Method for manufacturing magnesium alloy-stainless steel composite board

A technology of magnesium alloy plate and stainless steel, which is applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve problems such as constraints, and achieve the effect of solving easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

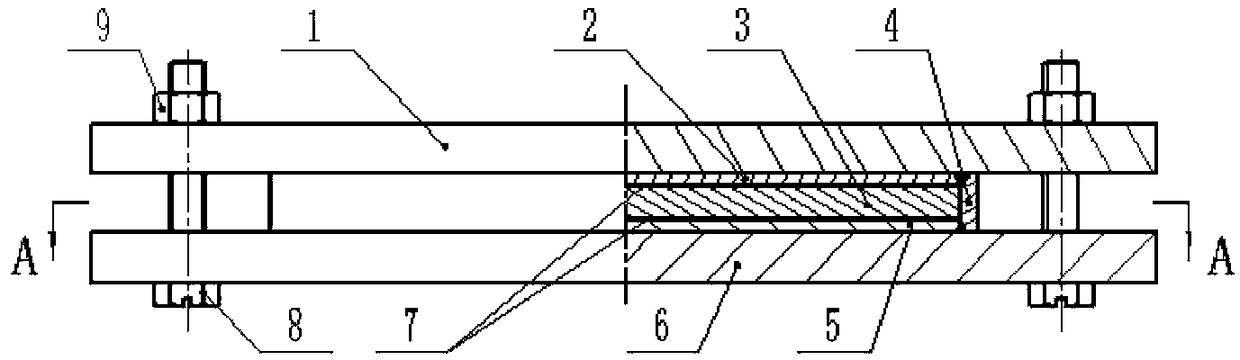

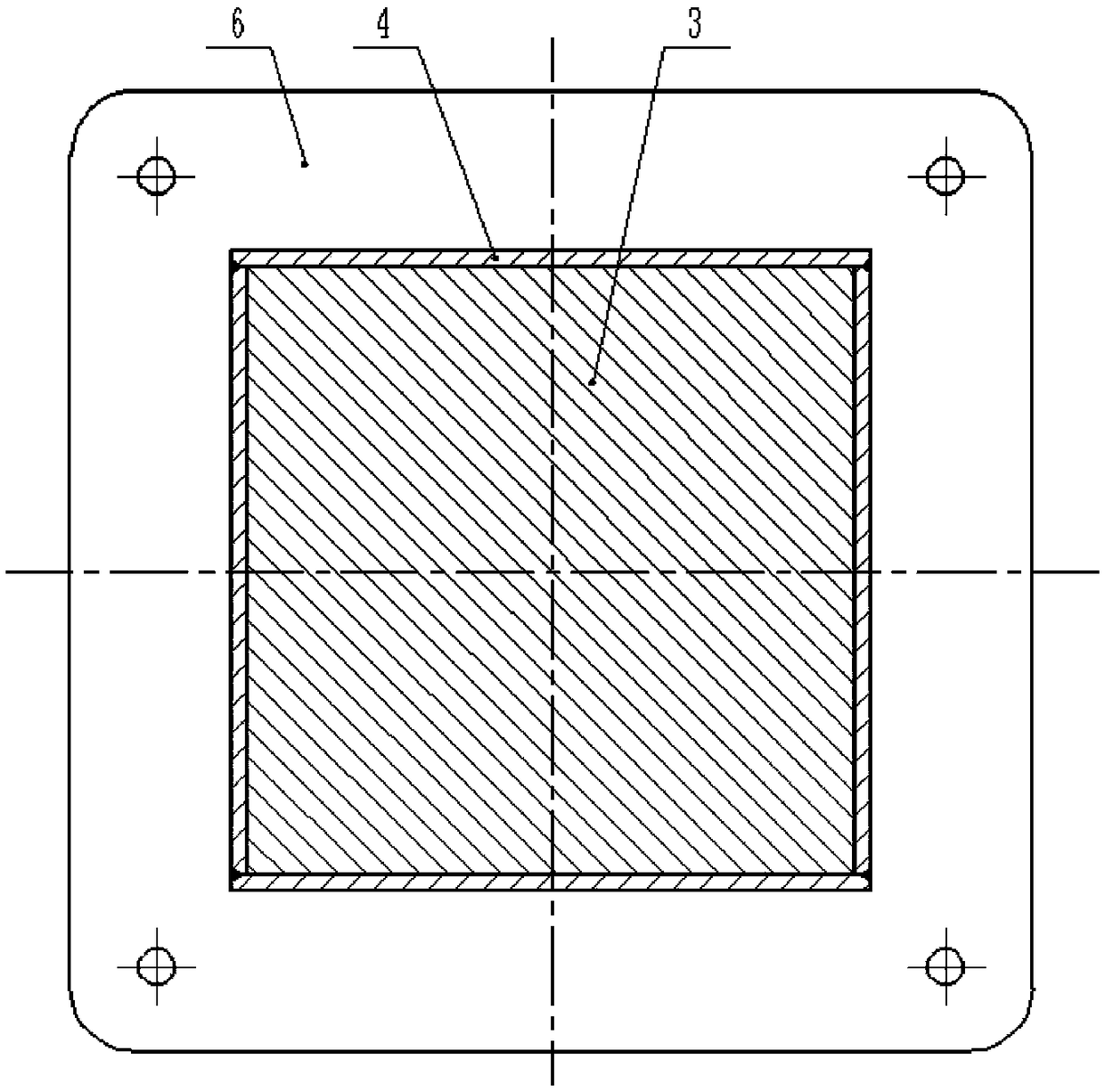

[0023] The implementation of the preparation of the magnesium alloy-stainless steel composite plate will be described in detail below in conjunction with the accompanying drawings. The thickness of the magnesium alloy plate 3 is 2 mm, and the thickness of the stainless steel upper plate 2 and the stainless steel lower plate 5 is 0.5 mm. The grade of the selected magnesium alloy plate is AZ31, and the grade of the stainless steel plate is 06Cr19Ni10.

[0024] Step (1): Firstly, the surfaces of the magnesium alloy plate 3 , the stainless steel upper plate 2 , the stainless steel lower plate 5 and the stainless steel sealing frame 4 need to be pretreated to remove organic impurities and surface oxides. The detailed process is as follows: first, use ethanol to clean the oil stains on the surface of the magnesium alloy plate and stainless steel plate to be composited, and rinse with water; wash with 20wt% NaOH aqueous solution for 3 minutes, and rinse with 10wt% HNO 3 The solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com