Technology for catalysis and quality improvement by using waste gasified gases

A gasification gas and catalyst technology, which is applied in the process field of catalytic upgrading of waste gasification gas, can solve the problems of incapable of fully utilizing tar energy and unreasonable economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

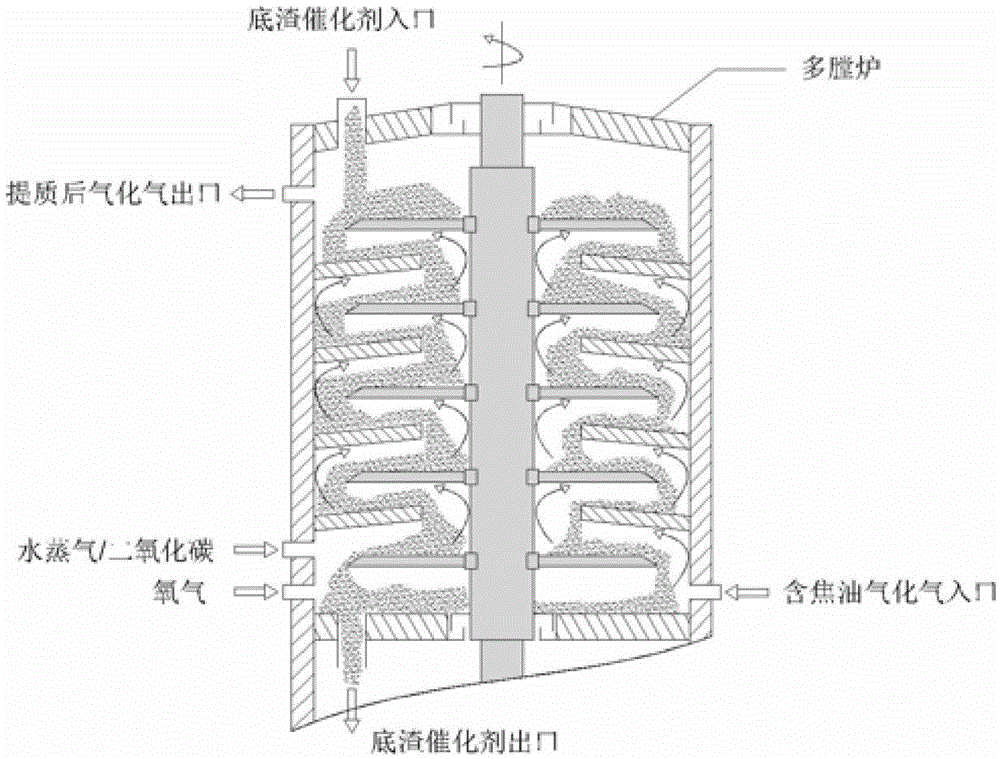

[0037] Such as figure 1 The above is a schematic diagram of a device for catalytically upgrading the bottom slag of a waste incinerator for waste gasification gas. The bottom slag produced after domestic waste is incinerated in a fluidized bed is taken, and then the bottom slag is crushed in a crusher to 1- 2mm small particles to increase the specific surface area to increase the gas-solid contact area. The bottom slag catalyst is fed from the upper inlet of the multi-hearth furnace, and is transported downward step by step on the inner spiral arm of the furnace; at the same time, the tar-containing gasification gas is fed from the lower side wall inlet of the multi-hearth furnace, and the tar-containing gasification gas is discharged in the furnace. There is sufficient contact time with the bottom slag catalyst, the tar in the gasification gas undergoes thermal cracking and catalytic cracking in the high-temperature catalytic section, and the tar is mainly converted into H 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com