Preparation method of stainless steel-magnesium alloy composite plate

A technology of stainless steel and magnesium alloy, applied in the field of preparation of stainless steel-magnesium alloy composite plate, can solve problems such as constraints, and achieve the effects of reducing weight, enhancing strength and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

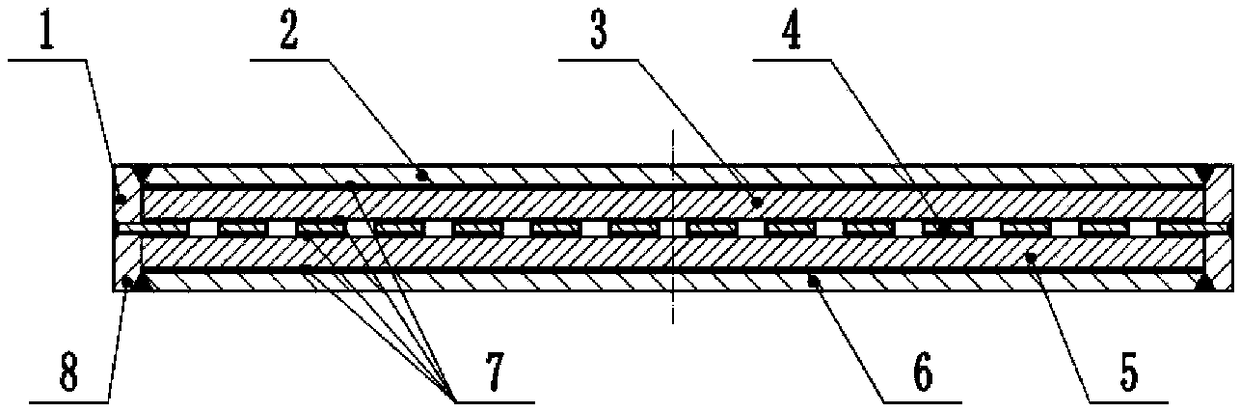

[0023] Attached below figure 1 And attached figure 2 The embodiment of the preparation of the stainless steel-magnesium alloy composite plate will be described in detail. The grade of the selected magnesium alloy plate is AZ31, and the grade of the stainless steel plate is 06Cr19Ni10. The magnesium alloy upper plate 3 and the magnesium alloy lower plate 5 have a thickness of 3 mm, and the stainless steel upper plate 2 , stainless steel middle plate 4 and stainless steel lower plate 6 have a thickness of 0.5 mm.

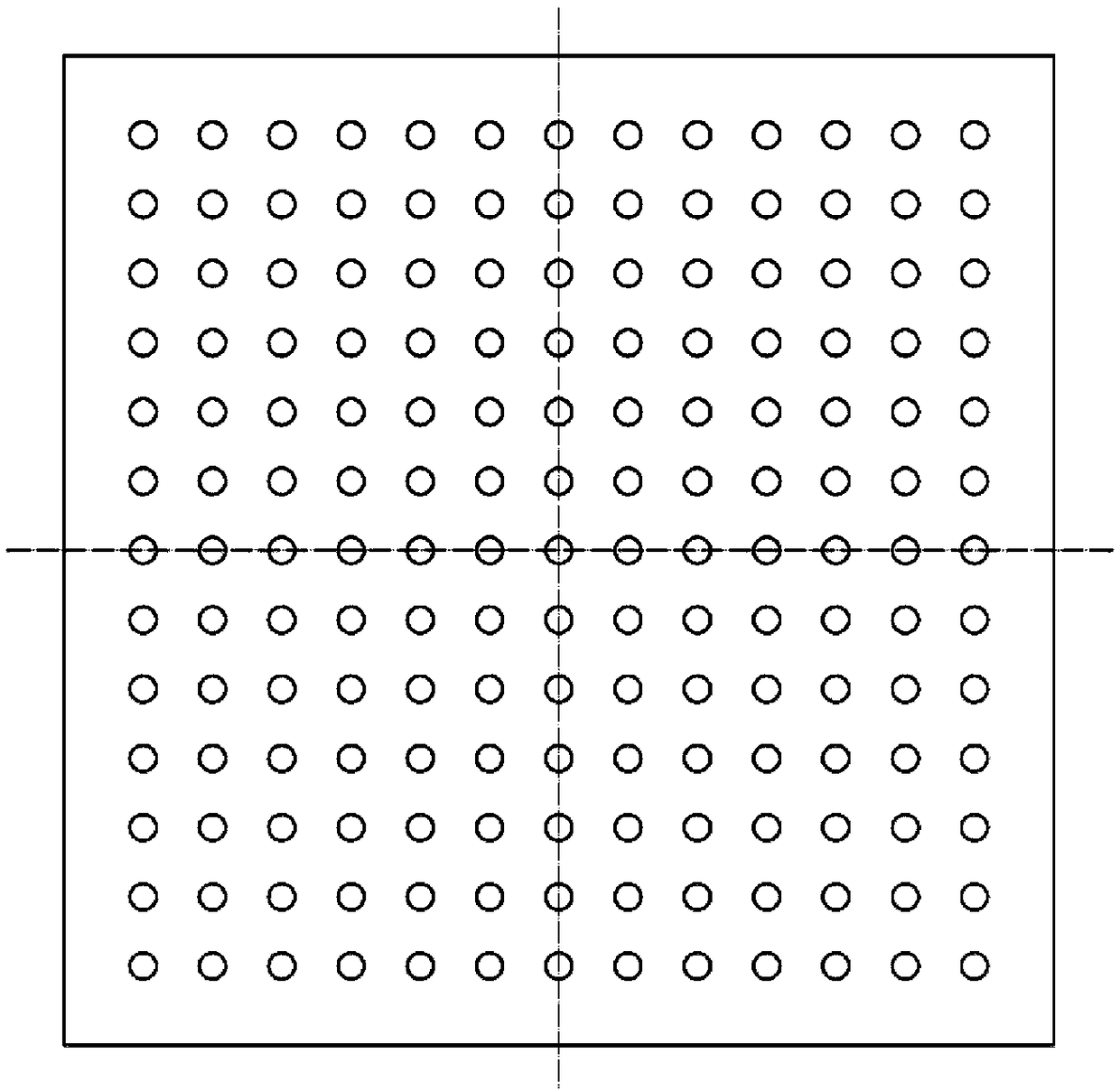

[0024] Step (1): The surface of the stainless steel middle plate 4 is uniformly punched with round holes, the diameter of the round holes is 5 mm, and the distance between the centers of the holes is 16 mm.

[0025] Step (2): Pretreat the surface of stainless steel sealed upper frame 1, stainless steel upper plate 2, magnesium alloy upper plate 3, stainless steel middle plate 4, magnesium alloy lower plate 5, stainless steel lower plate 6 and stainless steel sealed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com