from the molecular sieve inlet of the gas phase ultra-stable reactor to the molecular sieve outlet of the gas phase ultra-stable reactor under the condition that carrying gas is not used for conveying, and the molecular sieve and gas-phase silicon tetrachloride are contacted for reacting in the gas phase ultra-stable reactor. The conveying of the molecular sieve does not require inertia carrying gas, the technology flow is simplified, carrying gas amount is saved, and the consumption of silicon tetrachloride can be greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

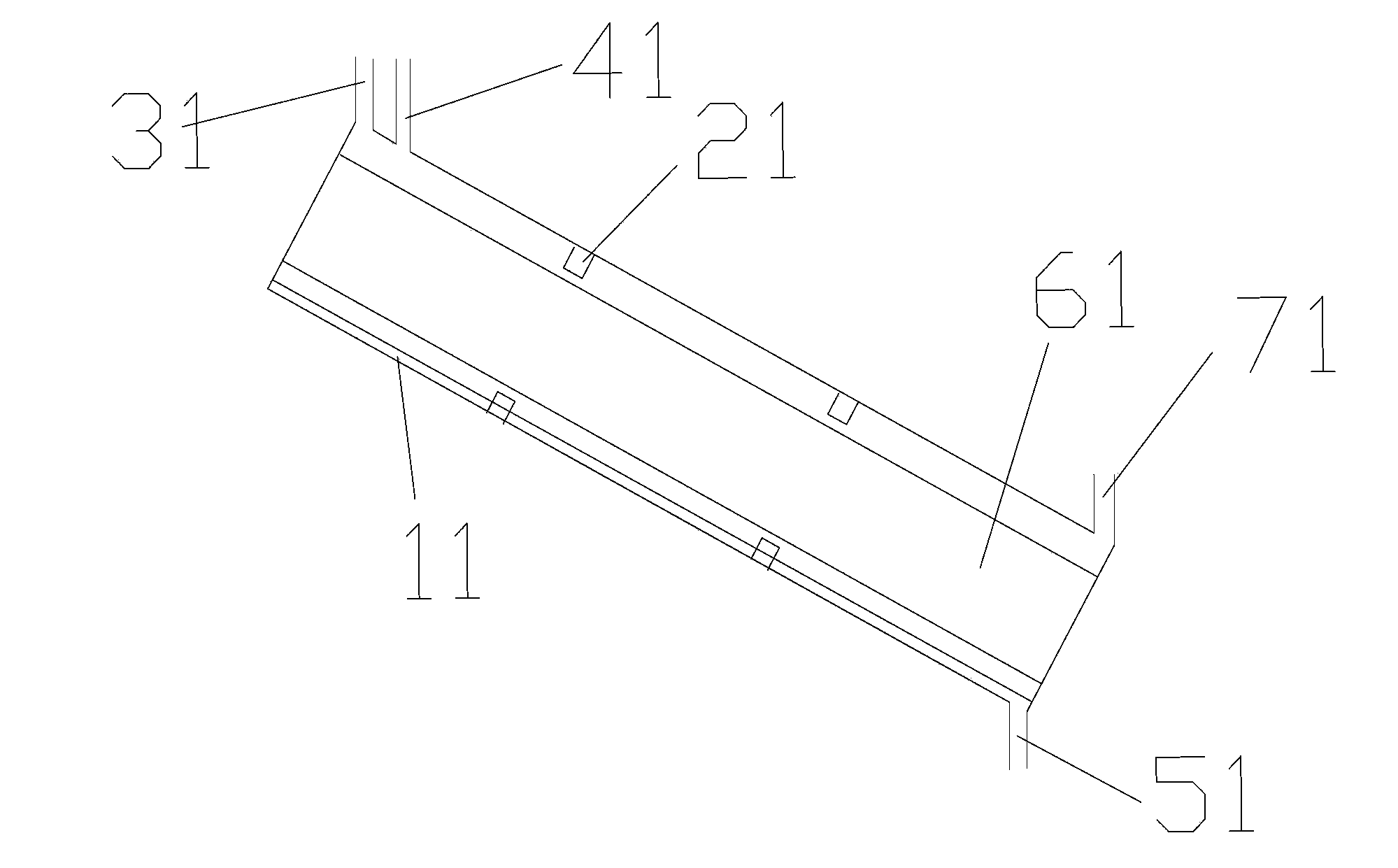

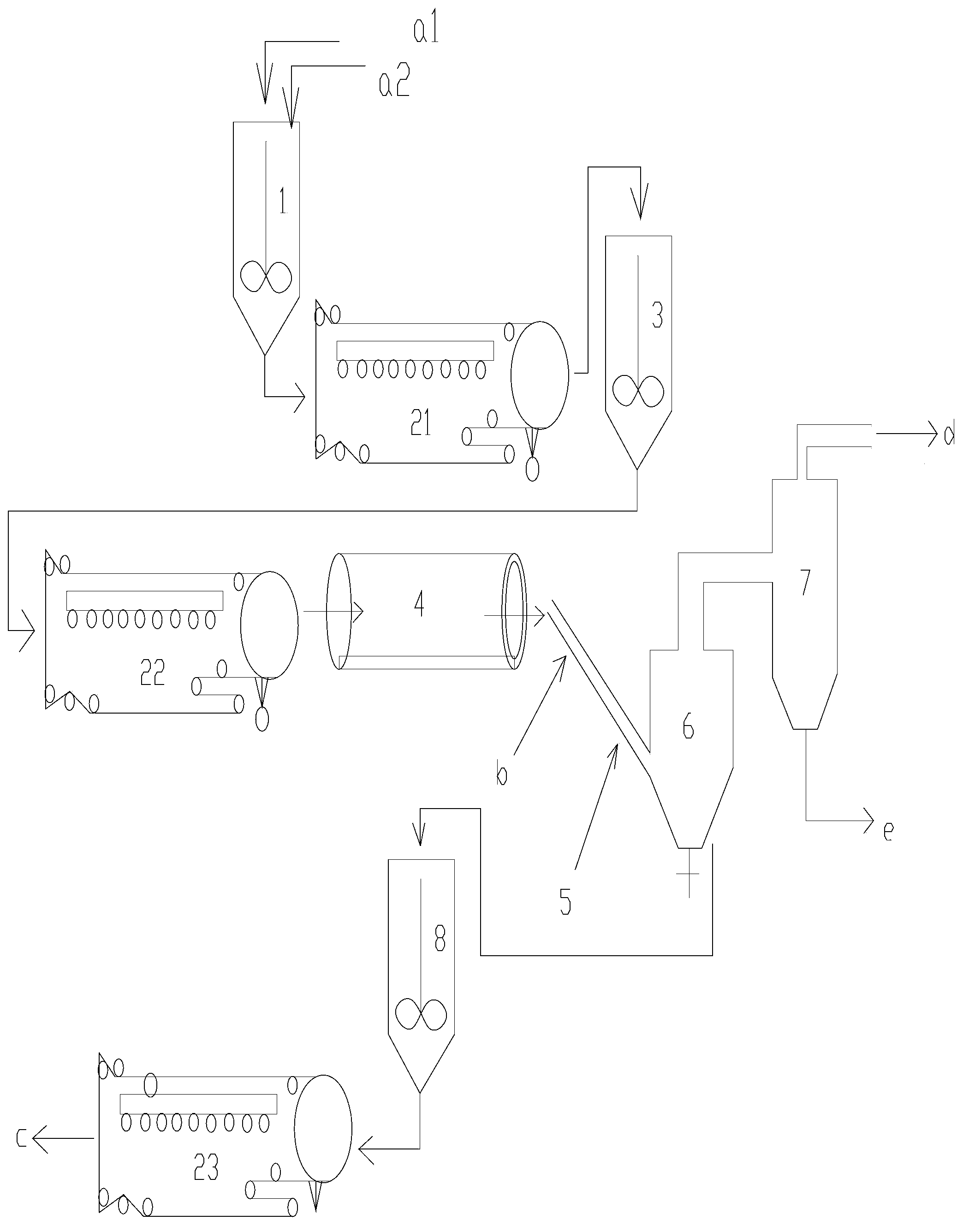

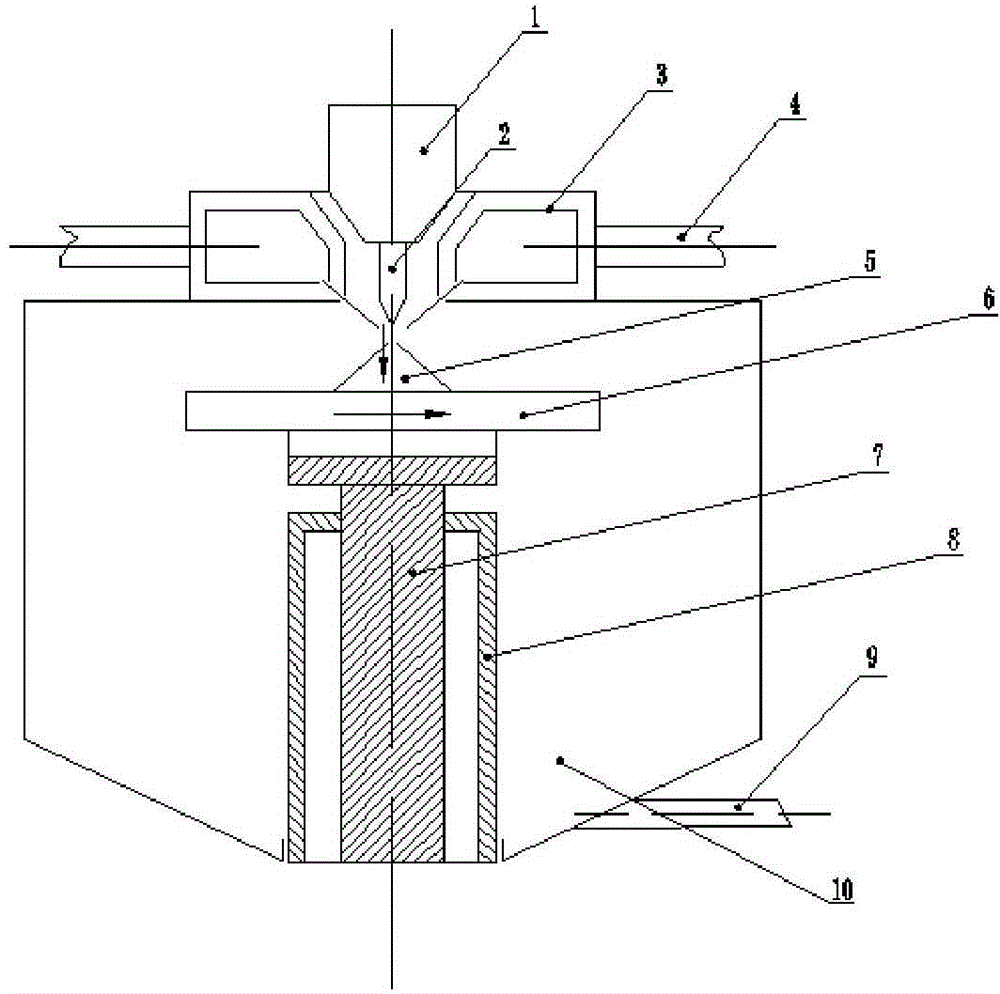

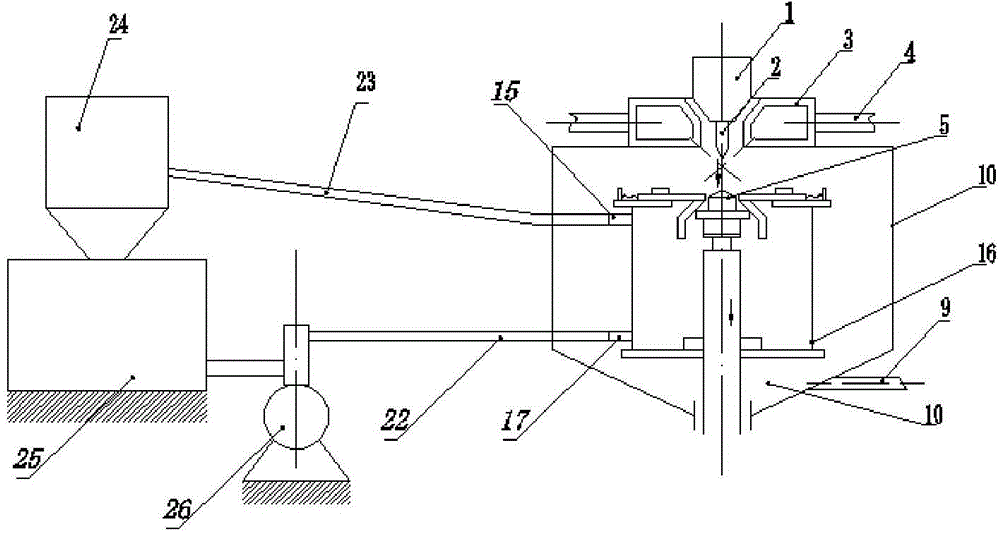

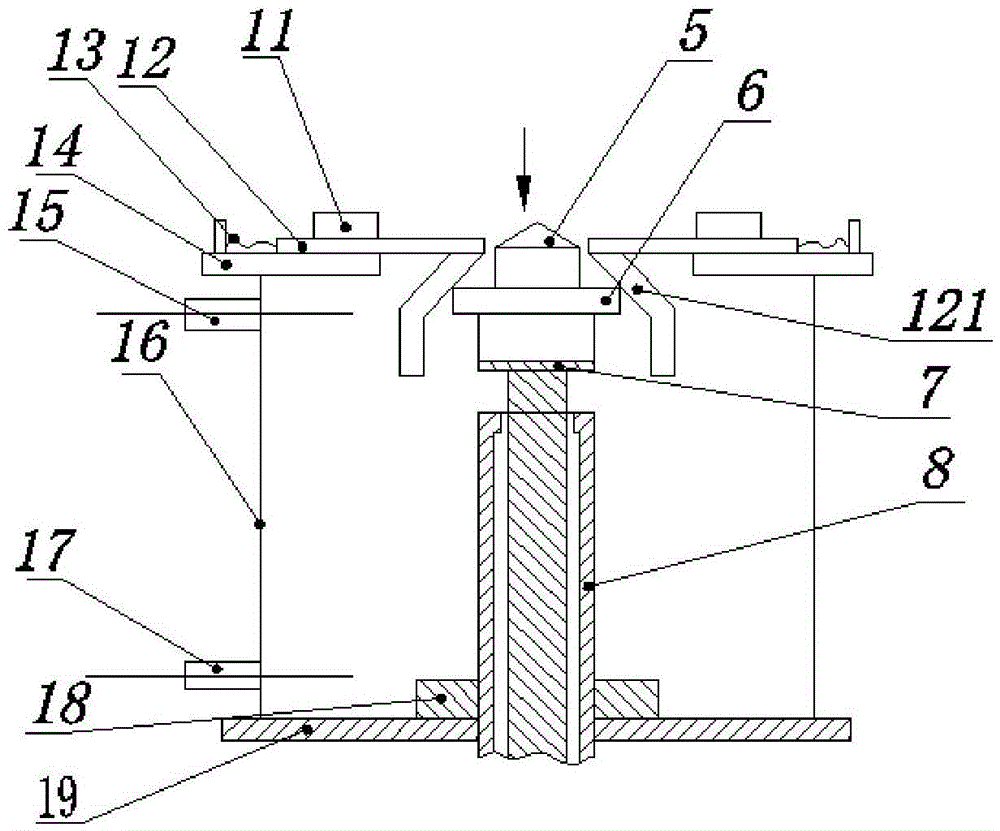

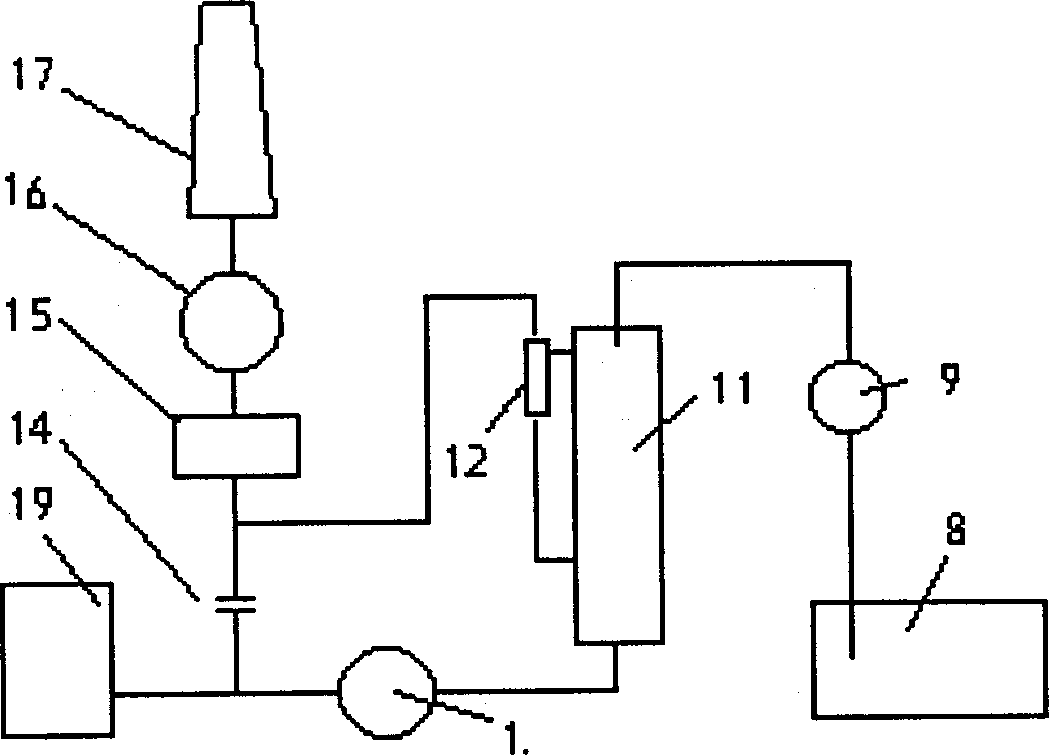

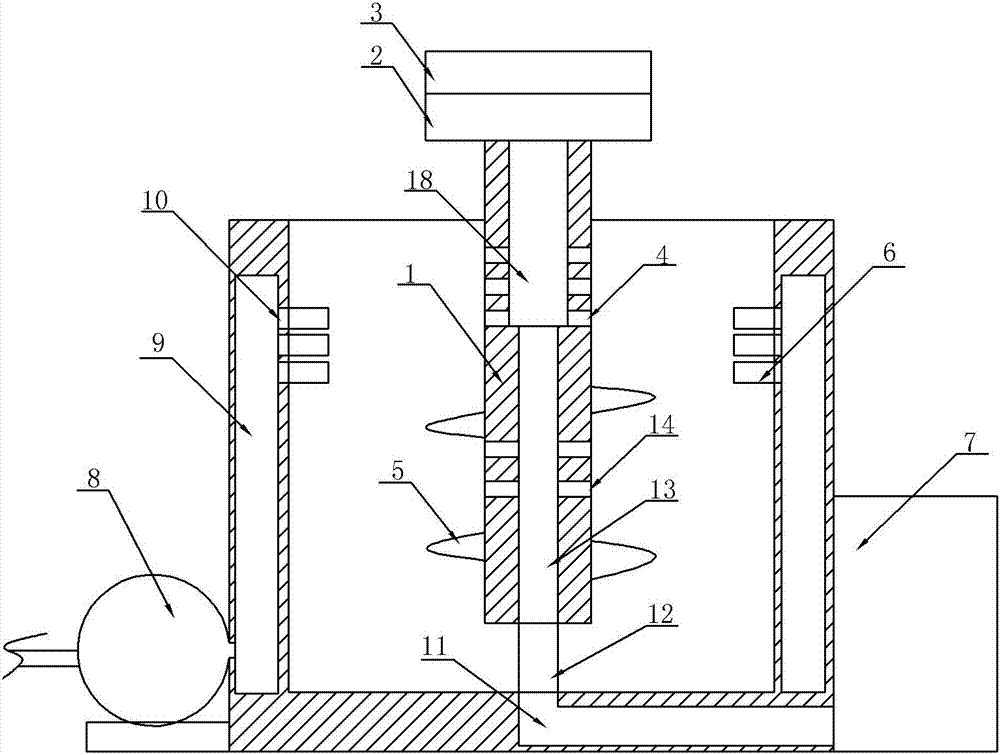

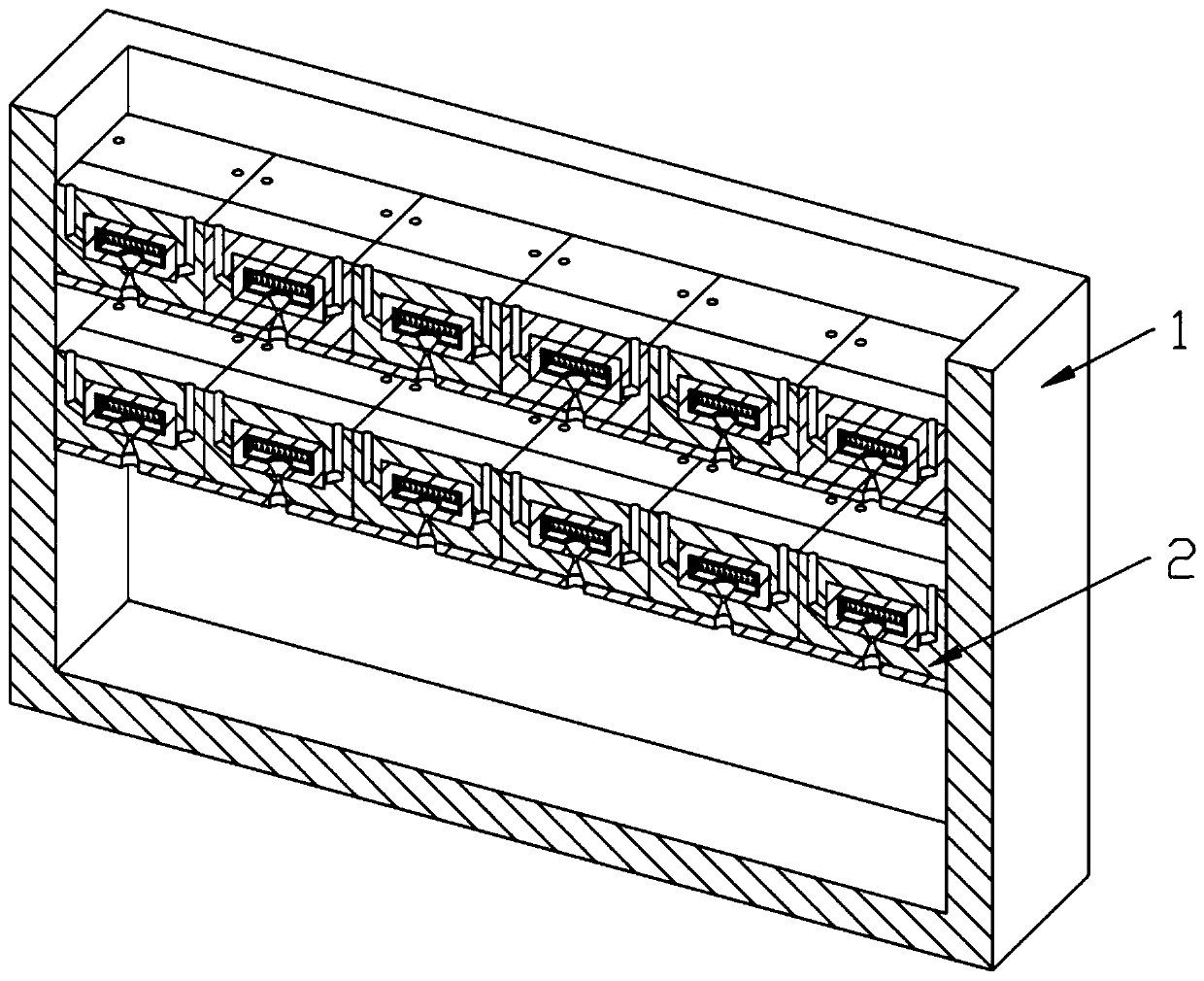

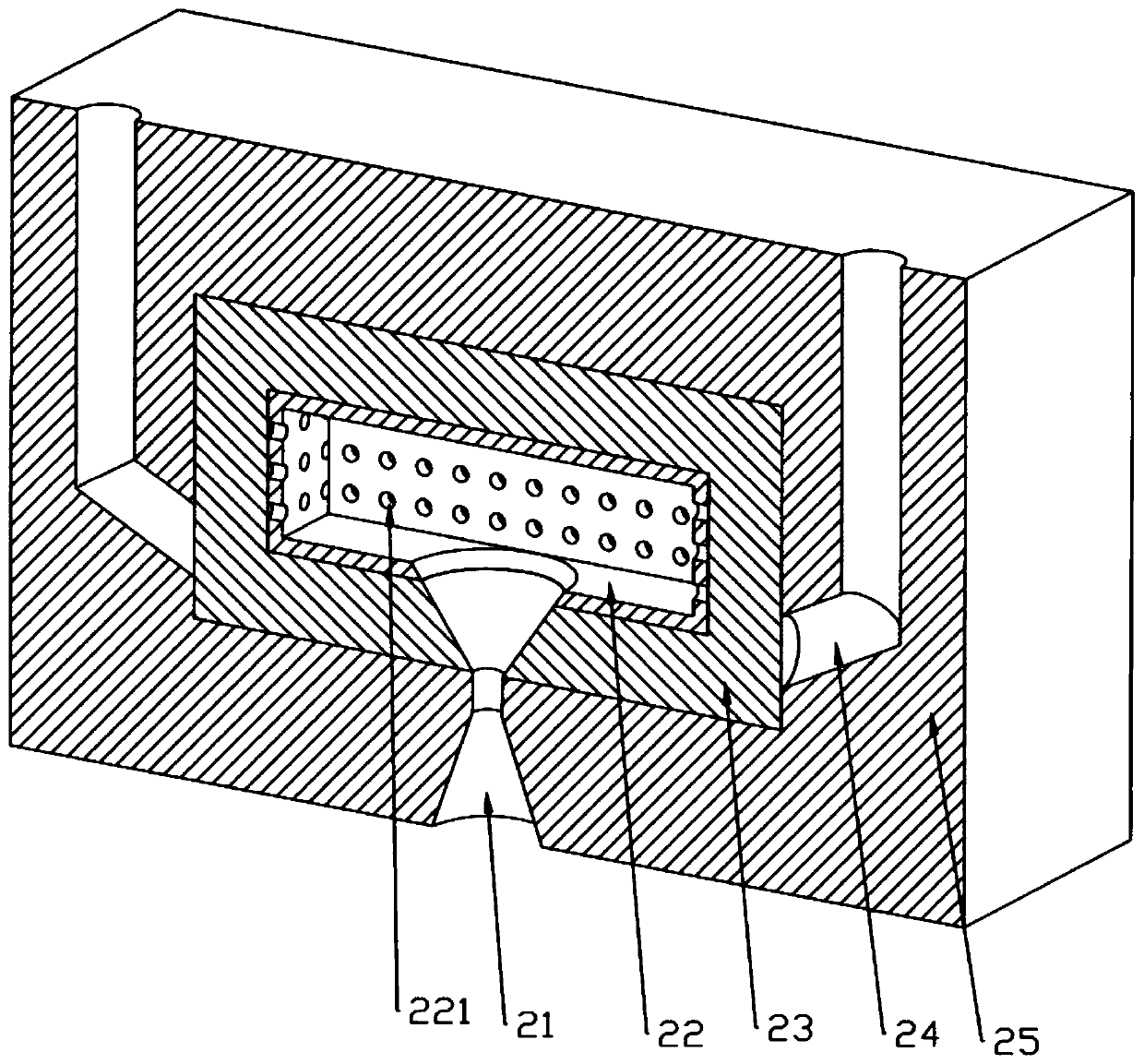

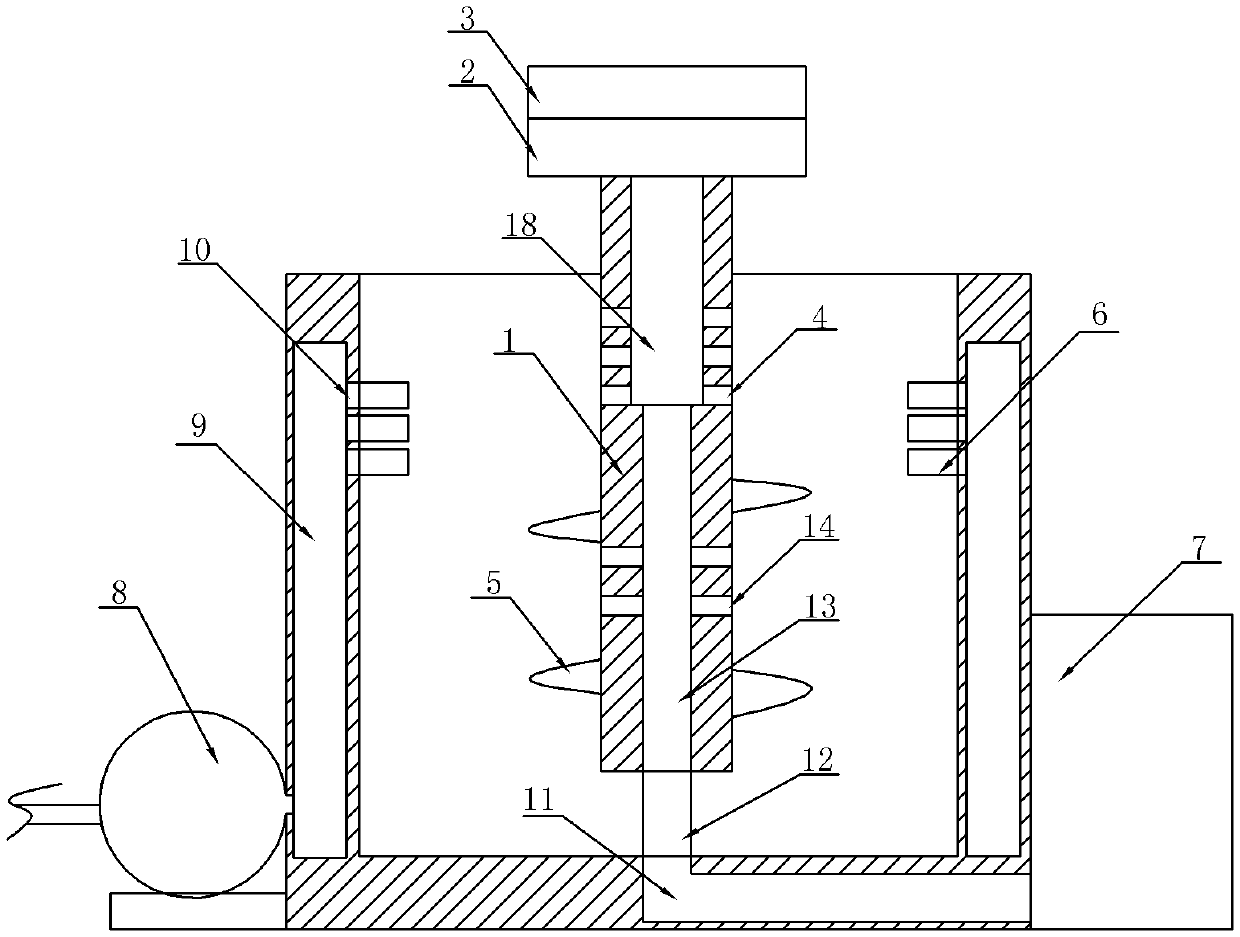

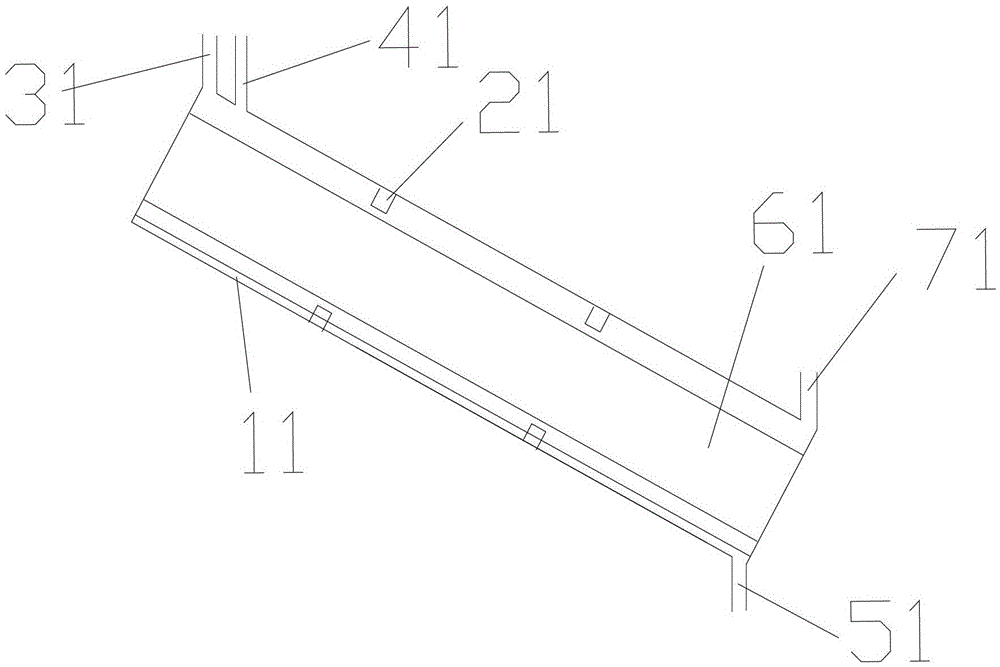

Molecular sieve production apparatus

ActiveCN103787353AFull residence timeFull contact timeCrystalline aluminosilicate zeolitesMolecular sieveCooking & baking

The invention relates to a molecular sieve production apparatus, which comprises a NaY molecular sieve exchange device, a baking furnace, a gas phase ultra-stable reactor and a gas-solid separation device, wherein the gas phase ultra-stable reactor comprises a molecular sieve inlet, a molecular sieve outlet and a silicon tetrachloride inlet. According to the present invention, with the gas phase ultra-stable reactor, the molecular sieve can move to the molecular sieve outlet of the gas phase ultra-stable reactor from the molecular sieve inlet of the gas phase ultra-stable reactor in the case of no requirement of conveying of the molecular sieve through carrier gas, and the molecular sieve and gas phase silicon tetrachloride can be subjected to a contact reaction in the gas phase ultra-stable reactor; and the apparatus can be used for continuous production of the high silicon molecular sieve, and further has characteristics of process simplifying, no requirement of molecular sieve fluidization carrier gas, and substantial silicon tetrachloride consumption reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

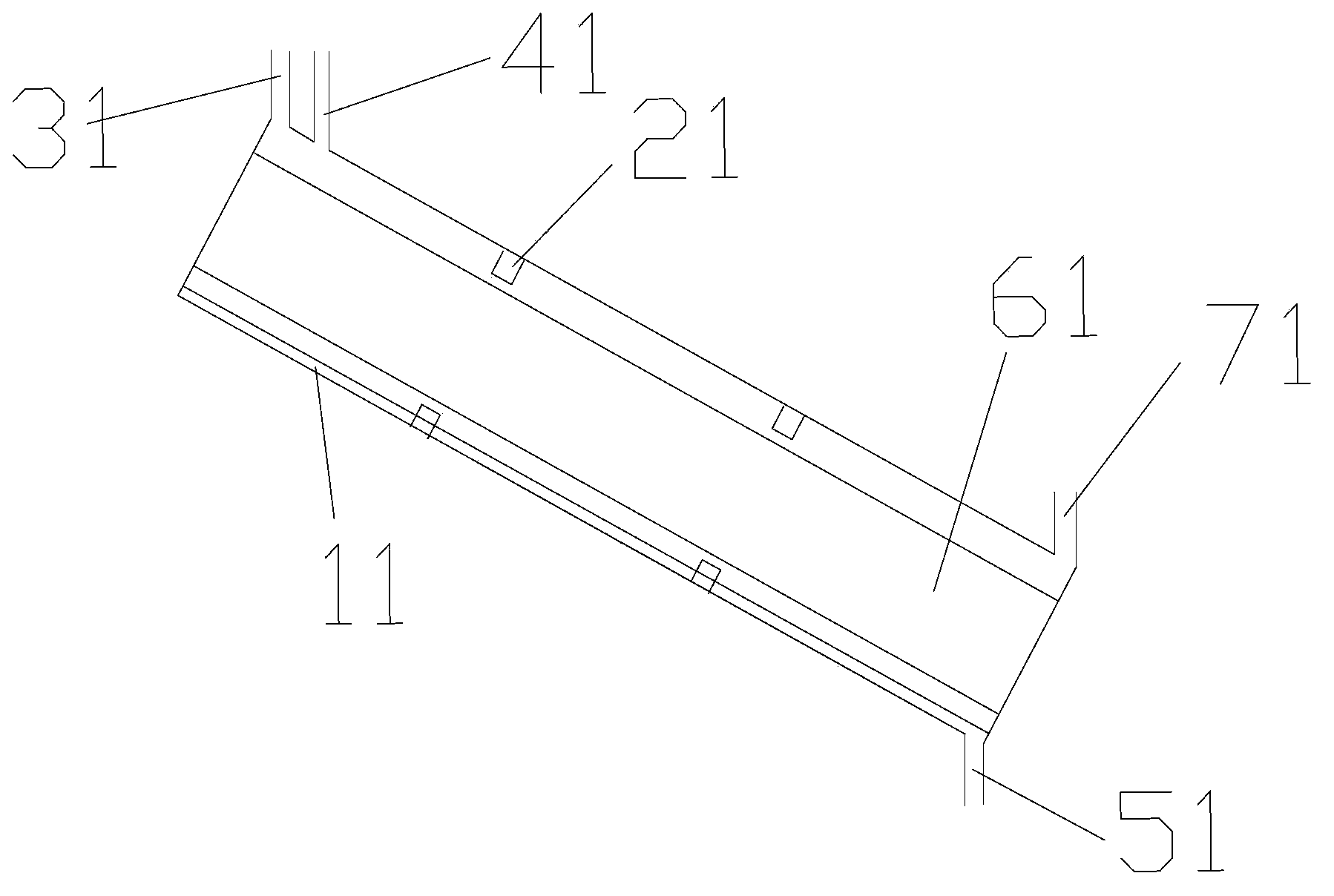

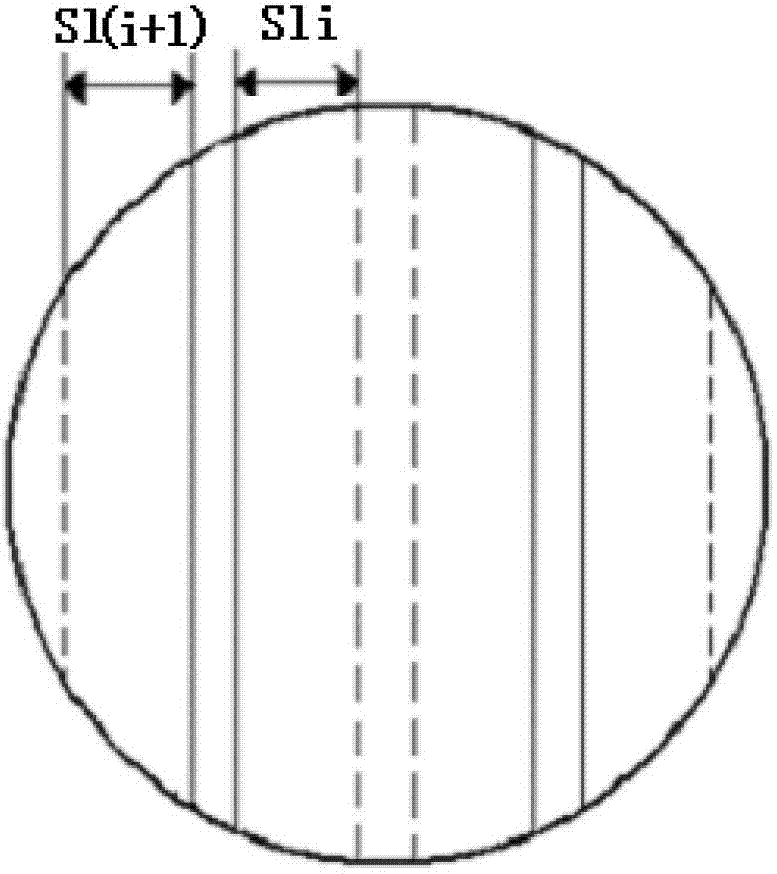

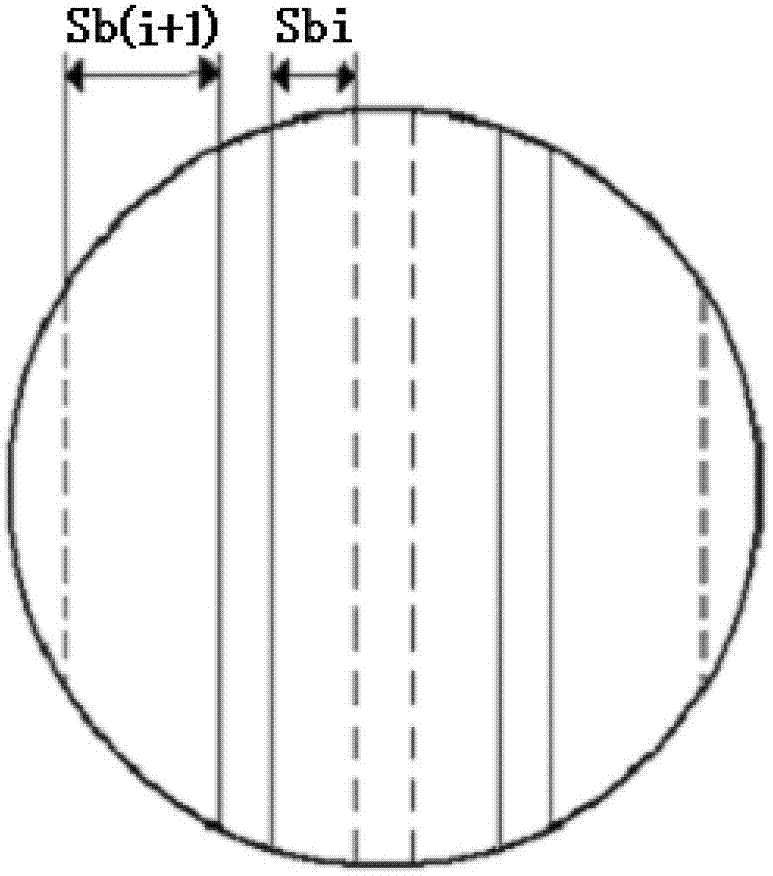

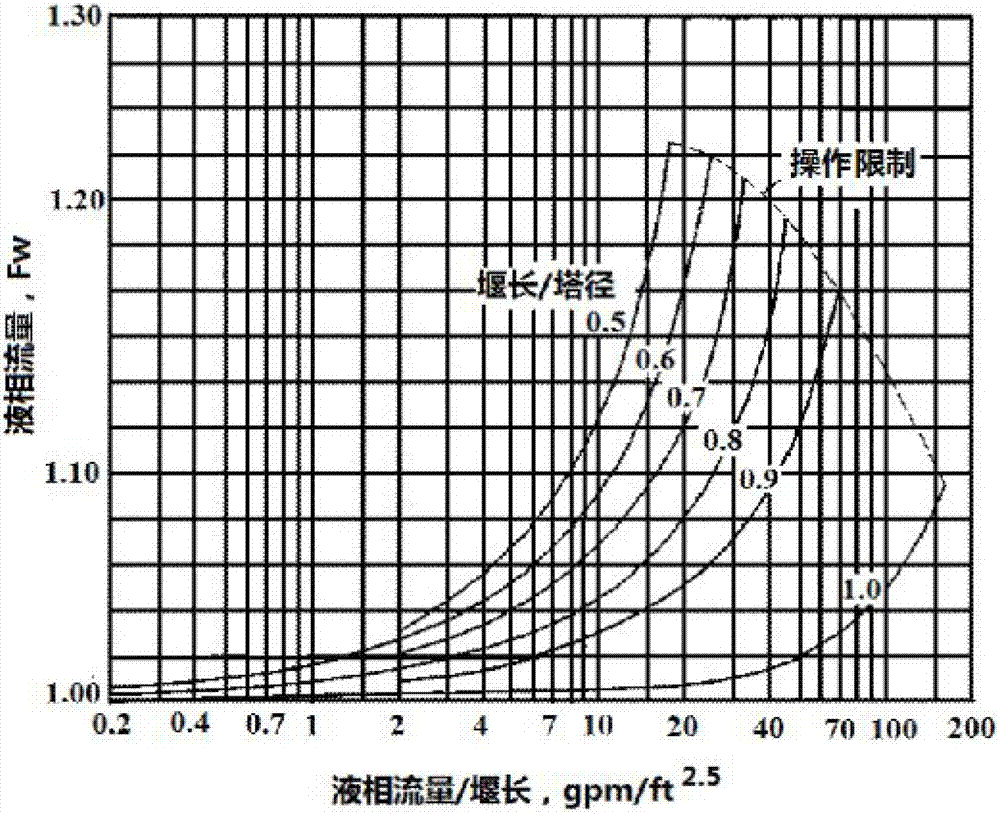

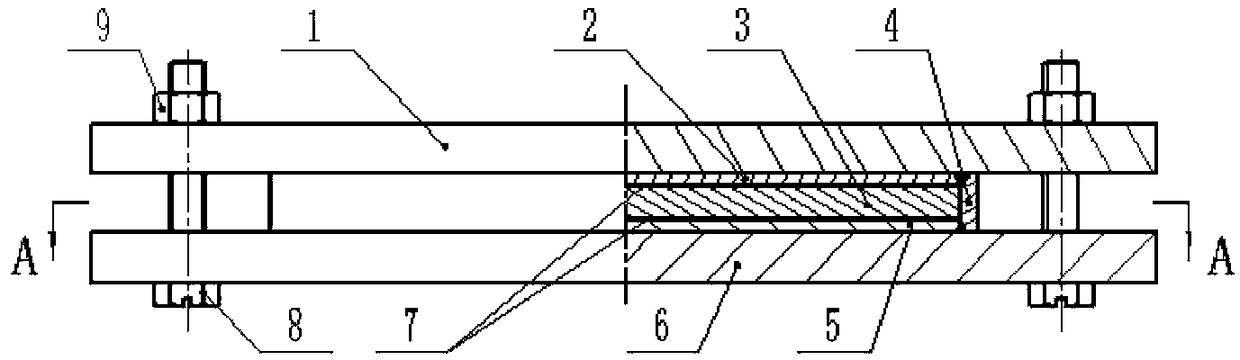

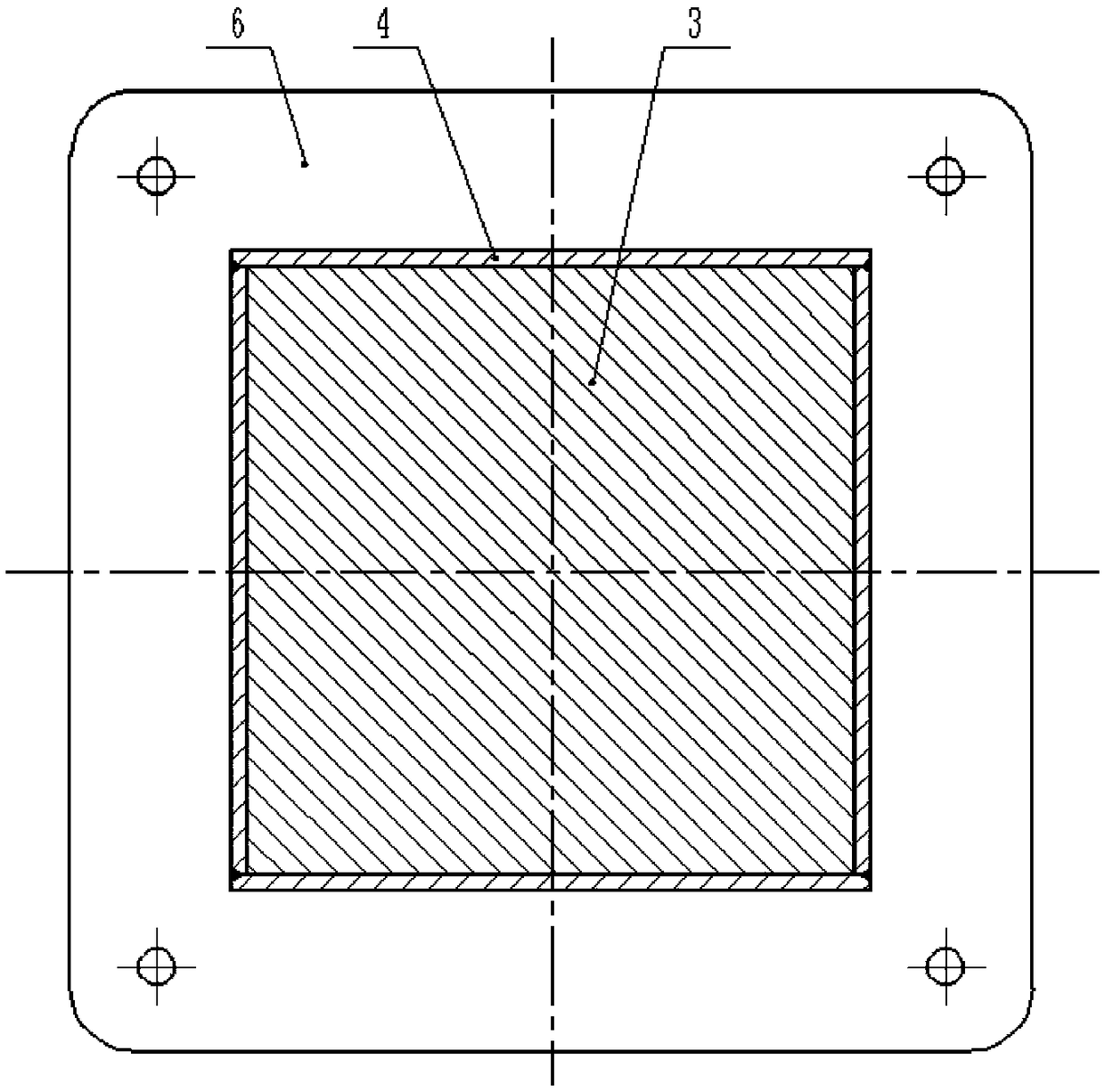

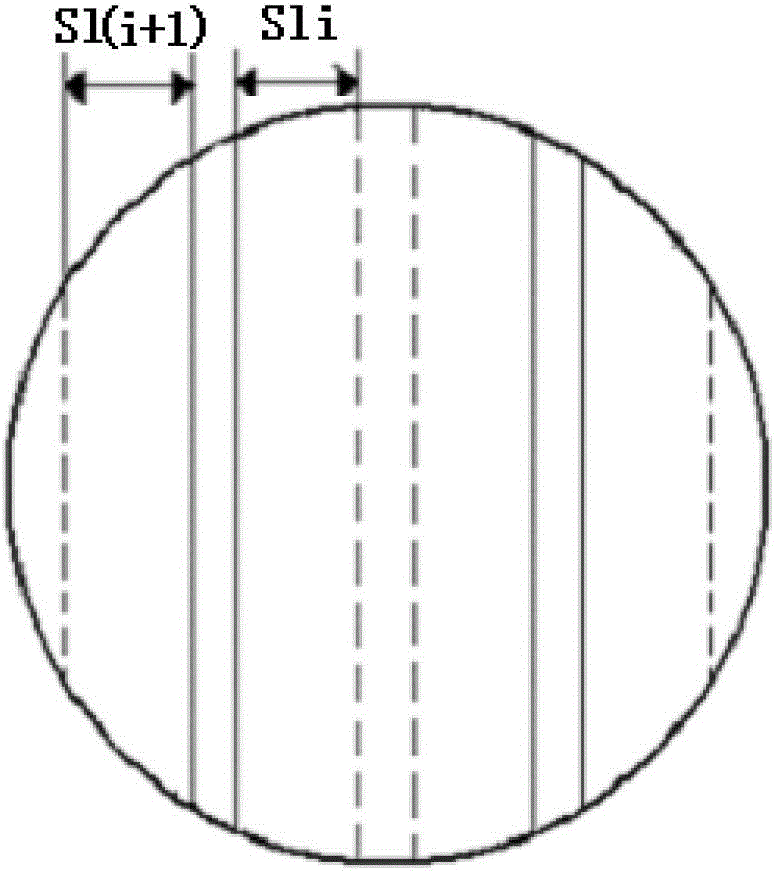

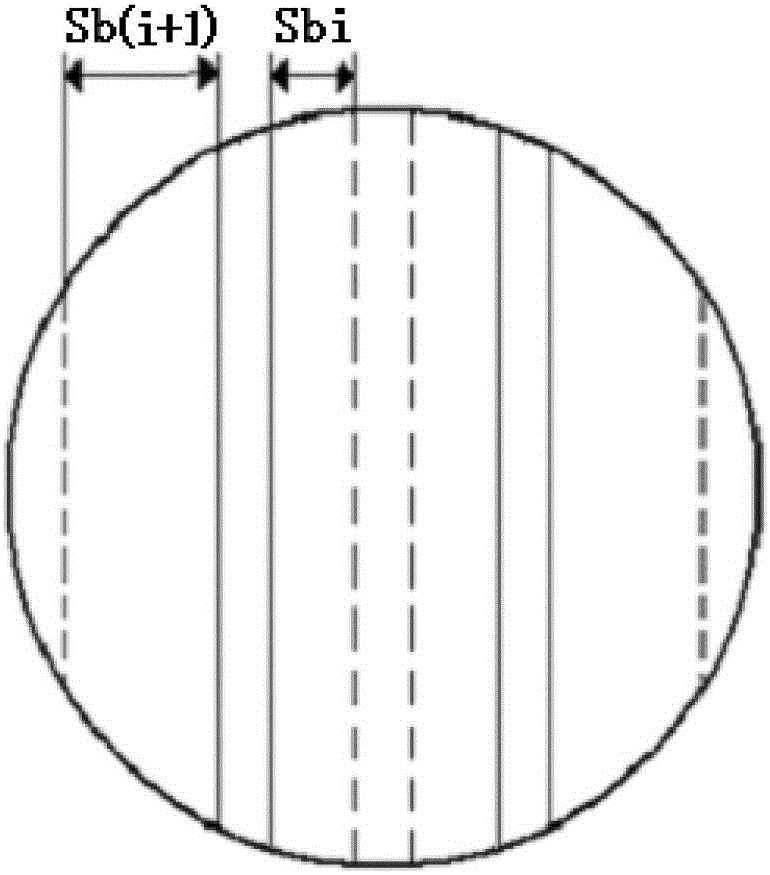

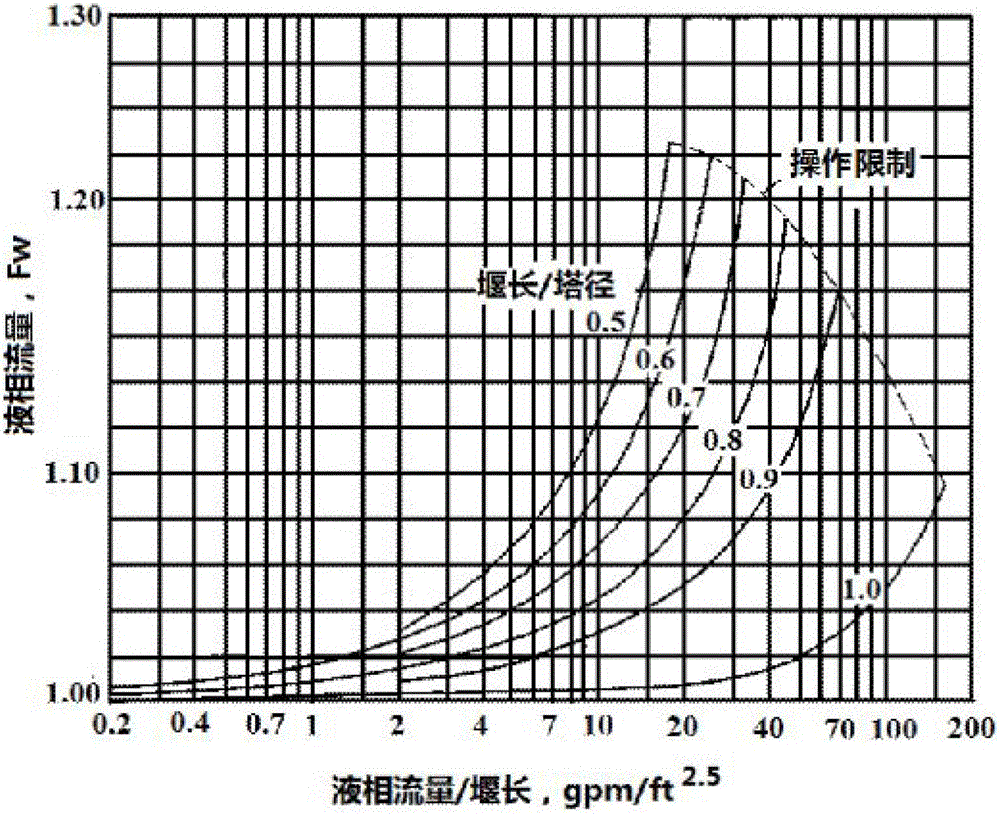

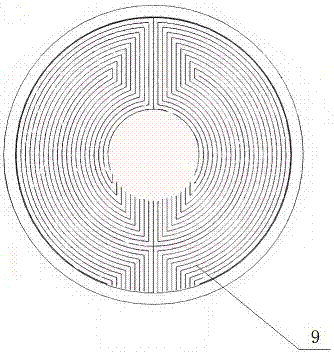

Method for designing multi-overflow tray by equal residence time method

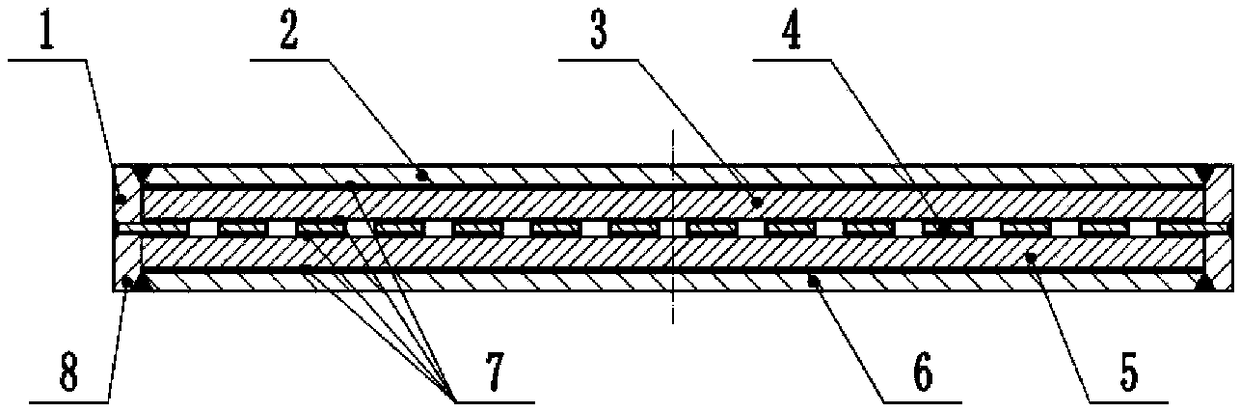

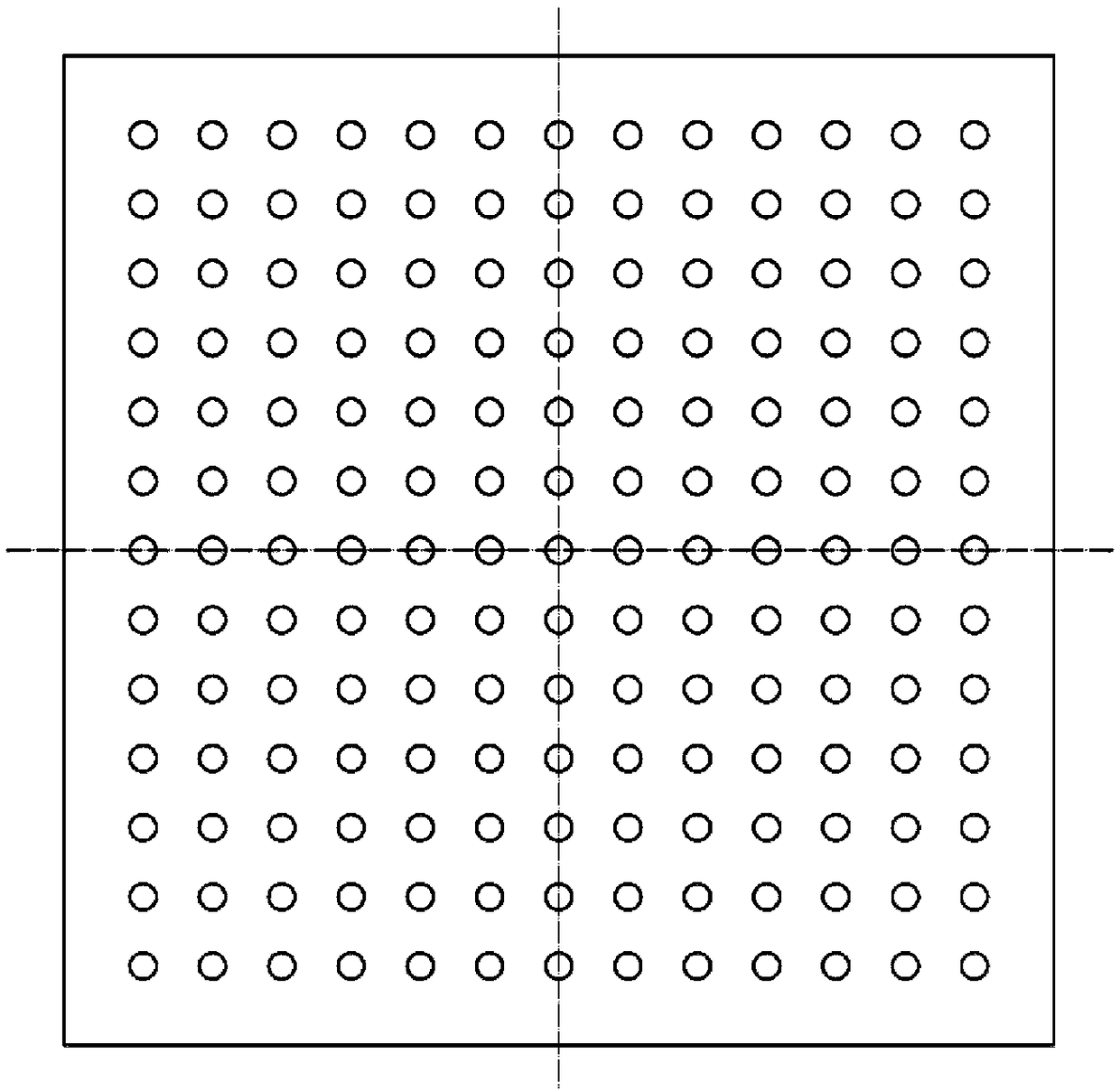

The invention relates to a method designing a multi-overflow tray by an equal residence time method, which is intended to raise tray mass transfer efficiency and processing capability, and alleviate amplification effect of equipment. The method is defined by residence time of the liquid on a tray bubbling zone, integrates advantages using an equal channel length method and an equal bubbling area method, takes regard of a contraction effect of a tower wall to a liquid flow and influence of physical property condition on the flow, and provides a calculating formula of the channel length in the tray bubbling zone under the equal residence time. Downcomer weirs on the edge at two sides of the tray are in a backswept weir structure, in order to increase overflow circumference length of the downcomer at two sides. A lower edge of an eccentric downcomer uses an arc or tooth-form structure, in order to balance a bottom gap outlet area of the downcomer. A liquid distribution plate is arranged in a liquid accepting plate, in order to balance liquid flow distribution at two sides of the downcomer. The method enables the liquid flow on each tray bubbling zone to have similar residence time and mass transfer efficiency, and achieves effects of reasonably distributing liquid, promoting gas and liquid uniform distribution and alleviating amplification effect of the tower equipment. The method is particularly suitable for large-scale tower equipment with high gas-liquid phase load.

Owner:PETROCHINA CO LTD +2

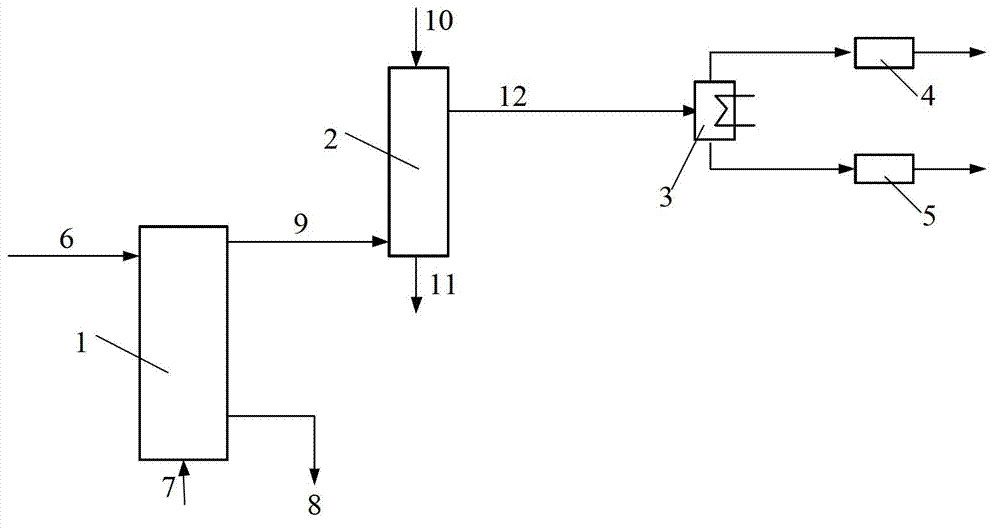

Device and method for performing pyrolysis on solid fuel and performing reductive coupling on iron ore

ActiveCN102888235AReduce dust contentAdequate responseDirect heating destructive distillationTreatment with plural serial stages onlyHydrogenCoupling

The invention relates to a device for performing pyrolysis on solid fuel and performing reductive coupling on iron ore. The device comprises a pyrolysis reactor, a counterflow moving bed reactor, a condensation separator, a gas purifier and a liquid purifier. A method for performing pyrolysis on the solid fuel and performing reductive coupling on the iron ore comprises the following steps of: performing pyrolysis on the solid fuel in the pyrolysis reactor under the action of inert gas or hydrogen-enriched reductive gas to obtain pyrolytic tar, pyrolysis gas and a semicoke product; feeding the pyrolytic tar and the pyrolysis gas into the counterflow moving bed reactor and performing countercurrent contact on the pyrolytic tar, the pyrolysis gas and the iron ore in the reactor to ensure that heavy components in the pyrolytic tar are subjected to pyrolysis continuously under the action of the iron ore to obtain light tar, and reducing the iron ore to obtain elementary substance iron; and condensing the generated pyrolysis gas and the light tar, separating and purifying to obtain the pyrolysis gas and the light tar product. The method has the characteristics that the light tar is obtained by performing pyrolysis on the heavy components in the tar by using the natural iron ore, so that the quality of the tar is improved; and meanwhile, the iron ore is reduced to form the elementary substance iron, so that the grade of ore is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

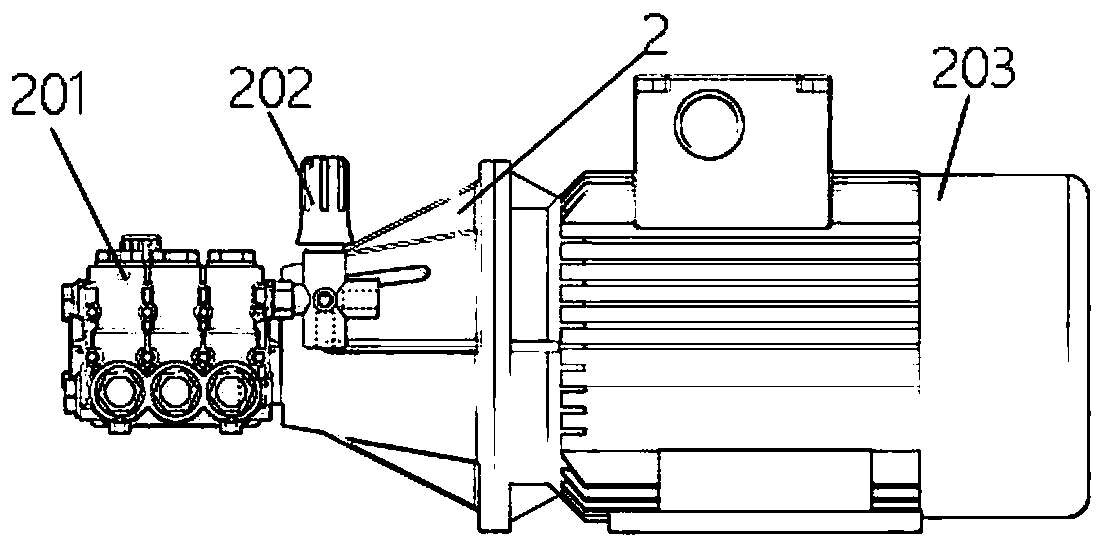

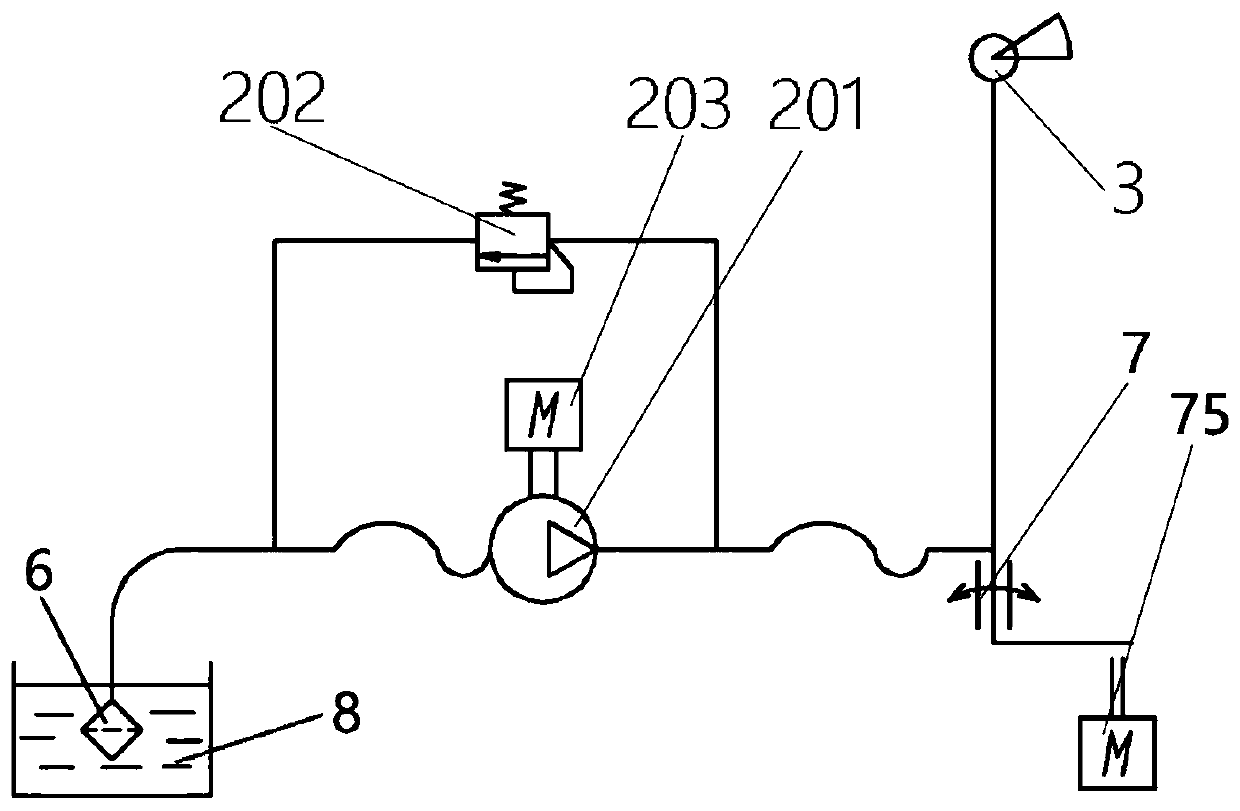

Spray forming cooling system and method for decreasing temperature of ingot blank through spray forming cooling system

The invention discloses a spray forming cooling system and a method for decreasing the temperature of an ingot blank through the spray forming cooling system. The system comprises a spray forming device and a cooling system, the cooling system comprises a heat absorption structure, a cooling device, a circulation power pump, heat conduction media and a heat conduction medium conveying pipeline which is sequentially connected with the heat absorption structure, the cooling device and the circulation power pump to form a heat condition loop. The heat absorption structure is located inside an atomization chamber of the spray forming device and used for cooling the ingot blank or a tray, and the cooling device is located outside the atomization chamber of the spray forming device and used for cooling the heat conduction media of which the temperature is increased because heat of the atomization chamber is absorbed. The heat conduction media flow inside the heat conduction loop in a circulation mode under the action of the circulation power pump to absorb heat in the atomization chamber and perform cooling inside the cooling device. The spray forming cooling system has the advantage that the heat conduction media are adopted for directly cooling the ingot blank or the tray, so that the ingot blank of which the performance meets the requirement is obtained.

Owner:天津佐源新材料科技有限公司

Preparation method of stainless steel-magnesium alloy composite plate

The invention discloses a preparation method of a stainless steel-magnesium alloy composite plate, and belongs to the field of metal composite plate machining. The problem that the application of thestainless steel-magnesium alloy composite plate in the industrial field is restricted due to the fact that the stainless steel-magnesium alloy composite plate with good interface connection is difficult to form according to an existing forming method is solved. The preparation method adopts the structure of wrapping sealing, so that the problem of liable oxidation in the heating process of magnesium alloy can be effectively solved, and therefore, no additional inert gas needs to be applied for protection during the heating process. As a transition element, a silver coating on the surface to bebonded can improve the wettability of the magnesium alloy on the surface of stainless steel and promote the metallurgical bonding of the bonded surface. A hot pressing furnace is heated to a temperature higher than the melting point of the magnesium alloy, heat preservation and pressure maintaining are carried out for a period of time, so that the contact time between a magnesium alloy melt and the stainless steel surface is sufficient, and interface elements are more conducive to diffusing under the pressure. The prepared stainless steel-magnesium alloy composite plate has good bonding interface quality, high tensile strength and good corrosion resistance performance.

Owner:JILIN UNIV

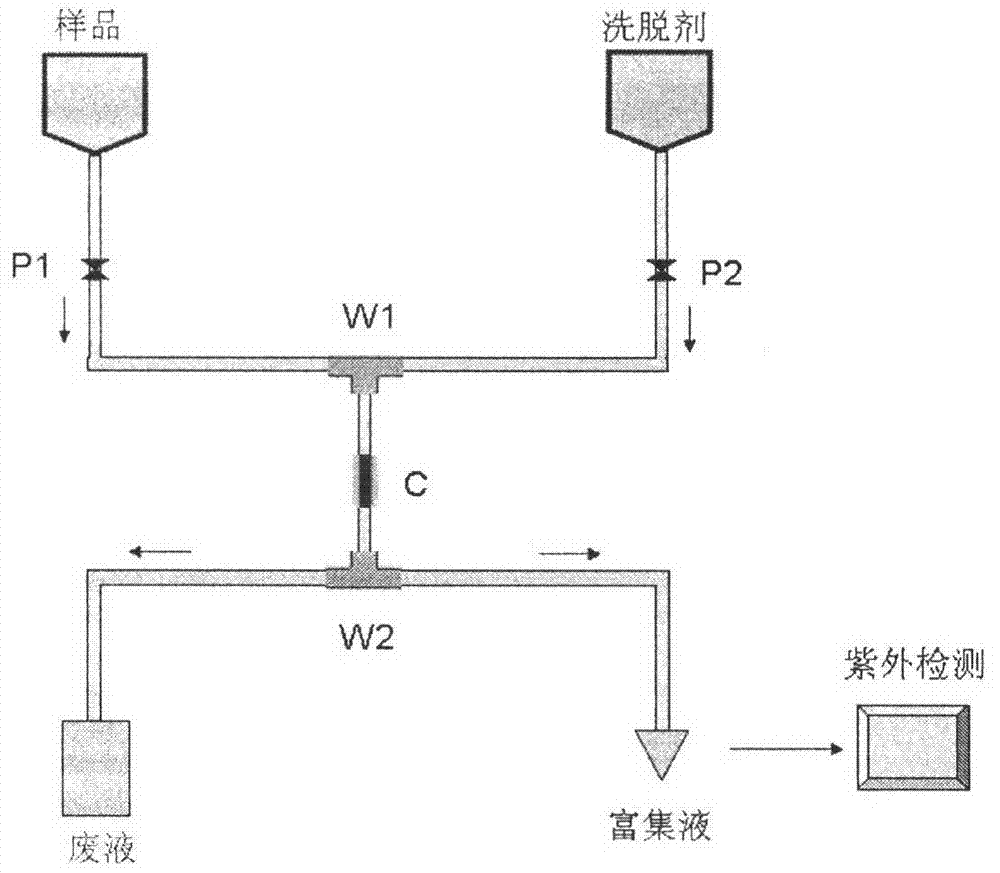

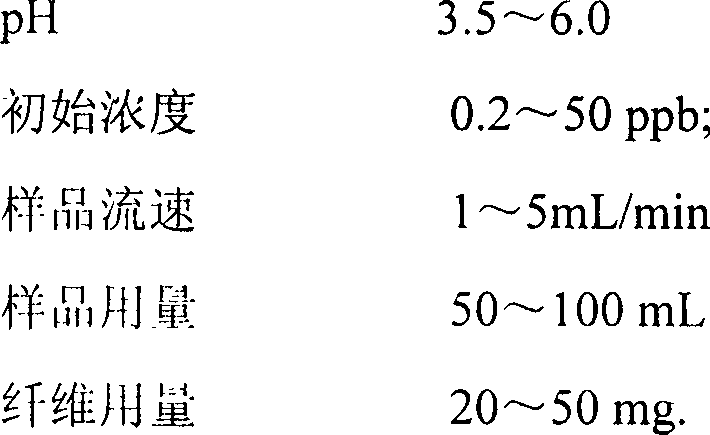

Method for fast enriching and detecting trace amount of As (V) and Cr (VI) contained in water by filling microcolumn by utilizing fiber

InactiveCN102967574AThe detection method is simpleHigh enrichment efficiencyPreparing sample for investigationColor/spectral properties measurementsFiberSolid phase adsorption

The invention provides a method for detecting a trace amount of As (V) and Cr (VI) which are contained in a water sample, and particularly relates to a method for enriching As (V) and Cr (VI) by filling quaternary ammonium fibers into a microcolumn and utilizing a solid-phase extraction method and detecting As (V) and Cr (VI) by adopting an ultraviolet spectrophotometry, relating to the technical field of waste water detection. The method solves the technical problem that the analysis of a trace amount of metal ions contained in the water sample is limited on water treatment as the conventional detection method is insufficient in selectivity and detection limit due to matrix effect and other interference existing during the analysis of the trace amount of metal ions contained in the water sample. The method for enriching As (V) and Cr (VI) by filling the quaternary ammonium fibers into the microcolumn and utilizing the solid-phase extraction method and detecting As (V) and Cr (VI) by adopting the ultraviolet spectrophotometry comprises the following steps: filling self-made quaternary ammonium ion exchange fibers into the microcolumn; placing into a solid-phase adsorption separation device so that As (V) and Cr (VI) are adsorbed to the self-made quaternary ammonium ion exchange fibers; and detecting eluted analytes by adopting the ultraviolet spectrophotometry. The method disclosed by the invention has the characteristics of simple process, little time consumption and easiness and convenience for operation without special pretreatment of the water sample and can meet the requirements for trace amount analysis by respectively achieving the detection limits of As (V) and Cr (VI) at 0.2 ppb and 0.8 ppb.

Owner:TIANJIN POLYTECHNIC UNIV

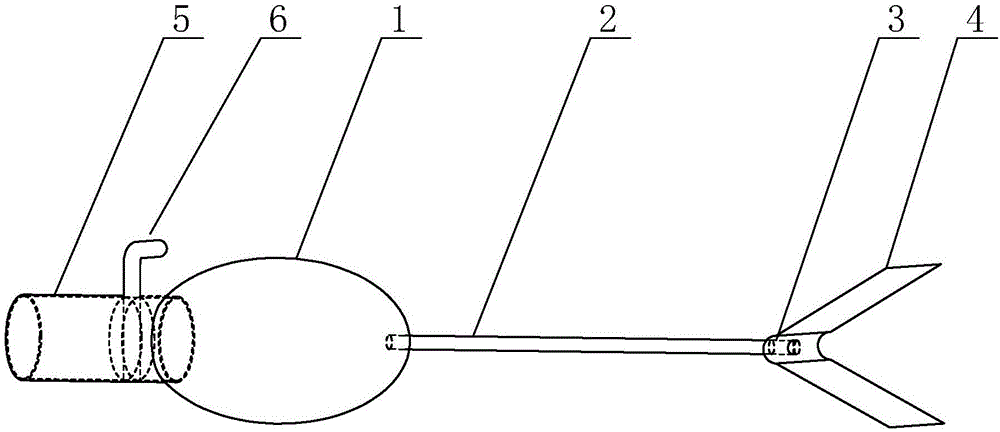

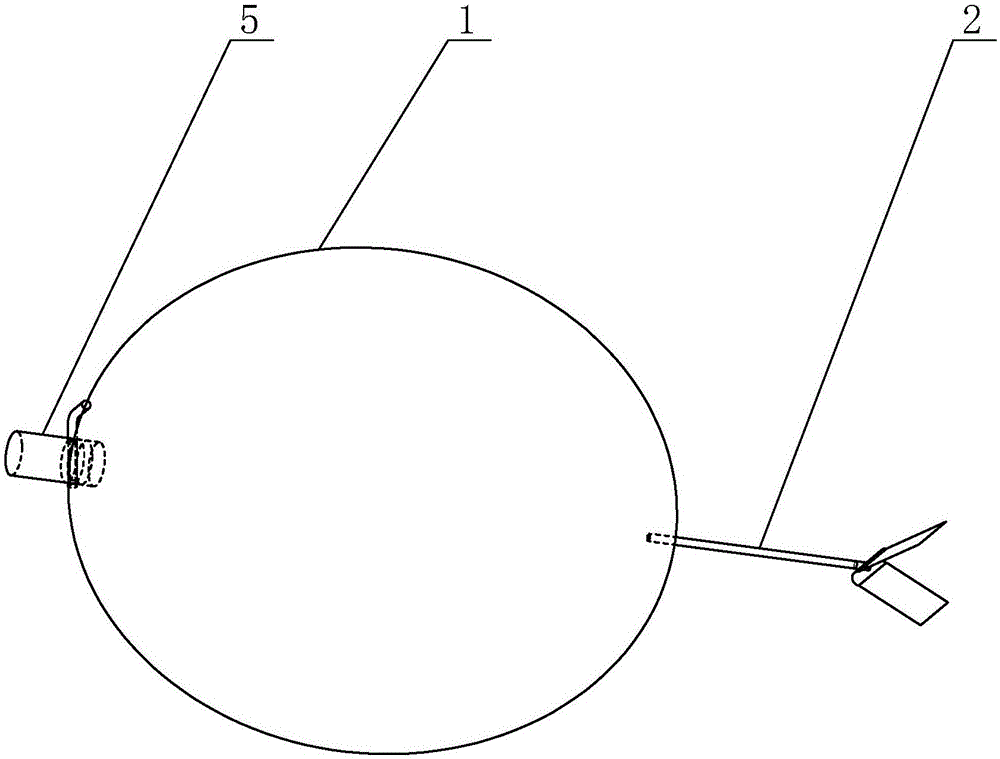

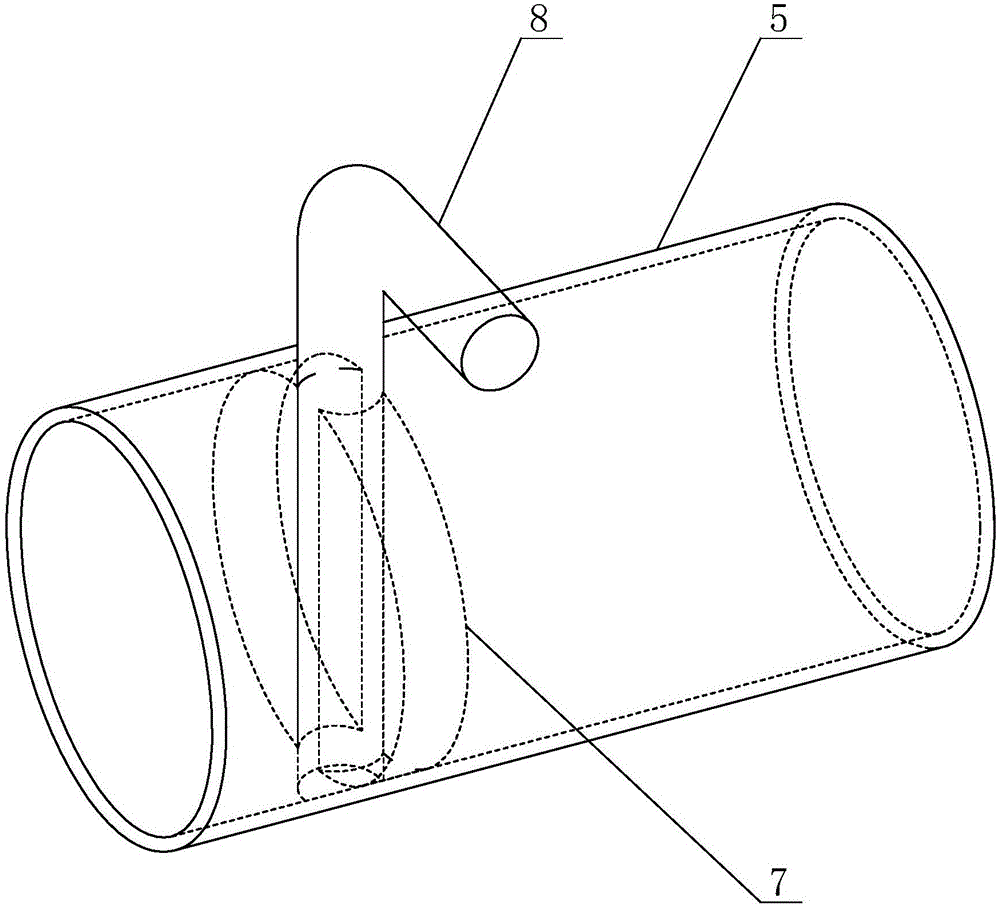

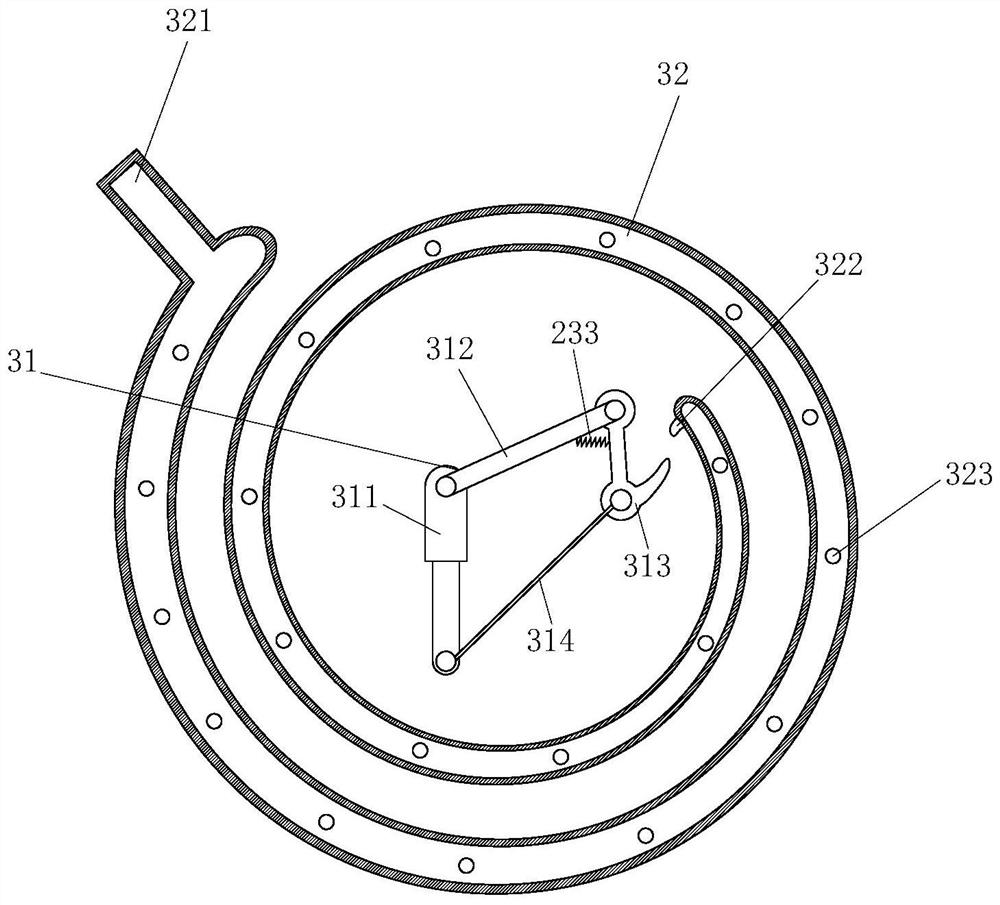

Internal type bladder irrigation chemotherapy pump

The invention discloses an internal type bladder irrigation chemotherapy pump, which comprises a chemotherapy pump elastic medicine storage bag, wherein an administration soft hose, which communicates with the chemotherapy pump elastic medicine storage bag, is arranged at one end of the chemotherapy pump elastic medicine storage bag; the end, away from the chemotherapy pump elastic medicine storage bag, of the administration soft hose is provided with an administration hard pipe which communicates with the administration soft hose; a clamp is arranged on the administration hard pipe; an administration pipe, which communicates with the chemotherapy pump elastic medicine storage bag, is arranged at the other end of the chemotherapy pump elastic medicine storage bag; and a valve is arranged on the administration pipe. According to the chemotherapy pump provided by the invention, medicines can be continuously applied to mucosa of a pathologically changed bladder wall through drop irrigation; the chemotherapy pump is fixed to the bladder mucosa by virtue of the clamp, and the medicines, which is applied through drop irrigation in a pipeline, can be siphoned and spread to surrounding bladder walls at the first time through the bladder mucosa, and finally the medicines can be siphoned and spread to the entire bladder wall; then, the medicines are mixed with urine, so that dilution of the medicines, before getting into contact with the bladder wall, is greatly relieved; an administration position is relatively precise; and the medicines, which are continuously discharged through drop irrigation, has a sufficient time to get into contact with the bladder wall, so that a recurrence rate of normuscle invasive bladder cancer which accepts transurethral resection of bladder tumor is reduced.

Owner:夏生俊

Traditional Chinese medicine plaster for treating tunica mucosa oris ulcer and its preparation method

InactiveCN1954843AAvoid discomfortImprove complianceDigestive systemSheet deliveryAdhesiveTunica mucosa oris

A Chinese medicine in the form of plaster for treating oral mucosa ulcer is composed of a medicinal layer made of the Chinese medicine for treating mucosa ulcer and adhesive and an isolating layer containing water isolating material. Its preparing process is also disclosed.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

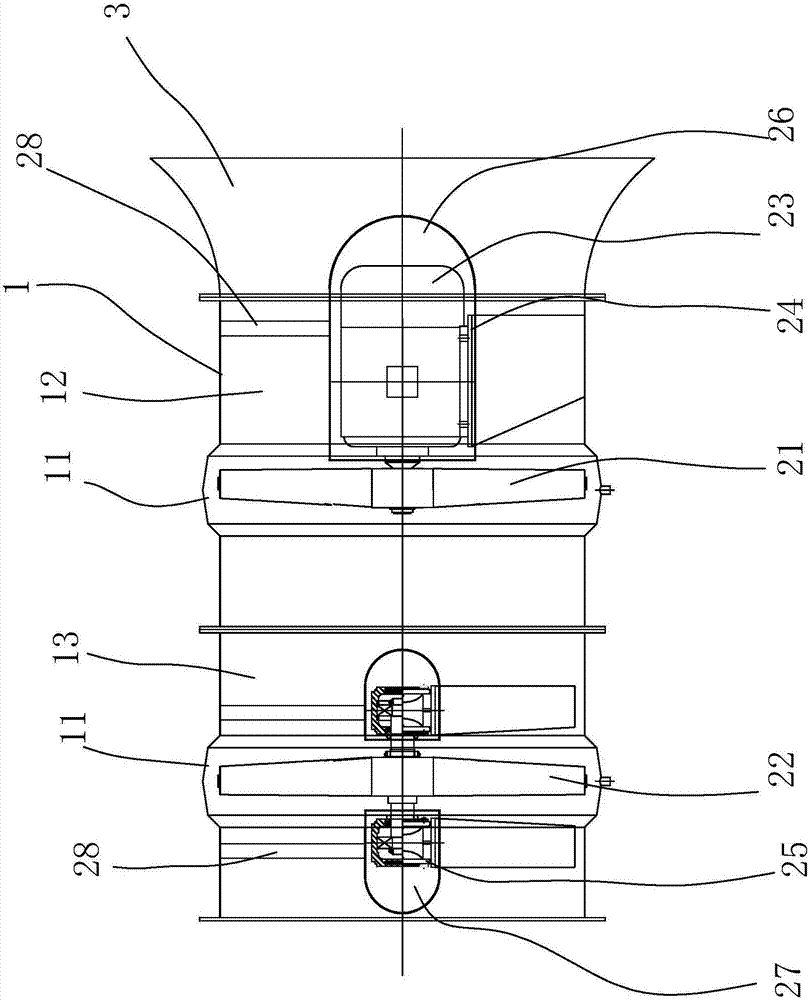

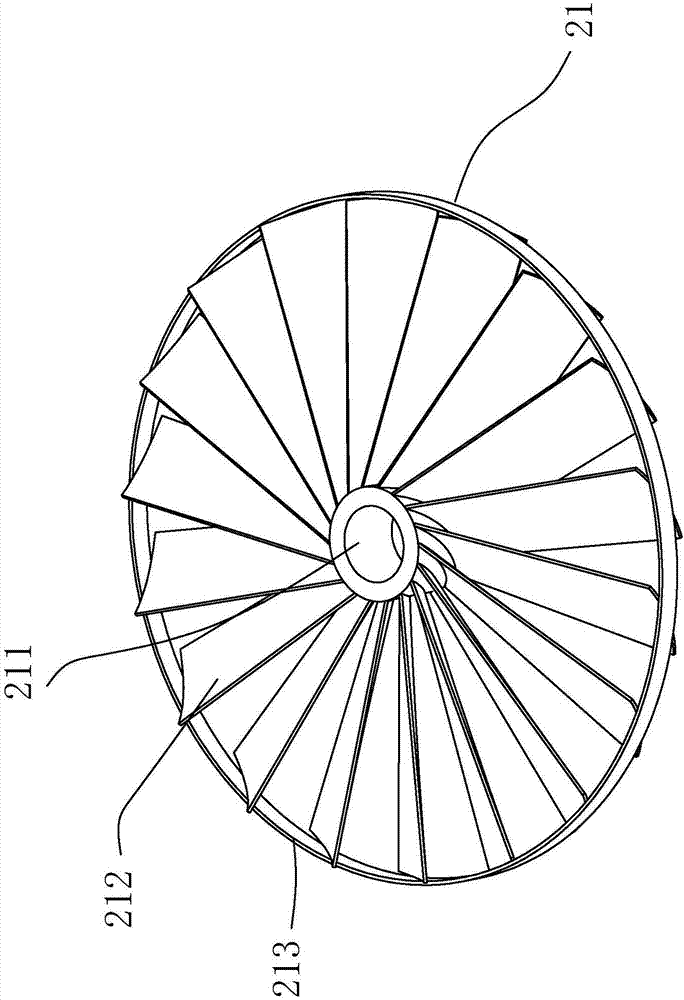

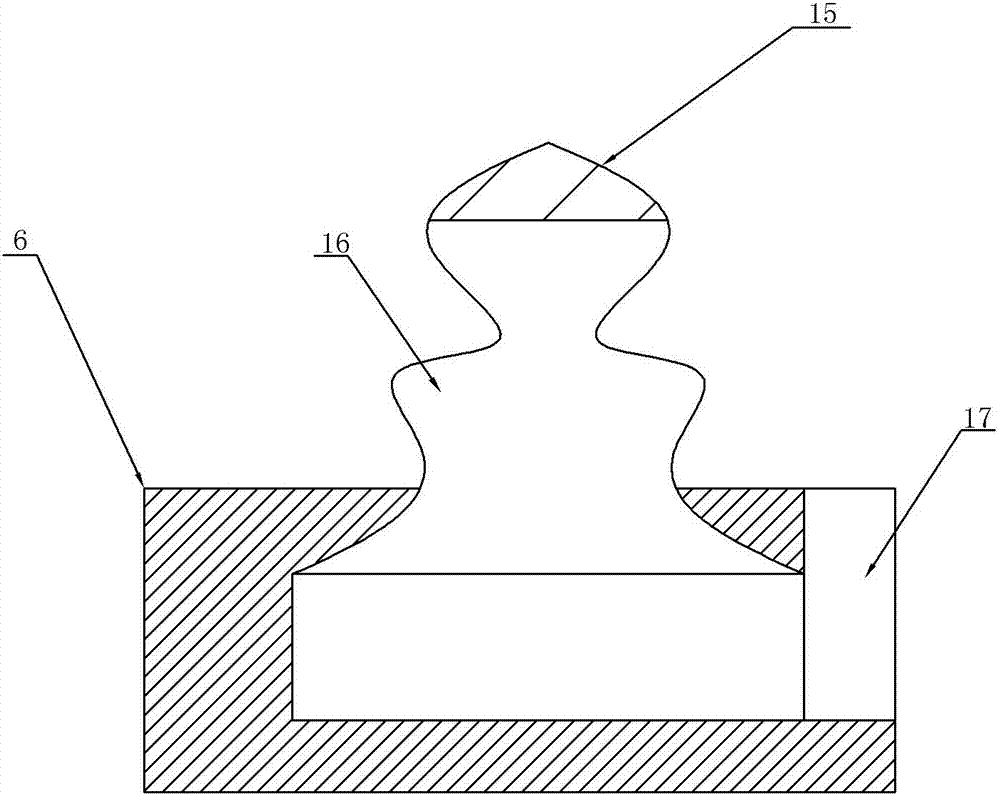

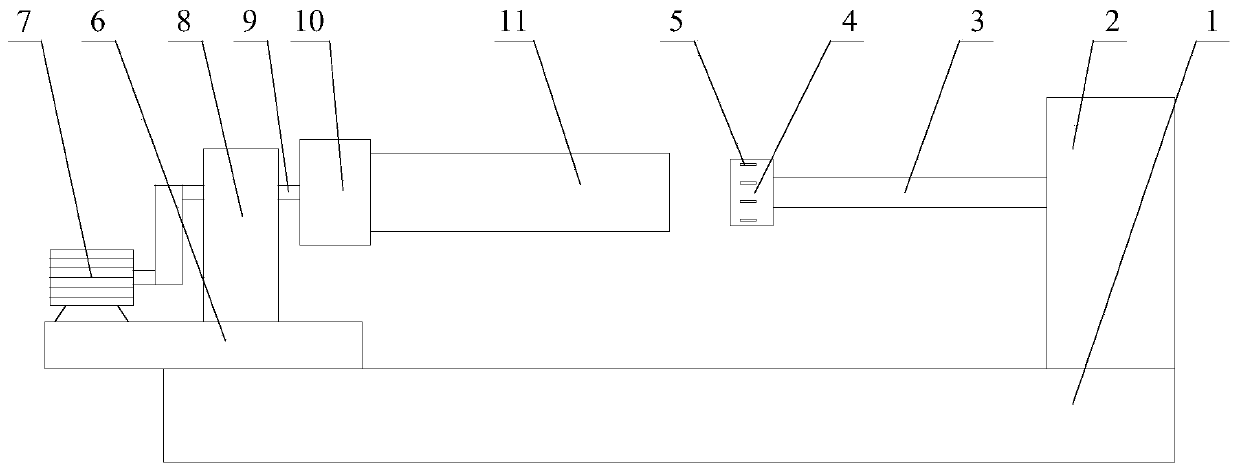

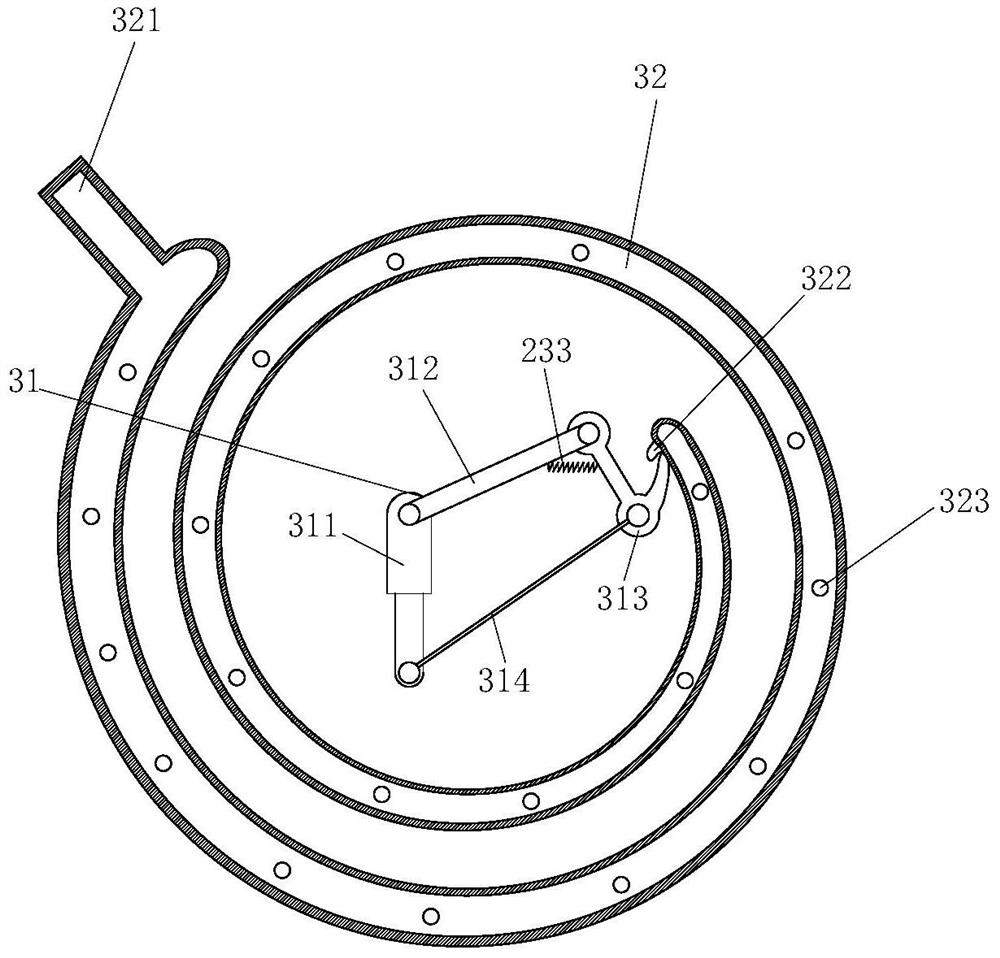

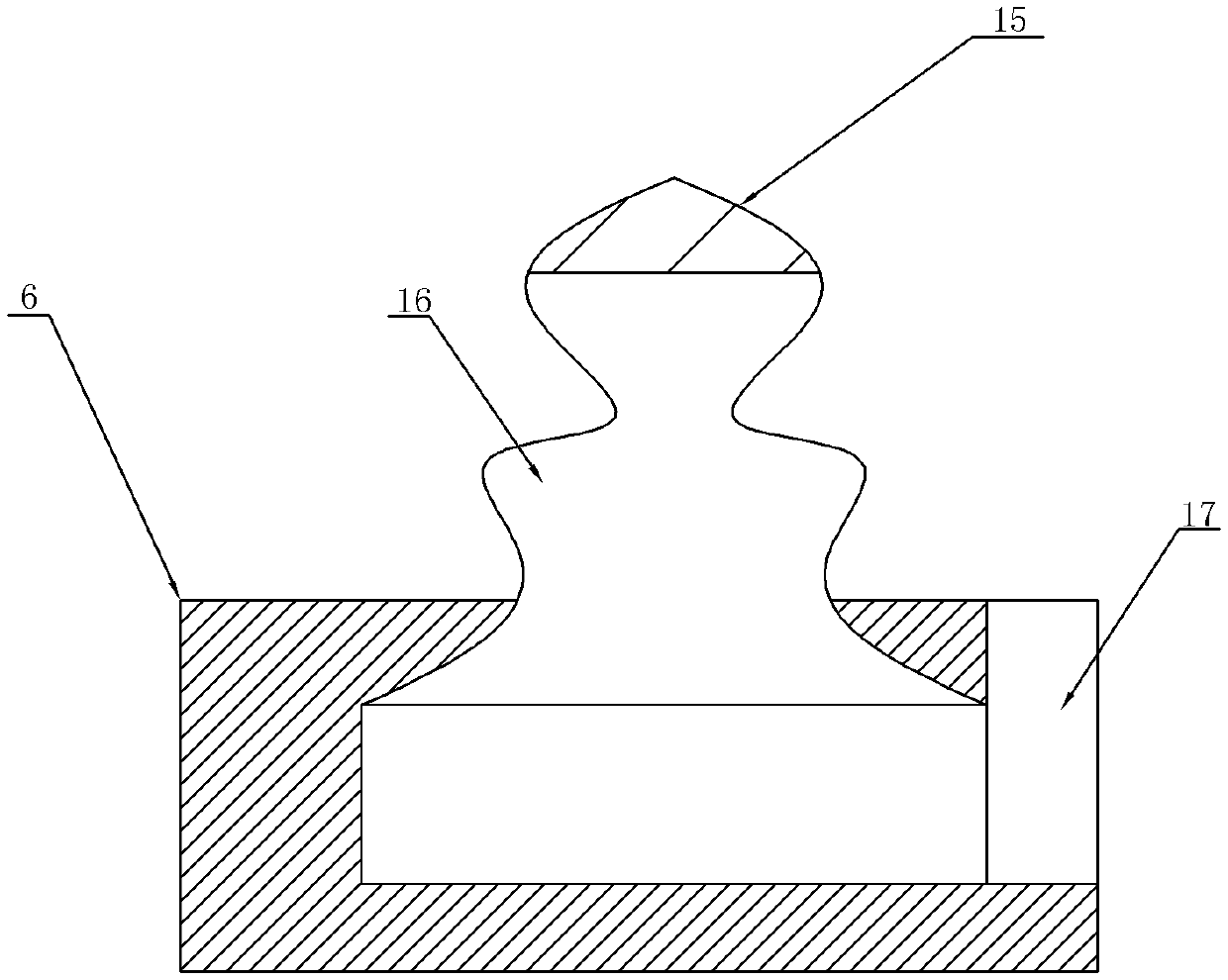

Cooking fume separating and purifying draught fan device

ActiveCN107449003AEasy to separateFull contact timeDomestic stoves or rangesLighting and heating apparatusElectric machineryStructural engineering

The invention discloses a cooking fume separating and purifying draught fan device. The cooking fume separating and purifying draught fan device comprises an air barrel. A draught fan is arranged in the air barrel and comprises a front separation impeller, a rear separation impeller and a motor. The motor is fixed to the middle of the air barrel through a supporting frame. The motor drives the front separation impeller to rotate, the rear separation impeller is connected with the air barrel through an installing base, the installing base is provided with a rotation shaft, and the rear separation impeller is connected with the rotation shaft. The axis of the rear separation impeller and the axis of the front separation impeller coincide with the axis of the air barrel. The rear separation impeller and the front separation impeller are in mirror symmetry. The two separation impellers on the same axis line are utilized, cooking fume is subjected to two-time cooking fume separation successively, and accordingly cooking fume separation is more thorough; meanwhile, the two separation impellers are driven only by one motor, one separation impeller actively rotates at a high speed, the other separation impeller passively rotates at a low speed, more sufficient contact time is provided for cooking fume and blades of the separation impellers, and accordingly the separation effect is better.

Owner:FOSHAN NANFANG RITCO ENERGY CLEAN TECH CO LTD

Method for manufacturing magnesium alloy-stainless steel composite board

ActiveCN109457263ASolve easy oxidationImprove wettabilityArc welding apparatusContact timeComposite plate

The invention discloses a method for manufacturing a magnesium alloy-stainless steel composite board, which belongs to the field of metal composite board processing and aims to solve the problem thatapplication, in the industrial field, of the magnesium alloy-stainless steel composite board with relatively good interface connection, which is difficulty formed by an existing forming method, is restrained. A packaging and sealing structure can be adopted to effectively solve the problem that oxidization is easily caused in a magnesium alloy heating process, so that inert gas does not need to additionally apply in a heating process for protection; a silver-coated layer of a to-be-combined surface can be taken as a transition element to improve wettability, on a stainless steel surface, of amagnesium alloy, so that metallurgical bonding of the combined surface is promoted; the temperature of a heating furnace exceeds a melting point of the magnesium alloy, and the magnesium alloy is quickly discharged out of the furnace for being quickly cooled after heat is preserved, so that magnesium alloy melt has sufficient contact time with the stainless steel surface, and therefore, diffusionof the interface element is facilitated; besides, the packaging sealing structure further can prevent the magnesium alloy melt from being heated to expand, so that pressure does not need to additionally apply through the method, relatively great stress is generated on the combined interface, and diffusion connection of the combined interface is promoted.

Owner:JILIN UNIV

Chroming mist recycling method

ActiveCN107376592AAchieve emission goalsDoes not require manual maintenanceGas treatmentUsing liquid separation agentFilling materialsWastewater

The invention discloses a chroming mist recycling method. A pure physical method is adopted for absorbing chroming mist generated in an electroplating production process into serially connected recycling treating units through a notch fan cover and then performing the processes of diffusing, colliding, coring, agglomerating and settling, so that the chroming mist is stopped and absorbed to the surfaces of a baffle plate and a filling material, and meanwhile, the chroming mist is intermittently and circularly flushed back to the present collecting tank, so that the chroming mist is intercepted, captured and recycled. No wastewater is discharged in the whole process, so that the purpose of environment-friendly emission of the chroming mist is achieved.

Owner:石家庄印钞有限公司

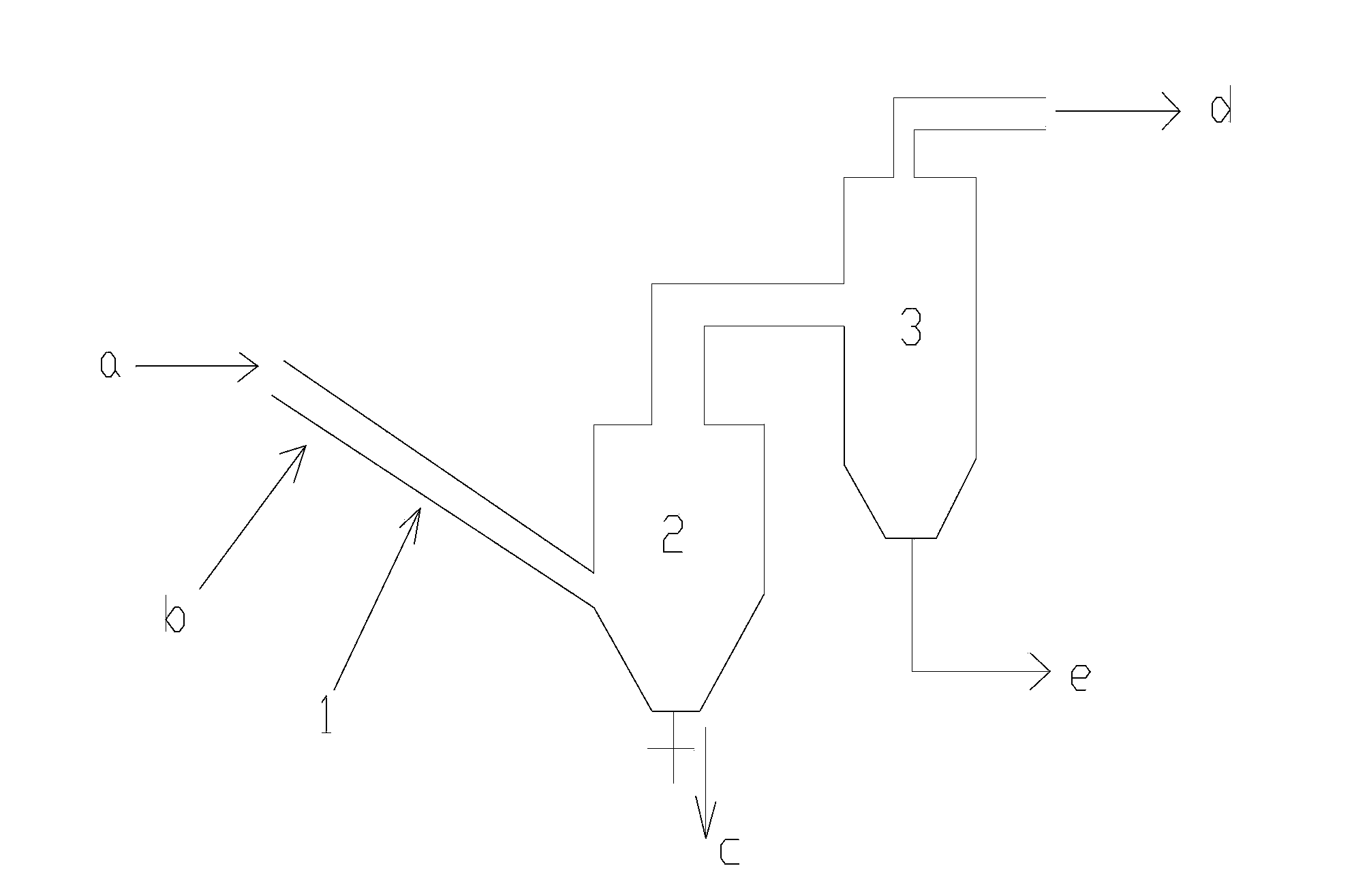

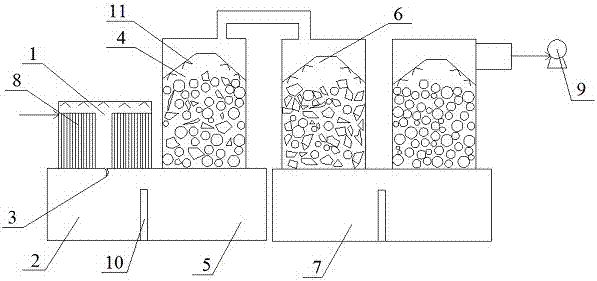

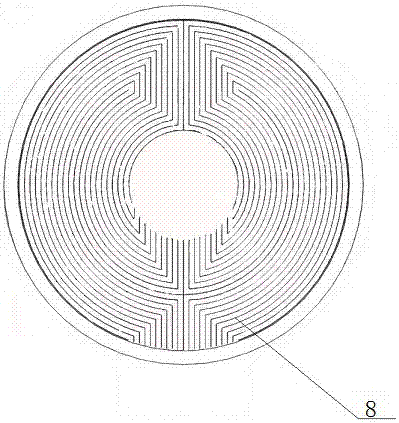

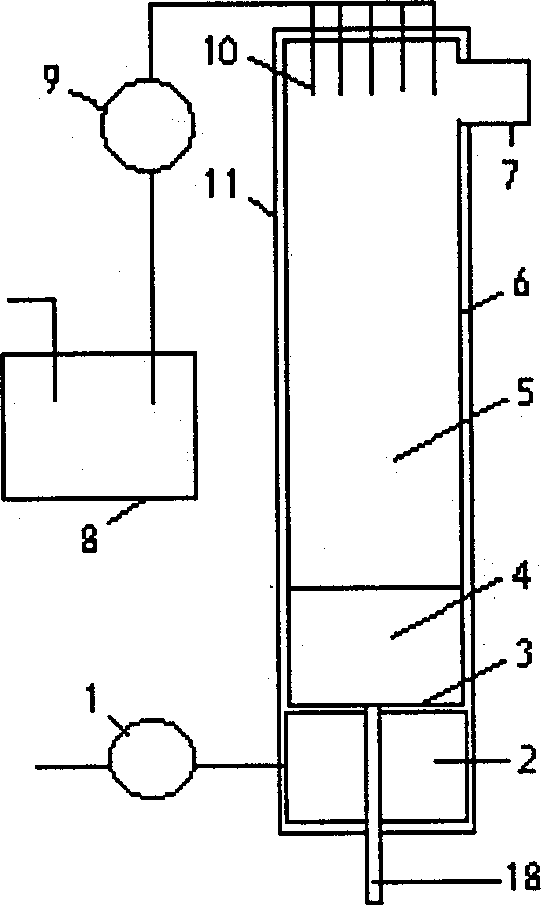

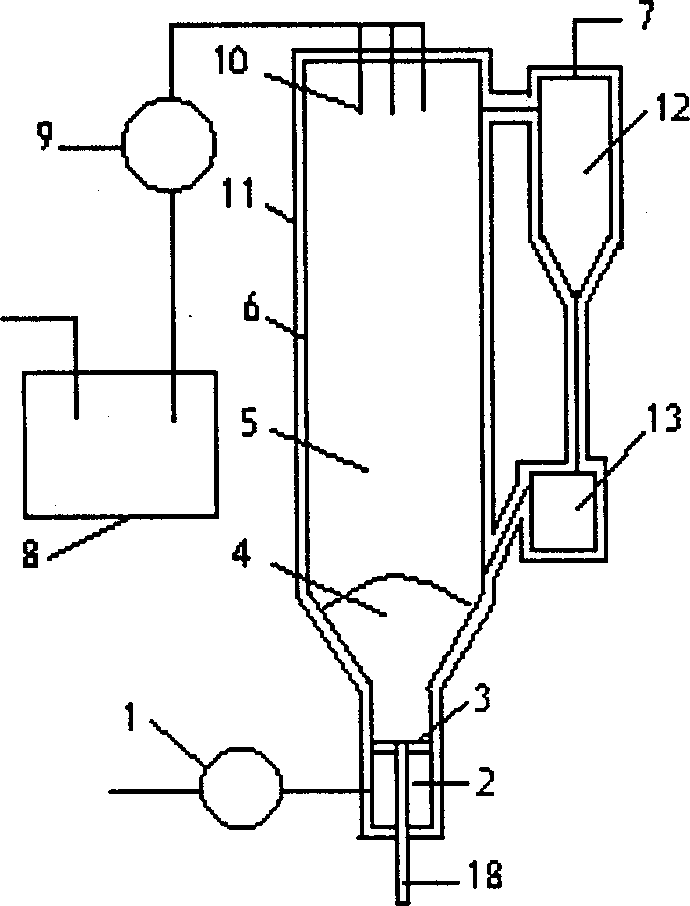

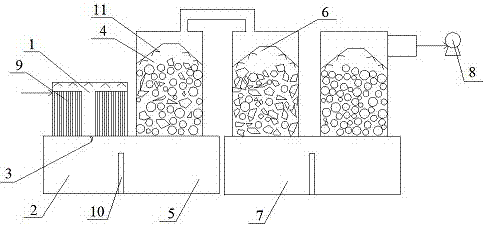

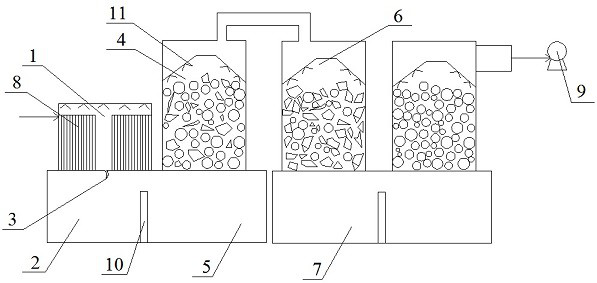

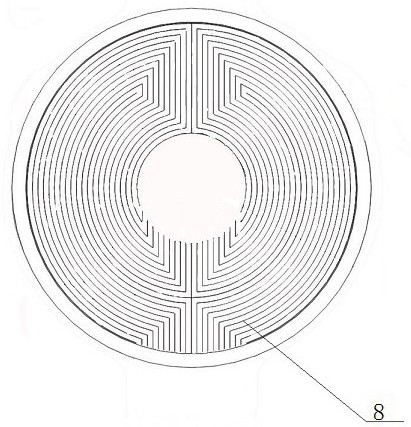

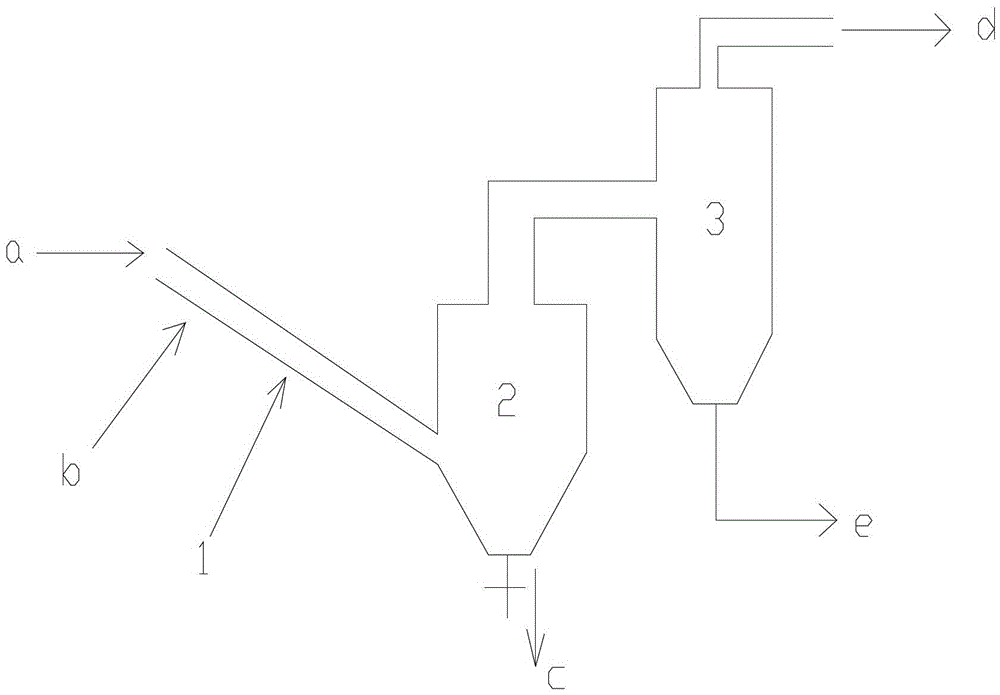

Flue gas desulfuring method and its device for density current fluidised bed

InactiveCN1391979ANo wearNo blockageDispersed particle separationChemical reactionVolumetric Mass Density

The present invention relates to the desulfurizing of gas containing sulfur oxide exhausted in industrial process and aims at providing flue gas desulfurizing device with low cost, simple structure and easy maintenance. Sulfur containing flue gas is made to enter to the fluidized reactor from bottom, desulfurizing slurry is made to enter to the reactor from the top, and flue gas is forced to pass through large particle coagulating area comprising large particle bed material and calcium hydroxide and the suspension area comprising calcium hydroxide particle, so that desulfurizing agent and SO2 can contact in sufficient time and space for full chemical reaction. The present invention has high desulfurizing efficiency and high desulfurizing agent utilization.

Owner:UNIV OF SCI & TECH BEIJING

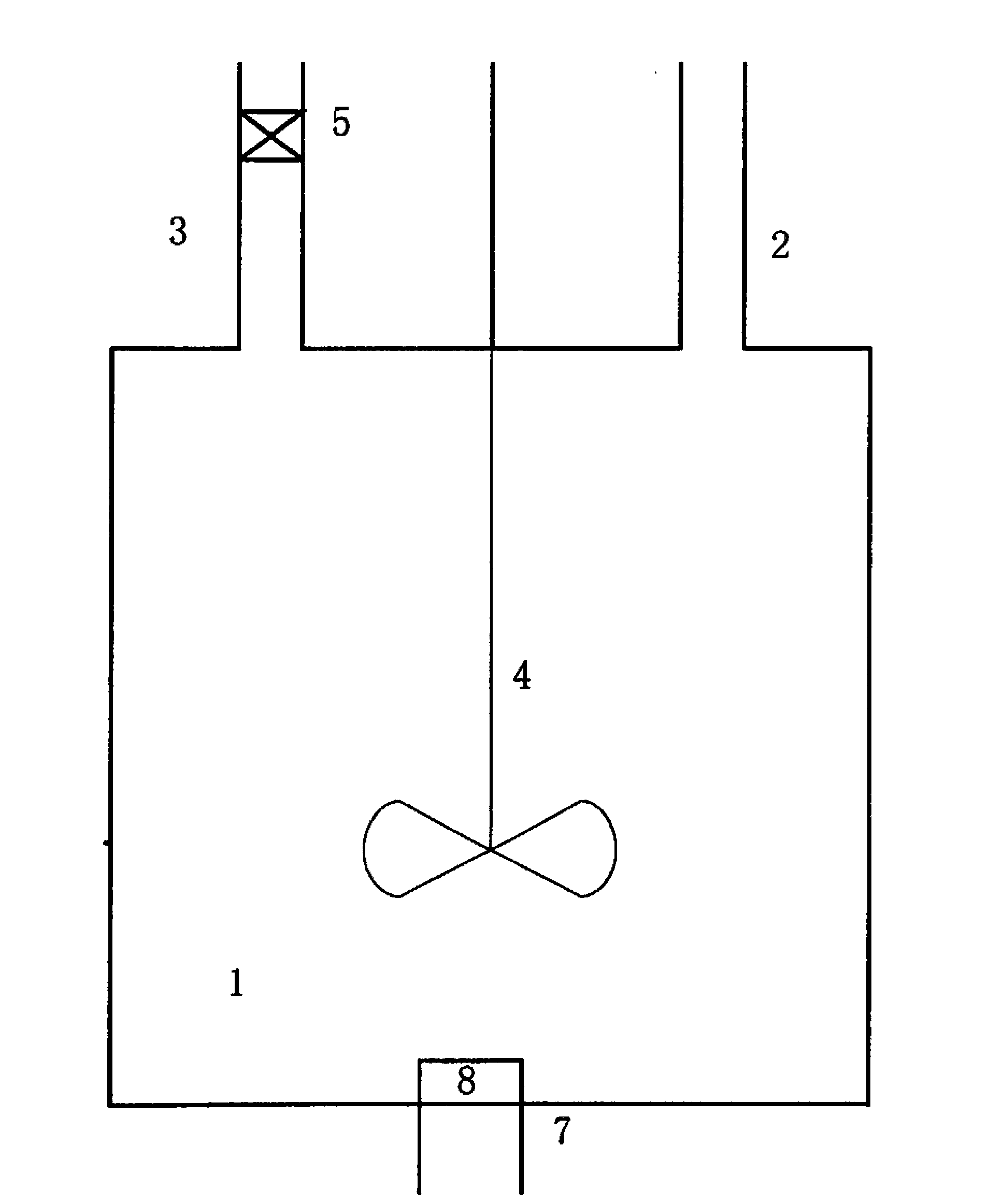

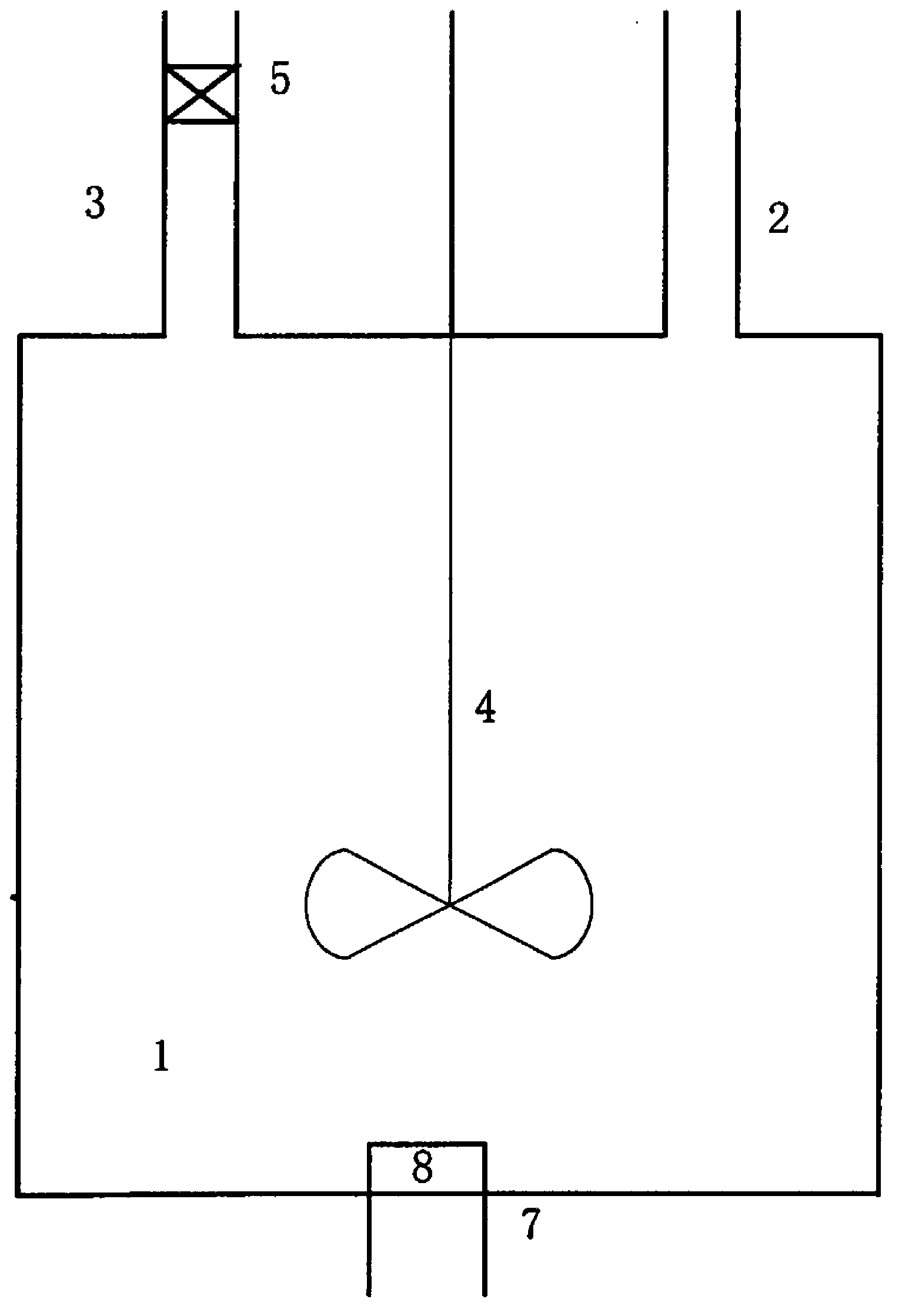

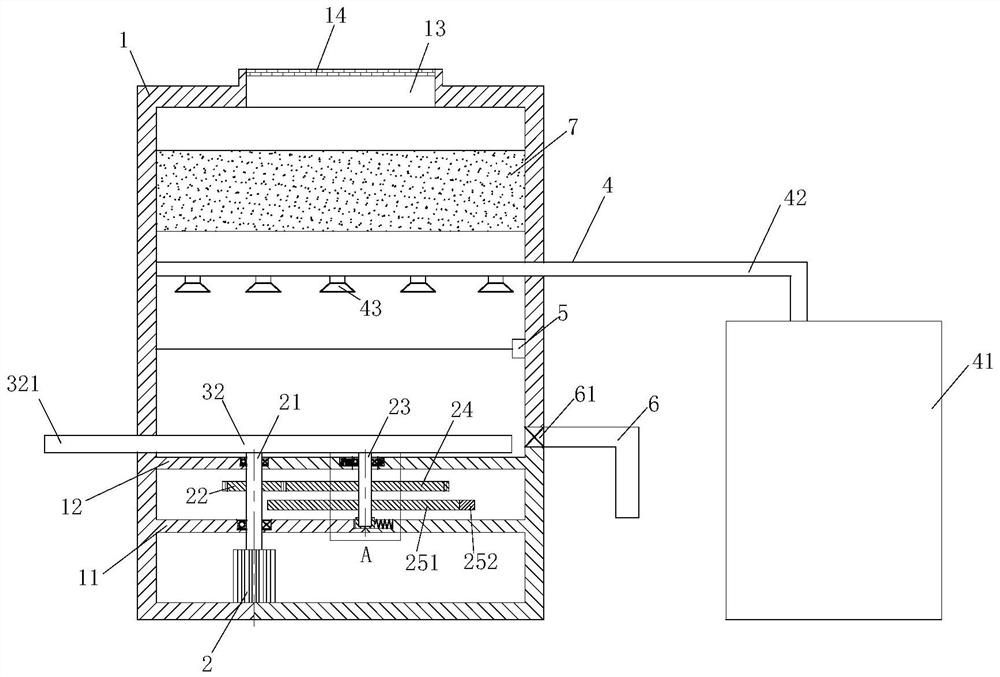

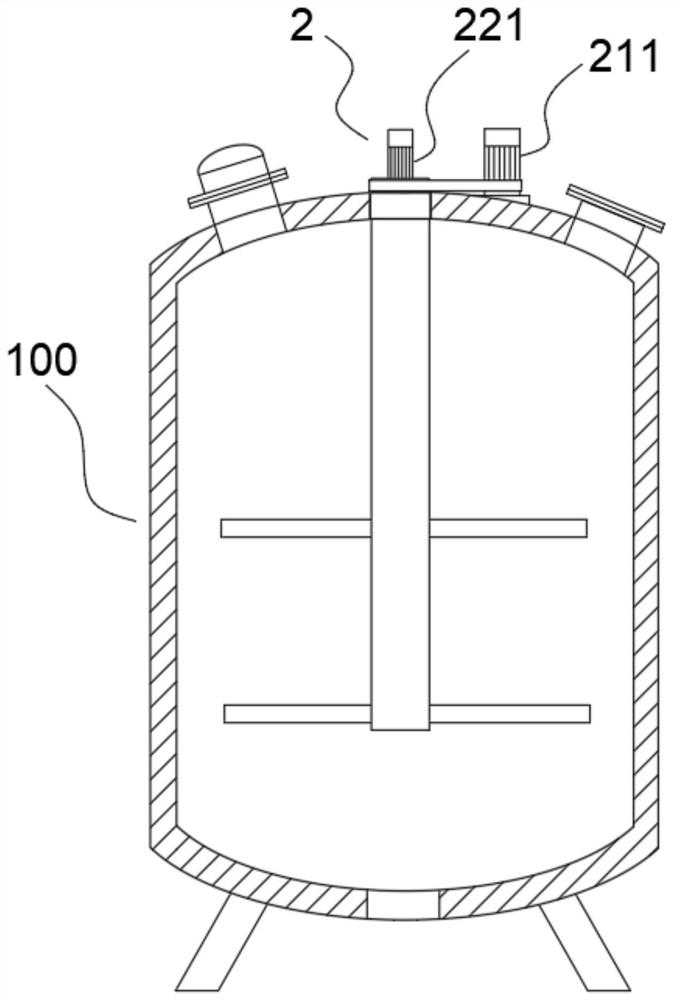

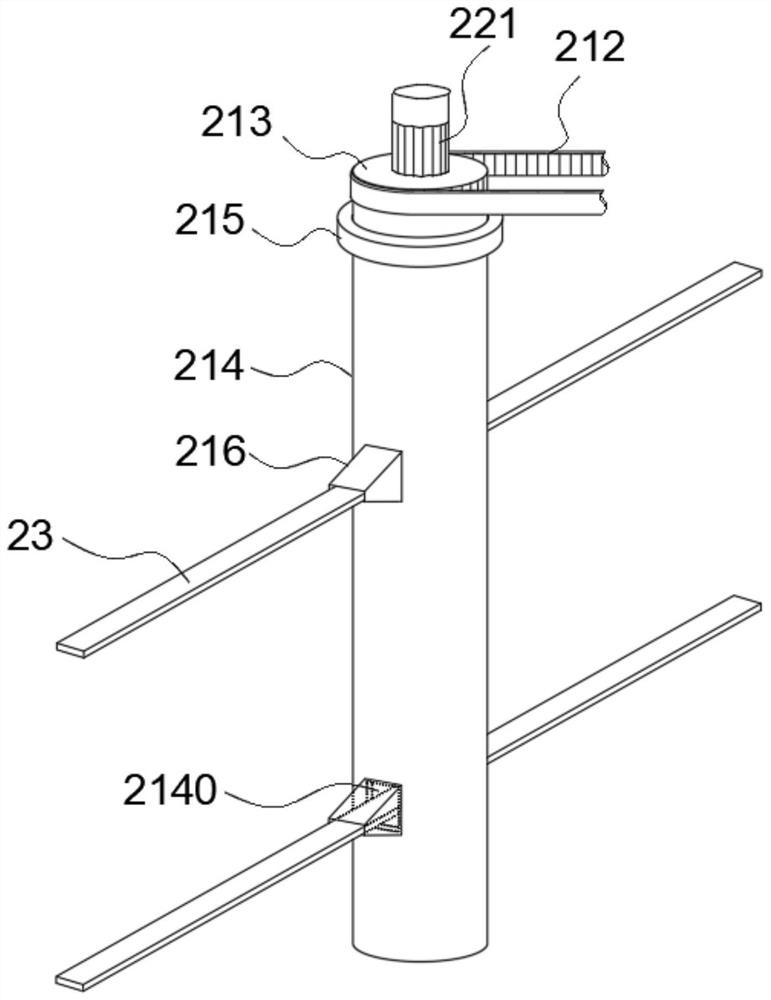

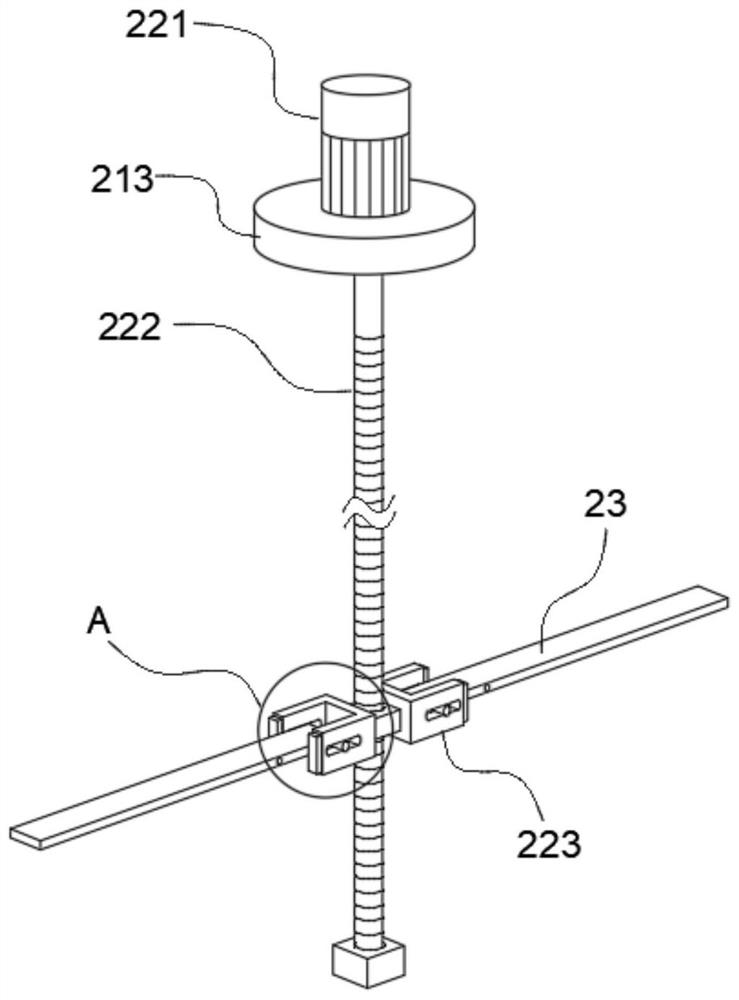

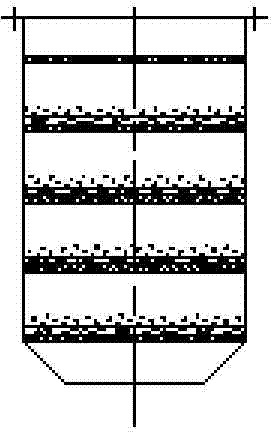

Stirring process based on solder paste production

ActiveCN107537371AFull contact timeSlow rotationRotary stirring mixersMixer accessoriesSolder pasteEngineering

The invention relates to the technical field of solder paste production and processing, and discloses a stirring process based on solder paste production. The stirring process is carried out by a solder paste stirring device which comprises a stirring barrel, a stirring shaft, a discharging box, a rack and a motor, wherein the stirring barrel is fixedly mounted on the rack; the stirring shaft is mounted in the stirring barrel; the discharging box is located above the stirring barrel and is fixedly connected with a lower part of the motor; the motor is fixedly mounted on the rack; an airbag isarranged on one side of the stirring barrel; an air cavity communicated with the airbag is formed in the stirring barrel; a dispersing mechanism is arranged on a side wall of the stirring barrel; thedispersing mechanism comprises a fixed base, a rubber bag and an extruding part; an inner cavity communicated with the air cavity is formed in the fixed base; an air outlet check valve with an air outlet toward the stirring shaft is arranged on the fixed base; the extruding part is fixedly mounted on the rubber bag; the rubber bag is communicated with the inner cavity; a material cavity communicated with the discharging box is formed in the upper part of the stirring shaft; a discharge hole is formed in the side wall of the material cavity. The stirring process provided by the invention has agood stirring effect and reduces production of bubbles of solder paste.

Owner:广东天高科技有限公司

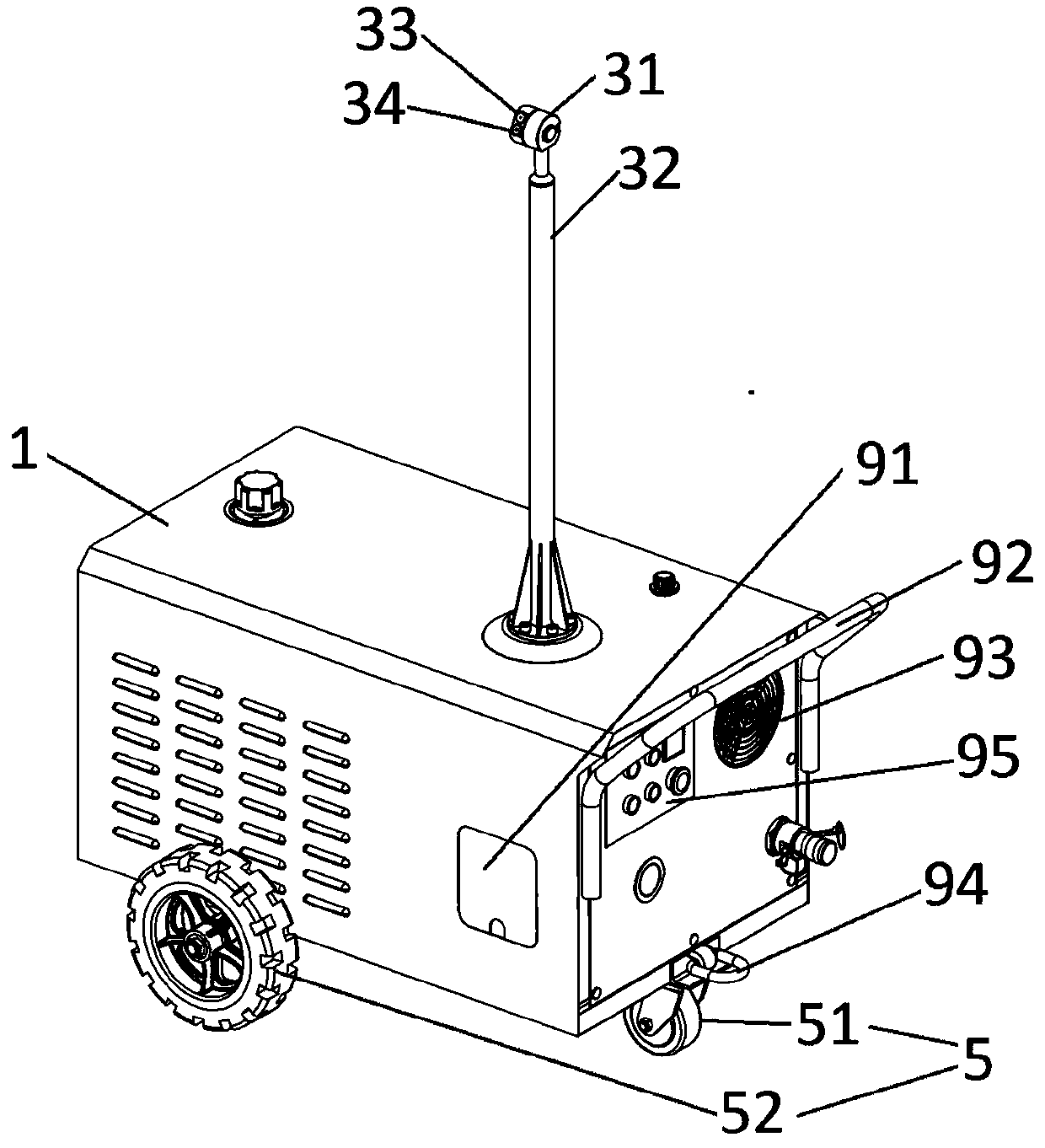

Spray type dust fall device

InactiveCN111097612ASimple structureGood effect of dust suppressionUsing liquid separation agentLiquid spraying apparatusWater storageSpray nozzle

The invention discloses a spray type dust fall device. The spray type dust fall device comprises a water storage device, a water pump, a rotary device and a spraying device. A water outlet of the water storage device is connected with a water inlet of the water pump. A water outlet of the water pump is connected with a water inlet of the spraying device. The water pressure at the water outlet of the water pump ranges from 4MPa to 15MPa. The spraying device comprises a spray head body, a short-range spray nozzle and a remote spray nozzle. The short-range spray nozzle and the remote spray nozzleare fixed to the front end of the spray head body from top to bottom in sequence. The rotary device is in rigid connection with the spray head body and is used to enable the front end of the spray head body to horizontally rotate clockwise or anticlockwise. According to the spray type dust fall device, because the water storage device, the water pump, an action mechanism and the spraying device are used in cooperation, sprayed water mist is uniform in mist droplets, large in density and broad in coverage area; and the spray type dust fall device is especially suitable for water mist spray ofa wide range.

Owner:WUHAN MAJOR DAY DIGITAL MACHINERY MFG CO LTD

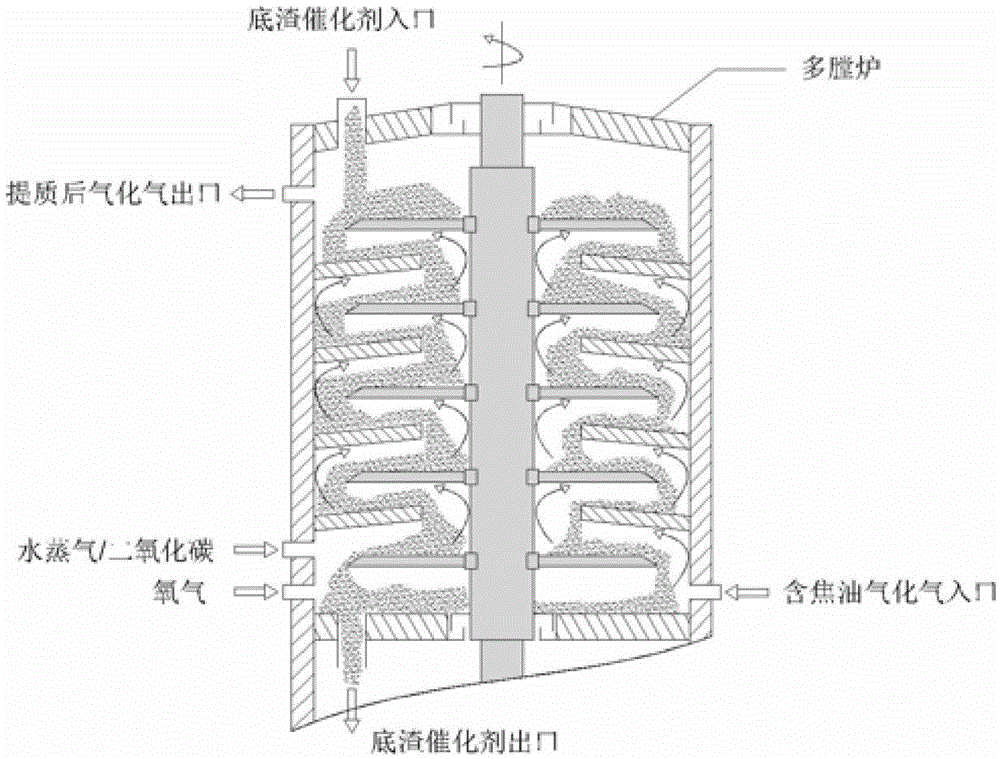

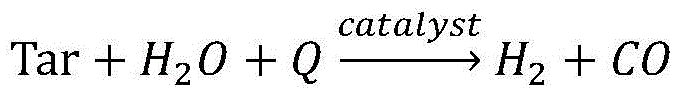

Technology for catalysis and quality improvement by using waste gasified gases

InactiveCN105602630AHigh catalytic activityMaintain catalytic activityGas purification by catalytic conversionChemical recyclingWater vaporDecomposition

The invention discloses a technology for catalysis and quality improvement by using waste gasified gases. A catalyst used for catalytic cracking of tar in gasified gases is selected from bottom slag in a domestic waste fluidized bed incinerator, crushed and activated bottom slag has a certain aperture structure, and calcium oxide and waste iron in the bottom slag have a catalytic cracking effect on the tar. The waste gasified gases are in full contact with the bottom slag catalyst in a multi-hearth furnace, the tar undergoes thermal cracking and catalytic cracking on the surface of the catalyst, and solid particles delay in the multi-hearth furnace. H2 generated after cracking of the tar reduces iron oxides in the catalyst into elemental iron, and CO2 and water vapor in the gasified gases react with carbon deposited on the surface of the catalyst to maintain the activity of the catalyst. The technology fully utilizes the bottom slag of the domestic waste fluidized bed incinerator, realizes waste recycling, realizes decomposition of dioxins in the bottom slag, also realizes recycling of the catalyst, purifies the waste gasified gases, and converts the tar into inflammable gases.

Owner:ZHEJIANG UNIV

Processing device for polishing special material

PendingCN110103088ANo jitterImprove machining accuracyRevolution surface grinding machinesSurface finishDrive shaft

The invention relates to a processing device for polishing a special material. The processing device comprises a base and a grinding wheel. A fixed table is fixedly mounted on one side of the base, and a fixed rod is fixedly assembled on the fixed table. The grinding wheel is mounted at the tail end of the fixed rod. A stepping workbench capable of doing reciprocating motion in the axial directionof the fixed rod is mounted and arranged on the other side of the base. A driving motor and a rotary shaft fixing frame are fixedly arranged on the stepping workbench, a driving shaft coaxial with the fixed rod is assembled on the rotary shaft fixing frame, the driving shaft is driven by the driving motor to rotate, and the output end of the driving shaft is fixedly connected with a workpiece fixing sleeve for fixing a processed workpiece. According to the processing device, the inner wall of a nodular cast iron pipe can be polished fast and efficiently, the processing precision is high, andthe surface smoothness is high.

Owner:HUANGSHI GAOCHAO IND & MINING MACHINERY

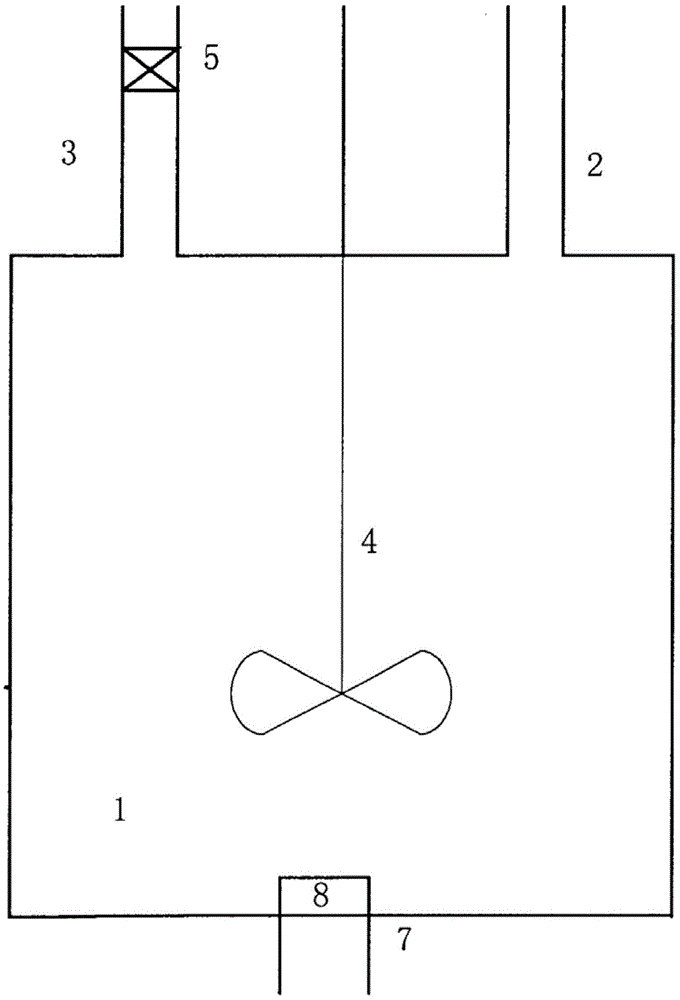

Air pollution abatement purification tower

PendingCN114177753AImprove purification efficiencyAdequate responseTransportation and packagingMixing methodsElectric machineryEnvironmental engineering

The invention relates to the technical field of environmental pollution abatement, in particular to an atmospheric pollution abatement purification tower which comprises a tower body, a first partition plate and a second partition plate are arranged in the tower body and are both parallel to the bottom face of the purification tower, and the second partition plate is located above the first partition plate; a motor is directly and fixedly installed on the first partition plate and the bottom face in the tower body, an air inlet mechanism is fixedly installed at the ends, away from the first partition plate, of the first rotating shaft and the second rotating shaft and located above the second partition plate, a purification mechanism is arranged on the portion, away from the air inlet mechanism, above the second partition plate, and an air outlet is formed in the upper end of the tower body. A filter plate is mounted at one end, away from the tower body, of the gas outlet. According to the invention, the inside of the reaction liquid is stirred by utilizing the contraction and deformation recovery process of the gas pipe, and compared with transmission stirring, the scheme does not generate vortexes during stirring, so that all gases have sufficient contact time with the reaction liquid, and the reaction is complete.

Owner:孙碧婷

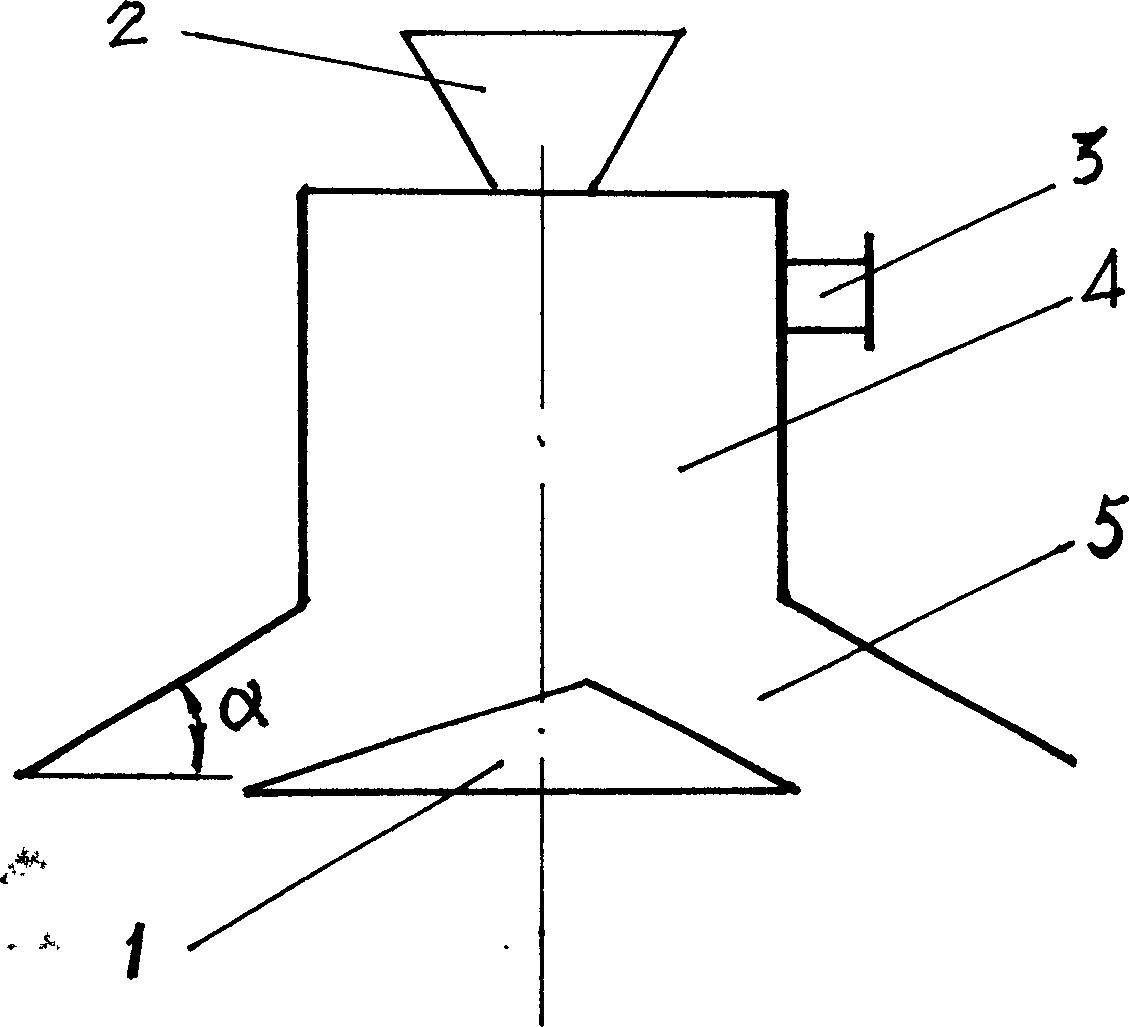

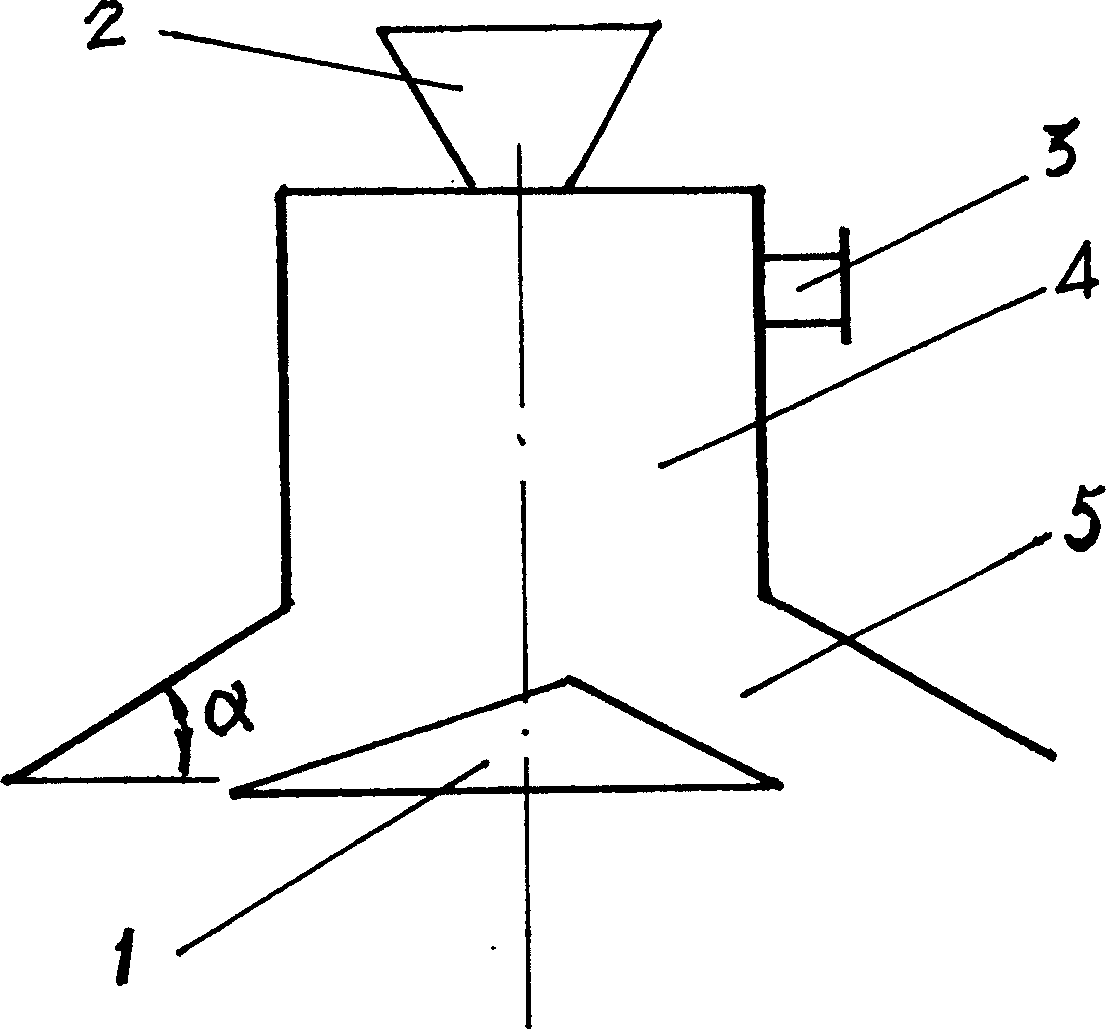

High-strength, low cost and wide coal kind gas producer

InactiveCN1435469AStrong penetrating powerIncreased chance of properly oriented collisionsCombustible gas productionHigh intensityProcess engineering

A gas generator is disclosed. Its features are high gasifying intensity (1600-1800 kg / sq.m.hr), broad spectrum of raw materials including soft coal, hard coal, coal gangue and combustible solid, and low cost.

Owner:陈科正

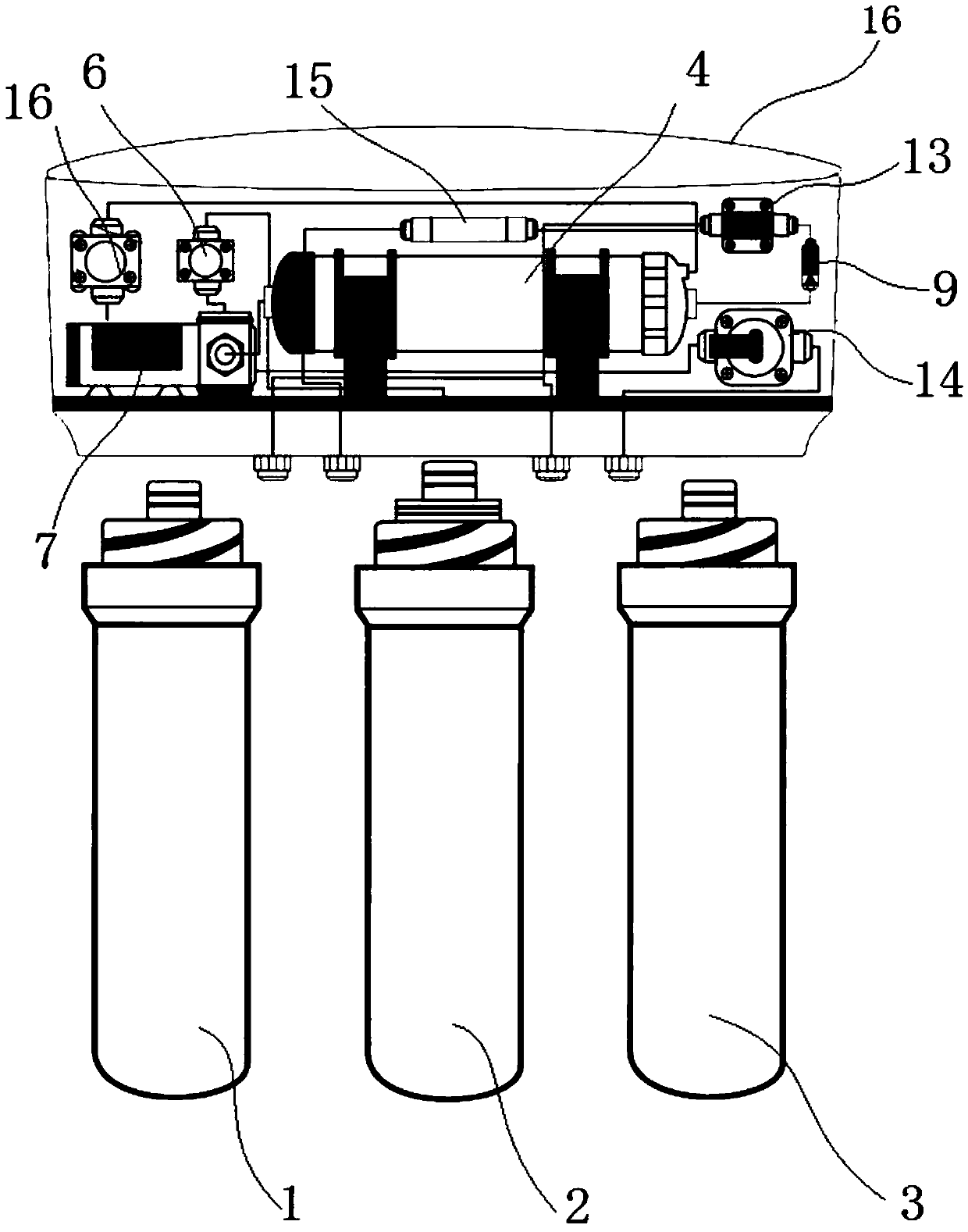

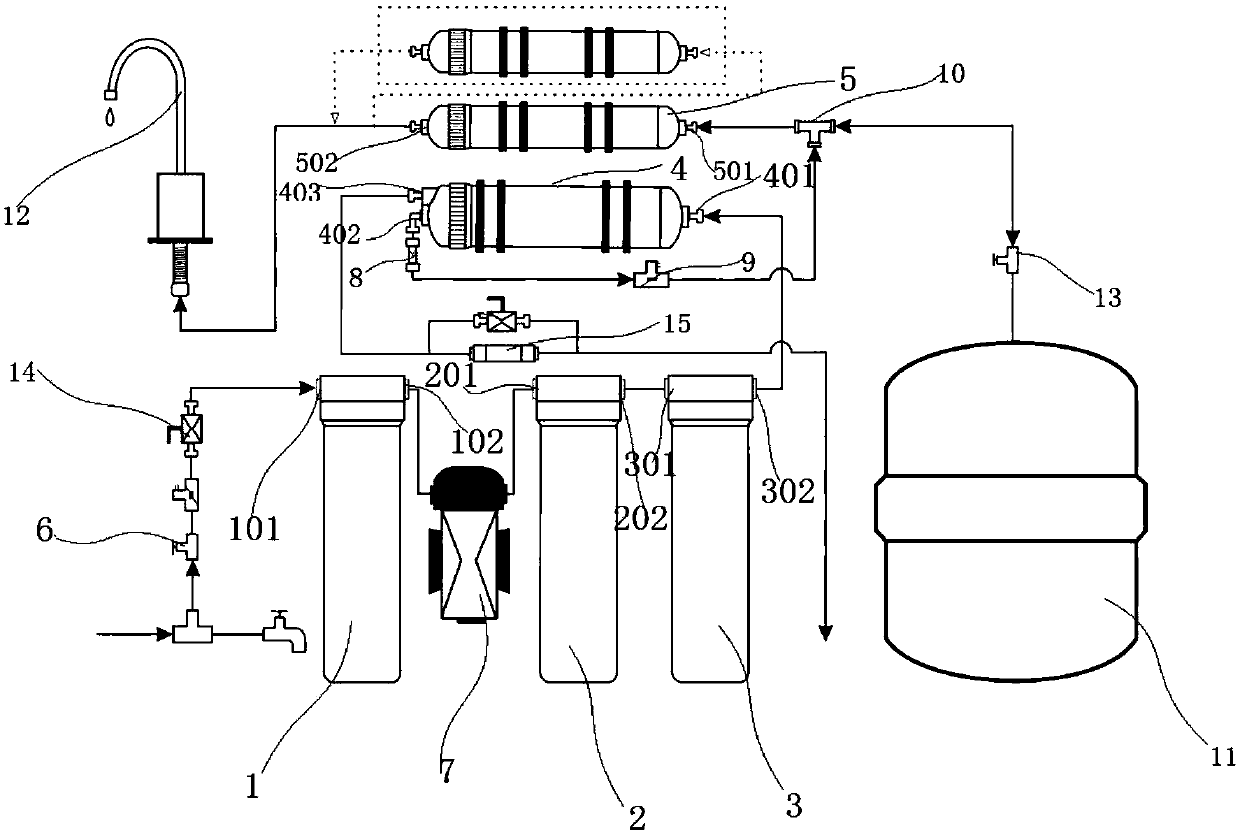

Small and integrated reverse osmosis water purifier

InactiveCN110316844ASmall integration implementationGive full play to the filtering effectTreatment involving filtrationMultistage water/sewage treatmentSufficient timeReverse osmosis

The invention discloses a small and integrated reverse osmosis water purifier and relates to water purifiers. The small and integrated reverse osmosis water purifier comprises a first filtering unit,a second filtering unit, a third filtering unit, a first rear filtering unit and a second rear filtering unit, wherein one end of the first rear filtering unit is provided with a fourth water inlet, the other end of the first rear filtering unit is provided with a fourth purified water outlet, one side of the further purified water outlet is provided with a wastewater outlet, and the further purified water outlet is sequentially connected with a washing electromagnetic valve and a check valve. According to the small and integrated reverse osmosis water purifier, through optimal design of a water route, water flowing through filters can flow in a scattered mode to enlarge the filtering area, ensure uniform contact, avoid filtering dead ends and accordingly give full play of the filtering effects of every filter material; by enlarging the filtering area and improving and optimizing the water flow path, filtering materials can have sufficient time for contact with water, so that the filtering effects can be greatly improved, and miniaturization and integration of the water purifier can be achieved.

Owner:沃世达(厦门)水科技有限公司

The Method of Designing Multiple Overflow Trays by Equal Residence Time Method

The invention relates to a method designing a multi-overflow tray by an equal residence time method, which is intended to raise tray mass transfer efficiency and processing capability, and alleviate amplification effect of equipment. The method is defined by residence time of the liquid on a tray bubbling zone, integrates advantages using an equal channel length method and an equal bubbling area method, takes regard of a contraction effect of a tower wall to a liquid flow and influence of physical property condition on the flow, and provides a calculating formula of the channel length in the tray bubbling zone under the equal residence time. Downcomer weirs on the edge at two sides of the tray are in a backswept weir structure, in order to increase overflow circumference length of the downcomer at two sides. A lower edge of an eccentric downcomer uses an arc or tooth-form structure, in order to balance a bottom gap outlet area of the downcomer. A liquid distribution plate is arranged in a liquid accepting plate, in order to balance liquid flow distribution at two sides of the downcomer. The method enables the liquid flow on each tray bubbling zone to have similar residence time and mass transfer efficiency, and achieves effects of reasonably distributing liquid, promoting gas and liquid uniform distribution and alleviating amplification effect of the tower equipment. The method is particularly suitable for large-scale tower equipment with high gas-liquid phase load.

Owner:PETROCHINA CO LTD +2

Two-phase flowing biological bed based on composite oil removal bacteria

ActiveCN111003797ARich pore structureImprove structural strengthTreatment using aerobic processesWater treatment compoundsPolyesterNutrition

The invention discloses a two-phase flowing biological bed based on composite oil removal bacteria. According to the two-phase flowing biological bed, fixed plates parallel to the bottom of an aerobicpool are arranged in the aerobic pool; the fixed plates are provided with gas holes for passing through of gas; the adjacent fixed plates are filled with aerobic filler blocks; an aeration device isarranged below the fixed plates; and the aerobic filler blocks are internally provided with a mixture of an active carrier, a composite oil removal bacterial agent and a nutrition agent thereof, wherein the active carrier is 20-40 parts of modified active carbon fiber, the composite oil removal bacterial agent comprises a plurality of bacteria selected from bacillus, yeast and micrococcus, and thenutrition agent is prepared from 2 to 6 parts of uric acid, 1 to 6 parts of phosphate, 8 to 16 parts of glucose, 0.4 to 1.2 parts of arachidonic acid, 0.3 to 0.9 part of sucrose polyester and 1 to 4parts of magnesium sulfate. According to the invention, the strain changes the hydrophobicity of the surface of the strain by releasing surface active substances on the surface of the strain, so thatthe strain is easily attached to the surfaces of hydrocarbon substances.

Owner:杭州卡锘新材料科技有限公司

Chromium plating fog recovery and purification device

The invention discloses a chromium plating fog recovery and purification device, and belongs to the technical field of chromium plating waste gas recovery processing technology. The chromium plating fog recovery and purification device includes a chromium fog channel, the chromium fog channel is formed by a plurality of stages of recovery and purification chambers, the plurality of stages of recovery and purification chambers are connected in series in turn, and are communicated with a chromium plating bath and a fan for pumping air. Each recovery and purification chamber comprises a condensing chamber and a recovery water tank, the upper part of the condensing chamber is provided with a spraying device, the recovery water tank is located below the condensing chamber, and the recovery water tank is correspondingly communicated with the condensing chamber, and a next-stage recovery water tank supplies water for the spraying device of a front-stage recovery and purification chamber. The plurality of stages of recovery and purification chambers are used for physical interception of chromium fog in the chromium plating bath, and the whole recovery and purification process is free of wastewater discharge and physical maintenance.

Owner:石家庄印钞有限公司

Traditional Chinese medicine plaster for treating tunica mucosa oris ulcer and its preparation method

InactiveCN1954843BAvoid discomfortImprove complianceDigestive systemSheet deliveryAdhesiveTunica mucosa oris

A Chinese medicine in the form of plaster for treating oral mucosa ulcer is composed of a medicinal layer made of the Chinese medicine for treating mucosa ulcer and adhesive and an isolating layer containing water isolating material. Its preparing process is also disclosed.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

Stirring Process Based on Solder Paste Production

ActiveCN107537371BFull contact timeSlow rotationRotary stirring mixersMixer accessoriesEngineeringAirbag

The invention relates to the technical field of solder paste production and processing, and discloses a stirring process based on solder paste production, which is carried out using a solder paste stirring device. The solder paste stirring device includes a stirring barrel, a stirring shaft, a discharge box, a frame and a motor, and the stirring barrel It is fixedly installed on the frame, the stirring shaft is installed in the mixing barrel, the discharge box is located above the mixing barrel and is fixedly connected with the lower part of the motor, and the motor is fixed on the frame; there is an air bag on one side of the mixing barrel, The bucket is provided with an air cavity connected with the air bag, and the side wall of the mixing tank is provided with a dispersing mechanism. The dispersing mechanism includes a fixing seat, a rubber bag and an extruded part. The air outlet is facing the air outlet one-way valve of the stirring shaft. The extruded part is fixedly installed on the rubber bag, and the rubber bag is connected with the inner cavity. The upper part of the stirring shaft is provided with a material chamber connected with the discharge box. hole. The invention has good stirring effect and reduces the generation of solder paste bubbles.

Owner:GUANGDONG TIANGAO TECH CO LTD

High-strength, low cost and wide coal kind gas producer

InactiveCN1238474CStrong penetrating powerIncreased chance of properly oriented collisionsCombined combustion mitigationCombustible gas productionHigh intensityProcess engineering

Owner:陈科正

Novel efficient plant deodorant and preparation method thereof

PendingCN114042373AImprove deodorizing effectGood deodorizing effectGas treatmentTransportation and packagingZinc atomZinc ricinoleate

The invention discloses a novel efficient plant deodorant and a preparation method thereof. The plant deodorant comprises the following components in parts by weight: 15-25 parts of zinc diricinoleate, 10-20 parts of plant essential oil, 1-4 parts of an antibacterial agent, 2-5 parts of a preservative, 8-15 parts of nano microspheres, 1-3 parts of an emulsifier and 70-80 parts of deionized water. According to the invention, the zinc diricinoleate and the plant essential oil have a synergistic effect, the deodorization effect of the plant deodorant is improved, activated zinc atoms in the zinc diricinoleate can form a very strong combination with nitrogen and sulfur atoms in odor, and therefore the odor is thoroughly eliminated. Meanwhile, the manganese oxide nanofiber microspheres are used as carriers to store formaldehyde and other odorous gases, so that zinc diricinoleate can act on the odorous gases to remove the odorous gases.

Owner:苏州市易柯露环保科技有限公司

A kind of chrome-plating mist recovery treatment method

ActiveCN107376592BAchieve emission goalsDoes not require manual maintenanceGas treatmentUsing liquid separation agentWater dischargeWastewater

The invention discloses a method for recovering and treating chromium-plating mist. The chromic acid mist generated in the electroplating production process is sucked step by step into series-connected recovery and treatment units through a notch wind cover through a purely physical method. , sedimentation and other processes, which are intercepted and adsorbed on the surface of the barrier plate and filling material, and recycled to the recovery tank of the same level after intermittent and circular washing, so as to achieve the interception, capture and recycling of chromic acid mist, and realize chrome plating without wastewater discharge in the whole process Exhaust gas meets the purpose of environmental protection emission.

Owner:石家庄印钞有限公司

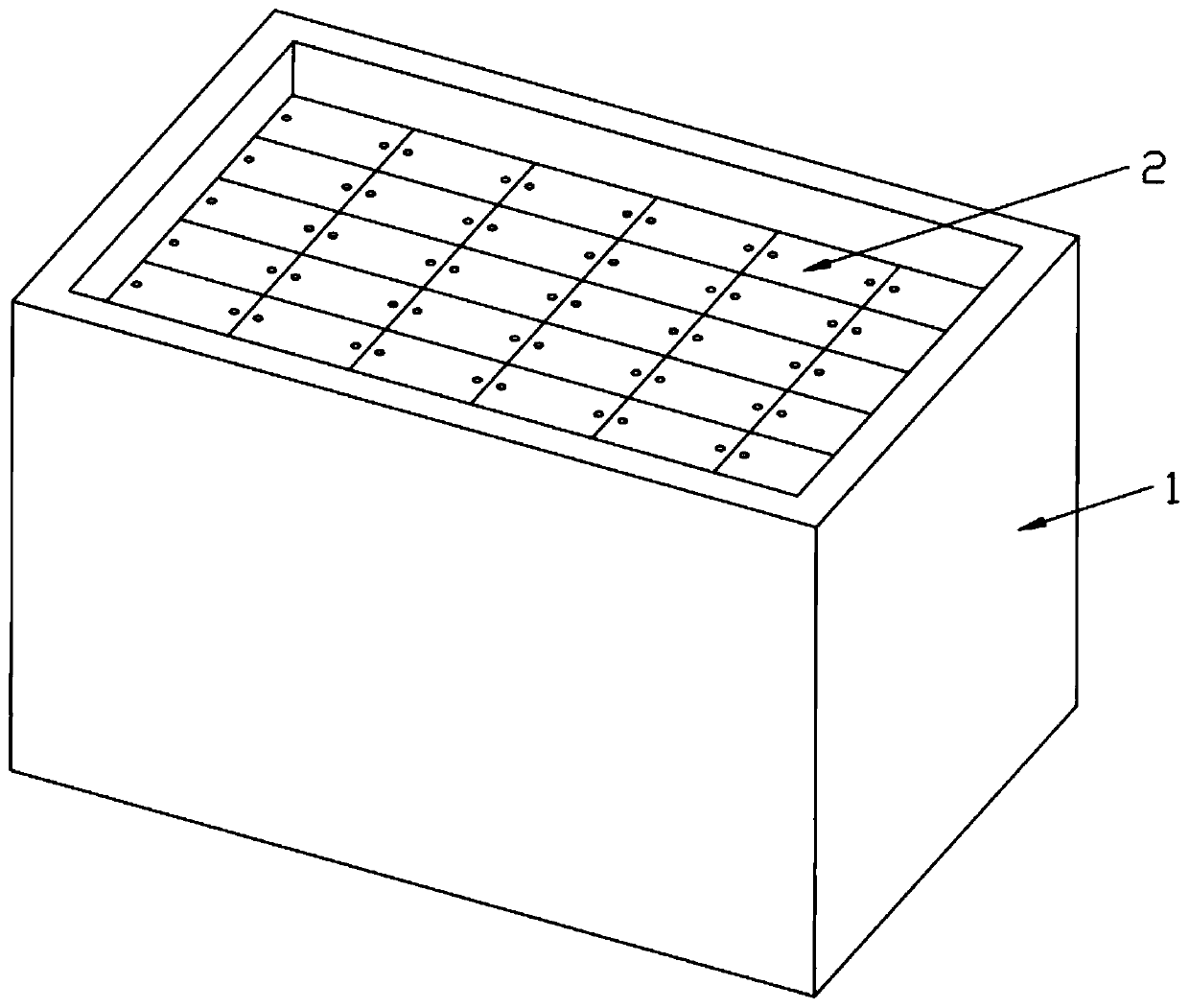

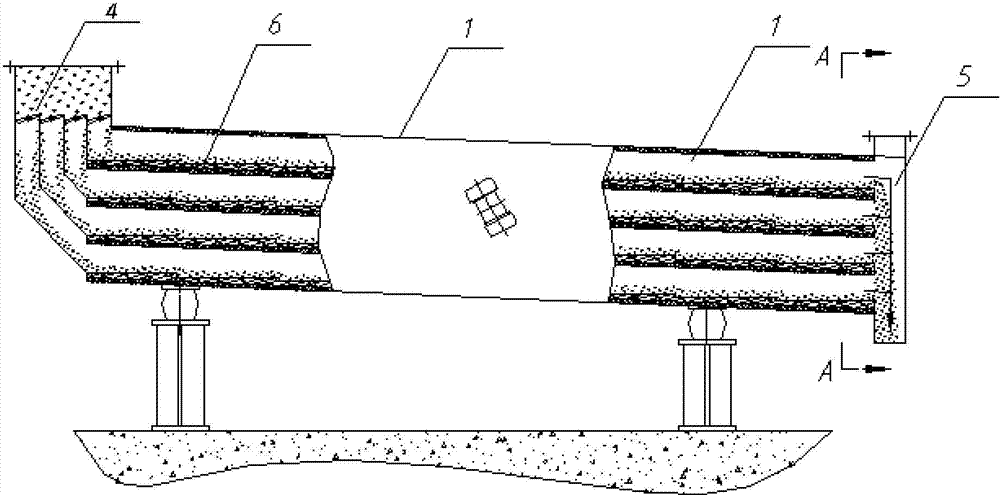

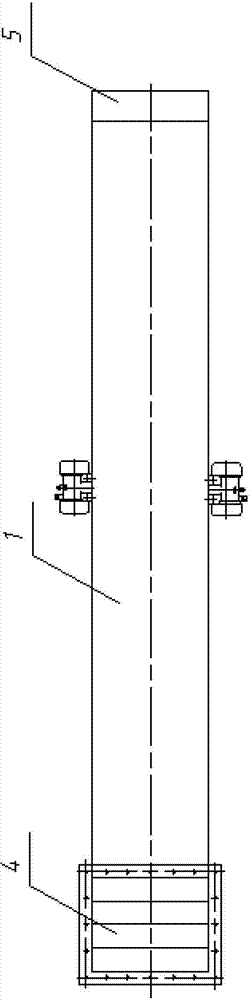

Vibrating hot film or heat pipe laminar flow grain dryer

The invention provides an oscillating heating-membrane heating-pipe laminar-flow grain dryer. Traditional tower type drying has great energy consumption during operation; the total power of a drying tower capable of drying 500 T of grains each day is 255 kw, which is totally operating power and is mainly used by a blower fan and an elevator without generation of drying heat. The oscillating heating-membrane heating-pipe laminar-flow grain dryer comprises a box (1) equipped with a damping device; the box is provided with a feed inlet (4) and a discharge outlet (5), an oscillating material bed (6) is arranged in the box, a material chamber (7) is arranged above the oscillating material bed, the feed inlet and the discharge outlet are communicated with the material chamber, and the bottom of the oscillating material bed is provided with a heating membrane (2) or a heating pipe (3). The oscillating heating-membrane heating-pipe laminar-flow grain dryer is used as a grain dryer or a rice airing machine.

Owner:HARBIN BEICANG GRAIN STORAGE PROJECT & EQUIP

A kind of method for preparing molecular sieve

ActiveCN103787352BFull residence timeFull contact timeCrystalline aluminosilicate zeolitesMolecular sieveGas phase

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com