Novel efficient plant deodorant and preparation method thereof

A deodorant and high-efficiency technology, which is applied in the field of high-efficiency plant deodorant and its preparation, can solve the problems of affecting the deodorant effect, revealing the processing efficiency, and increasing the processing cost, so as to achieve the effect of improving the deodorant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

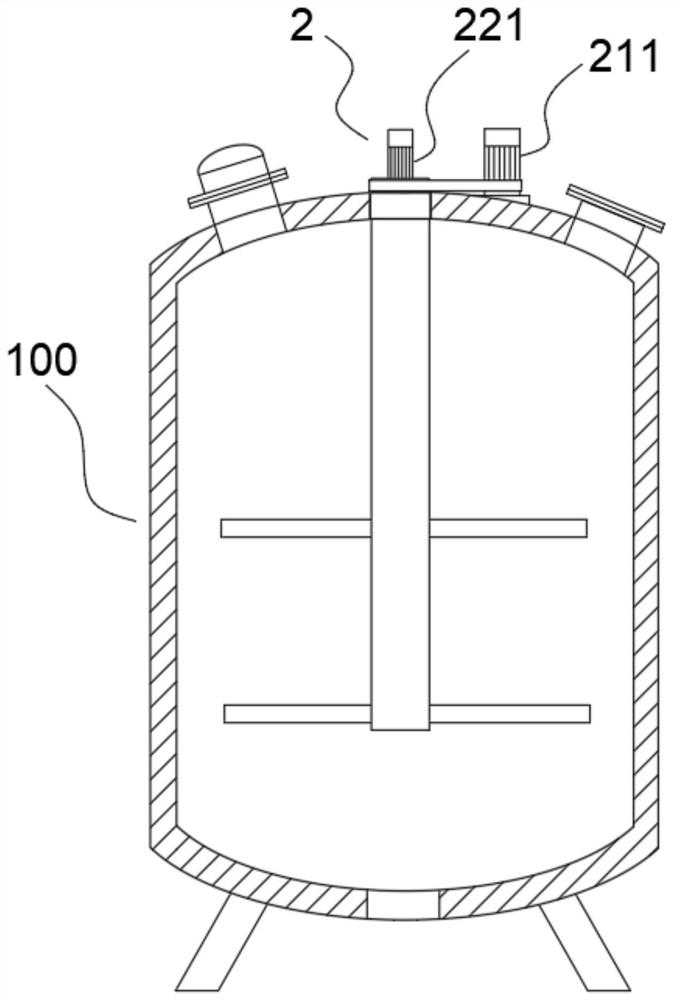

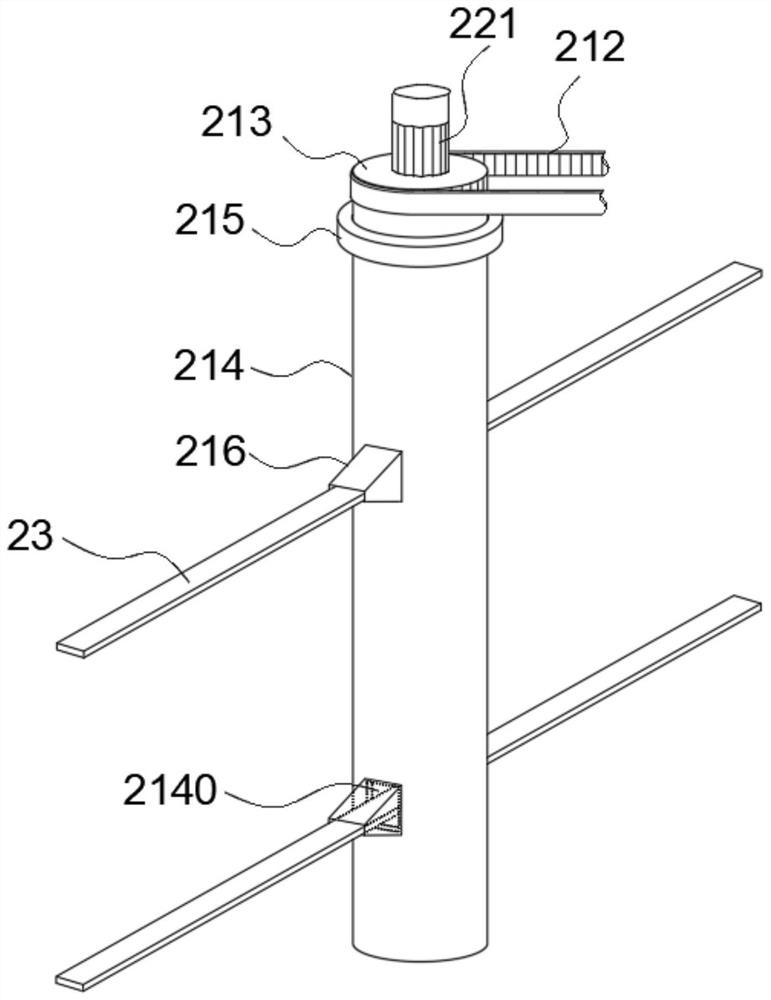

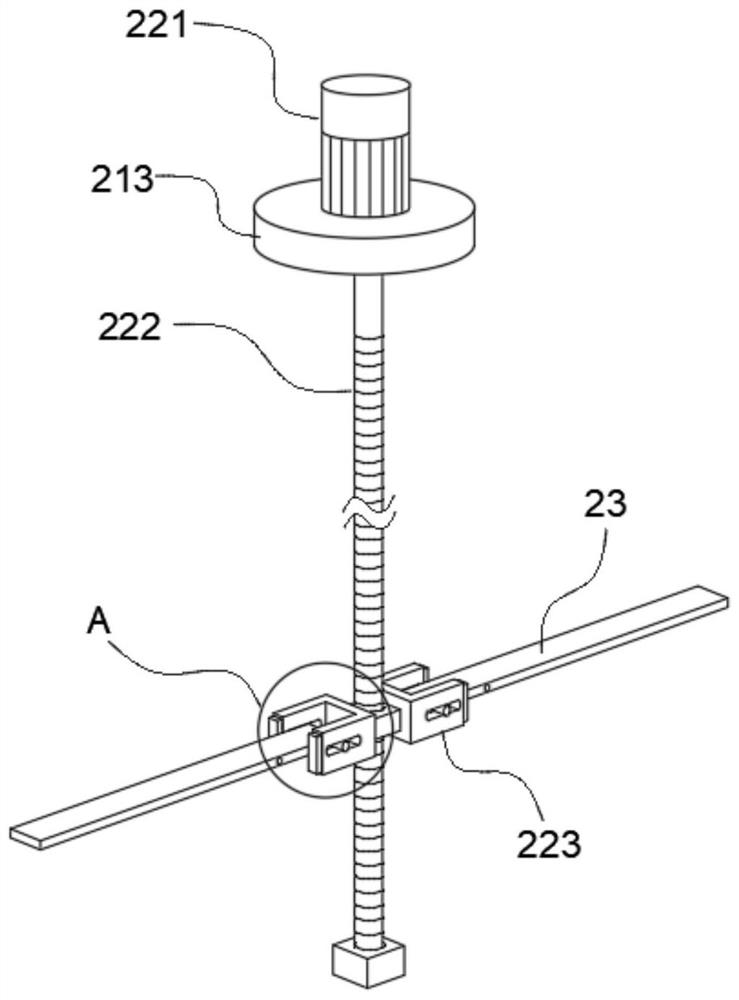

[0030] A novel high-efficiency plant deodorant, comprising the following components in parts by weight: 18 parts of zinc ricinoleate, 15 parts of rosemary oil, 2 parts of antibacterial agent, 3 parts of sodium benzoate, 12 parts of nano microspheres, fatty acid 2 parts of monoglyceride and 75 parts of deionized water.

[0031] The preparation method is as follows: S1) accurately weigh each component; S2) add deionized water and fatty acid monoglyceride into the reaction kettle, and stir evenly through a stirring device; S3) mix zinc ricinoleate, rosemary oil and nano Add the microspheres into the reaction kettle, and stir evenly through the stirring device; S4) add the antibacterial agent and sodium benzoate into the batching tank, stir evenly through the stirring device, and discharge the material to prepare a new type of high-efficiency plant deodorant.

Embodiment 2

[0033] A novel high-efficiency plant deodorant, comprising the following components in parts by weight: 23 parts of zinc ricinoleate, 10 parts of rosemary oil, 2 parts of antibacterial agent, 2 parts of sodium benzoate, 10 parts of nano microspheres, 2 parts of sugar alcohol fat and 75 parts of deionized water.

[0034] The preparation method is as follows: S1) accurately weigh each component; S2) add deionized water and sorbitol fat into the reaction kettle, and stir evenly through a stirring device; S3) mix zinc ricinoleate, rosemary oil and nano Add the microspheres into the reaction kettle, and stir evenly through the stirring device; S4) add the antibacterial agent and sodium benzoate into the batching tank, stir evenly through the stirring device, and discharge the material to prepare a new type of high-efficiency plant deodorant.

Embodiment 3

[0036] A novel high-efficiency plant deodorant, comprising the following components in parts by weight: 16 parts of zinc ricinoleate, 17 parts of lavender oil, 3 parts of antibacterial agent, 3 parts of sodium benzoate, 15 parts of nano microspheres, sorbose 2 parts of alcohol fat and 75 parts of deionized water.

[0037] The preparation method is as follows: S1) accurately weigh each component; S2) add deionized water and sorbitol fat into the reaction kettle, and stir evenly through a stirring device; S3) mix zinc ricinoleate, lavender oil and nano micro Put the balls into the reaction kettle and stir evenly through the stirring device; S4) add the antibacterial agent and sodium benzoate into the batching tank, stir evenly through the stirring device, and discharge the material to prepare a new type of high-efficiency plant deodorant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com