High-strength, low cost and wide coal kind gas producer

A gas generator and gas outlet technology, which is applied in the manufacture of combustible gas, petroleum industry, joint combustion mitigation, etc., can solve the problems of poor adaptability of coal types and high cost of gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

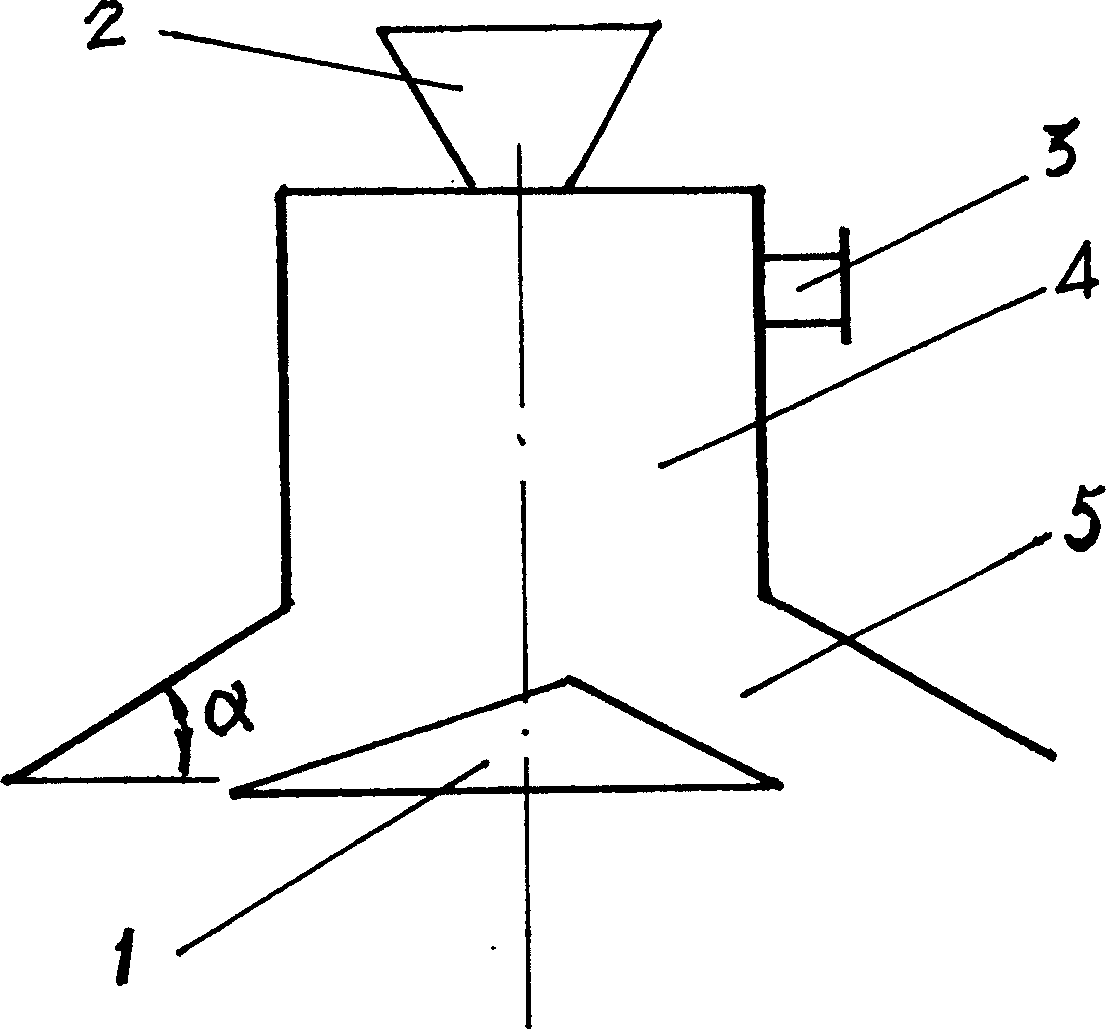

Image

Examples

Embodiment

[0006] 1 Renovate the gas furnace in the existing chemical fertilizer plant, the gasification intensity index B = 1600 kg / m2·hour, and can realize continuous gas production, which can increase the efficiency by more than 10%, and reduce the cost of synthetic ammonia per ton by tens of yuan.

[0007] 2 Renovate the existing second-stage gas furnace, the gasification intensity index B = 1600 kg / m2·hour, and expand the types of gasification coal.

[0008] 3 Design a single-stage atmospheric fixed-bed gas furnace with gasification intensity index B = 1700 kg / m2·hour, which can gasify solid fuels such as bituminous coal and anthracite.

[0009] 4 Retrofit the pressurized gasification gas furnace, the gasification intensity index B = 1800 kg / m²·hour, the gasification agent pressure can be reduced by more than 90% compared with the original process, and the gasification cost is significantly reduced.

[0010] In addition, the gas generator installed in kilns and small boilers is desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com