Vibrating hot film or heat pipe laminar flow grain dryer

A grain dryer, vibrating technology, applied in the direction of storing seeds by drying, etc., to achieve the effects of low equipment cost, strong applicability and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

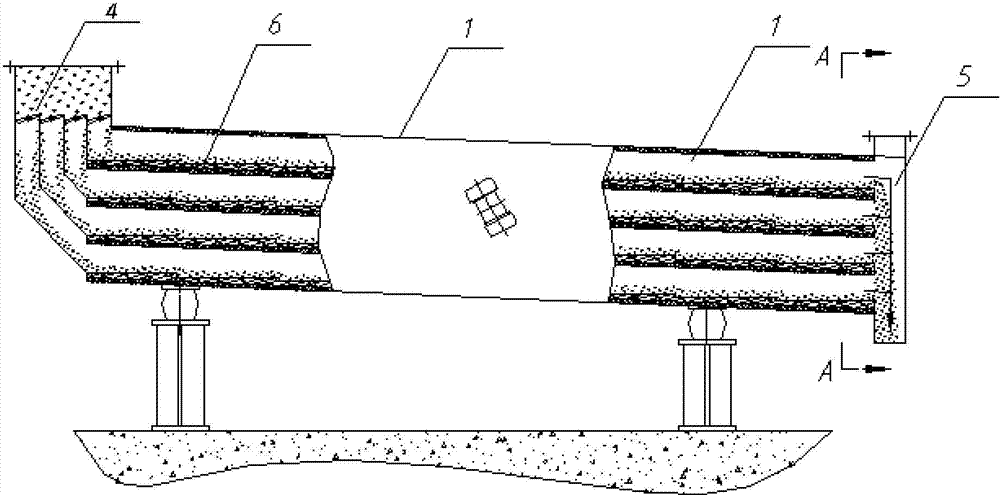

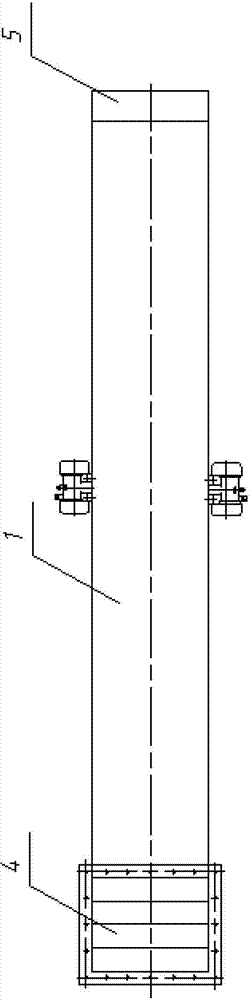

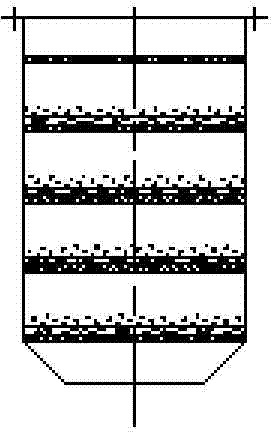

[0052] Vibrating hot film or heat pipe laminar flow grain dryer, its composition includes: a box body 1 with a shock absorbing device, the box body has a material inlet 4 and a material outlet 5, and the box body is equipped with There is a vibrating material bed 6, the upper part of the vibrating material bed is a material chamber 7, the described feed inlet and the discharge port are communicated with the described material chamber, and the bottom of the vibrating material bed is equipped with a heating film 2 or There are heating tubes 3.

[0053] After the heated grain enters the vibrating material bed 6 from the feed port 4, the vibrating material bed will convey the heated grain to the discharge port. The heating body and the vibrating material bed contact to evaporate the water and dry the grain. The gas for heating is heated under the vibrating material bed 6 after it enters from the air inlet.

Embodiment 2

[0055] Embodiment 1 In the vibrating hot film or heat pipe laminar flow grain dryer, the vibrating material bed is 1-15 layers, generally about 10 layers, and the height of the material chamber is less than 20 cm, usually about 15 cm .

Embodiment 3

[0057] In the vibrating hot-film or heat-pipe laminar flow grain dryer described in Embodiment 1 or 2, the vibrating material bed has a stepped turning platform; the vibrating material bed has an inclination angle of 1-15 degrees.

[0058] The length of the vibrating material bed is more than 2 meters. The material bed has a heating film with a far-infrared coating on the downward side, or a far-infrared heating tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com