Flue gas desulfuring method and its device for density current fluidised bed

A technology of fluidized bed and fluidized bed reactor, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as system complexity and increased operating costs, and achieve simple maintenance, reduced operating costs, The effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

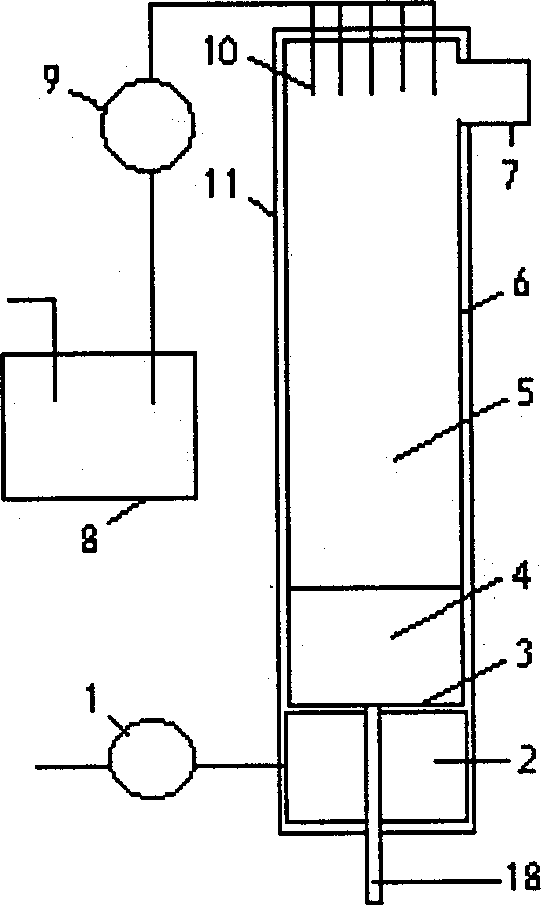

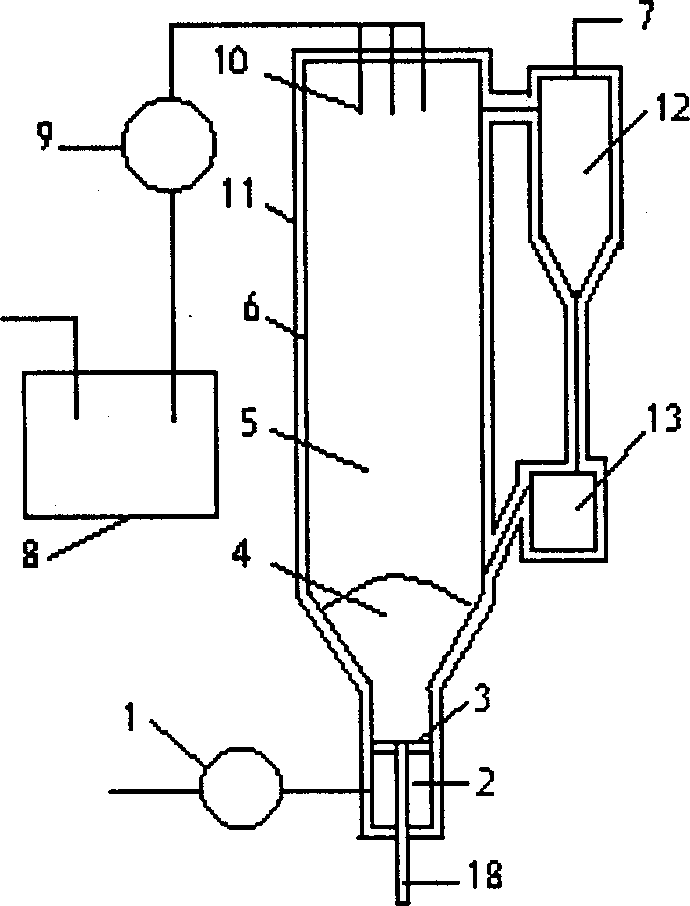

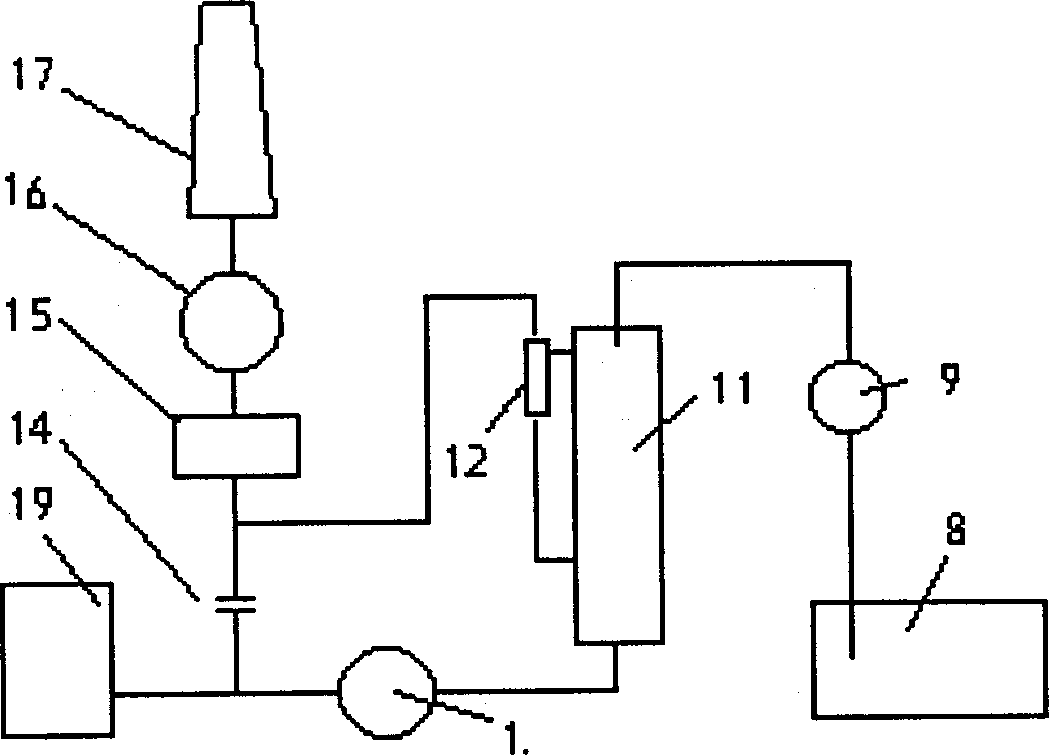

[0012] Figure 1 is Different density fluidized bed flue gas desulfurization device configured for 4t / h boiler. After the flue gas from the boiler is boosted to 6000Pa by the blower, it enters the fluidized bed reactor to fluidize the bed material, passes through the different density fluidized bed composed of quartz sand bed material and calcium hydroxide particles, and carries a part of the hydrogen oxidation The fine calcium particles continue to undergo desulfurization reaction in the suspension space. At this time, the molar ratio of calcium to sulfur is 1.5, and the desulfurization efficiency is 98%. The reactor is composed of machine-made red bricks, steel frame and anti-corrosion lining; the air distribution plate is composed of stainless steel plate and stainless steel mesh. The opening rate of the stainless steel plate is 5%. In order to prevent the loss of bed material, a stainless steel mesh is installed under the air distribution plate , the stencil specification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com