Method for preparing deodorant master-batch

A technology of deodorizing masterbatch and masterbatch, which is applied in the field of chemical deodorant preparation to achieve good deodorization of ammonia and improve deodorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

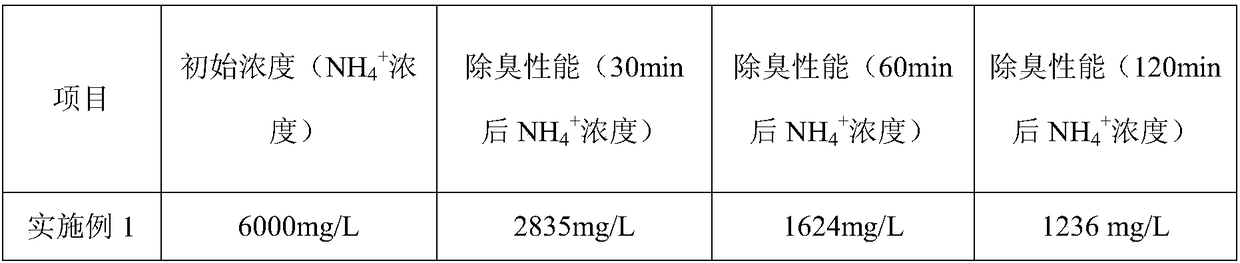

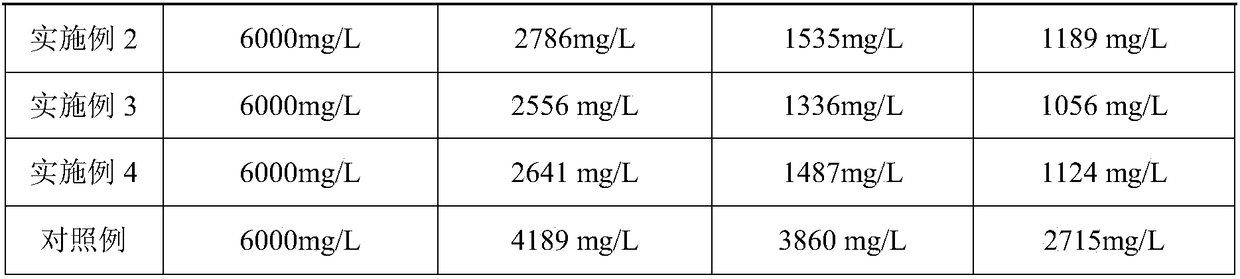

Examples

Embodiment 1

[0016] A preparation method for deodorant masterbatch, comprising the following steps:

[0017] Step 1, mix 10 parts by weight of PET, 5 parts of PP, 1 part of dimethyl methylphosphonate, 1 part of sodium carbonate and 0.5 part of sodium tripolyphosphate to obtain mixture 1, which is mixed uniformly and stirred The rotating speed is 180 rpm, and the mixing time is 20 minutes;

[0018] Step 2, put the mixture one in the reaction kettle, add 2 parts by weight of methyl tetrahydrophthalic anhydride, 1 part of butyl acrylate, 0.3 parts of sodium borohydride, and heat to Stir at 70°C for 20 minutes at a stirring speed of 60 rpm to obtain mixture 2;

[0019] Step 3, add 25 parts by weight of silica sol, 0.5 parts of barium stearate and 1 part of hypromellose to mixture 2, mix well, and extrude in a twin-screw extruder at a temperature of 180 -200°C to obtain a deodorant masterbatch.

Embodiment 2

[0021] A preparation method for deodorant masterbatch, comprising the following steps:

[0022] Step 1, mix 13 parts by weight of PET, 6 parts of PP, 2 parts of dimethyl methylphosphonate, 2 parts of sodium carbonate and 0.6 part of sodium tripolyphosphate to obtain mixture 1, which is uniformly mixed and stirred The rotating speed is 188 rpm, and the mixing time is 23 minutes;

[0023] Step 2, put the mixture one in the reaction kettle, add 3 parts by weight of methyl tetrahydrophthalic anhydride, 2 parts of butyl acrylate, 0.4 parts of sodium borohydride, and heat under the protection of argon to 75°C, stirring for 26 minutes at a stirring speed of 70 rpm to obtain mixture 2;

[0024] Step 3, add 3 parts by weight of silica sol, 0.6 parts of barium stearate and 2 parts of hypromellose to mixture 2, mix well, and extrude in a twin-screw extruder at a temperature of 180 -200°C to obtain a deodorant masterbatch.

Embodiment 3

[0026] A preparation method for deodorant masterbatch, comprising the following steps:

[0027] Step 1, mix 17 parts by weight of PET, 8 parts of PP, 2 parts of dimethyl methylphosphonate, 3 parts of sodium carbonate and 0.8 part of sodium tripolyphosphate to obtain mixture 1, which is mixed uniformly and stirred The rotating speed is 190 rpm, and the mixing time is 26 minutes;

[0028] Step 2, put the mixture one in the reaction kettle, add 3 parts by weight of methyl tetrahydrophthalic anhydride, 2 parts of butyl acrylate, 0.5 part of sodium borohydride, and heat to Stir at 78°C for 26 minutes at a stirring speed of 70 rpm to obtain mixture 2;

[0029] Step 3, add 4 parts by weight of silica sol, 0.8 parts of barium stearate and 2 parts of hypromellose to mixture 2, mix well, and extrude in a twin-screw extruder at a temperature of 180 -200°C to obtain a deodorant masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com