Chrome-plated mist recovery and purification device

A purification device and mist recovery technology, applied in the direction of gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of environmental pollution, poor treatment effect, difficult operation and maintenance, etc., to increase the pollution treatment process, slow flow speed, The effect of strengthening the attachment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below:

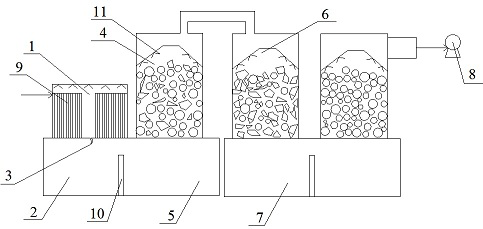

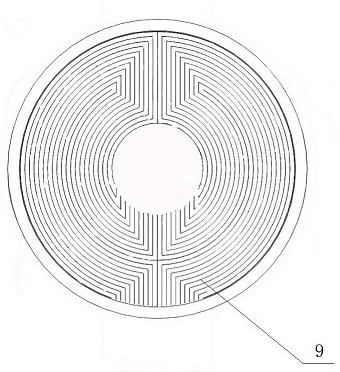

[0028] The chromium-plating mist recovery and purification device of the present invention comprises a chromium mist channel formed by several stages of recovery and purification chambers connected in series with the chrome-plating tank and the fan 8 for exhausting the chrome-plating tank. The recovery and purification chambers of each level include: The coagulation chamber of the shower device 11 and the recovery water tank located at the lower part of the coagulation chamber and correspondingly communicated with the coagulation chamber. The condensation chamber Ⅰ1 of the first-stage recovery and purification room is connected to the exhaust duct of the chrome-plating tank, and the last-stage recovery and purification room is connected to the fan 8 for exhausting the chrome-plating tank; the spray device 11 in the final-stage recovery and purification room is connected to the pure water source for chrome plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com