Plant component deodorant and preparation method thereof

A deodorant and plant technology, which is applied to the field of plant component deodorant and its preparation, can solve the problems of polluting the surrounding environment of fermentation, unfavorable to the work of experimenters, easy to produce irritating ammonia smell and the like, and achieves the deodorization effect. Safe, reliable, easy to use, and effective in deodorizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

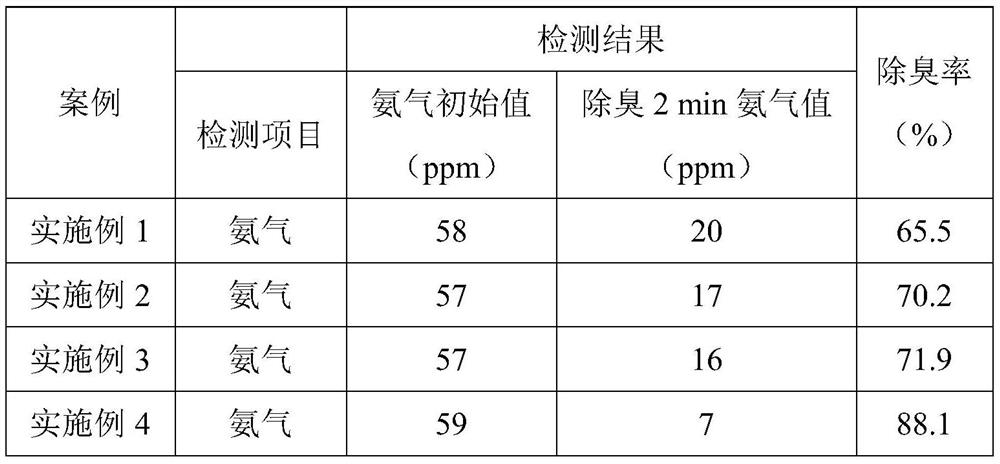

Examples

Embodiment 1

[0025] A plant-based deodorant made from:

[0026] Pomegranate peel extract 5g, eucalyptus leaf extract 3g, clove extract 2.5g, cinnamon bark extract 4g, camphor leaf extract 2g, catechin 0.2g, monoglyceride 0.1g, benzalkonium bromide 0.05g, Deionized water 83.15g.

[0027] Preparation method, the steps are as follows:

[0028] (1) Dissolving: add pomegranate peel extract, eucalyptus leaf extract, clove extract, cinnamon bark extract, camphor leaf extract and catechin into deionized water, heat up to 45°C and stir to dissolve for 10 minutes.

[0029] (2) Centrifugation: centrifuge the dissolved mixed solution, remove the precipitate and take the supernatant for later use. Wherein, the centrifugal speed is 4000rpm, and the centrifugal time is 20min.

[0030] (3) Dissolving again: take out the centrifuged supernatant and add deionized water to dilute it according to 3 times its weight, heat up to 55°C, stir and add monoglycerides of fatty acids, then stir at constant temperat...

Embodiment 2

[0034] A plant-based deodorant made from:

[0035] Pomegranate peel extract 6g, eucalyptus leaf extract 3g, clove extract 3g, cinnamon bark extract 5g, camphor leaf extract 3g, catechin 0.2g, monoglyceride 0.1g, benzalkonium bromide 0.05g, Ionized water 79.65g.

[0036] Preparation method, the steps are as follows:

[0037] (1) Dissolving: Add pomegranate peel extract, eucalyptus leaf extract, clove extract, cinnamon bark extract, camphor leaf extract and catechin into deionized water, heat up to 38°C and stir to dissolve for 20 minutes.

[0038] (2) Centrifugation: centrifuge the dissolved mixed solution, remove the precipitate and take the supernatant for later use. Wherein, the centrifugation speed is 3800rpm, and the centrifugation time is 22min.

[0039] (3) Dissolving again: take out the centrifuged supernatant and add deionized water to dilute it according to 4 times its weight, heat up to 60°C, stir and add monoglycerides, then stir at constant temperature for 20 mi...

Embodiment 3

[0043] A plant-based deodorant made from:

[0044] Pomegranate peel extract 10g, eucalyptus leaf extract 4g, clove extract 5g, cinnamon bark extract 8g, camphor leaf extract 4g, catechin 0.2g, monoglyceride 0.2g, benzalkonium bromide 0.05g, Ionized water 68.55g.

[0045] Preparation method, the steps are as follows:

[0046] (1) Dissolving: Add pomegranate peel extract, eucalyptus leaf extract, clove extract, cinnamon bark extract, camphor leaf extract and catechin into deionized water, heat up to 42°C and stir to dissolve for 15 minutes.

[0047] (2) Centrifugation: centrifuge the dissolved mixed solution, remove the precipitate and take the supernatant for later use. Wherein, the centrifugation speed is 3300rpm, and the centrifugation time is 27min.

[0048] (3) Dissolving again: take out the centrifuged supernatant and add deionized water to dilute it according to 3 times its weight, heat up to 58°C, stir and add monoglycerides of fatty acids, then stir at constant tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com