Chroming mist recycling method

A mist recovery and treatment method technology, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of chromic acid loss, influence on the surrounding environment, pollution of the environment, etc., to save labor and increase pollution in the treatment process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below:

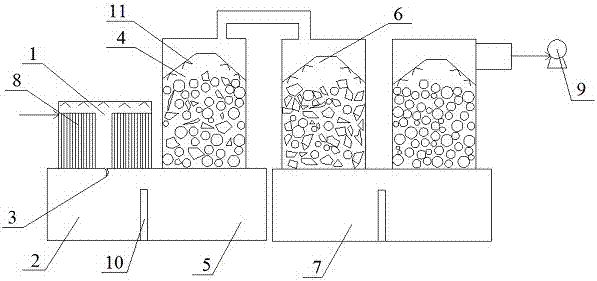

[0027] The invention provides a method for recovering and treating chromium-plating mist. The chromic acid mist in the chrome-plating tank is introduced from the air inlet of the first-level purification treatment unit through the fog-collecting cover, and then discharged from the bottom after being treated, and then discharged from the second-level after passing through the first-level liquid collection tank. The bottom of the purification treatment unit enters, the top is discharged, and enters the third-level purification treatment unit through the air duct. The treated waste gas enters from the bottom of the fourth-level purification treatment unit through the third-level liquid collection tank, and enters from the top of the fourth-level purification treatment unit. Discharge, and so on, can finally be safely discharged after reaching the standard.

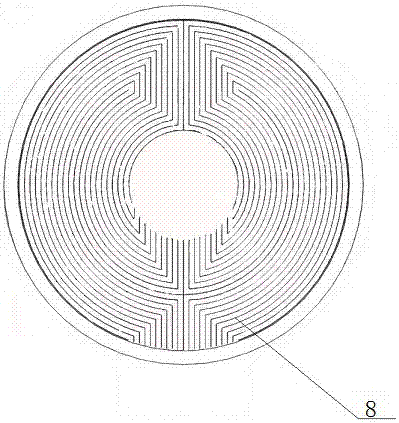

[0028] like figure 1 As shown, the purification treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com